Method of preparing nano-carbon fiber using coal tar asphalt as raw material

A technology of coal tar pitch and nano-carbon fiber, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of large energy consumption, serious pollution in the production process, and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

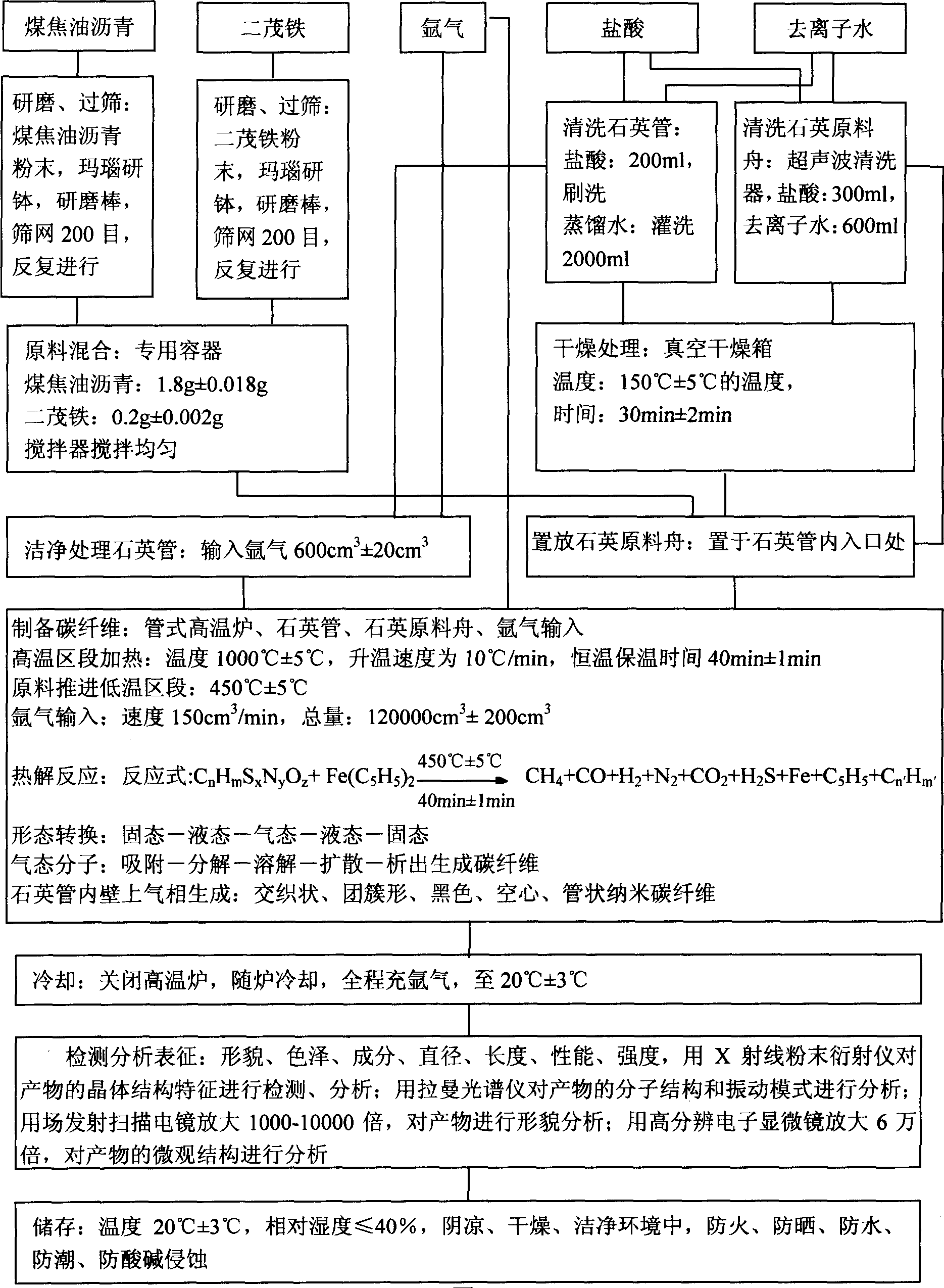

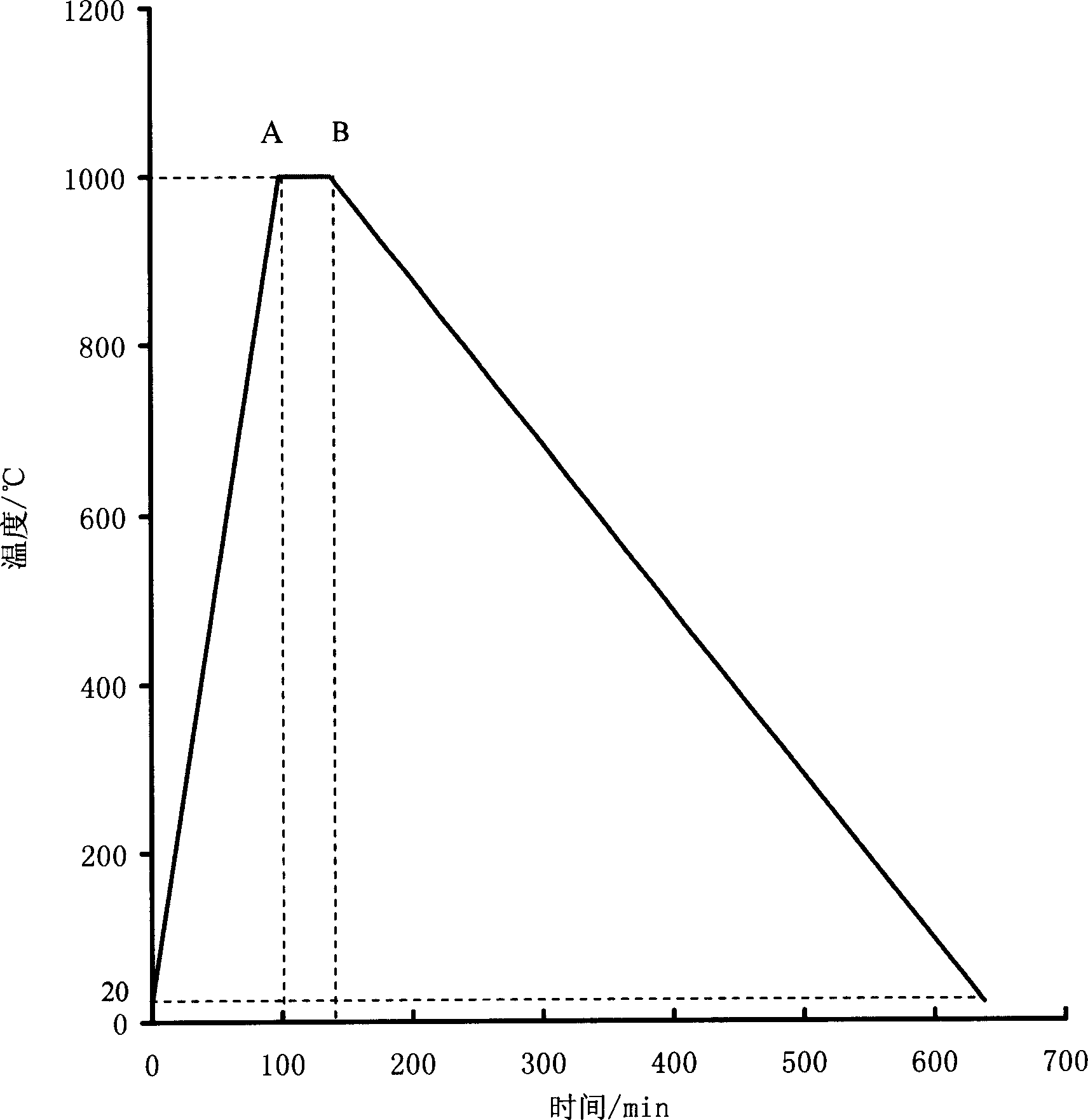

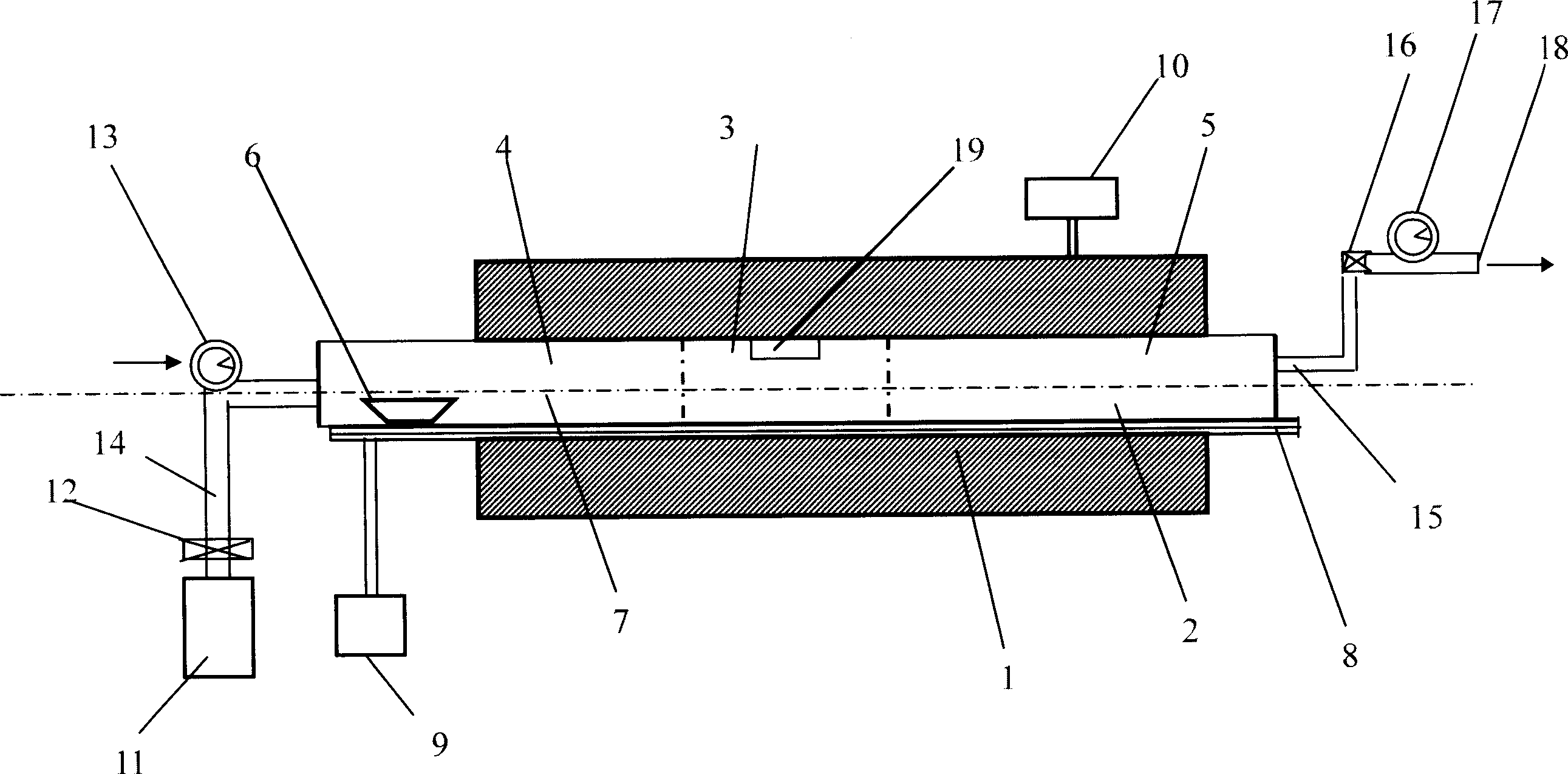

Method used

Image

Examples

Embodiment 1

[0157] All production equipment is in ready working condition;

[0158] Select chemical raw materials and conduct purity control;

[0159] Grinding and sieving:

[0160] Put 18.0 g of coal tar pitch raw material in a mortar, grind it with a grinding rod, sieve it with a 200-mesh sieve, grind and sieve it repeatedly, and leave 1.8 g ± 0.018 g of fine powder;

[0161] Put 2.0 g of ferrocene in a mortar, grind with a grinding rod, sieve through a 200-mesh sieve, grind and sieve repeatedly, leaving 0.2 g ± 0.002 g of fine powder;

[0162] To clean the quartz tube:

[0163] Scrub the inner wall of the quartz tube with 200ml of hydrochloric acid;

[0164] Rinse the inner wall of the quartz tube with 2000ml deionized water;

[0165] Clean the quartz raw material boat:

[0166] Wash with 300ml hydrochloric acid and ultrasonic cleaner for 20min±1min;

[0167] Clean with 600ml of deionized water and ultrasonic cleaner for 30min±2min;

[0168] Dry quartz tube, quartz raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com