Method for manufacturing multi-rod converging valve type space net shell node

A production method and node technology, applied in the direction of architecture, building structure, etc., can solve the problems of unfavorable mass production operations, heavy node assembly workload, high production cost, etc., achieve short production process, reduce production cost, and produce high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

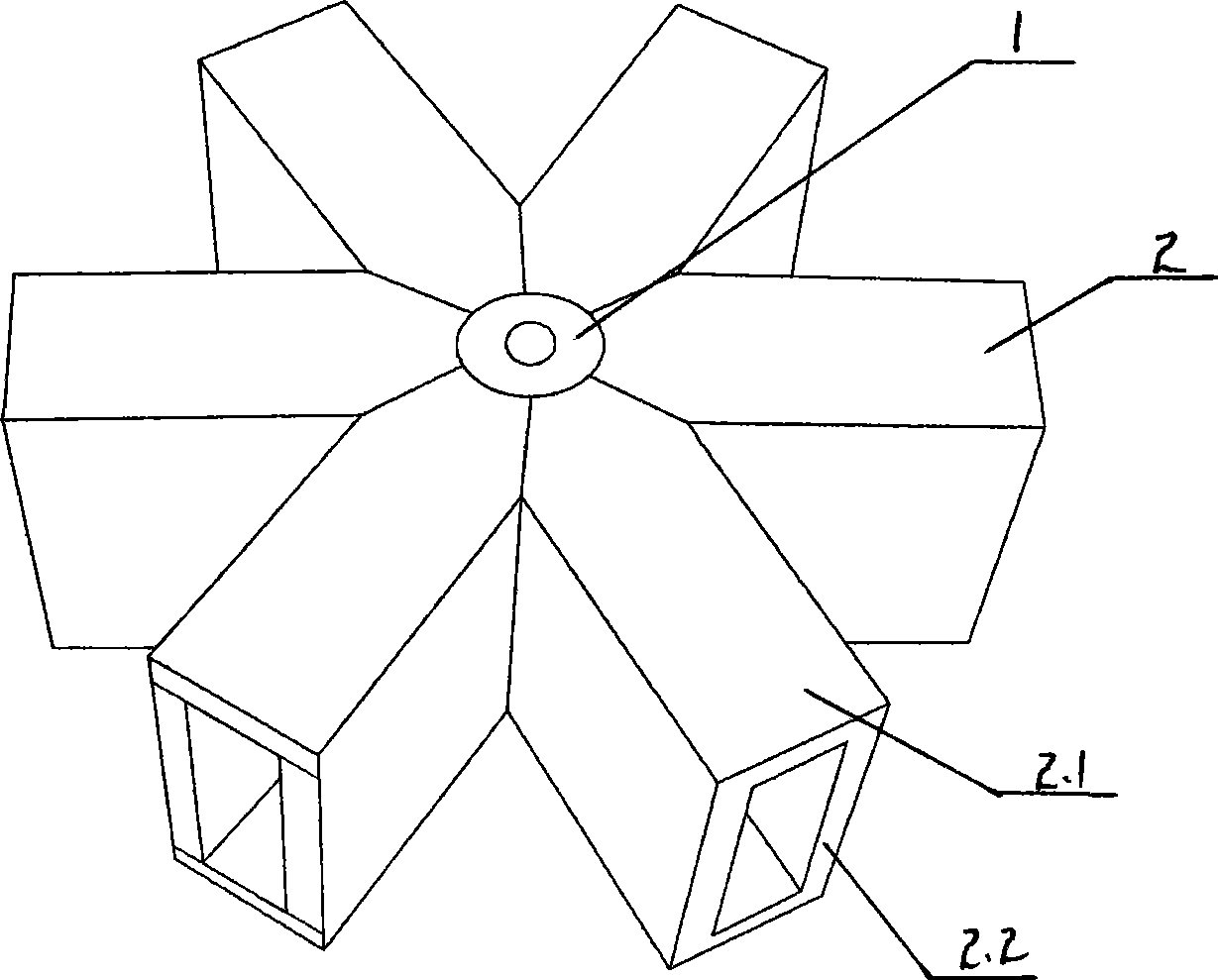

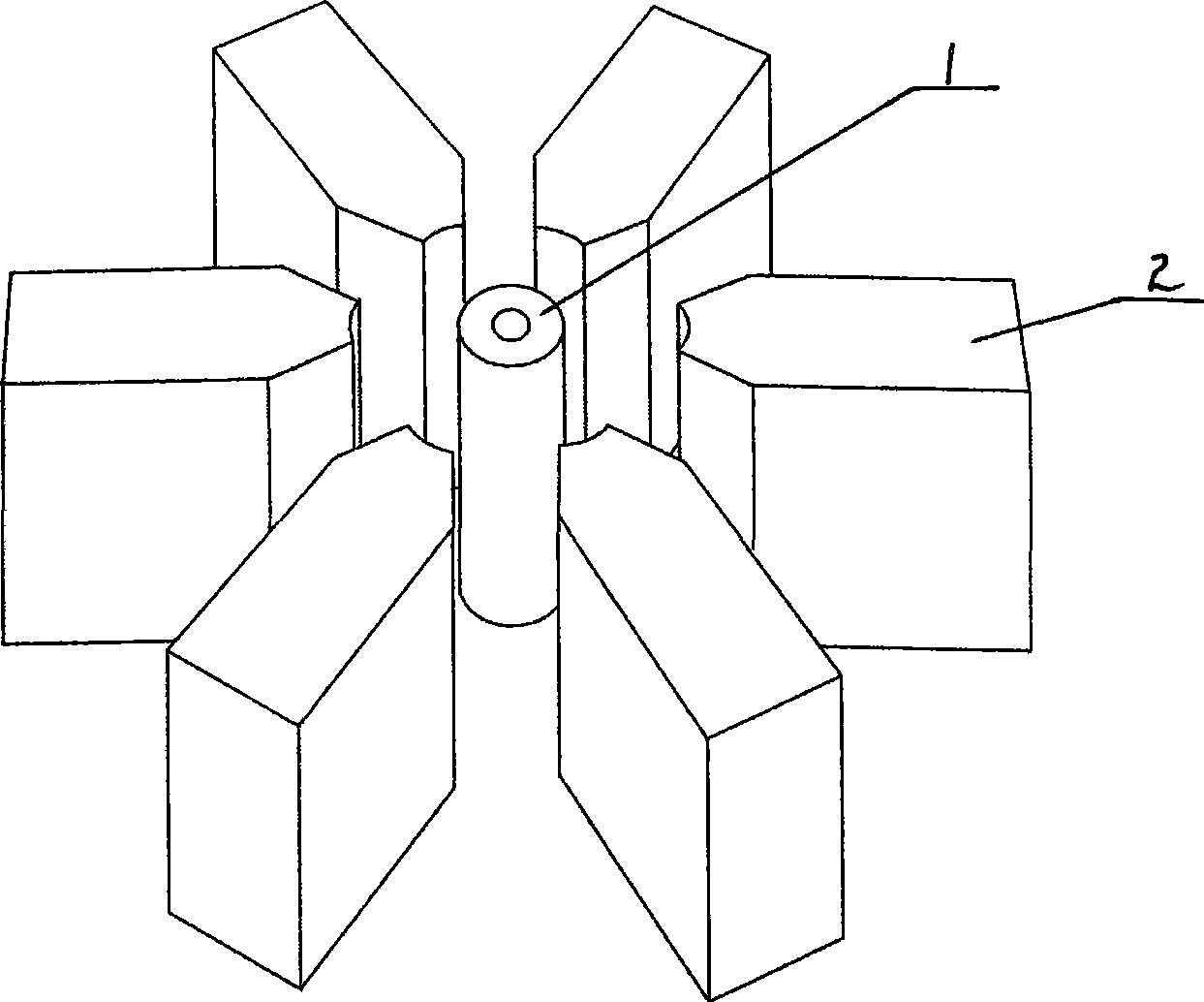

