Distillation apparatus

一种蒸馏装置、蒸馏釜的技术,应用在洗涤装置、蒸馏分离、真空蒸馏等方向,能够解决冷凝液化难以适当地进行、溶剂蒸气冷却不充分、加大缓冲罐溶剂热容量等问题,达到防止结霜、高效冷却、提高设置的自由度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

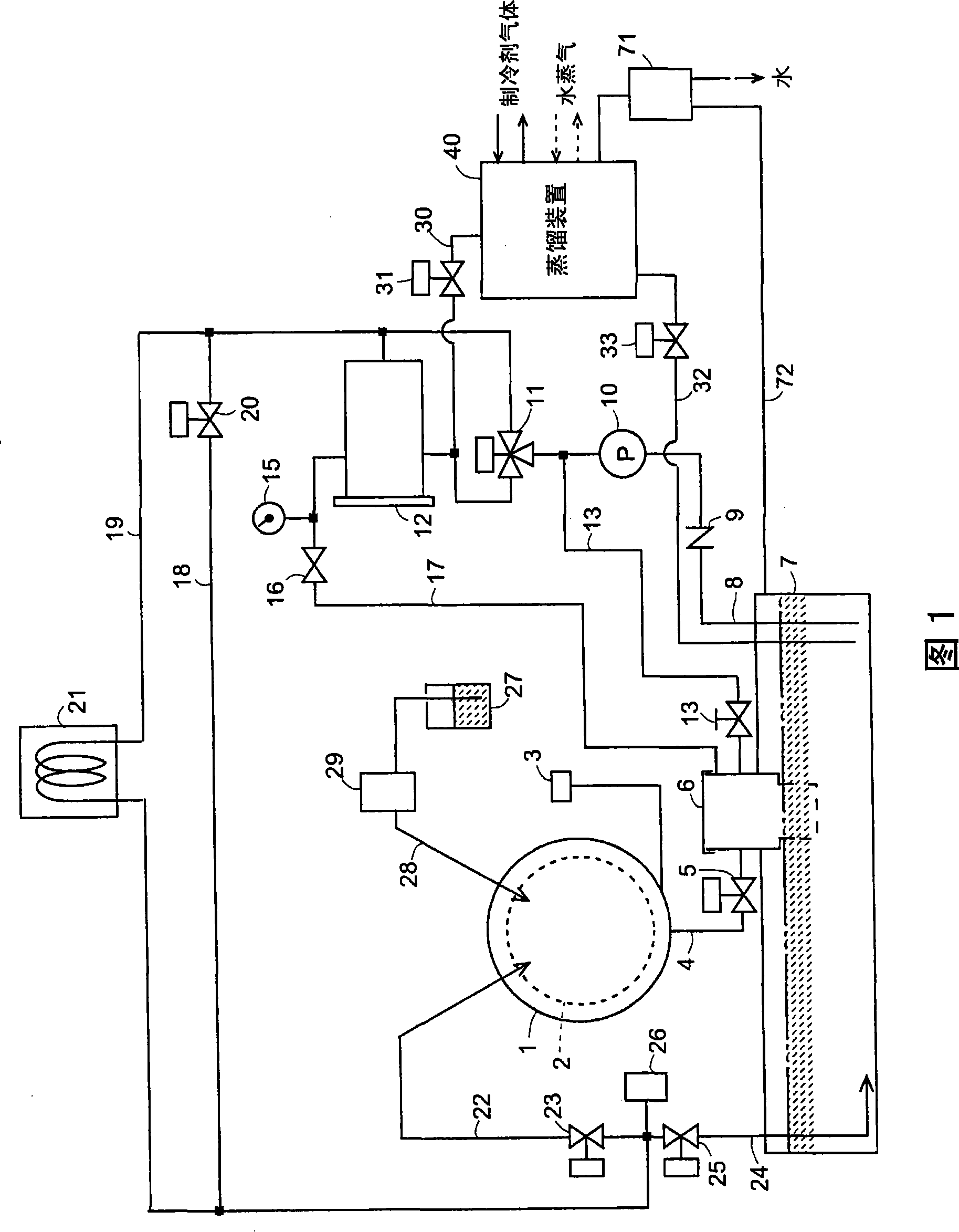

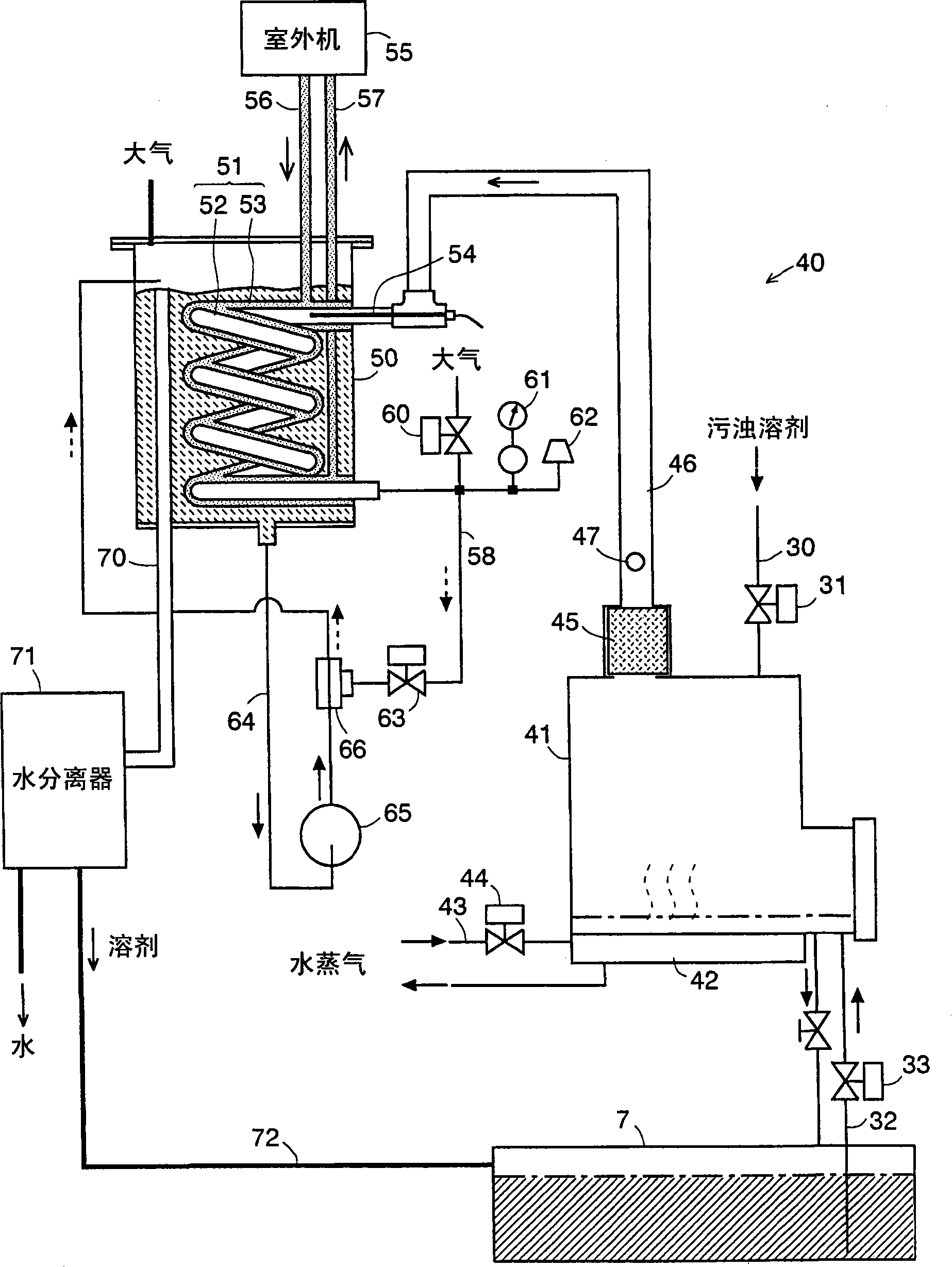

[0042] Referring to Figure 1 below, figure 2 An example in which the distillation apparatus of the present invention is used in a dry cleaning machine will be described. Fig. 1 is a structural view of main parts centering on the piping passage of the dry cleaning machine using the distillation apparatus of this embodiment, figure 2 It is a block diagram centering on the piping passage of the distillation apparatus of this embodiment. Here, the liquid to be treated in the present invention is a petroleum-based or silicone-based solvent used for cleaning operation.

[0043] In Fig. 1, a cylinder-shaped drum 2 is rotatably supported in the outer tank 1, and the drum 2 has a plurality of liquid holes around it, and the liquid level of the solvent stored in the outer tank 1 can pass through the liquid level. detected by sensor 3. A drain valve 5 is provided in a drain line 4 connected to the bottom of the outer tank 1, and is connected to a solvent tank 7 through a button trap f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com