Tobacco stem multistage utilization method based on supercritical CO2 extraction technology

An extraction technology and supercritical technology are applied in the field of multi-stage utilization of tobacco stems based on supercritical CO2 extraction technology, and can solve the problems of large loss of tobacco aroma components, inability to achieve efficient utilization of tobacco stem raw materials, and extensive process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

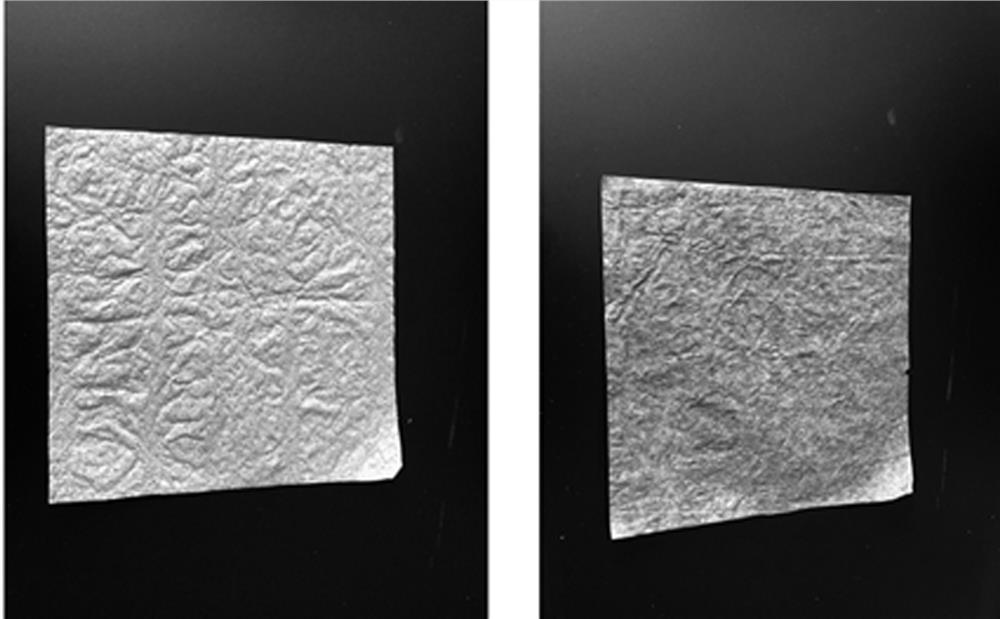

Image

Examples

Embodiment 1

[0031] S1: cutting the tobacco stem raw material into long sections, the tobacco stem raw material is cut into 2 cm long sections, and the impurities are removed through the air separation and impurity removal device to obtain tobacco stem sections;

[0032] S2: Fill the tobacco stem section with supercritical CO 2 In the extraction kettle of the extractor;

[0033] S3: Put the entrainer into the entrainer tank, use ethyl acetate with a concentration of 2% as the entrainer, and the amount of the entrainer added is 3% of the mass of the tobacco stem raw material;

[0034] S4: Start the carbon dioxide refrigeration and circulation system, control the pressure of the extraction kettle to 20MPa, the temperature to 40°C, the analytical pressure of the primary separation kettle to 4MPa, the temperature to 25°C, the analytical pressure of the secondary separation kettle to 1.5MPa, and the temperature to 10°C; the extraction time is 60-240min, After the system reaches the set value o...

Embodiment 2

[0041] S1: cutting the tobacco stem raw material into long sections, the tobacco stem raw material is cut into 4 cm long sections, and the impurities are removed through the air separation and impurity removal device to obtain tobacco stem sections;

[0042] S2: Fill the tobacco stem section with supercritical CO 2 In the extraction kettle of the extractor;

[0043] S3: Put the entrainer into the entrainer tank, use ethyl acetate with a concentration of 5% as the entrainer, and the amount of the entrainer added is 10% of the mass of the tobacco stem raw material;

[0044] S4: Start the carbon dioxide refrigeration and circulation system, control the pressure of the extraction kettle to 20-35MPa, the temperature to 50℃, the analytical pressure of the primary separation kettle to 6MPa, the temperature to 37℃, the analytical pressure to the secondary separation kettle to 3MPa, and the temperature to 20℃; the extraction time is 60-240min After the system reaches the set value of ...

Embodiment 3

[0051] S1: cutting the tobacco stem raw material into long sections, the tobacco stem raw material is cut into 6 cm long sections, and the impurities are removed through the air separation and impurity removal device to obtain tobacco stem sections;

[0052] S2: Fill the tobacco stem section with supercritical CO 2 In the extraction kettle of the extractor;

[0053] S3: Put the entrainer into the entrainer tank, use ethyl acetate with a concentration of 8% as the entrainer, and the amount of the entrainer added is 18% of the mass of the tobacco stem raw material;

[0054] S4: Start the carbon dioxide refrigeration and circulation system, control the pressure of the extraction kettle to 35MPa, the temperature to 460°C, the analytical pressure of the primary separation kettle to 8MPa, the temperature to 50°C, the analytical pressure of the secondary separation kettle to 4MPa, and the temperature to 30°C; the extraction time is 60-240min, and the system After reaching the set va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com