Preparation method for pulp fiber-reinforced starch plastic

A pulp fiber and starch plastic technology, applied in the field of biodegradable plastics, can solve problems such as poor water resistance, insufficient strength, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The pulp fiber reinforced starch plastic is obtained according to the following method:

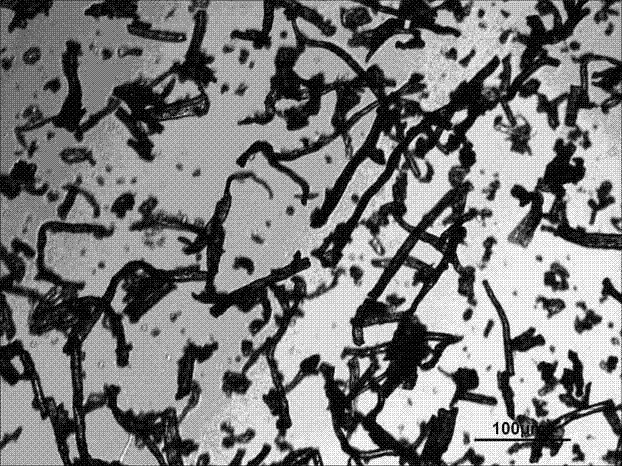

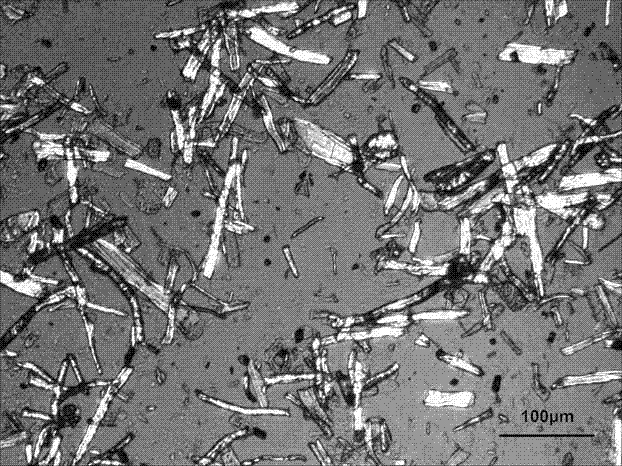

[0024] ① Cut 100 parts by weight of pulp fiberboard into small pieces, put it in a beaker, add 100 parts by weight of NaOH aqueous solution with a concentration of 15% by mass, moisten it for 0.5 hours, quickly add a little excess HCl to neutralize, and use No. 2 Sand core funnel suction filtration, then wash with distilled water until the pH is neutral, and dry;

[0025] ② Take another beaker, add 100 parts by weight of the above sample, and then add 100 parts by weight of 55% H 2 SO 4 Aqueous solution, heated up to 45°C, stirred at constant temperature, after 0.5h of reaction, filtered under reduced pressure, dried for later use;

[0026] ③ Add 5 parts by weight of the above-mentioned pulp fibers to 100 parts by weight of starch, and quickly mix them uniformly through a high-speed disperser, then add 15 parts by weight of a degradable plasticizer, and mix and disperse evenly ag...

Embodiment 2

[0028] The pulp fiber reinforced starch plastic is obtained according to the following method:

[0029] ① Cut 100 parts by weight of pulp fiberboard into small pieces, put it in a beaker, add 100 parts by weight of NaOH aqueous solution with a concentration of 20% by mass, wet it for 0.5 hours, quickly add a little excess HCl to neutralize, and use No. 2 Sand core funnel suction filtration, then wash with distilled water until the pH is neutral, and dry;

[0030] ② Take another beaker, add 100 parts by weight of the above sample, and then add 100 parts by weight of H with a concentration of 60% by mass. 2 SO 4 Aqueous solution, heated up to 50°C, stirred at constant temperature, after 0.5h of reaction, filtered under reduced pressure, dried for later use;

[0031] ③ Add 10 parts by weight of the above-mentioned pulp fibers to 100 parts by weight of starch, and quickly mix them uniformly through a high-speed disperser, then add 20 parts by weight of a degradable plasticizer, ...

Embodiment 3

[0033] The pulp fiber reinforced starch plastic is obtained according to the following method:

[0034] ① Cut 100 parts by weight of pulp fiberboard into small pieces, put it in a beaker, add 100 parts by weight of NaOH aqueous solution with a concentration of 25% by mass, wet it for 0.5 hours, quickly add a little excess HCl to neutralize, and use No. 2 Sand core funnel suction filtration, then wash with distilled water until the pH is neutral, and dry;

[0035] ② Take another beaker, add 100 parts by weight of the above sample, and then add 100 parts by weight of H with a concentration of 65% by mass. 2 SO 4 Aqueous solution, heated up to 55°C, stirred at constant temperature, after 0.5h of reaction, filtered under reduced pressure, dried for later use;

[0036] ③ Add 15 parts by weight of the above-mentioned pulp fibers to 100 parts by weight of starch, and quickly mix them uniformly through a high-speed disperser, then add 25 parts by weight of a degradable plasticizer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com