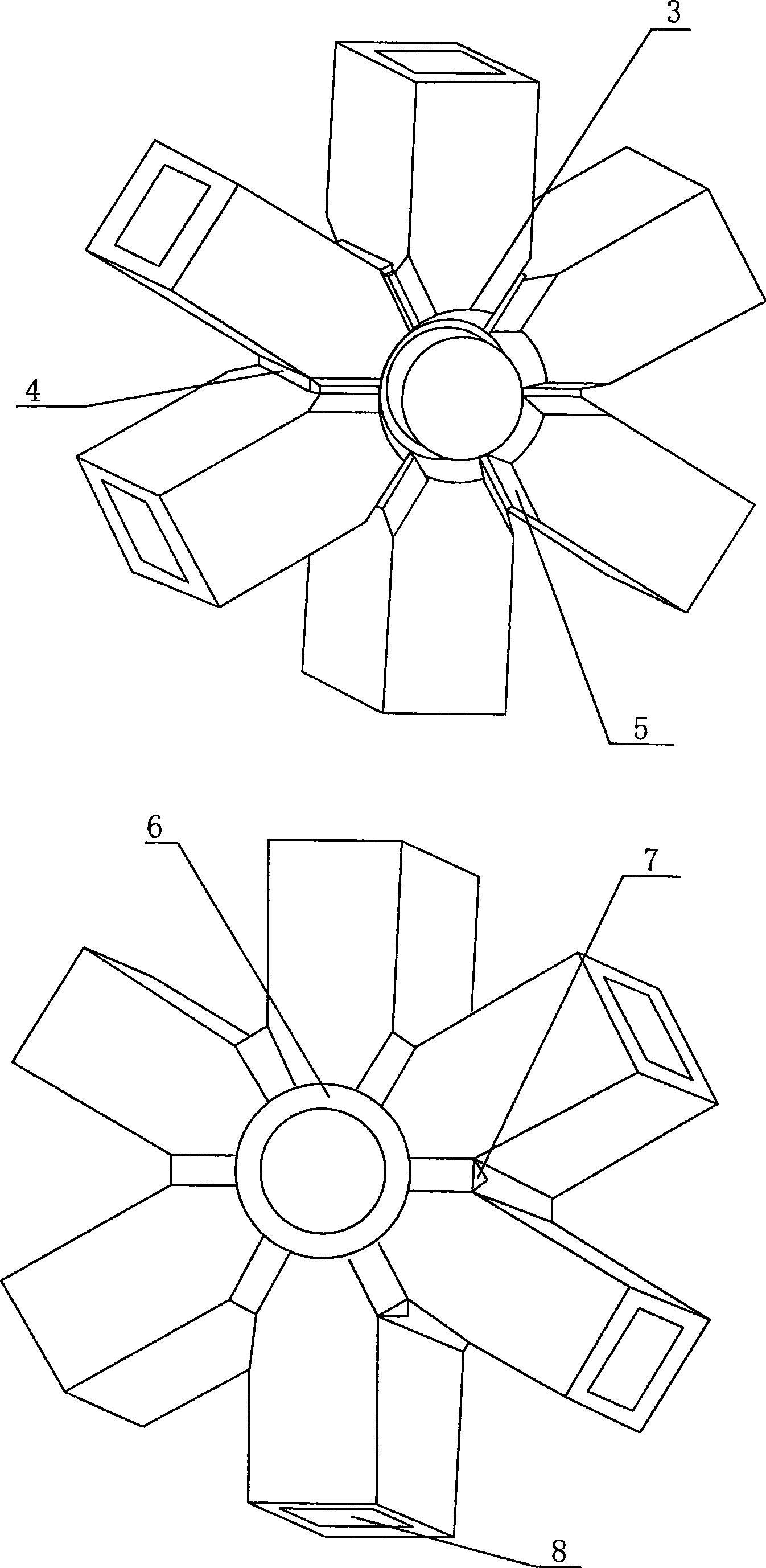

[0028] 1), in the described step of decomposing nodes, first construct the isotangent plane between each node lobe (that is, the bisector of the angle between the adjacent nodal lobe), and utilize the isotangent plane to evenly decompose the node into number and the number of petals of the node The same node lobe and a central cylinder; and number the nodal lobe according to a certain direction (clockwise or counterclockwise), then collect the geometric data of each structural unit, and generate a formatted data file containing node geometric information;

[0029] 2), in the blank making step of described structural unit, the size of the node flap blank is the maximum size that can form each node flap unit module shape after the above-mentioned decomposition, such as a cuboid of standard length, also can be triangular prism, cylinder body etc. The central cylinder can be obtained by machining standard round steel or cast round steel;

[0030] Production of node flap blanks: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com