Photocatalytic composite material taking coal ash hollow microspheres as substrate and preparation method of photocatalytic composite material

A technology of hollow microspheres and composite materials, applied in the field of photocatalytic materials, can solve problems such as numerous steps and complicated operations, and achieve the effects of high photocatalytic activity, short preparation process and effective treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Measure 15 mL of absolute ethanol and add it to a 100 mL beaker, add 1.8 mL of tetrabutyl titanate dropwise and stir for 15 minutes, then add 30 mL of hydrochloric acid with a weight concentration of 37%, stir for 15 minutes, then add deionized water dropwise until the total volume of the mixed solution is 60 mL.

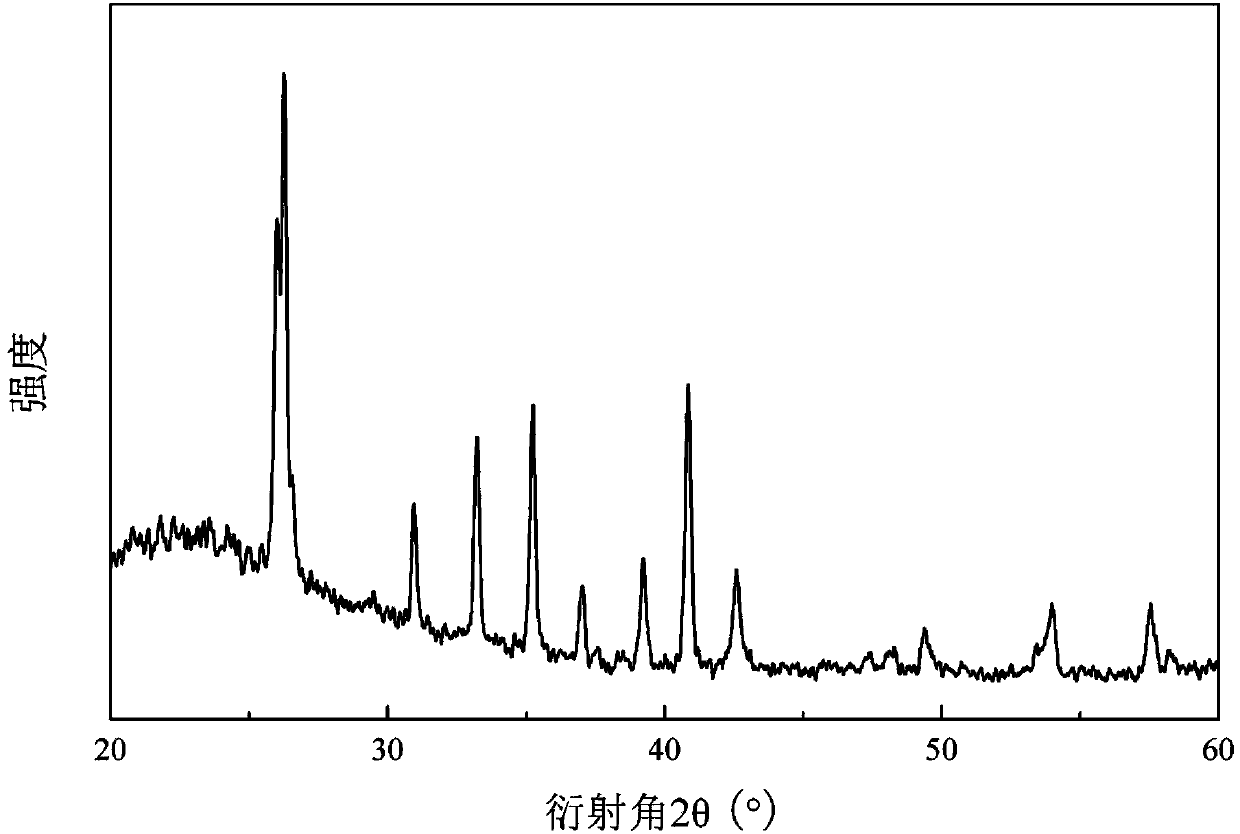

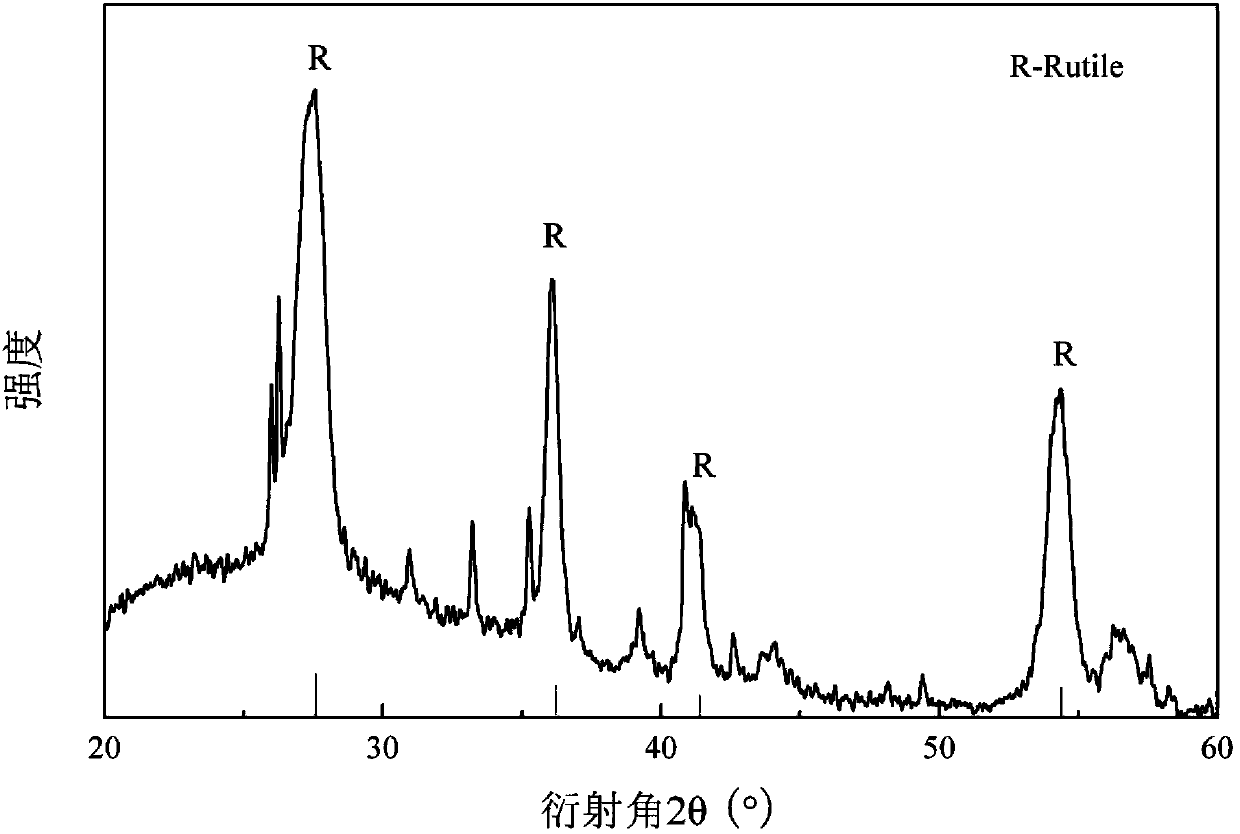

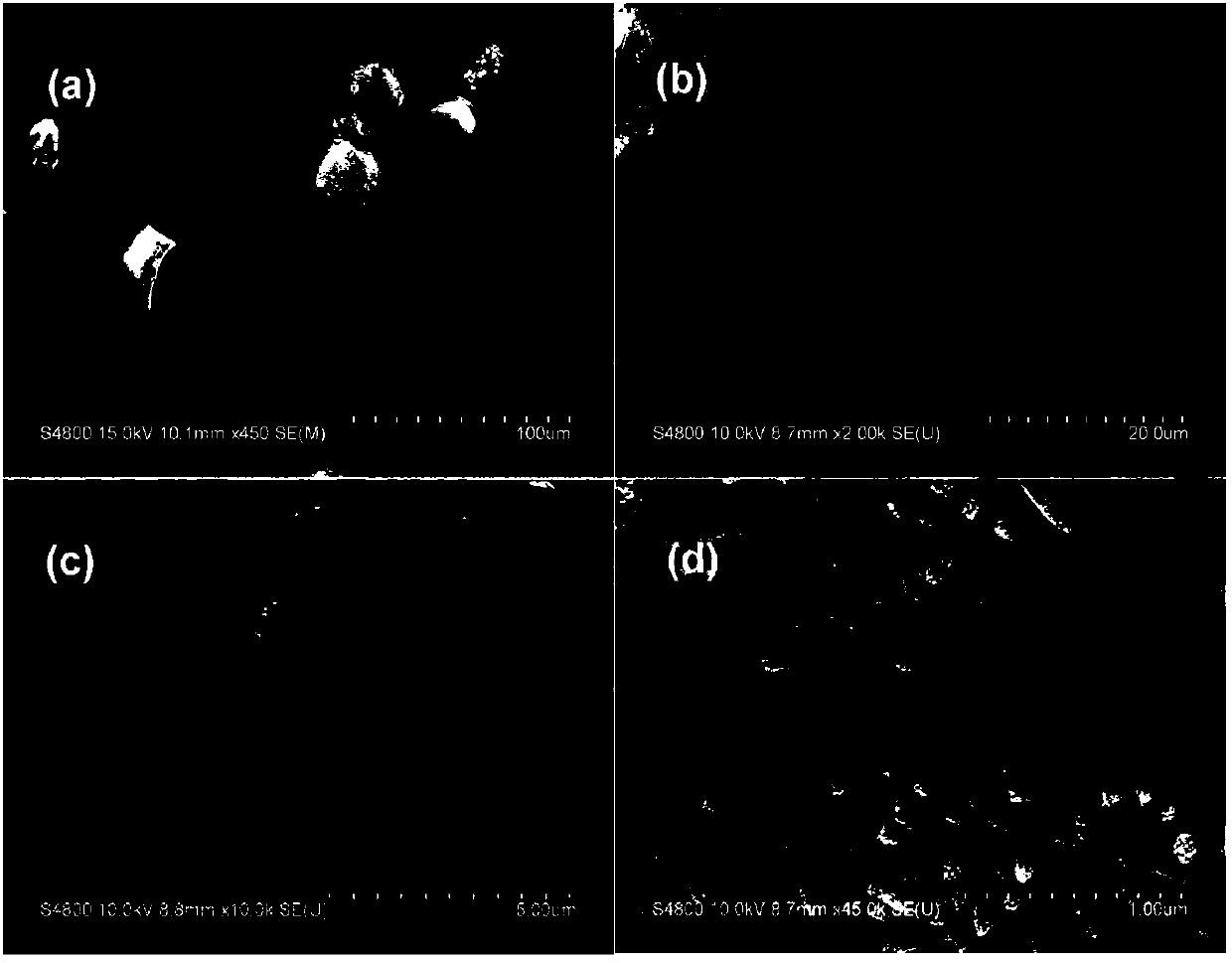

