A kind of preparation technology of tremella polysaccharide of whole series molecular weight

A tremella polysaccharide and preparation technology, which is applied in the field of cosmetic material production equipment, can solve the problems of poor product quality and low extraction rate, and achieve the effects of increasing distillation speed, increasing extraction rate, and improving the state of precipitated materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

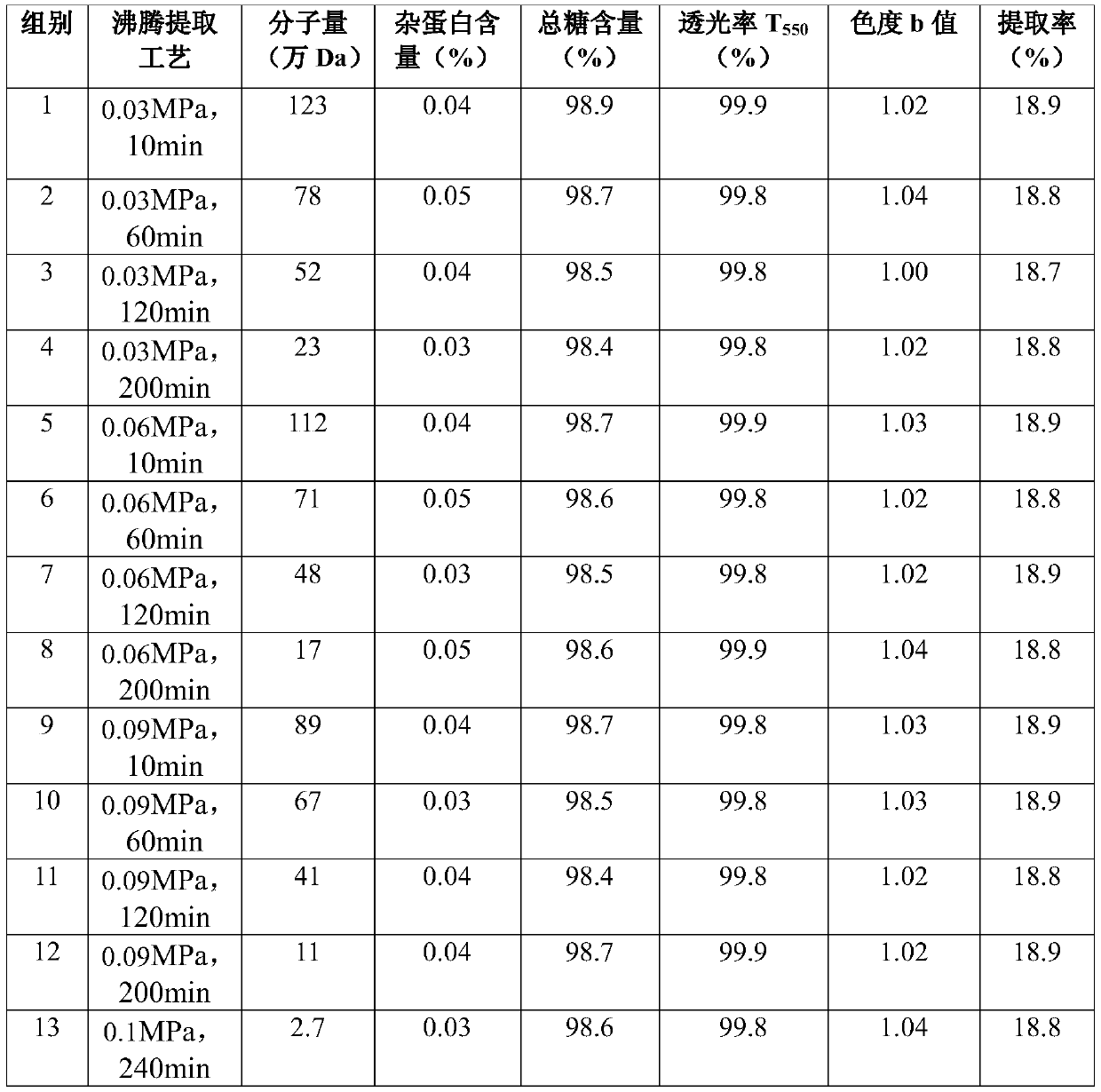

[0023] Each group selects 3kg of whole white fungus raw materials without mildew and puts them into the extraction pot, the ratio of material to water is 1:60, add 0.2% defoamer and enzymolysis accelerator polyoxypropylene polyoxyethylene glyceryl ether, and steam first The jacket is heated up, and after the temperature rises to 95°C, steam is passed into the tank for boiling extraction. The temperature of the material liquid for boiling extraction is maintained at 110°C-121°C. The tank pressure and pressure-holding boiling extraction time of each group are shown in the following table 1 :

[0024]After the feed liquid after boiling extraction is discharged, the colloid mill is used for wet pulverization, and the particle size of suspended solids after pulverization is 80 μm. The feed liquid after wet pulverization is extracted with a high-efficiency enzyme activity accelerator combined with a compound enzyme, and 2% sodium acetate and 0.2% magnesium sulfate are added to the f...

