A kind of distillation cooling device and cooling method of nylon powder for sls

A technology for cooling and cooling nylon powder, which is used in manufacturing, solid material additive processing, and additive processing. Controllable size, reduced adverse effects, high bulk density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

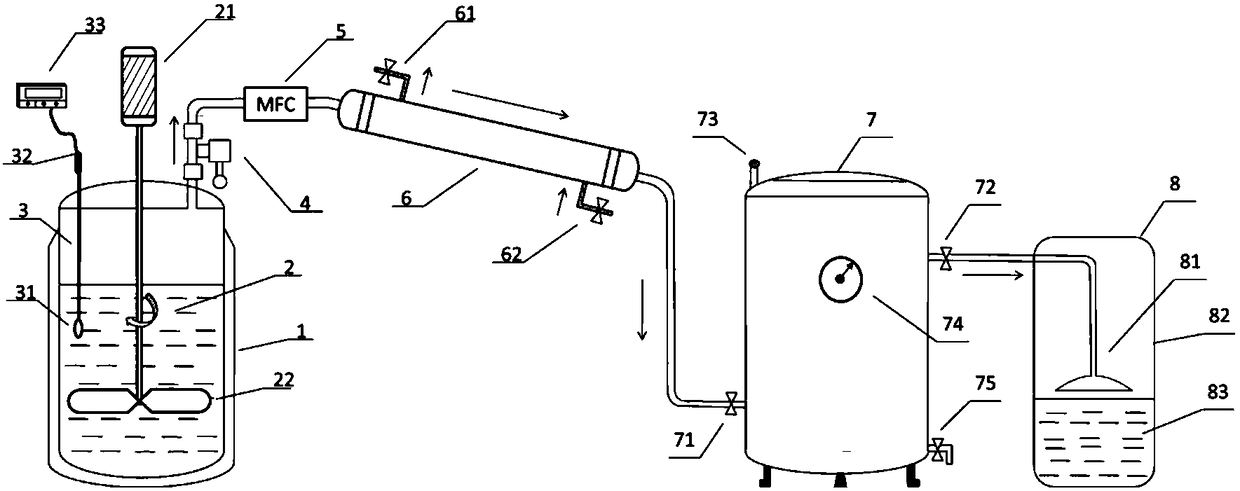

Method used

Image

Examples

Embodiment 2

[0074] The distillation cooling and cooling device is the same as in Example 1.

