Al-Ti-Si alloy target material and preparation method thereof

A silicon alloy and target technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of inability to meet the use requirements of the coating layer on the surface of the tool and mold, and achieve the goal of promoting the use and production. The effect of low cost and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

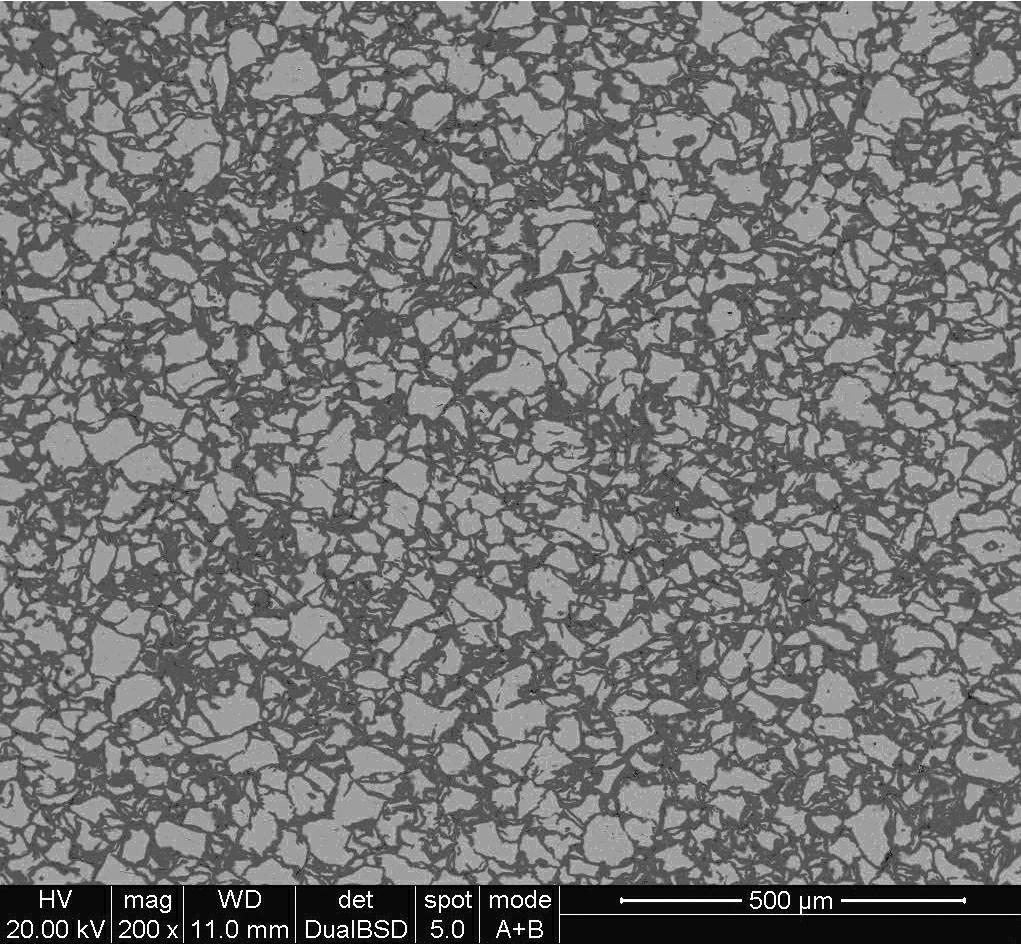

Image

Examples

Embodiment 1

[0026] The aluminum-titanium-silicon alloy target of the present invention is made of the following raw materials in mass percentage: 9% aluminum, 90% titanium, and 1% silicon;

[0027] The average particle size of the aluminum powder is 10 μm;

[0028] The average particle size of the titanium powder is 10 μm;

[0029] The average particle size of the silicon powder is 10 μm;

[0030] The purity of the aluminum powder is 99.6%, the purity of the titanium powder is 99.5%, and the purity of the silicon powder is 99.9%.

[0031] The preparation method of the aluminum-titanium-silicon alloy target in this embodiment includes the following steps:

[0032] (1) Weigh aluminum powder, titanium powder, and silicon powder, and mix them in a three-dimensional mixer for 0.5 hours. During the mixing process, fill the mixing cylinder with argon gas to reduce oxidation during the powder mixing process;

[0033] (2) Put the uniformly mixed aluminum, titanium and silicon mixed powder i...

Embodiment 2

[0039] The aluminum-titanium-silicon alloy target of the present invention is made of the following raw materials in mass percentage: 90% aluminum, 5% titanium, and 5% silicon;

[0040] The average particle size of the aluminum powder is 25 μm;

[0041] The average particle size of the titanium powder is 200 μm;

[0042] The average particle size of the silicon powder is 200 μm;

[0043] The purity of the aluminum powder is 99.4%, the purity of the titanium powder is 99.2%, and the purity of the silicon powder is 99.3%.

[0044] The preparation method of the aluminum-titanium-silicon alloy target of the present invention comprises the following steps:

[0045] (1) Weigh aluminum powder, titanium powder, and silicon powder, and mix them in a three-dimensional mixer for 6 hours. During the mixing process, fill the mixing cylinder with argon gas to reduce oxidation during the powder mixing process;

[0046] (2) Put the uniformly mixed aluminum, titanium and silicon mixed p...

Embodiment 3

[0052] The aluminum-titanium-silicon alloy target of the present invention is made of the following raw materials in mass percentage: aluminum 67%, titanium 30%, silicon 3%;

[0053] The average particle size of the aluminum powder is 10 μm;

[0054] The average particle size of the titanium powder is 100 μm;

[0055] The average particle size of the silicon powder is 100 μm;

[0056] The purity of the aluminum powder is 99.5%, the purity of the titanium powder is 99.5%, and the purity of the silicon powder is 99.5%.

[0057]The preparation method of the aluminum-titanium-silicon alloy target in this embodiment includes the following steps:

[0058] (1) Weigh aluminum powder, titanium powder, and silicon powder, and mix them in a three-dimensional mixer for 3 hours. During the mixing process, fill the mixing cylinder with argon gas to reduce oxidation during the powder mixing process;

[0059] (2) Put the uniformly mixed aluminum, titanium and silicon mixed powder in the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com