A method for removing heteroatoms in coal tar

A technology of coal tar and heteroatoms, which is applied in the field of removal of heteroatoms in coal tar, can solve the problems of difficult removal, high consumption of metal ions and ash impurities, and achieve good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

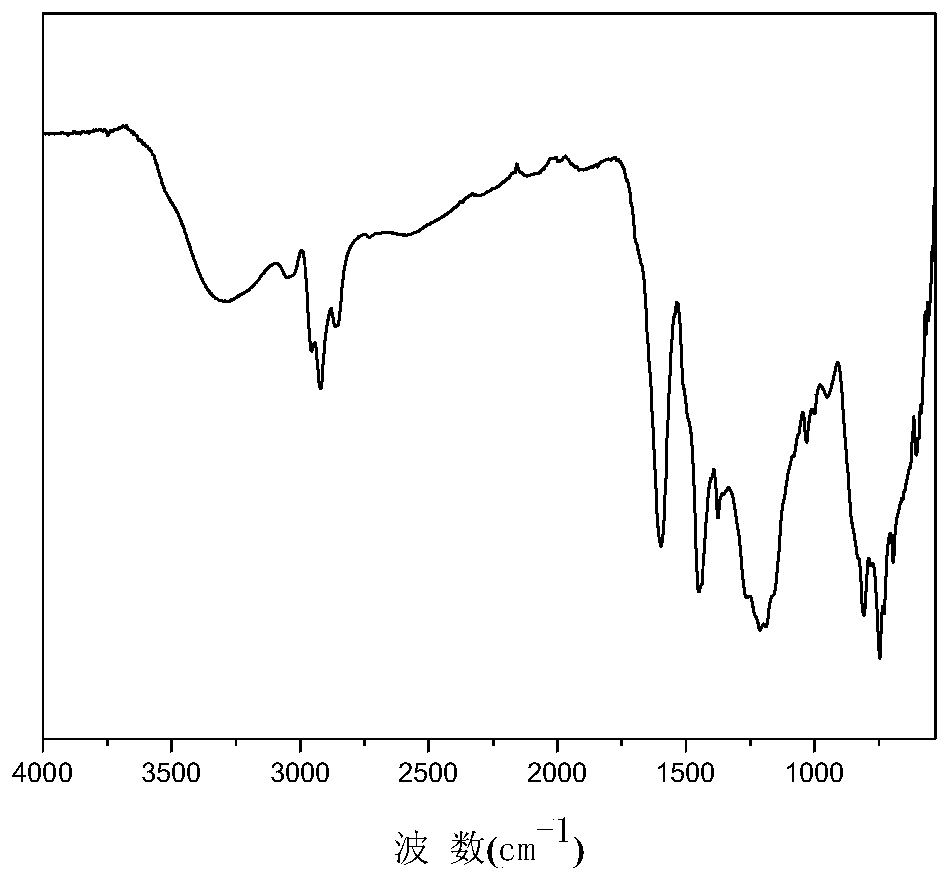

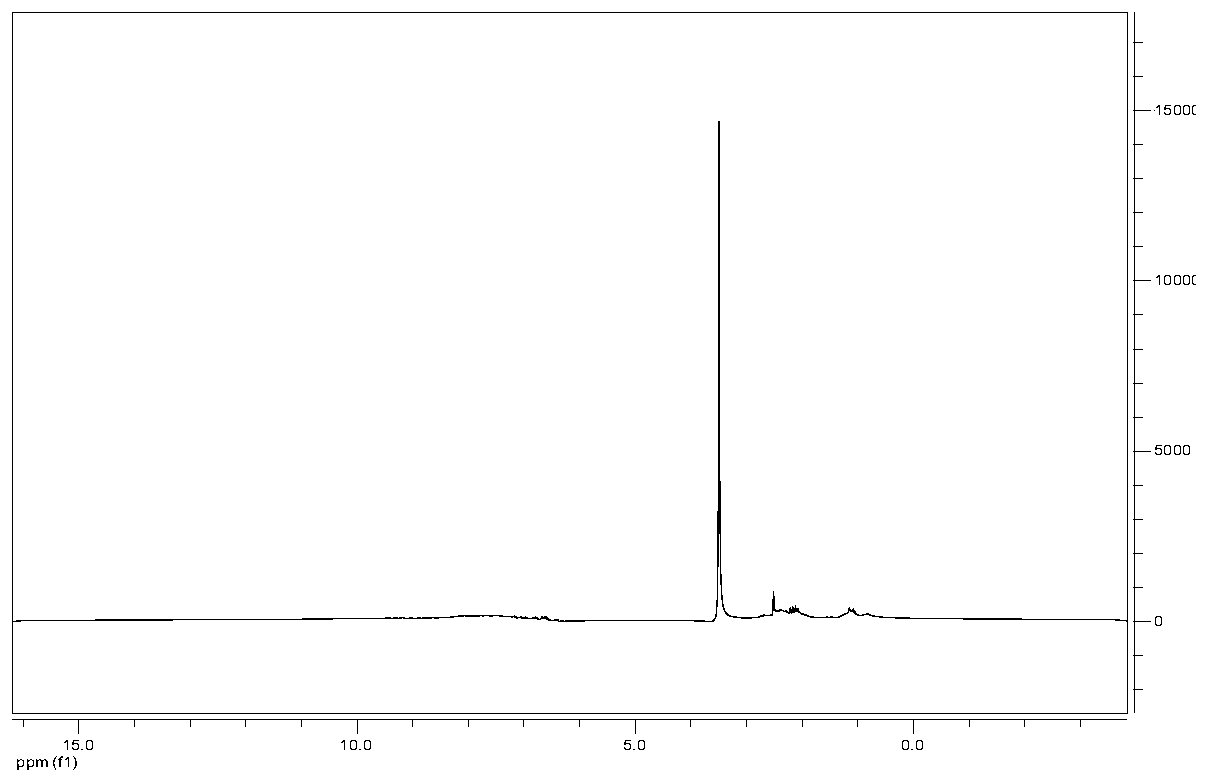

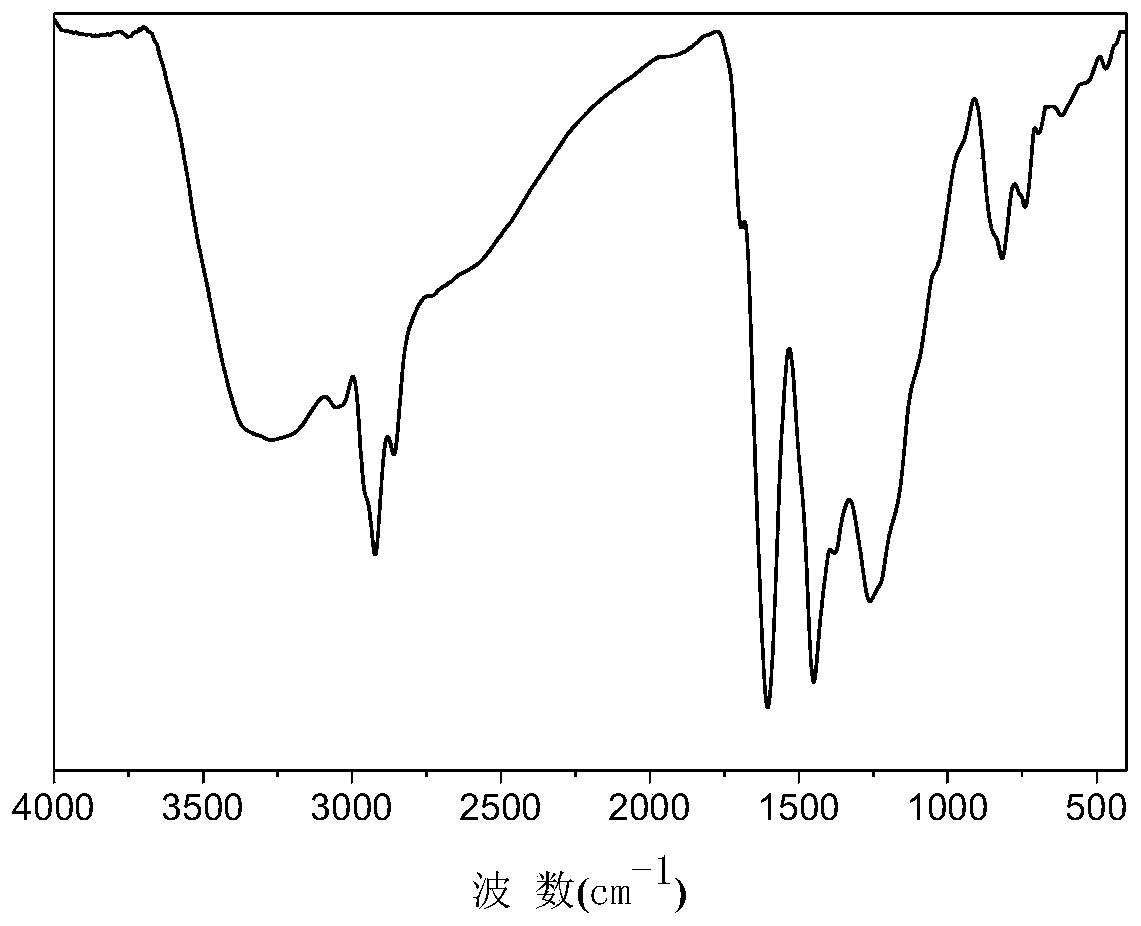

Image

Examples

Embodiment 1

[0058] In this embodiment, according to the operation steps of the above-mentioned method, calculated with the total weight of 150g coal tar, the multifunctional composite agent used has the following component distribution ratio:

[0059] Multifunctional Compound A 1 Including: acidic ion denitrification agent 85 μg / g, demetallization agent 70 μg / g, demulsifier 60 μg / g, synergist 30 μg / g, water 5wt%, mixed and prepared;

[0060] Multifunctional Compound B 1 It consists of: 70 μg / g asphalt flocculant, 20 μg / g accelerator and 60 μg / g dispersant, and is prepared by mixing.

