Chemical warfare agent self-disinfection MOF (metal organic framework) fiber filtering membrane and preparation method thereof

A fiber membrane and organic framework technology, which is applied in the field of chemical warfare agent self-disinfection metal-organic framework fiber membrane and its preparation, can solve the limitation of the amount of metal-organic framework added, affect the effect of catalysis, cannot make macroscopic forms, etc. problems, achieving excellent catalytic properties, short half-life, favorable transport and exposure of catalytic sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for preparing a chemical warfare agent self-sterilizing metal-organic framework UiO-66 fiber filter membrane, comprising the following steps:

[0055] (1) Preparation of spinning solution

[0056] Add 0.3g of PVPK-90 to 5mL of absolute ethanol and stir, add 10g of zirconium acetate aqueous solution with a mass concentration of 20-25% to the mixed solution, and stir at room temperature to obtain a spinning solution;

[0057] (2) ZrO 2 Preparation of fiber membrane

[0058] Electrospinning the spinning solution obtained in step (1), the conditions are: spinning voltage 20kV, electrode distance 250mm, temperature 25°C, relative humidity 20%, to obtain ZrO 2 fiber membrane precursor; the resulting ZrO 2 The fiber film precursor is calcined at 500°C for 2 hours to obtain it.

[0059] (3) Preparation of UiO-66 fiber membrane

[0060] 0.1g ZrO 2 Fiber film, 1ml 99wt% glacial acetic acid, 10g terephthalic acid aqueous solution (5wt%) were added to a 50mL reactor ...

Embodiment 2

[0067] A kind of preparation method of chemical warfare agent self-sterilizing metal-organic framework UiO-67 fiber membrane, as described in Example 1, the difference is:

[0068] In step (3), the organic ligand solution is 10 g of an aqueous solution of diphthalic acid with a concentration of 10 wt%.

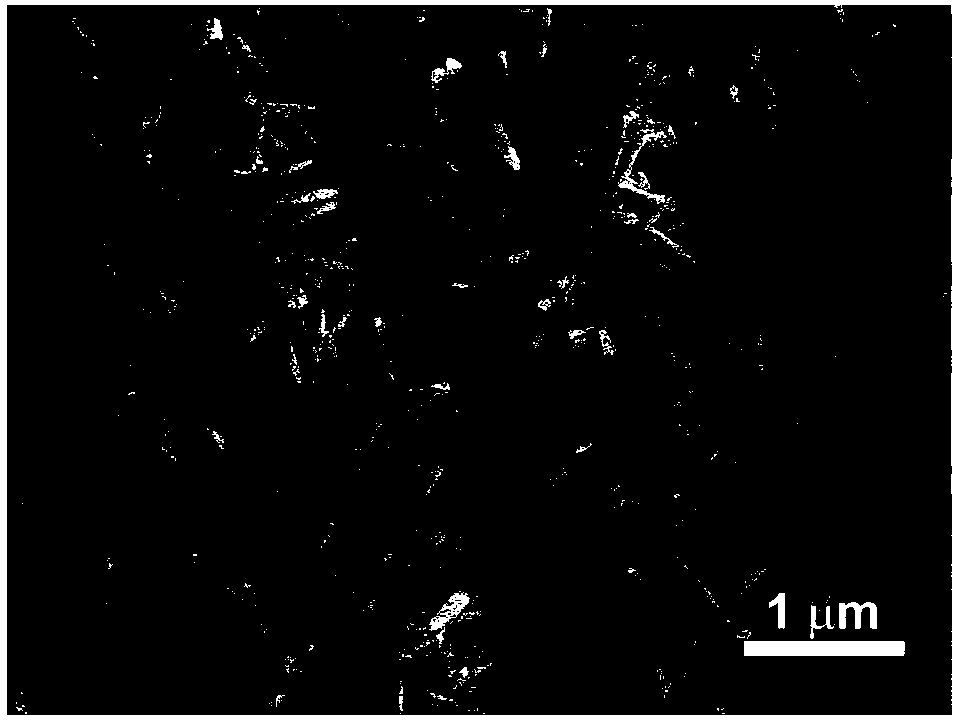

[0069] The scanning electron microscope picture of the UiO-67 fiber membrane that the present embodiment makes is as Figure 6 shown by Figure 6 It can be seen that the fiber filter membrane prepared in this example is composed of fibers composed of needle-like nanosheets, and the fiber diameter is about 2 μm.

