Low-temperature shearing rheological die casting technology

A technology of shear flow and process, which is applied in the field of semi-solid slurry rheological forming technology, can solve the problem that the pouring system and waste products cannot be recycled immediately, the storage and transportation of semi-solid slurry is inconvenient, and the quality of slurry is in storage and storage. Transportation deterioration and other problems, to achieve uniform microstructure distribution, fine intermetallic compounds and eutectic Si, and solve the effects of difficult storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

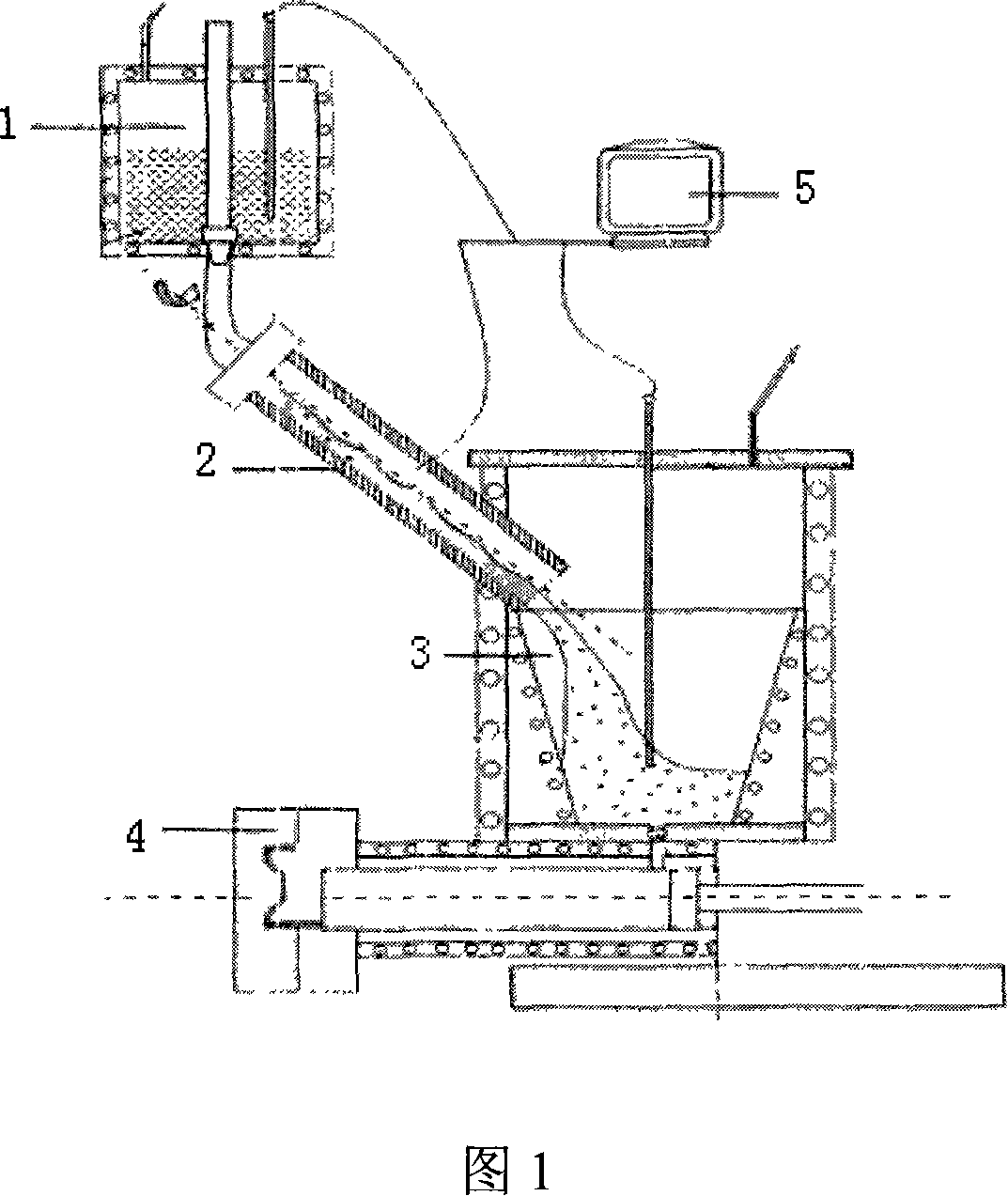

[0012] As shown in Figure 1, its process preparation method steps are as follows:

[0013] 1. The alloy melt enters the rotating conveying pipe mechanism 2 through the feeding device 1, and the low-speed conveying pipe is used to control the cooling to realize the rapid cooling of the molten metal and the stirring at the initial stage of solidification, so that the temperature of the melt flowing through the conveying pipe reaches ±3°C of the alloy liquid line , to stimulate the nucleation of the melt, strengthen the free grains, and reduce the melting of free grains;

[0014] 2. The melt carrying a large number of crystal nuclei flows into the crystallization furnace 3, and the growth form of the primary phase and the solid phase ratio of the slurry are controlled and detected through the online slurry quality control system 5 to obtain high-quality semi-solid slurry;

[0015] 3. When the solid phase ratio reaches 20%-40%, the slurry is injected into the die-casting machine 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com