Embodiment 2

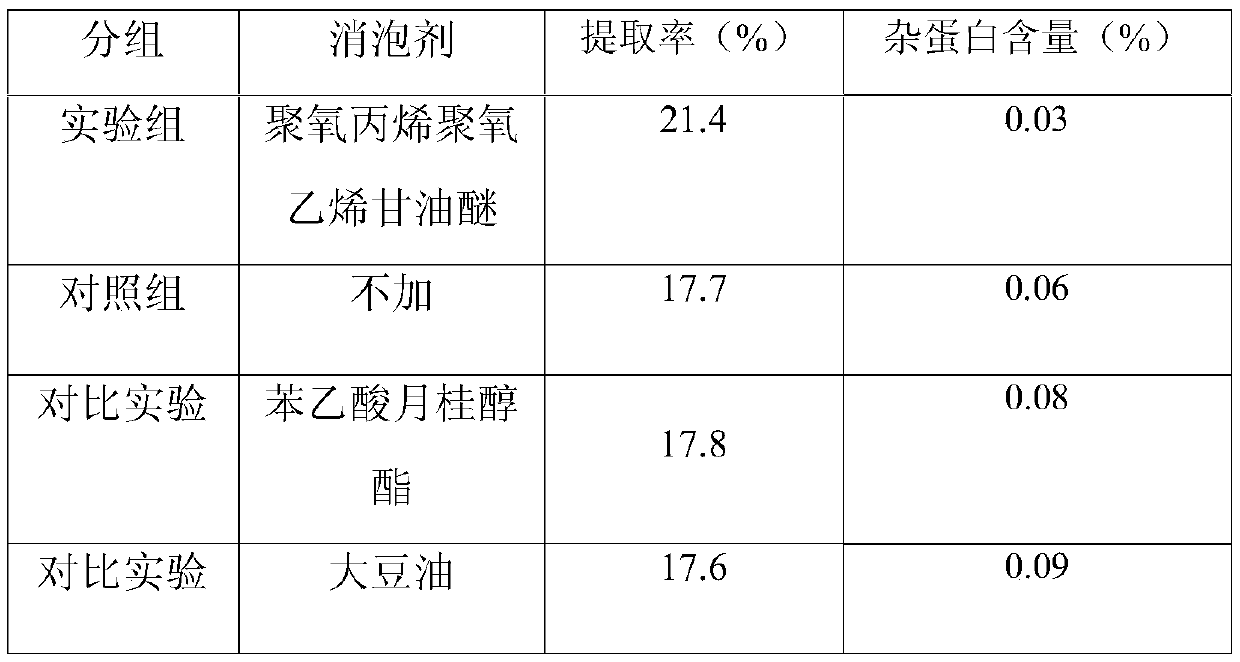

[0029] In order to more intuitively demonstrate the technological advantages of the compound enzymolysis of the present invention, the new process technology of the present invention, which can be customized to prepare high-purity Tremella polysaccharides with a full range of molecular weights, different enzymes, different enzymatic hydrolysis, and different enzymatic hydrolysis accelerators Carry out the comparative example of Tremella polysaccharide preparation, grouping and experimental results are shown in the following table 2, including the following steps:

[0030] Each group selects 3 kg of whole white fungus raw materials without mildew and puts them into the extraction pot, the ratio of material to water is 1:70, with or without adding 0.2% defoamer and enzymolysis accelerator polyoxypropylene polyoxyethylene glyceryl ether, First pass the steam jacket to heat up the temperature. After the temperature rises to 95°C, pass steam into the tank for boiling extraction. The...

Embodiment 3

[0035] In order to more intuitively demonstrate the technological advantages of steam pressure-preserved boiling extraction of the present invention, each group selects 3 kg of whole white fungus raw materials without mildew and puts them into the extraction pot. The ratio of material to water is 1:40, according to the grouping in Table 3 below, Add or not add 0.2% defoamer, first pass the steam jacket to heat up the temperature, after the temperature rises to 95°C, pass steam into the tank for boiling extraction, the temperature of the liquid extracted by boiling is maintained at 110°C-121°C, each The tank pressure of the group is 0.06MPa, and the pressure-holding boiling extraction time is 1h; after the boiling extraction is discharged, the colloid mill is used for wet pulverization, and the particle size of the suspended solids after pulverization is 50 μm. Add 2% sodium acetate and 0.02% magnesium sulfate to the feed liquid after wet pulverization as enzymolysis accelerator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com