A metal-organic framework fiber membrane for filtering tobacco smoke particles and its application

An organic skeleton, smoke particle technology, applied in filtration separation, dispersed particle filtration, membrane technology, etc., to achieve the effect of high efficiency filtration and excellent filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

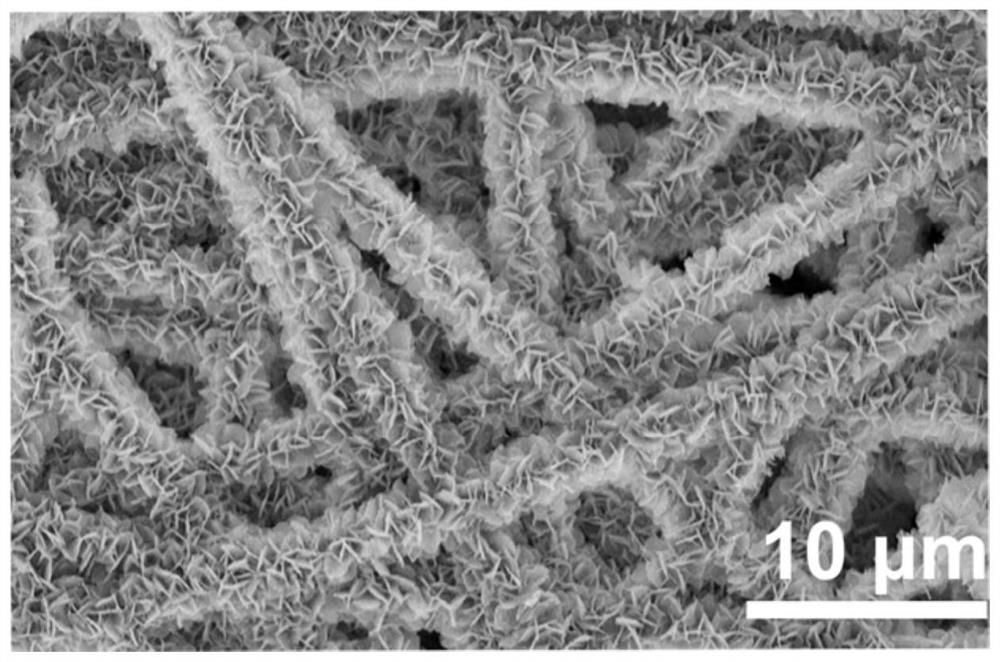

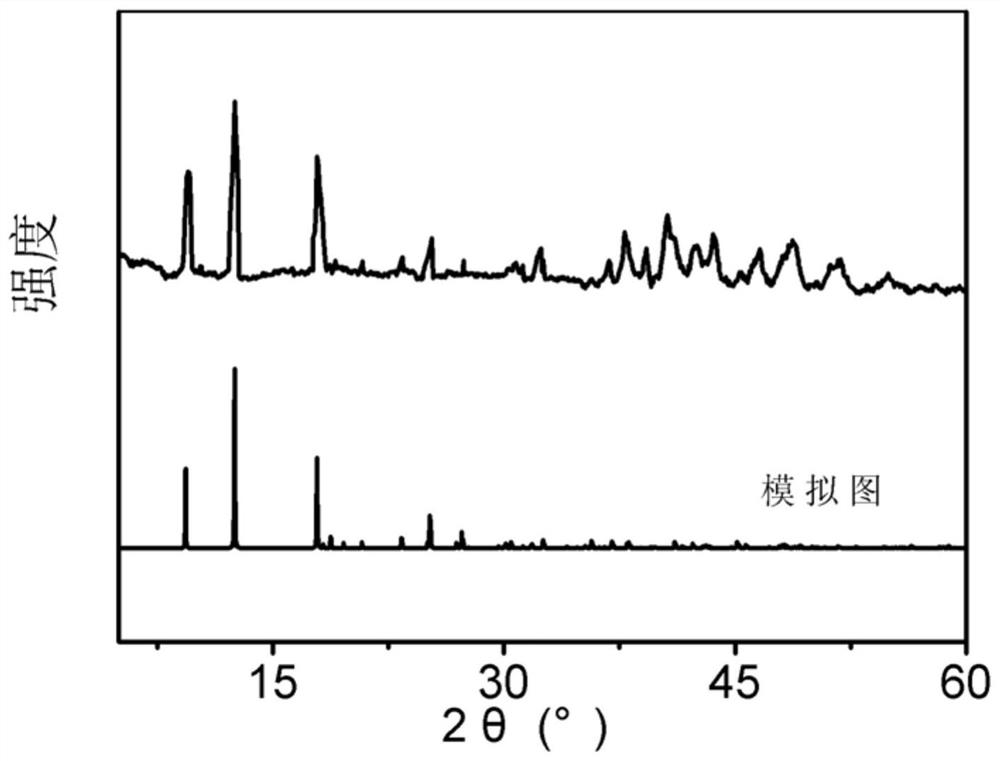

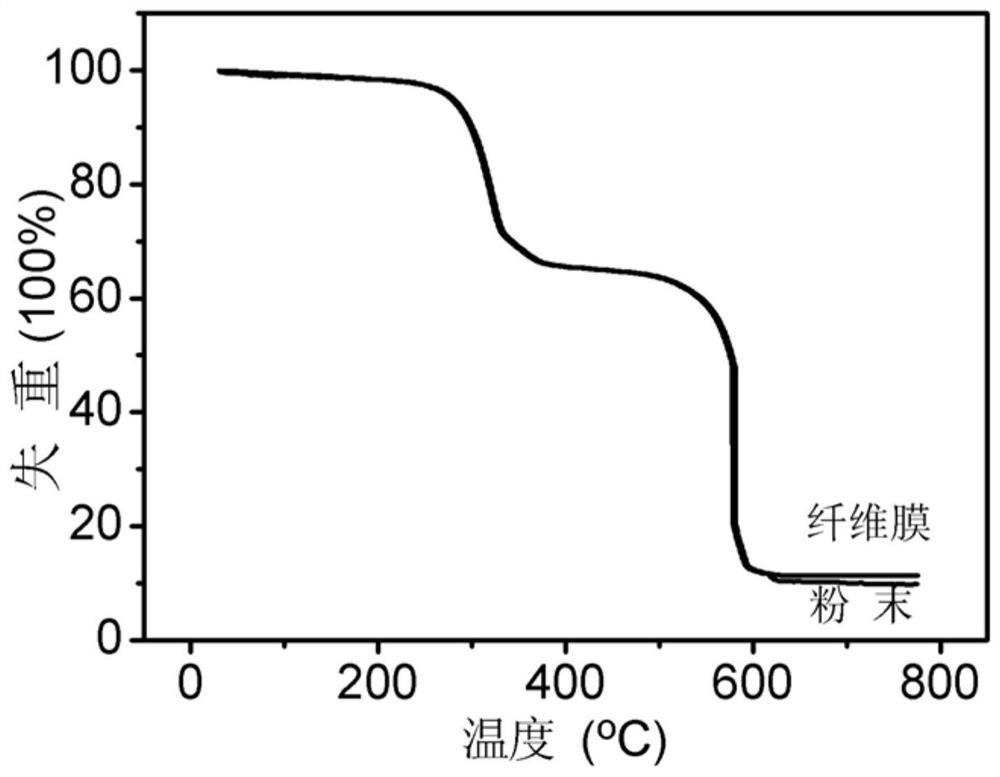

[0040] A kind of MOF fiber film that is used for filtering tobacco smoke particle, this fiber film is MIL-53 (Al) fiber film, and preparation method comprises steps as follows:

[0041] (1)Al 2 o 3 Preparation of fiber membrane

[0042] Add 1.08g of aluminum powder to a mixed solution of 6.03mL of formic acid solution (88wt%), 6.86mL of glacial acetic acid (99.5wt%) and 17.28mL of water under stirring conditions, reflux and stir at 60-80°C until the aluminum powder is completely dissolved, filter To obtain a clear solution, add 0.1g of PEO, and continue to stir for 2 hours to obtain a spinning solution; use the electrospinning SS-2535H equipment of Beijing Yongkang Leye Company to perform electrospinning on the obtained spinning solution, and the conditions are: spinning voltage 18kV , the electrode distance is 180mm, the temperature is 15°C, and the relative humidity is 20%, the fiber film precursor is obtained; the obtained fiber film precursor is calcined at 600°C for 2h,...

Embodiment 2

[0048] As described in Example 1, the difference is:

[0049] Step (1) is with embodiment 1;

[0050] In step (2), the concentration is an aqueous solution of 1 wt% terephthalic acid.

Embodiment 3

[0052] As described in Example 1, the difference is:

[0053] Step (1) is with embodiment 1;

[0054] In step (2), the concentration is an aqueous solution of 5wt% terephthalic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com