Immobilized catalyst for deep sludge treatment

A supported catalyst, advanced treatment technology, applied in physical/chemical process catalysts, dewatering/drying/concentrating sludge treatment, sludge oxidation treatment, etc. Realize problems such as oxidative degradation of sludge granule organic matter micellar structure membrane and bacterial cell membrane, and achieve the effect of improving oxidation effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

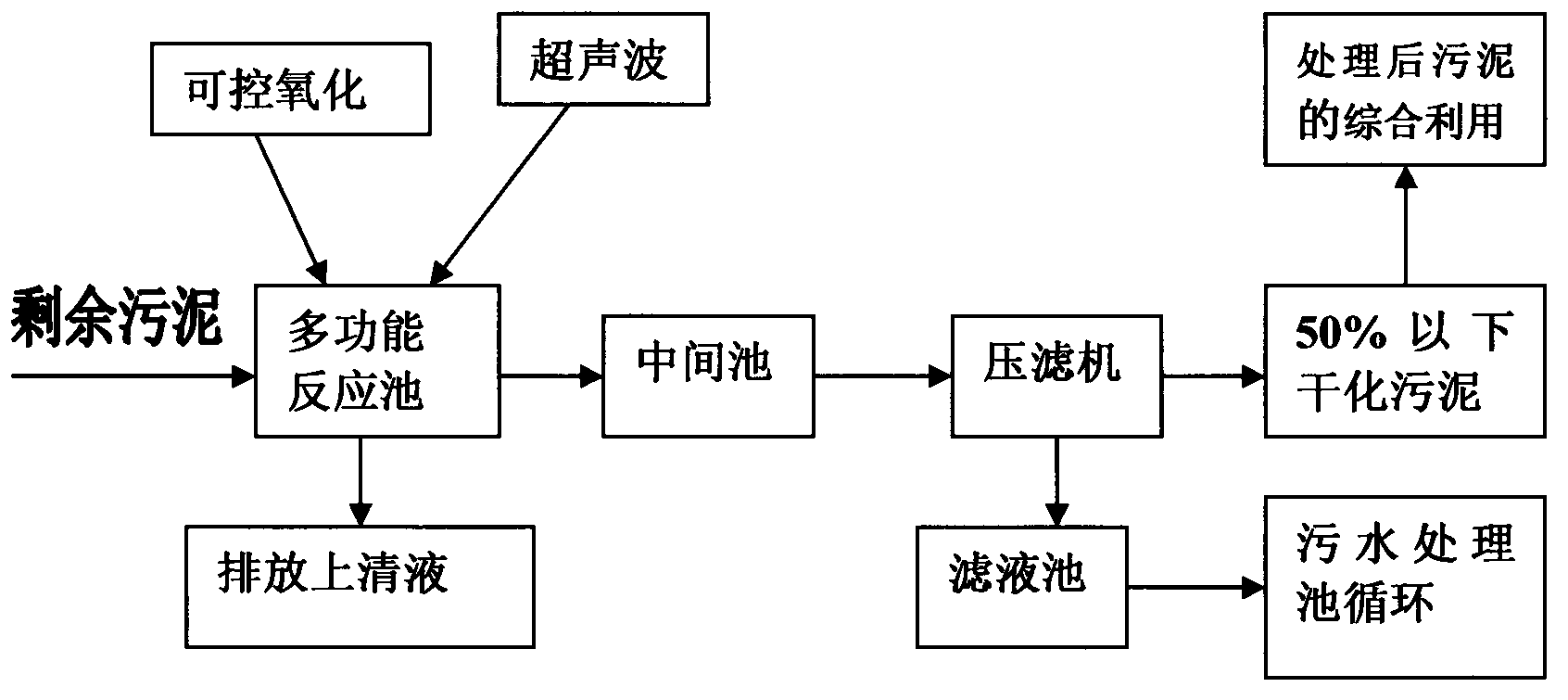

Method used

Image

Examples

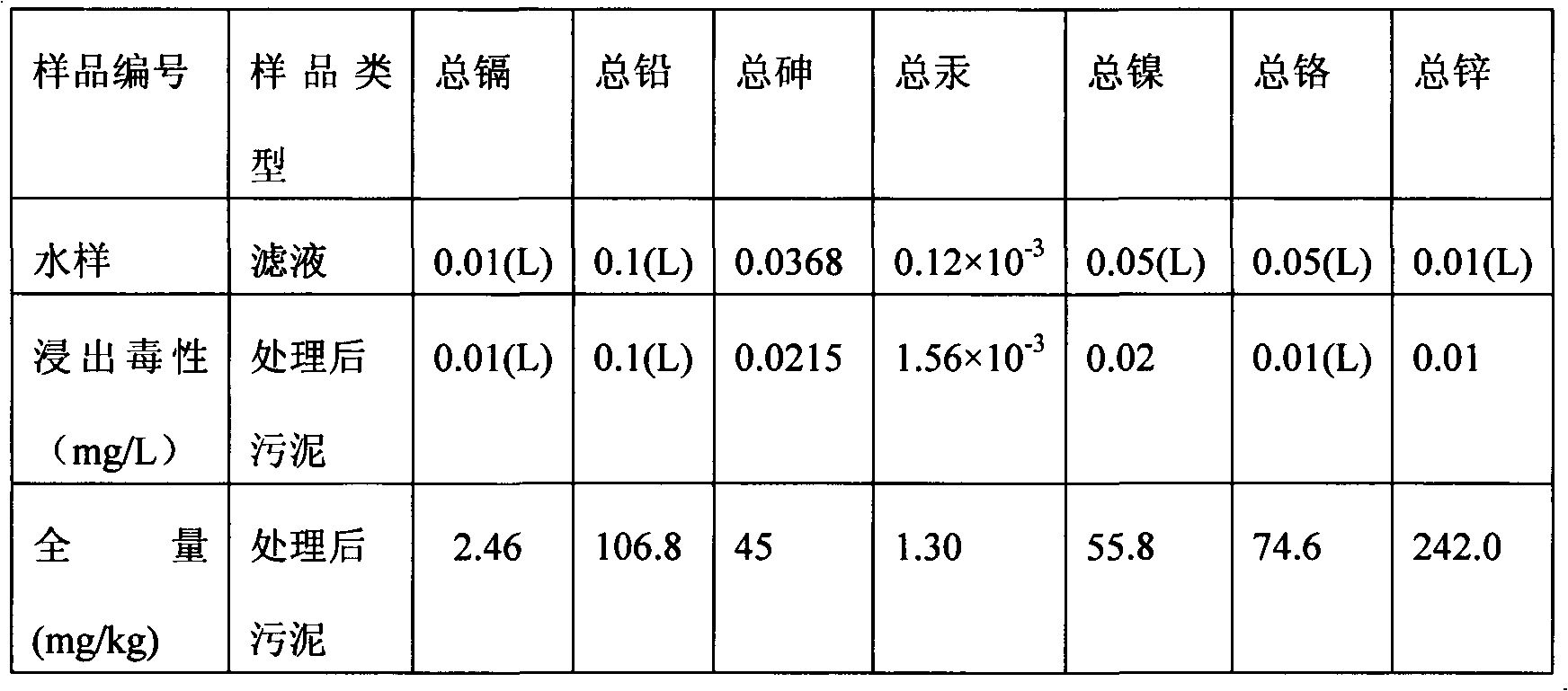

Embodiment 1

[0033] The excess sludge with a concentration of 20100mg / L is introduced into the reaction tank, and the import volume is 74.3m 3 , then add the loaded catalyst in the reaction tank, (fly ash 58kg, diatomite 1.3kg, FeCl 3 6.0kg, titanium dioxide 0.70kg) after stirring for 5min, then pass through the gas phase mass transfer instrument, pass into ozone to carry out the oxidation reaction, add the coagulation agent (FeCl 3 15.0kg, PAC 15.0kg, CPAM 1.95kg), after 5mi, the supernatant in the reaction tank is discharged into the drainage system of the sewage treatment plant, and the sludge is discharged into the intermediate tank, which is lifted to the diaphragm filter press by the screw pump, and passed through the ordinary pressure Filter to obtain sludge with a moisture content of 49.8%.

Embodiment 2

