Device and method for preparing high-purity nano ZnO through hydrogen cycle reduction

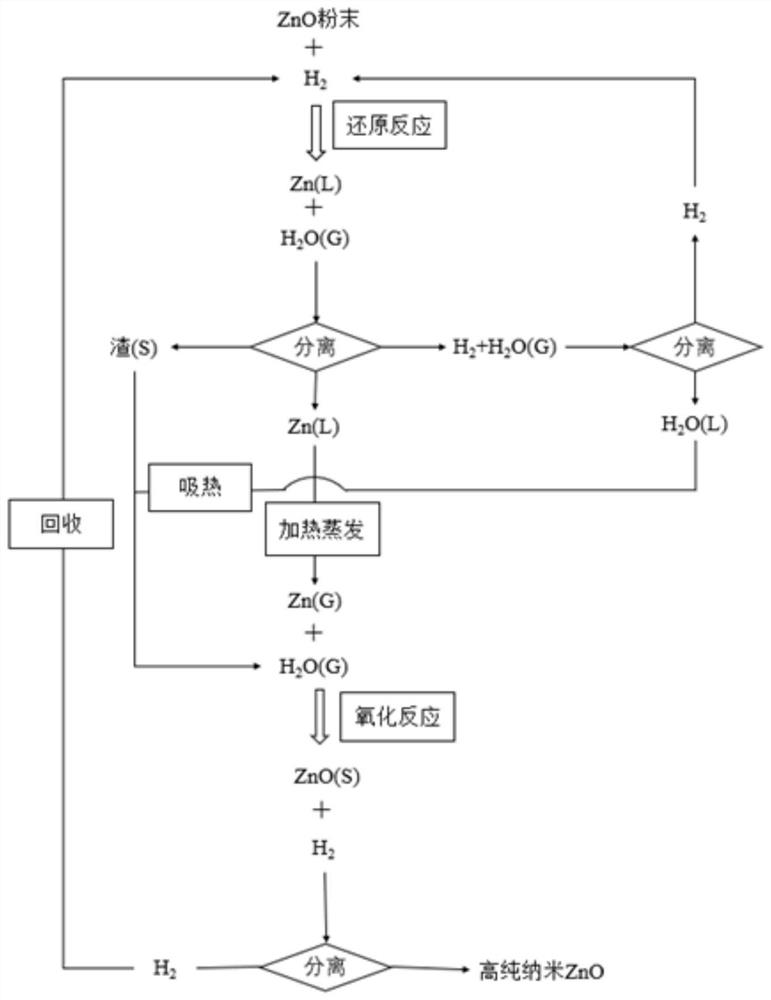

A hydrogen and nanotechnology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of long nano-zinc oxide process, high cost and energy consumption, and high emissions, so as to improve uniformity, purity and output, reduce consumption, Good oxidizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific content of the present invention will be further explained in detail below in conjunction with the examples, but it is not intended to limit the present invention.

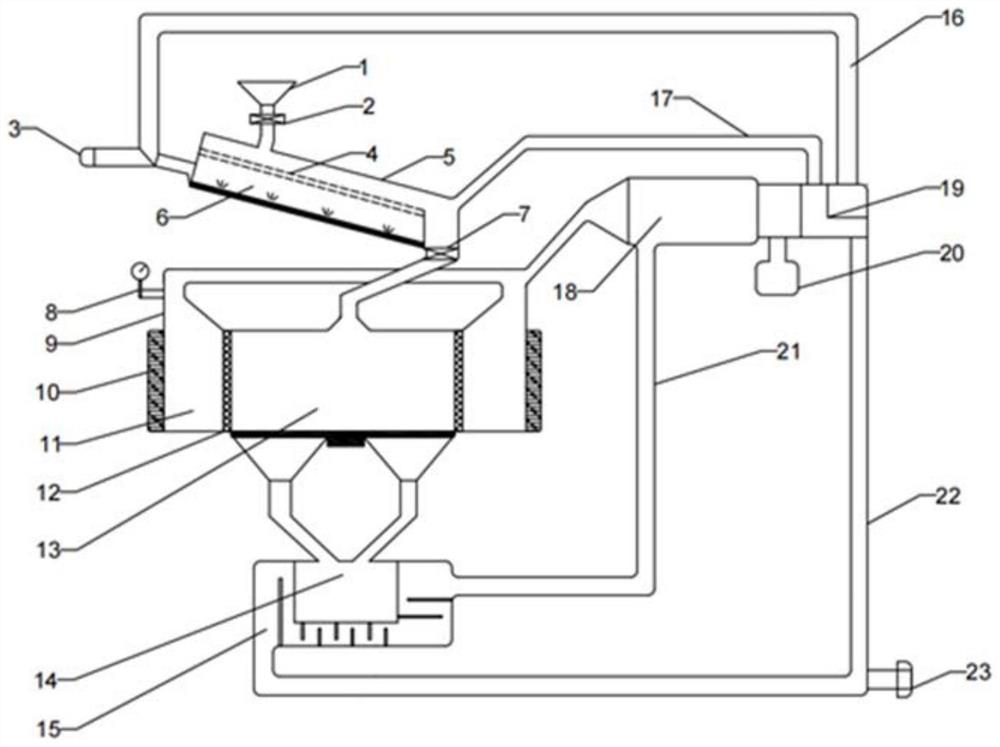

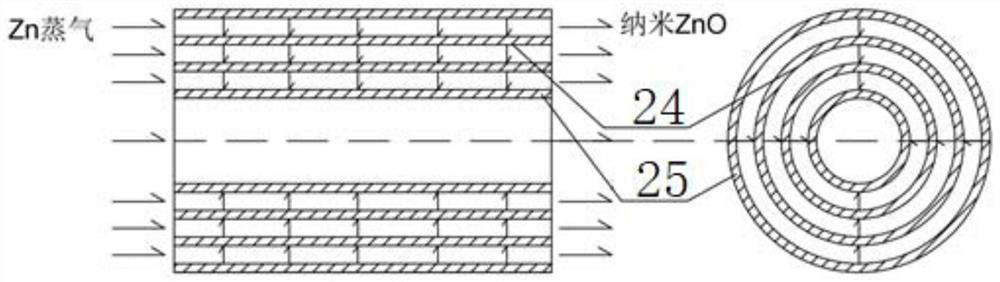

[0046] Such as figure 2 , image 3 As shown, a device for preparing high-purity nano-ZnO through hydrogen circulation reduction includes a reduction furnace 5, a solid-liquid separation and vaporization furnace 9, a waste heat recovery device 15, and an oxidation chamber 18;

[0047] The top of the reduction furnace 5 is connected with a feed bin 1 through a pipeline, the bottom of the feed bin 1 is connected with a discharge device 2, and the bottom of the discharge device 2 is connected with the reduction furnace 5, so that the zinc oxide calcine can be continuously and quantitatively Slowly enter the reduction furnace 5, so as to fully contact with hydrogen; the bottom plate of the reduction furnace 5 is the first porous plate 4, the lower part of the first porous plate 4 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com