Novel polysilicate ferric magnesium flocculant

A technology of magnesium iron polysilicate and flocculant, which is applied in the fields of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, energy and wastewater treatment, etc., can solve the problems of low stability, secondary pollution, restricted development, etc. Achieve the effect of low treatment cost, safe water quality and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

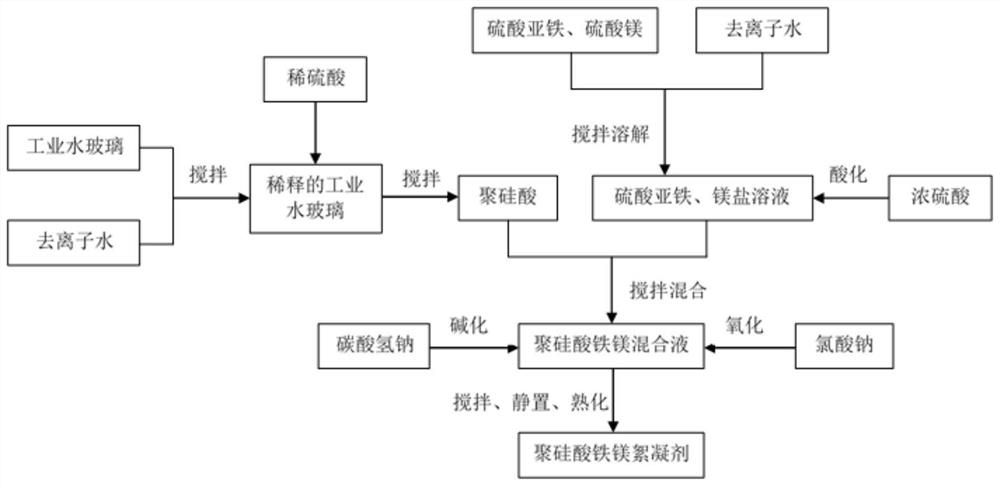

[0028] A novel polymagnesium iron polysilicate flocculant, the method comprises the following steps:

[0029] (1) Use a constant temperature water bath to control the temperature at 25°C, add 66mL of deionized water to 5mL of industrial water glass and stir to dilute, then add it to 16mL of dilute sulfuric acid with a mass fraction of 20%, and add sodium hydroxide dropwise solution and dilute sulfuric acid to adjust the pH of the solution to 1.0, and then stir rapidly with an electric mixer to prepare polysilicic acid with a mass fraction of silicon dioxide of 2%.

[0030] (2) Keeping the temperature constant, take 8.43g of ferrous sulfate heptahydrate and 7.46g of magnesium sulfate heptahydrate and dissolve them in 20mL of deionized water, add 4 to 5 drops of concentrated sulfuric acid for acidification to prevent the precipitation of iron ions, and then pass through a peristaltic pump to The rate of 1.5mL / min is added in the solution that step (1) prepares, obtains the solut...

Embodiment 2

[0034] The method described in this example is basically the same as Example 1, the difference is that the pH controlled in step (1) and step (3) is 2, and keeping other conditions constant, the obtained polymagnesium iron silicate flocculant 2 .

Embodiment 3

[0036] The method described in the present embodiment is basically the same as that of Example 1, the difference is that the dosage of industrial water glass in step (1) is 2.5mL, and the polysilicic acid that the mass fraction of silicon dioxide is 1% is prepared, and the step (2) The dosages of ferrous sulfate heptahydrate and magnesium sulfate heptahydrate in the medium were 4.22g and 3.73g respectively, and the dosage of sodium bicarbonate solution in step (3) was 9.1mL, keeping other conditions constant, the polysilicon obtained by reaction Magnesium iron flocculant 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com