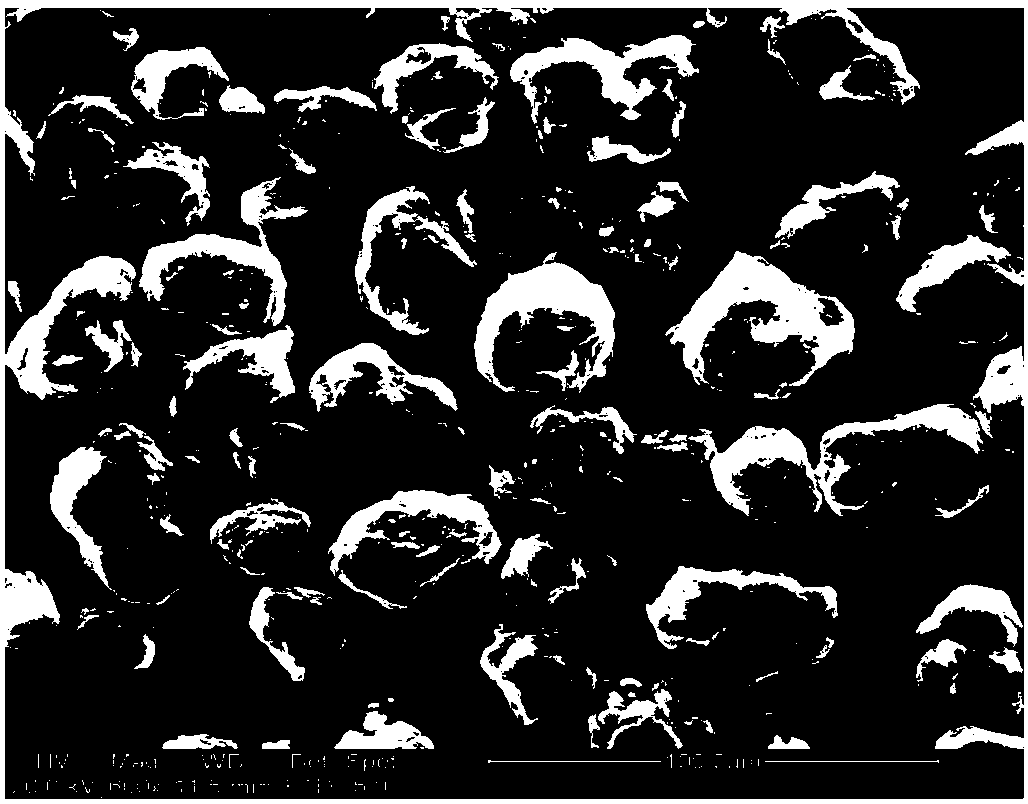

[0075] A solvent precipitation method to prepare nylon powder for SLS. First, nylon 11, ethanol and other additives are placed in the kettle body 1 according to a certain ratio, and the temperature is raised to 150°C at a certain heating rate, and then cooled according to the following distillation Cooling method for cooling operation:

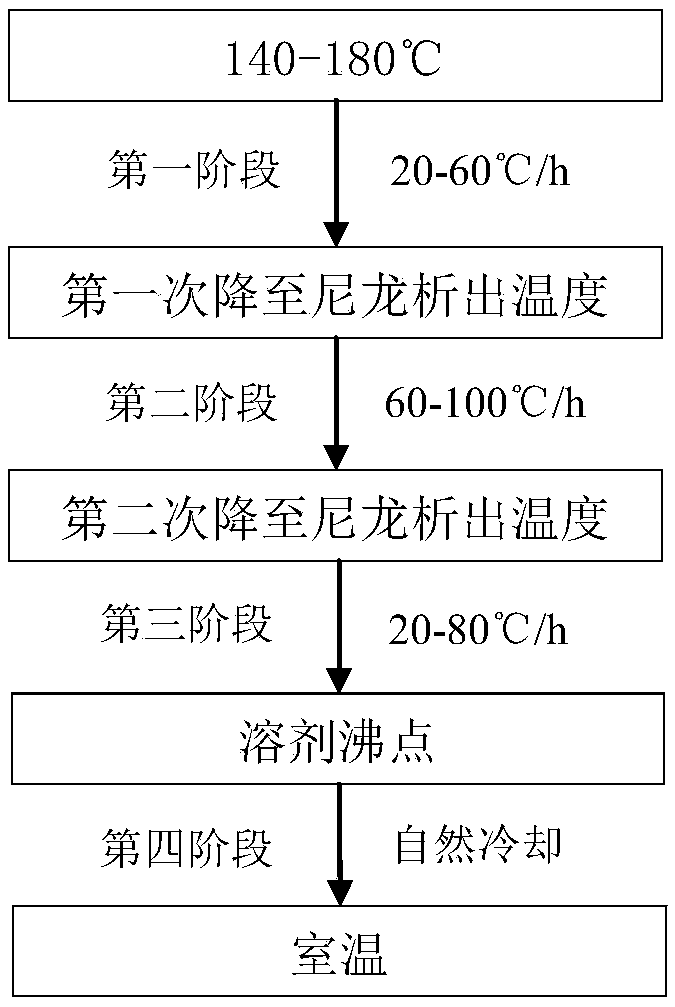

[0076] (1) After nylon 11 is kept at 150°C for 2.5 hours, before the cooling process starts, the mass flow rate of the gas is set to 6.3L / min through the MFC, so that the cooling rate is controlled at 40°C / h;

[0077] (2) open control valve 4, start distillation cooling process;

[0078] (3) When the temperature drops close to the nylon 11 crystallization temperature of 110°C, set the MFC to 12.6L / min, increase the gas mass flow rate, speed up the distillation rate, and control the cooling rate at 80°C / h, and observe the temperature change at all times , so tha...

Embodiment 3

[0082] The distillation cooling and cooling device is the same as in Example 1.

[0083] A solvent precipitation method to prepare nylon powder for SLS. First, nylon 6, ethanol and other additives are placed in the kettle body 1 according to a certain ratio, and the temperature is raised to 180°C at a certain heating rate, and then cooled according to the following distillation Cooling method for cooling operation:

[0084] (1) After nylon 6 is kept at 180°C for 3 hours, before the cooling process starts, the mass flow rate of the gas is set to 3.2L / min through the MFC, and the cooling rate is controlled at 20°C / h;

[0085] (2) open control valve 4, start distillation cooling process;

[0086] (3) When the temperature drops close to the nylon 6 crystallization temperature of 120°C, set the MFC to 9.5L / min, increase the gas mass flow rate, speed up the distillation speed, control the cooling rate at 60°C / h, and observe the temperature change at all times. Allow the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com