A kind of production equipment and technology of zirconium sponge

A production equipment and technology of zirconium sponge, applied in the field of production equipment and technology of zirconium sponge, can solve the problems of low efficiency, waste of zirconium tetrachloride, low efficiency of reduction reaction of zirconium sponge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

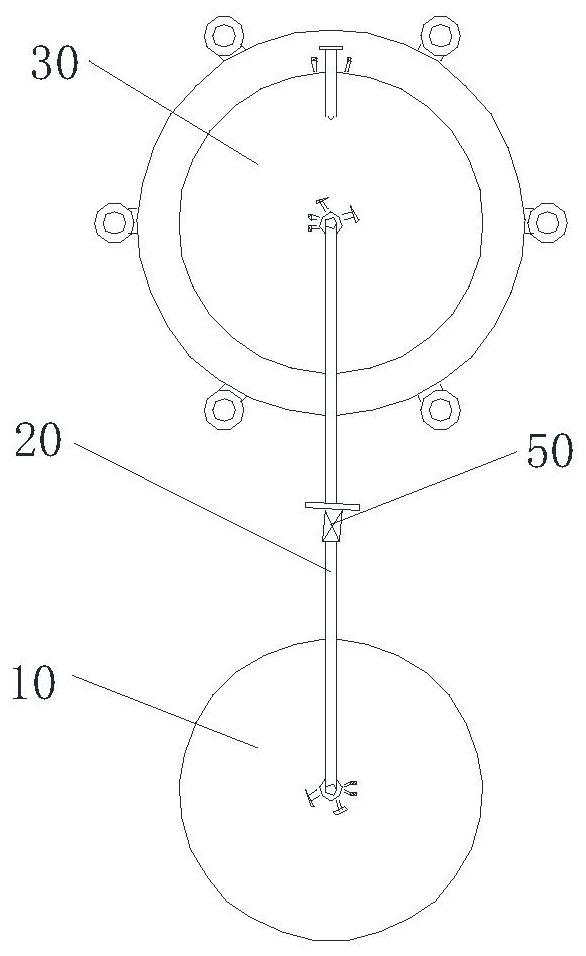

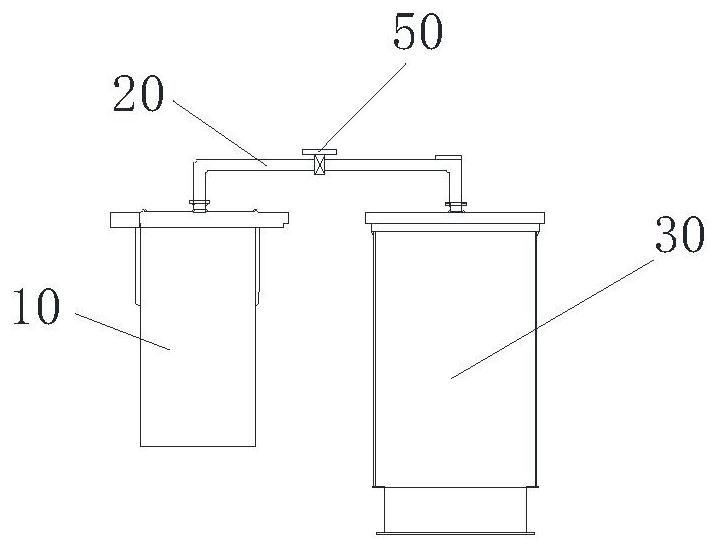

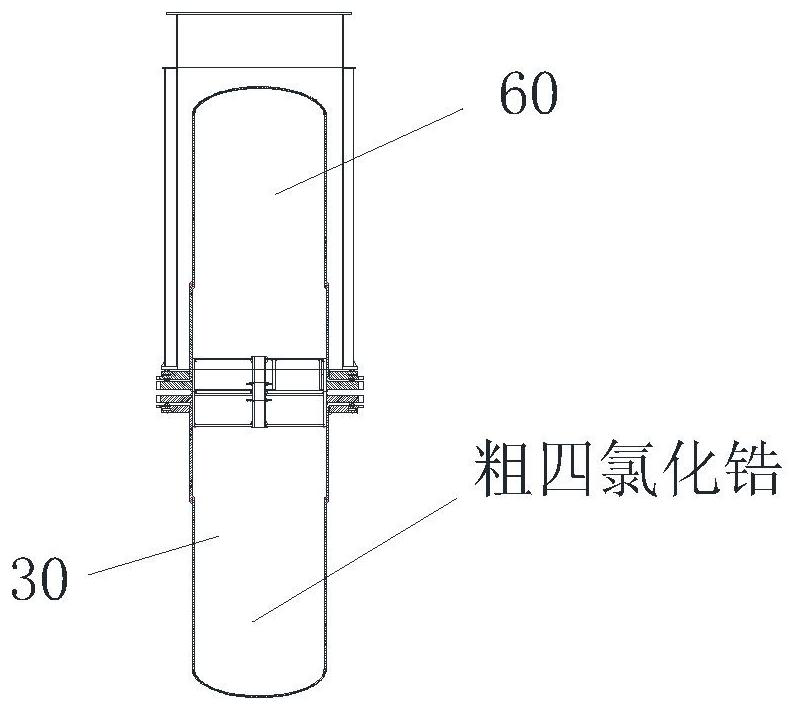

[0003] In order to solve the above-mentioned technical problems, the present invention provides a kind of production equipment and technology of sponge zirconium, by setting the gas explosion tube structure of inert gas on the production equipment of sponge zirconium and gas explosion in the magnesium liquid of furnace gall and let explosive body Explosively increasing the reduction efficiency process achieves the purpose of improving the efficiency of zirconium sponge reduction reaction and improving the quality of zirconium sponge. In order to achieve the purpose of the above invention, the present invention provides a zirconium sponge production equipment, including a sublimation furnace and a first reduction furnace communicated with each other through a channel provided on the top, the channel is provided with a first one-way valve, the first A furnace body of a reduction furnace is provided with a furnace and a circulating water device, an insulating charge is provided be...

Embodiment 2