[0035] The excess sludge with a concentration of 19800mg / L is introduced into the reaction tank, and the import volume is 78.3m 3 , then add the loaded catalyst in the reaction tank, (fly ash 62kg, diatomaceous earth 1.4kg, FeCl 3 6.3kg, titanium dioxide 0.70kg), after stirring for 5 minutes, pass through the gas phase mass transfer instrument, pass into ozone to carry out oxidation reaction, add coagulation agent (FeCl 3 16.0kg, PAC15.5.0kg, CPAM2.2kg), after 5mi, the supernatant in the reaction tank is discharged into the drainage system of the sewage treatment plant, and the sludge is discharged into the intermediate tank, which is lifted to the diaphragm filter press by the screw pump, and passed through the ordinary Press filtration to obtain sludge with a water content of 48.5%.

Embodiment 3

[0037] The excess sludge with a concentration of 20560mg / L is introduced into the reaction tank, and the import volume is 69.8m 3 , then add the loaded catalyst in the reaction tank, (fly ash 58kg, diatomite 1.3kg, FeCl 3 5.9kg, titanium dioxide 0.65kg), after stirring for 5 minutes, pass through the gas phase mass transfer instrument, pass into ozone to carry out oxidation reaction, add coagulation agent (FeCl 3 15.0kg, PAC14.6kg, CPAM1.87kg), after 5 minutes, discharge the supernatant in the reaction tank into the drainage system of the sewage treatment plant, discharge the sludge to the intermediate tank, lift it to the diaphragm filter press through the screw pump, and pass through the ordinary press Filter to obtain sludge with a moisture content of 49.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com