Mercury catalyst processing device

A treatment device and mercury catalyst technology, applied in the direction of improving process efficiency, can solve the problems of uneven heating of mercury-containing materials, not being completely distilled, reducing mercury recovery rate, etc. Contaminated by impurities, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

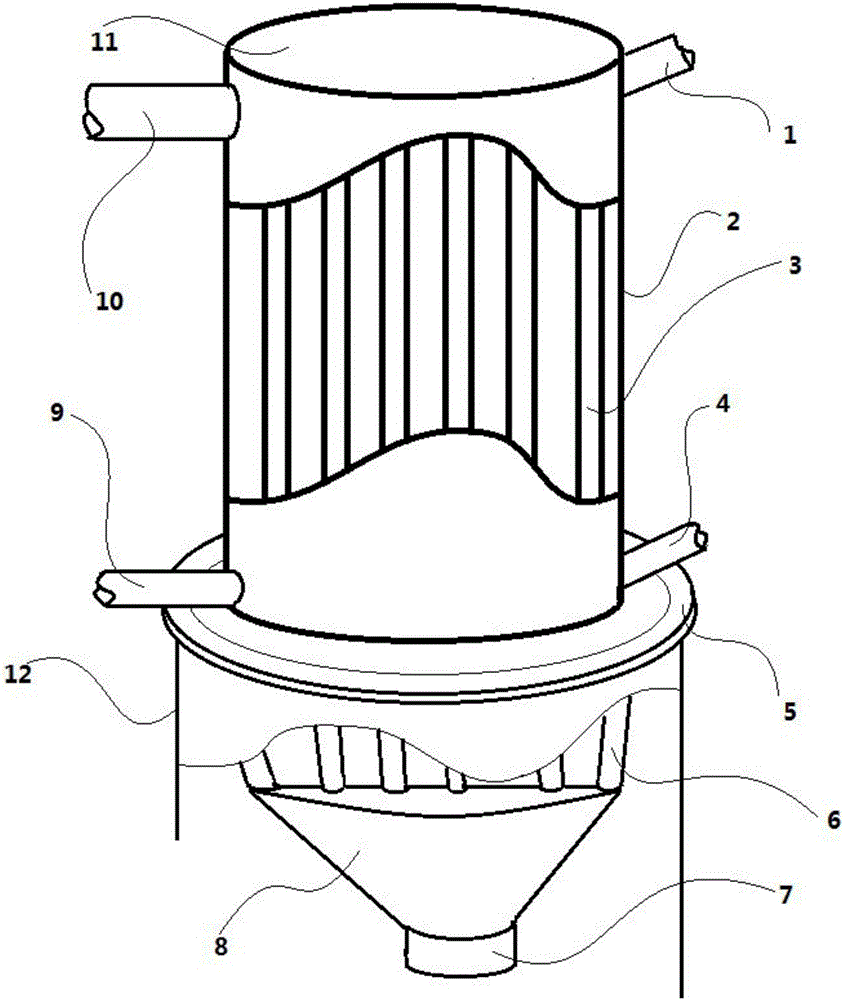

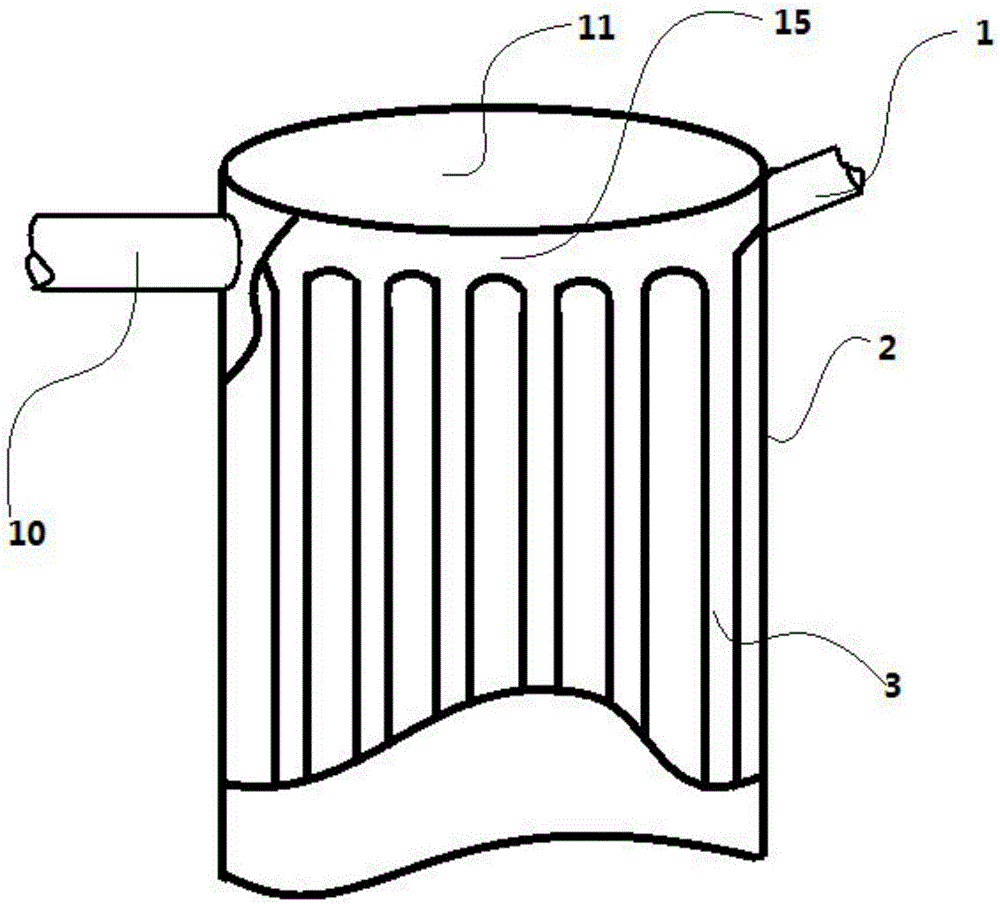

[0022] Such as figure 1 , figure 2 , image 3 As shown, a mercury catalyst treatment device is composed of a step 5, a distillation chamber arranged on the step 5 and a waste collection part arranged under the step 5.

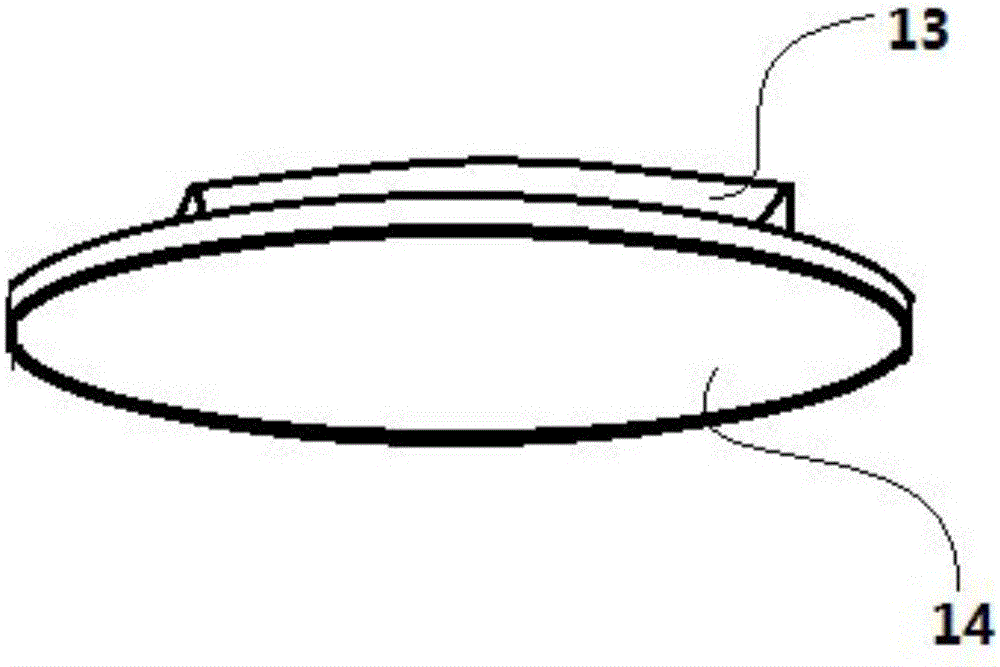

[0023] Described distillation furnace chamber, it is made up of furnace wall 2 and the material inlet 11 at the top of distillation furnace chamber, and the cover plate 14 that can coincide with material inlet 11, the oxygen supply pipe 4 that is arranged on the bottom of furnace wall 2 and gas inlet 9. The distillation tube 3 is vertically arranged inside the furnace wall 2. A combustion chamber is formed between the distillation pipe 3 and the furnace wall 2. The oxygen supply pipe 4 and the gas inlet 9 communicate with the combustion chamber; the furnace wall 2 is close to the material inlet 11 Tail gas outlet 10 and mercury vapor outlet 1 are arranged at the place, wherein tail gas outlet 10 is communicated with combustion chamber; The top of described d...

Embodiment 2

[0044] On the basis of embodiment 1, a kind of preparation method of mercury catalyst treatment device comprises the following steps:

[0045] (1) Preparation of the aggregate warehouse: Use bricks to build a double-layer wall according to the method of building a wall, and open a door at a certain part of the aggregate warehouse. The door width is 3-5m, and the door height is 1-2m. The door is welded and inlaid with steel plates to form a door frame. The thickness of the steel plate is 10-20mm, the width of the steel plate is 20-30mm, and the thickness of the steel plate embedded in the wall is half of the thickness of the steel plate; Cover the upper part of the wall with steps, and the thickness of the steps is set to 15-20cm. The steps are made of concrete pouring, and the outermost edge of the steps is wider than the outermost edge of the aggregate warehouse;

[0046](2) Preparation of the distillation furnace chamber: after the preparation of the steps is completed, the ...

Embodiment 3

[0049] In the process of using the mercury catalyst treatment device prepared in Example 1 or Example 2 to carry out mercury catalyst treatment and carry out mercury distillation treatment, the mercury catalyst is added into the distillation tube through the material inlet, so that the distillation tube reaches the mercury vapor collection chamber. The mercury catalyst is all filled, and then the cover plate 14 is covered on the material inlet, and then through the gas inlet and the oxygen supply pipe into the combustion chamber of the distillation furnace, the gas is burned in the combustion chamber, and then the distillation process is achieved. The distillation treatment of the mercury catalyst in the tube 3 makes the mercury volatilize into the mercury vapor collection chamber in the form of steam, and then it is discharged from the distillation furnace through the mercury vapor outlet and sent to be cooled and collected; while the residue material after the distillation is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com