A preparing method for an iron based catalyst

A technology of catalyst and catalyst carrier, which is applied in the field of coal chemical industry, can solve the problems of a large amount of waste water, and achieve the effects of reducing water consumption, easy operation, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

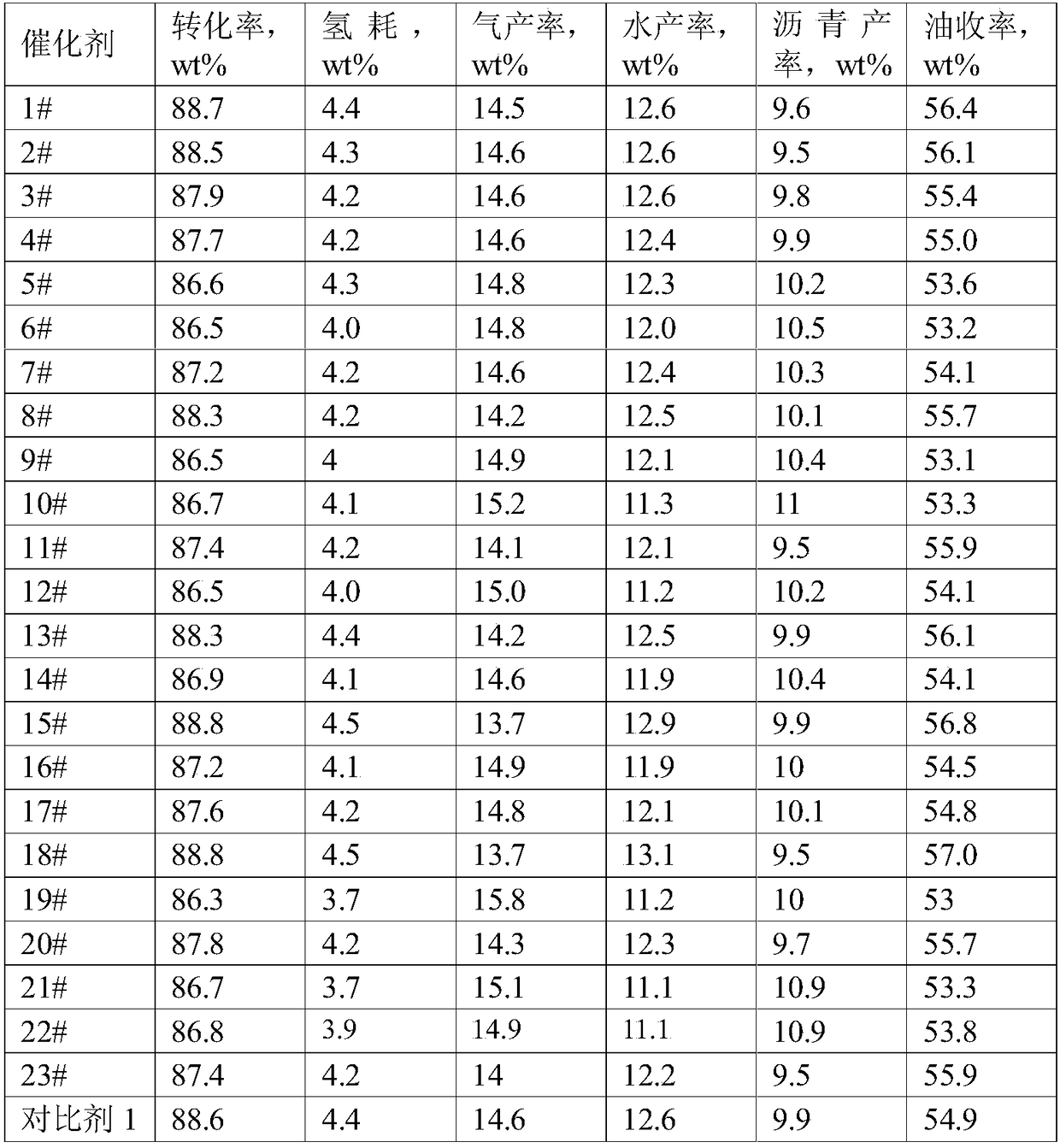

Examples

preparation example Construction

[0022] As described in the background art, the existing methods for preparing iron-based catalysts have the problem of generating a large amount of waste water. In order to solve the above-mentioned technical problems, the present invention provides a method for preparing an iron-based catalyst. The active component of the iron-based catalyst is FeOOH. The preparation method comprises: loading an iron-containing soluble salt solution on the catalyst carrier by spraying, Obtain the primary product; react the alkaline aqueous solution with the primary product to obtain the secondary product; and optionally oxidize the above secondary product according to the valence state of the iron ion in the iron-containing soluble salt solution, and then obtain the iron-based product through crystal phase transformation. catalyst.

[0023] Specifically, in a preferred embodiment, when the iron ion in the iron-containing soluble salt is +2, the above preparation method includes: loading the i...

Embodiment 1

[0047] Preparation 4kg concentration is 20wt% ferrous sulfate solution and 0.4kg concentration is 15wt% ammonia solution. Weigh 15 kg of dry coal powder ground to a particle size of less than 150 μm and place it in a 50 L reactor, and start the reactor to stir so that the coal powder is in a state of rapid stirring. The ferrous sulfate solution is transported to the nozzle installed on the upper part of the reaction kettle through the metering pump for atomization, and the mist is sprayed on the surface of the stirred coal powder, and wait for 1 hour; then the ammonia solution is transported to the nozzle through the metering pump for atomization , the spray droplets are sprayed onto the surface of the pulverized coal being stirred. The nozzle diameter of the nozzle is 0.4mm, which can make most of the droplet diameter within 200μm. After spraying, the reactor was heated to 120°C, and at the same time, compressed air preheated to 100°C was passed through for 8 hours to oxidiz...

Embodiment 2

[0049] Preparation 3.5kg concentration is 25wt% ferric sulfate solution and 0.25kg concentration is 25wt% sodium carbonate solution. Weigh 15 kg of dry coal powder ground to a particle size of less than 150 μm and place it in a 50 L reactor, and start the reactor to stir so that the coal powder is in a state of rapid stirring. The ferrous sulfate solution and the ammonia solution are transported to the nozzle installed on the upper part of the reactor for atomization through the metering pump, and the mist is sprayed on the surface of the stirred coal powder, and wait for 1 hour; then the ammonia solution is transported to the nozzle through the metering pump Atomization is carried out, and the mist is sprayed onto the surface of the stirred coal powder. The nozzle diameter of the nozzle is 0.4mm, which can make most of the droplets within 200μm, and the droplets can be sprayed to the surface of the stirred coal powder. After spraying, the reactor was heated to 150°C, and at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com