[0036] Take by weighing 1.2g fly ash hollow microspheres (the XRD spectrogram is shown in figure 1 ), added to the above mixed solution, and then transferred to a 100mL hydrothermal reaction kettle, heated to 180°C and kept for 8h. Cool the product to room temperature, then filter with suction, wash with ethanol, wash with deionized water, and dry at 50°C for 15 hours to obtain TiO grown on the surface of fly ash hollow microspheres. 2 nanorods, XRD tests show that TiO 2 The crystal form of nanorods is rutile (see figure 2 ), SEM photographs show TiO 2 The length of the nanorod is 0.5 ~ 1 μm, and the diameter is less than 100nm (see image 3 ).

Embodiment 2

[0038] Measure 12 mL of absolute ethanol and add it to a 100 mL beaker, add 1.8 mL of titanium tetrachloride dropwise and stir for 15 min, then add 30 mL of hydrochloric acid with a weight concentration of 37%, stir for 15 min, then add deionized water dropwise until the total volume of the mixed solution is 60 mL.

[0039] Weigh 1.2g of fly ash hollow microspheres (same as Example 1), add to the above mixed solution, then transfer to a 100mL hydrothermal reaction kettle, heat to 210°C and keep it warm for 4h. Cool the product to room temperature, then filter with suction, wash with ethanol, wash with deionized water, and dry at 80°C for 6 hours to obtain TiO grown on the surface of fly ash hollow microspheres. 2 Nano stave. SEM photo shows TiO 2 The length of the nanorod is 1-1.5 μm, and the diameter is less than 100 nm (see Figure 4 ).

Embodiment 3

[0041] The same method as in Example 1, except that 21mL of concentrated nitric acid with a weight concentration of 65% is used instead of concentrated hydrochloric acid with a weight concentration of 37%, to obtain TiO grown on the surface of fly ash hollow microspheres. 2 The length of the nanorods is 1-1.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com