Silicon removal agent and preparation method and application thereof

A technology of medicament and polyaluminum chloride, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of affecting water hardness index and low efficiency of silicon removal, etc. Achieve good research prospects and application value, fast speed, and high silicon removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is a silicon removal agent CG-1, which is composed of the following components by weight: 75 parts of polyaluminum chloride, 12 parts of sodium metaaluminate, 6 parts of polyaluminum sulfate, 5 parts of polyferric sulfate, activated alumina 2 servings. Weigh the raw materials, grind, stir, and fully mix to prepare.

[0034] An oilfield in Dongying, Shandong Province conducts advanced treatment of heavy oil sewage, and reuses the thermal recovery boiler after reaching the standard. According to the Specifications for Design of Feedwater Treatment of Steam Generators and SY 5854-2012 "Safety Specifications for Wet Steam Generators Special for Oilfields", the content of silicate in boiler water (in terms of SiO 2 count) cannot exceed 50mg / L. The silicon content in sewage seriously exceeds the standard.

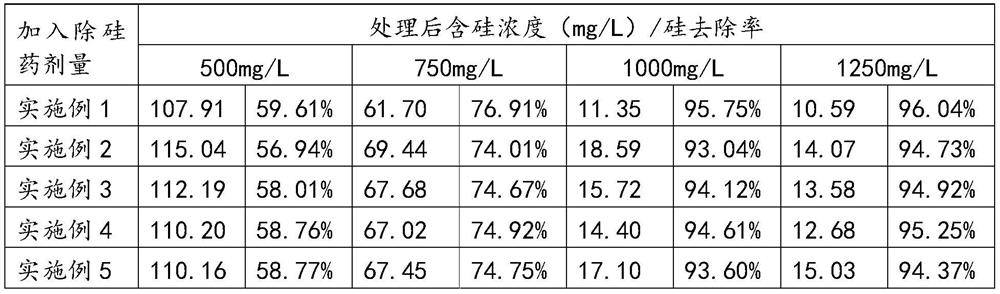

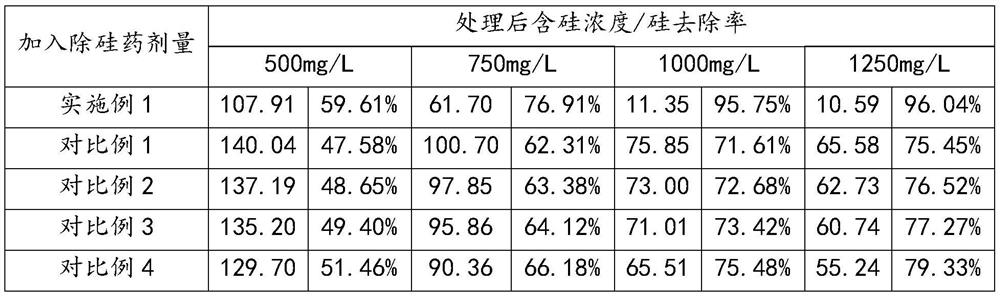

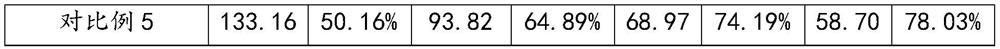

[0035] The silicon-removing agent CG-1 prepared in this example was used to treat silicon-containing sewage to investigate the treatment capacity and tr...

Embodiment 2

[0038] This embodiment is a silicon removal agent CG-2, which consists of the following components by weight: 73 parts of polyaluminum chloride, 14 parts of sodium metaaluminate, 5 parts of polyaluminum sulfate, 6 parts of polyferric sulfate, activated alumina 2 servings. It is prepared by weighing raw materials with a fixed mass fraction, grinding, stirring, and fully mixing. The same silicon-containing sewage as in Example 1 was treated with the silicon-removing agent, and the treatment method was the same as in Example 1. The results are shown in Table 1.

Embodiment 3

[0040] This embodiment is a silicon removal agent CG-3, which is composed of the following components by weight: 74 parts of polyaluminum chloride, 12 parts of sodium metaaluminate, 8 parts of polyaluminum sulfate, 5 parts of polyferric sulfate, activated alumina 1 serving. It is prepared by weighing raw materials with a fixed mass fraction, grinding, stirring, and fully mixing. The same silicon-containing sewage as in Example 1 was treated with the silicon-removing agent, and the treatment method was the same as in Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com