Activated carbon based nano TiO2 composite MnO2 catalytic material and preparation method therefor

A catalytic material and activated carbon technology, applied in chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., can solve the problems of small particle size of nanoparticles, easy electron-hole recombination, low photon utilization rate, etc., to achieve removal Strong capacity, good adsorption performance, and short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

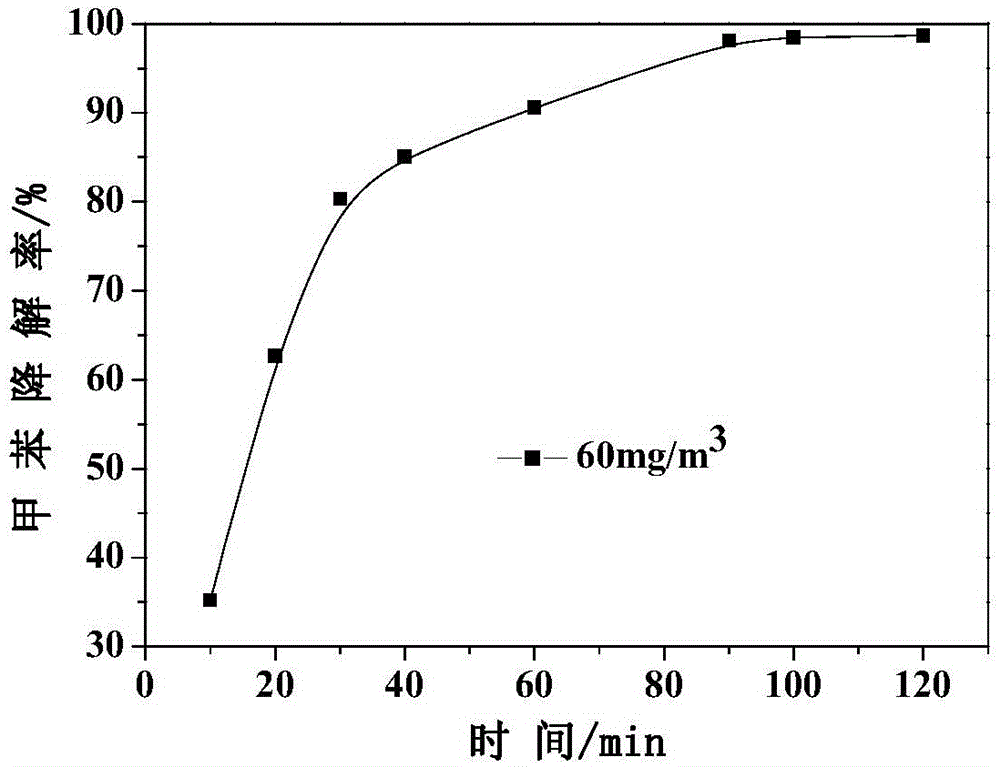

[0049] Specific embodiment 1: basis Figure 5

[0050] At room temperature of 25°C, the prepared composite catalytic material was applied to degrade low-concentration indoor toluene gas, and the degradation was carried out under ultraviolet light irradiation. Samples are taken at regular intervals to detect the concentration of toluene gas. Depend on Figure 5 It can be seen that the composite catalytic material provided by the present invention can treat low-concentration indoor toluene gas at normal temperature. In the first 30 minutes of degradation, the degradation rate of toluene increased rapidly. After 60 minutes, the degradation rate of toluene reached over 90%. Therefore, the composite catalytic material provided by the present invention has excellent catalytic effect at normal temperature.

specific Embodiment 2

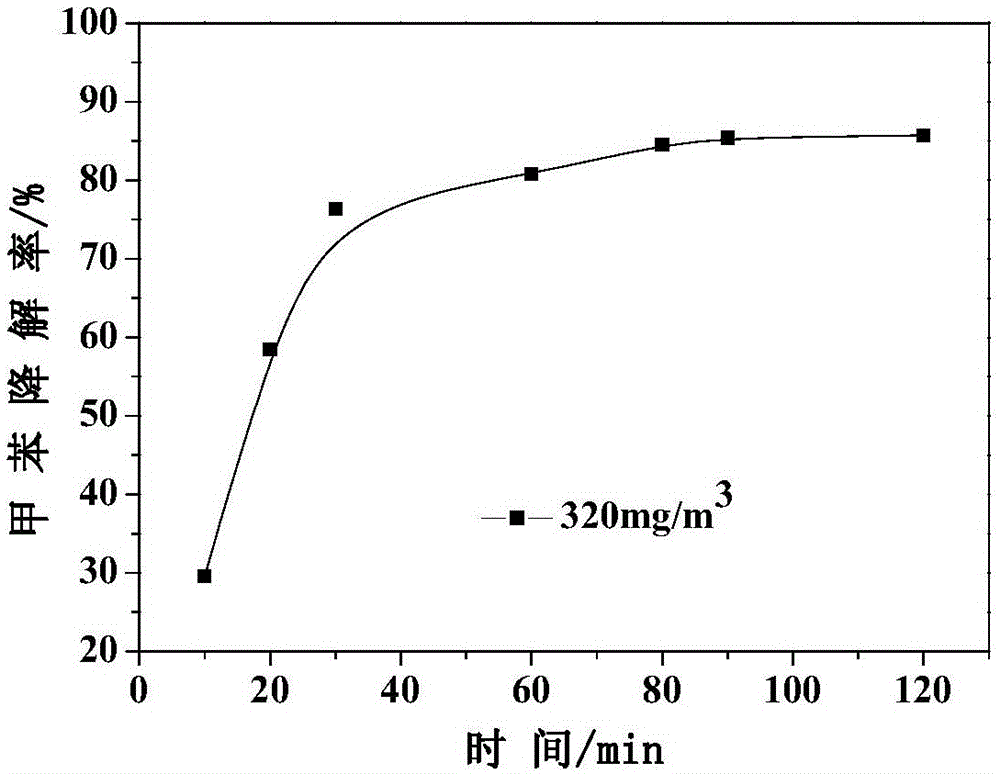

[0051] Specific embodiment 2: basis Figure 6

[0052] Under the temperature condition of 80°C, the prepared composite catalytic material was applied to treat high-concentration industrial toluene gas, and degraded under ultraviolet light irradiation. Samples are taken at regular intervals to detect the concentration of toluene gas. Depend on Figure 6 It can be seen that high-concentration toluene gas can be efficiently degraded at a temperature of 80°C. In the first 60 minutes of degradation, the degradation rate of toluene increased rapidly, and at 80-90 minutes, the degradation rate of toluene reached more than 85%. After 90 minutes, the degradation rate of toluene basically remained unchanged, and the degradation rate of toluene could reach 90%. Therefore, the composite catalytic material provided by the invention has an excellent catalytic degradation effect on high-concentration toluene at high temperature.

[0053] Through the above-mentioned specific embodiments, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com