[0005] Embodiment 2 This embodiment is further improved on the basis of Embodiment 1, the difference is: Figure 6 As shown, in the zirconium sponge production equipment provided in this embodiment, a trachea branch is provided between the intake pipe 107 and the second one-way valve 108, and a third one-way valve 117 and an explosive body 118 are provided on the trachea branch. The storage box 116 has several explosive bodies 118 stored in the storage box 116. The air pump 109 first uses the negative pressure to suck the explosive body 118 into the branch circuit, and then uses the generated positive pressure to press the explosive body 118 into the intake pipe 107 And in the gas explosion tube 104 , the explosive body 118 is pushed out from the bottom of the gas explosion tube 104 by the pressure of argon gas and explodes in the magnesium liquid in the furnace 115 . In this embodiment, as shown in FIG. 7, the explosive body 118 is arranged in a spherical structure, the oute...

Embodiment 3

[0006] In this embodiment, the shell 119 is made of graphite, and the graphite is mainly composed of carbon, which can react with impurities in zirconium tetrachloride, such as reacting oxygen in it to produce carbon monoxide or carbon dioxide, which can be Oxygen in zirconium tetrachloride is removed, and the quality of zirconium sponge produced is higher; the preferred technical solution, because the shell 119 is made of a mixture of graphite and calcium carbonate, wherein calcium carbonate can form impurities with zirconium tetrachloride The reaction generates slag, and the slag will float on the surface of the first reduction furnace 10 liquid magnesium to absorb impurities and improve the quality of zirconium sponge; in addition, calcium carbonate can also react with chlorine in zirconium tetrachloride to generate chlorine Calcium and zirconium, increase the efficiency of the reduction reaction. In this embodiment, because the explosive body 118 is pressed out from the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com