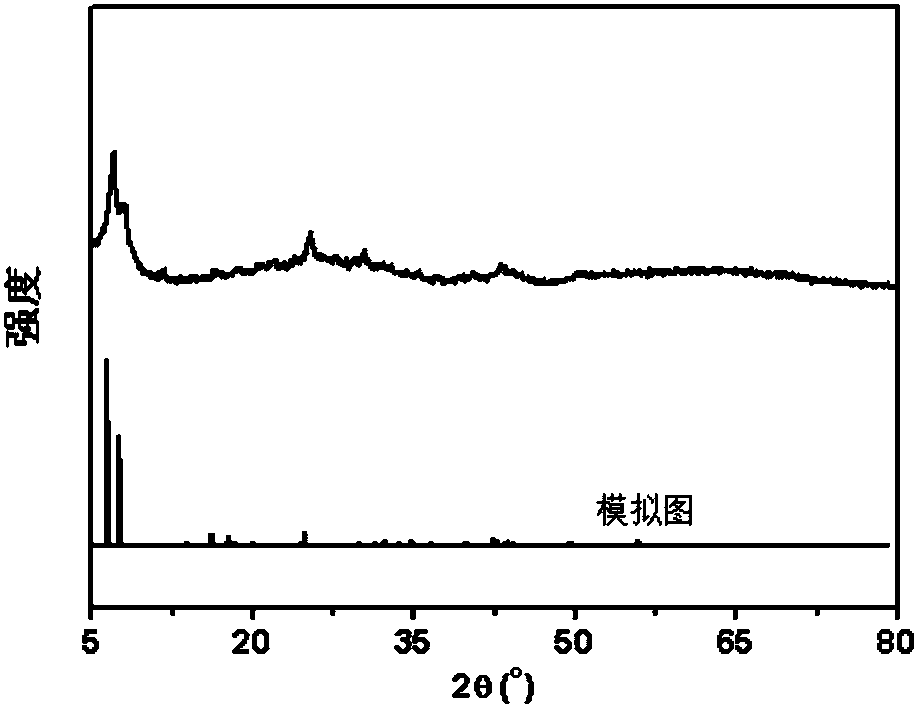

[0070] The X-ray diffraction spectrogram of the UiO-67 fiber filter membrane that present embodiment makes is as Figure 7 shown by Figure 7 It can be seen that the UiO-67 fiber filter membrane was successfully prepared in this example.

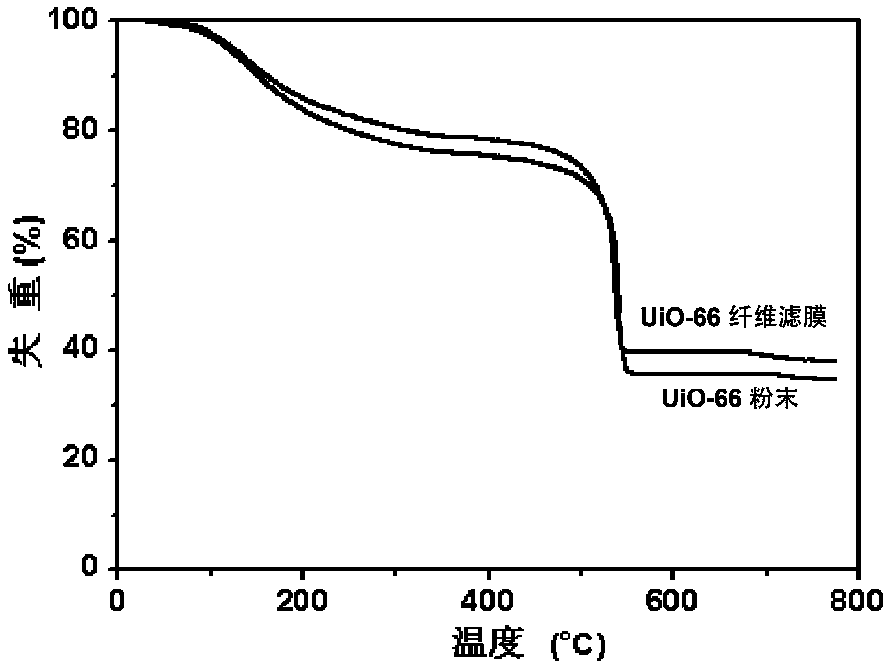

[0071] The thermogravimetric analysis curve of the UiO-67 fiber filter membrane that present embodiment makes is as Figure 8...

Embodiment 3

[0075] A self-sterilizing metal-organic framework UiO-66-NH as a chemical warfare agent 2 The preparation method of fiber membrane, as described in embodiment 1, difference is:

[0076] In step (3), the organic ligand solution is an aqueous solution of 10 g of aminoterephthalic acid with a concentration of 10 wt%.

[0077] The UiO-66-NH that present embodiment makes 2 Scanning electron microscope images of fiber filters Figure 11 shown by Figure 11 It can be seen that the fiber filter membrane prepared in this example is composed of fibers composed of spherical nanoparticles, and the fiber diameter is about 2 μm.

[0078] The UiO-66-NH that present embodiment makes 2 The X-ray diffraction spectrum of the fiber filter membrane is as follows Figure 12 shown by Figure 12 It can be seen that this example successfully prepared UiO-66-NH 2 fiber membrane.

[0079] The UiO-66-NH that present embodiment makes 2 The thermogravimetric analysis curve of the fiber filter memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com