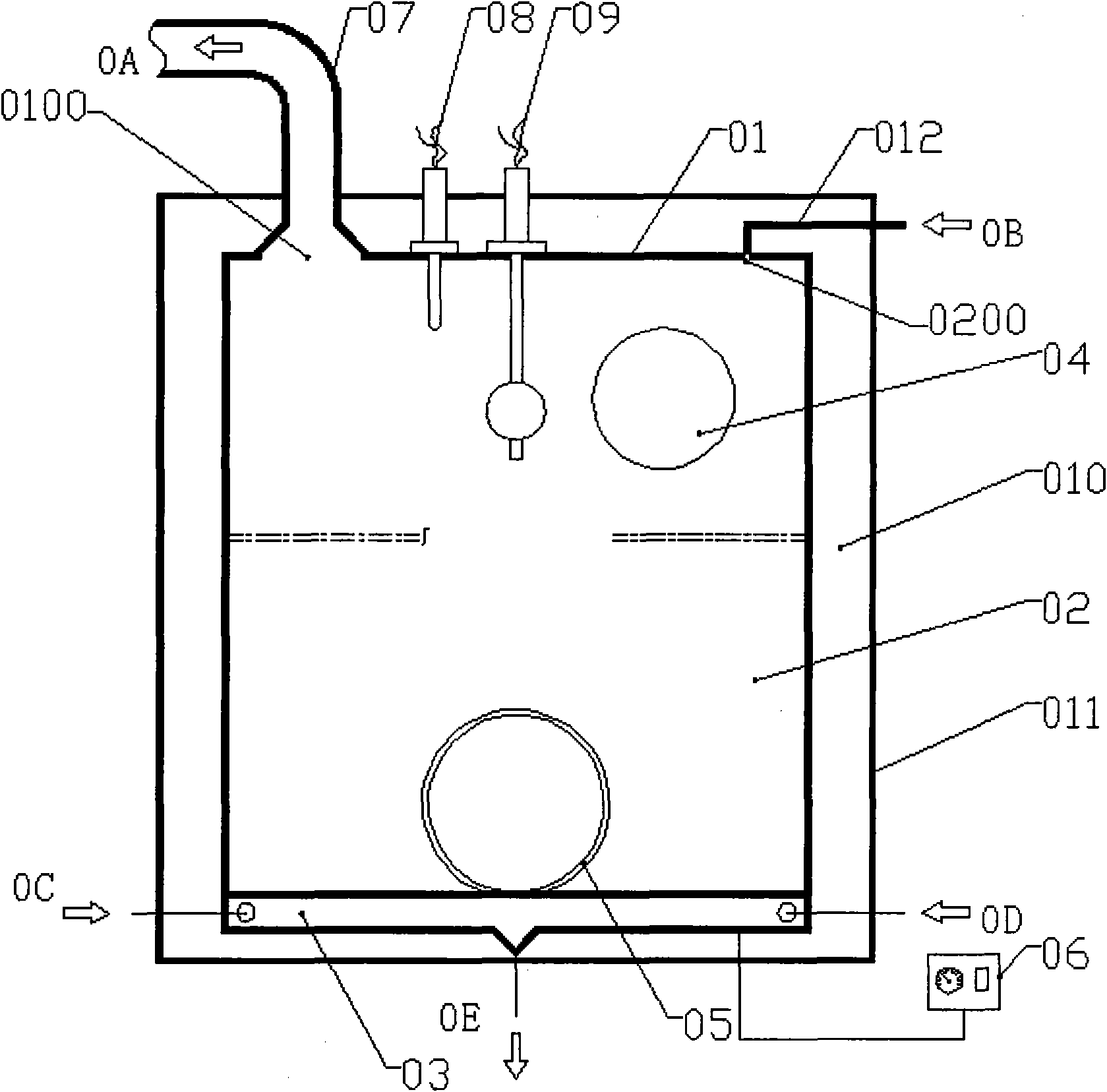

Interporosity flow double-distilled box structure in fur defatting machine

The technology of degreasing machine and double distillation is applied in the field of distillation box, which can solve the problems of uninterrupted use of equipment, concave and convex deformation of the bottom surface of the solvent chamber, affecting the service life of the distillation box, etc. Reduce energy consumption and increase the effect of steam cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