[0061] Wherein: the acidic ion denitrification agent is 1-methyl-3-methylimidazole dimethyl sulfate; the metal removal agent is composed of 80wt% acetic acid and 20wt% polyaspartic acid; the demulsifier is 60wt% polyoxyethylene poly It is prepared by mixing oxypropylene polyether with 40wt% polyoxyethylene; the synergist is sulfate ester salt; the flocculation agent is polyacrylamide; the accelerator is po...

Embodiment 2

[0083] In this embodiment, according to the operation steps of Example 1, calculated with the total weight of 150g of coal tar, the multifunctional composite agent used has the following component distribution ratio:

[0084] Multifunctional Compound A 2 : 70 μg / g of acidic ion denitrification agent, 55 μg / g of metal removal agent, 50 μg / g of demulsifier, 20 μg / g of synergist, 3wt% of water, mixed and prepared;

[0085] Multifunctional Compound B 2 : 60 μg / g asphalt flocculation agent, 15 μg / g accelerator, and 50 μg / g dispersant, prepared by mixing, calculated on the basis of the total weight of 150 g of coal tar.

[0086] Wherein: the acidic ion denitrification agent is 1-ethyl-3-methylimidazole dihydrogen sulfate; the metal removal agent is composed of 80wt% acetic acid and 20wt% polyaspartic acid; the demulsifier is 60wt% polyoxyethylene poly It is prepared by mixing oxypropylene polyether with 40wt% polyoxyethylene; the synergist is sulfate ester salt; the asphalt floccu...

Embodiment 3

[0090] In this embodiment, according to the operation steps of Example 1, calculated with the total weight of 150g of coal tar, the multifunctional composite agent used has the following component distribution ratio:

[0091] Multifunctional Compound A 3 : Acidic ion denitrification agent 90 μg / g, metal removal agent 75 μg / g, demulsifier 65 μg / g, synergist 35 μg / g, water 8wt%, mixed and prepared;

[0092] Multifunctional Compound B 3 : 75 μg / g asphalt flocculation agent, 30 μg / g accelerator, and 65 μg / g dispersant, prepared by mixing, calculated on the basis of the total weight of 150 g of coal tar.

[0093] Wherein: the acidic ion denitrification agent is 1-methyl-3-methylimidazole dimethyl sulfate; the demetallization agent is composed of 80wt% metaphosphoric acid and 20wt% polyaspartic acid; the demulsifier is 60wt% alkylphenol aldehyde The resin and 40wt% polyoxyethylene are mixed; the synergist is sulfate ester salt; the asphalt flocculation agent is polyacrylamide; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com