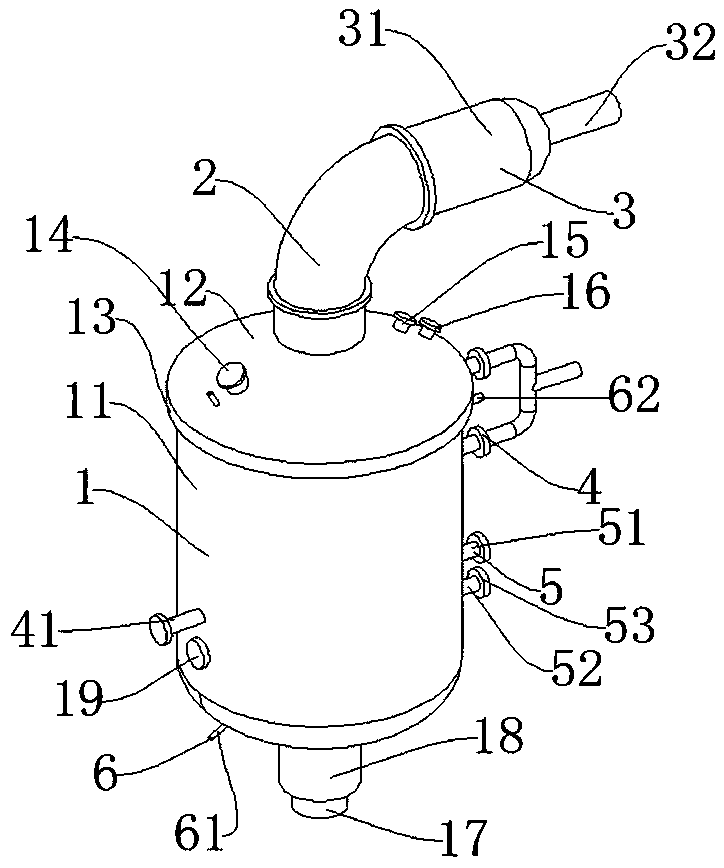

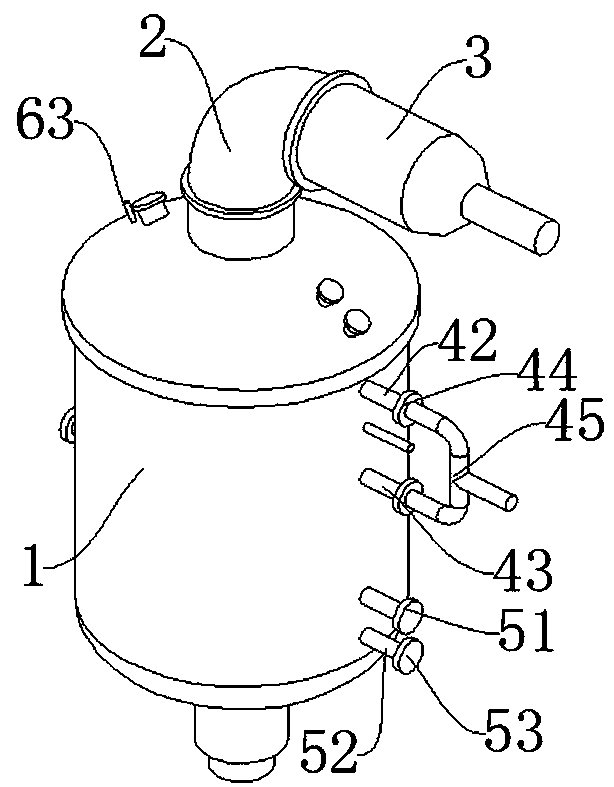

Terpene resin distillation pot and distillation method

A technology of terpene resin and distillation pot, which is applied in the direction of distillation in boiler/distillate, distillation separation, separation method, etc., which can solve the problems of poor heat transfer effect, low heat transfer coefficient, slow production speed, etc., and achieve less failure in production , Improve the distillation speed and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for using a terpene resin still, comprising the following steps:

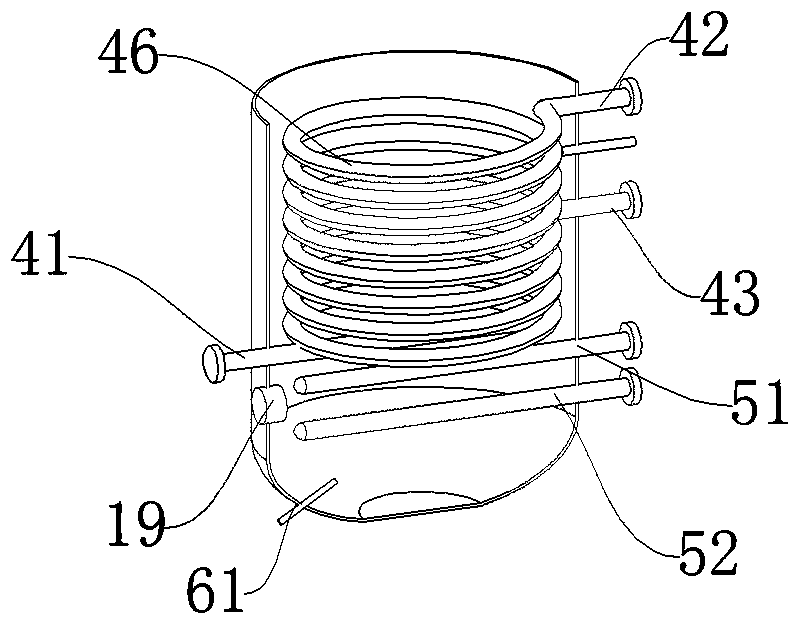

[0050] a. When the liquid terpene resin needs to be distilled, the raw material of the liquid terpene resin is injected into the still 11 through the first material dripping pipe 14, the gas electric control valve 53 is closed first, and the heat transfer oil is fed into the liquid pipe 41. The first heat transfer oil outlet pipe 42 and the second heat transfer oil outlet pipe 43 are connected to the external heat transfer oil, and the low-heat heat transfer oil is passed into the heat transfer pipe 46. At this time, the liquid level sensor 62 is used to monitor the height of the internal liquid level. When the liquid level When the height is higher than the liquid level sensor 62, the heat transfer oil electric control valve 44 on the first heat transfer oil outlet pipe 42 is opened; when the liquid level is lower than the liquid level sensor 62, the heat transfer oil on the second heat transfer...

Embodiment 2

[0056] A method for using a steaming terpene resin still, comprising the following steps:

[0057] a. When the liquid terpene resin needs to be distilled, the raw material of the liquid terpene resin is injected into the still 11 through the first material dripping pipe 14, the gas electric control valve 53 is closed first, and the heat transfer oil is fed into the liquid pipe 41. The first heat transfer oil outlet pipe 42 and the second heat transfer oil outlet pipe 43 are connected to the external heat transfer oil, and the low-heat heat transfer oil is passed into the heat transfer pipe 46. At this time, the liquid level sensor 62 is used to monitor the height of the internal liquid level. When the liquid level When the height is higher than the liquid level sensor 62, the heat transfer oil electric control valve 44 on the first heat transfer oil outlet pipe 42 is opened; when the liquid level is lower than the liquid level sensor 62, the heat transfer oil on the second heat...

Embodiment 3

[0063] A method for using a steaming terpene resin still, comprising the following steps:

[0064] a. When the liquid terpene resin needs to be distilled, the raw material of the liquid terpene resin is injected into the still 11 through the first material dripping pipe 14, the gas electric control valve 53 is closed first, and the heat transfer oil is fed into the liquid pipe 41. The first heat transfer oil outlet pipe 42 and the second heat transfer oil outlet pipe 43 are connected to the external heat transfer oil, and the low-heat heat transfer oil is passed into the heat transfer pipe 46. At this time, the liquid level sensor 62 is used to monitor the height of the internal liquid level. When the liquid level When the height is higher than the liquid level sensor 62, the heat transfer oil electric control valve 44 on the first heat transfer oil outlet pipe 42 is opened; when the liquid level is lower than the liquid level sensor 62, the heat transfer oil on the second heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com