Production method of chemi-mechanical pulp

A production method and a technology for chemical-mechanical pulping, which are used in pulp bleaching, cellulose raw material pulping, cellulose pulp post-processing, etc., can solve the problem that the beating degree is difficult to meet the design requirements, the single fiberization rate is low, and the refining is increased. Difficulty and other problems to achieve the effect of improving service life, improving beating effect and reducing lumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

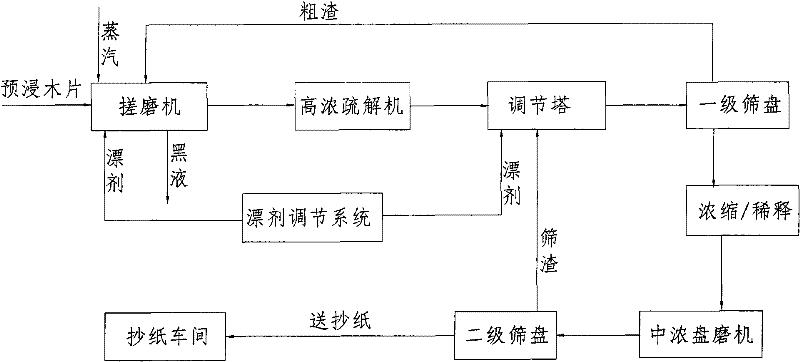

[0034] A kind of chemical mechanical pulp production method of present embodiment, such as figure 1 As shown, the pulp raw materials are firstly refined and bleached to obtain a decomposed pulp; then the decomposed pulp is screened and thickened, and then medium-consistency grinding is performed to obtain a single fiberized chemical-mechanical pulp and directly sent to Papermaking workshop. Specifically:

[0035] (1) Alkali is used to pre-impregnate the wood chips used as pulp raw materials, and then the pre-impregnated wood chips and steam are sent into the rubbing mill for rubbing, and the bleaching agent adjustment system adds bleaching agent to the rubbing mill at the same time. The raw materials are initially bleached, the black liquor is discharged from the system, and the slurry is sent to the high-consistency deflaker;

[0036] (2) The high-concentration debulking machine decomposes and breaks up the slurry obtained by rubbing, and obtains the decomposed slurry, whic...

Embodiment 2

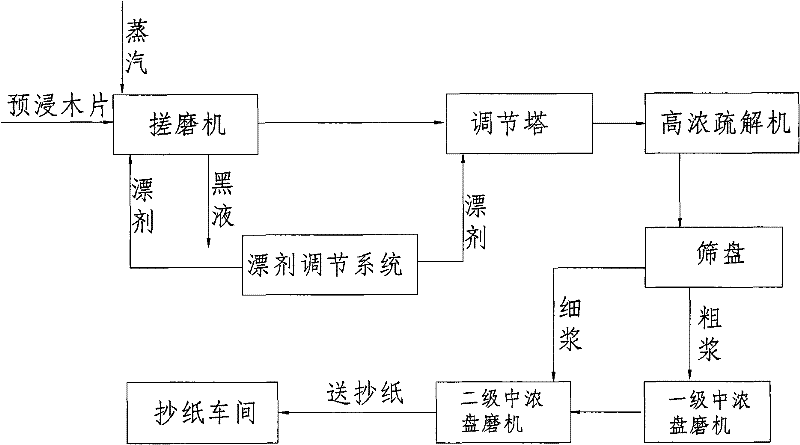

[0046] A kind of chemical mechanical pulp production method of present embodiment, such as figure 2As shown, the pulp raw materials are firstly refined and bleached to obtain a decomposed pulp; then the decomposed pulp is screened and thickened, and then medium-consistency grinding is performed to obtain a single fiberized chemical-mechanical pulp and directly sent to Papermaking workshop. Specifically:

[0047] (1) Alkali is used to pre-impregnate the wood chips used as pulp raw materials, and then the pre-impregnated wood chips and steam are sent into the rubbing mill for rubbing, and the bleaching agent adjustment system adds bleaching agent to the rubbing mill at the same time. The raw material is initially bleached, the black liquor is discharged from the system, and the slurry is sent to the regulating tower;

[0048] (2) The adjustment tower stores the slurry, and at the same time, the bleaching agent adjustment system adds bleaching agent to the adjustment tower to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com