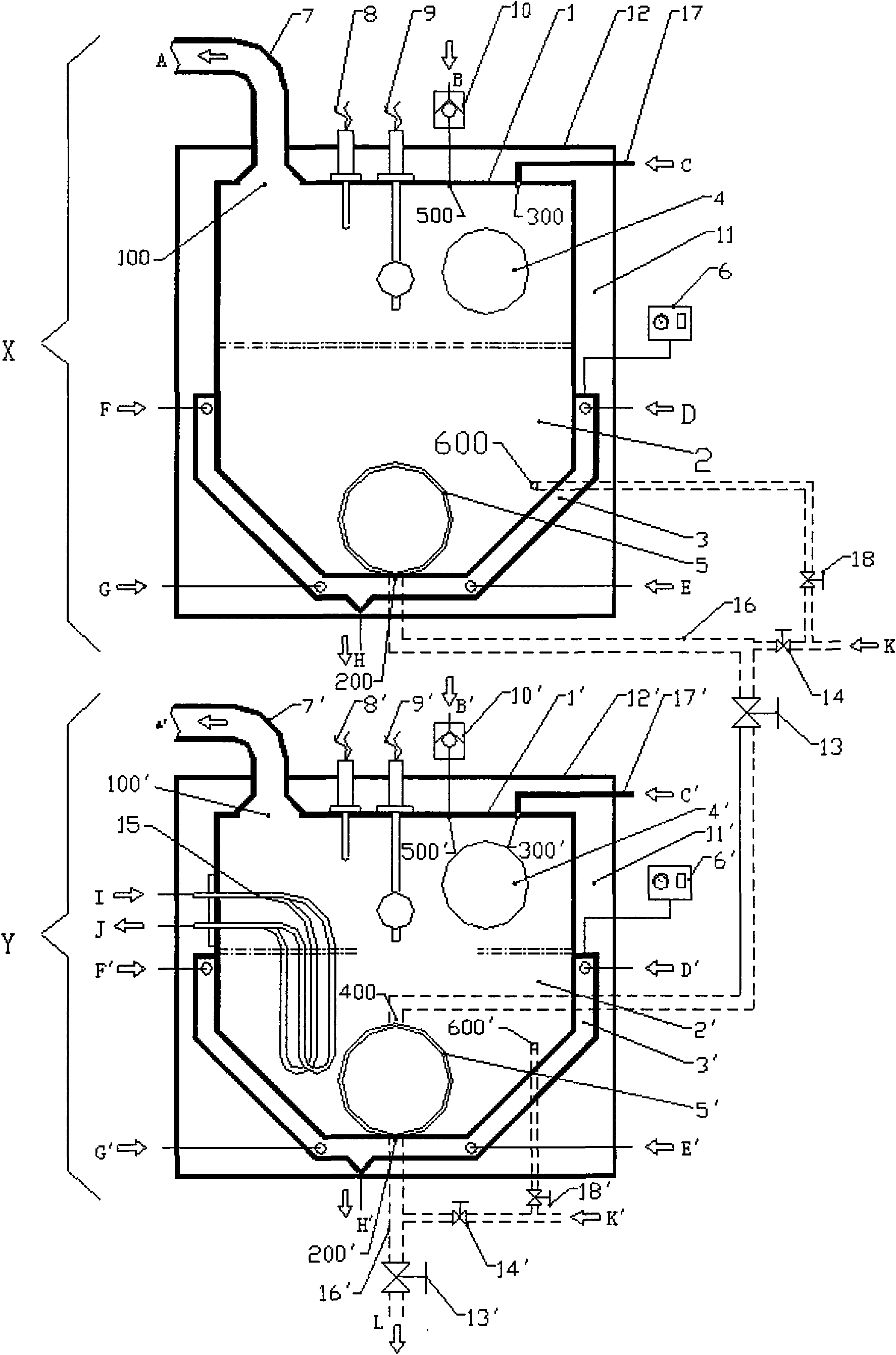

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0020] by figure 2 It can be seen that the present invention includes: an upper distillation box X; also includes a lower distillation box Y; the solvent cavity 2 in the upper distillation box X passes through the blow-by liquid discharge outlet 200 and the solvent cavity 2'in the lower distillation box Y The lower tank's liquid inlet 400 is connected;

[0021] The inner bladder in the upper distillation box X and the lower distillation box Y is a welding component with a rectangular box shape with a polygonal bottom;

[0022] A pressure check valve is respectively arranged in the solvent cavity of the upper distillation box X and the lower distillation box Y;

[0023] A lower tank auxiliary heater 15 is also arranged in the solvent cavity 2'of the lower distillation tank Y;

[0024] A steam cleaning inlet is respectively arranged in the solvent cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com