Gob-side entry retaining mining support process method

A process method and technology of retaining roadway, which are applied to temporary shields, mining equipment, earth-moving drilling, etc., can solve the problems of large damage to monomers and sheds, high consumption of monomers and wood, and low recovery and reuse rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

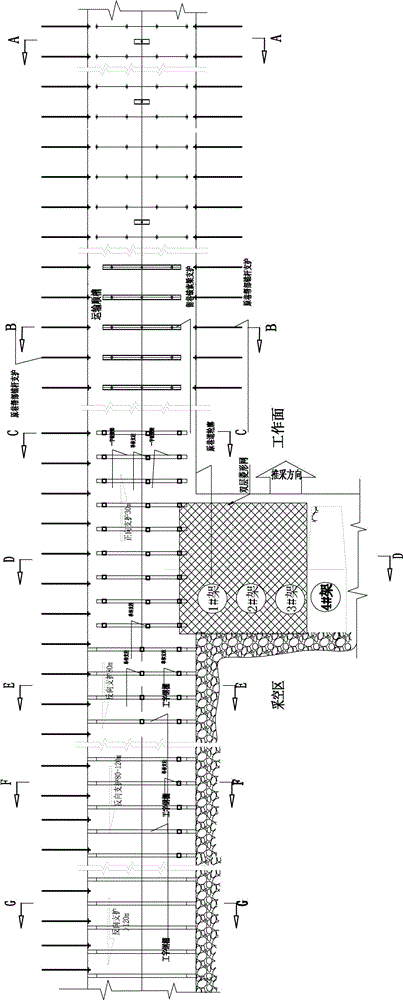

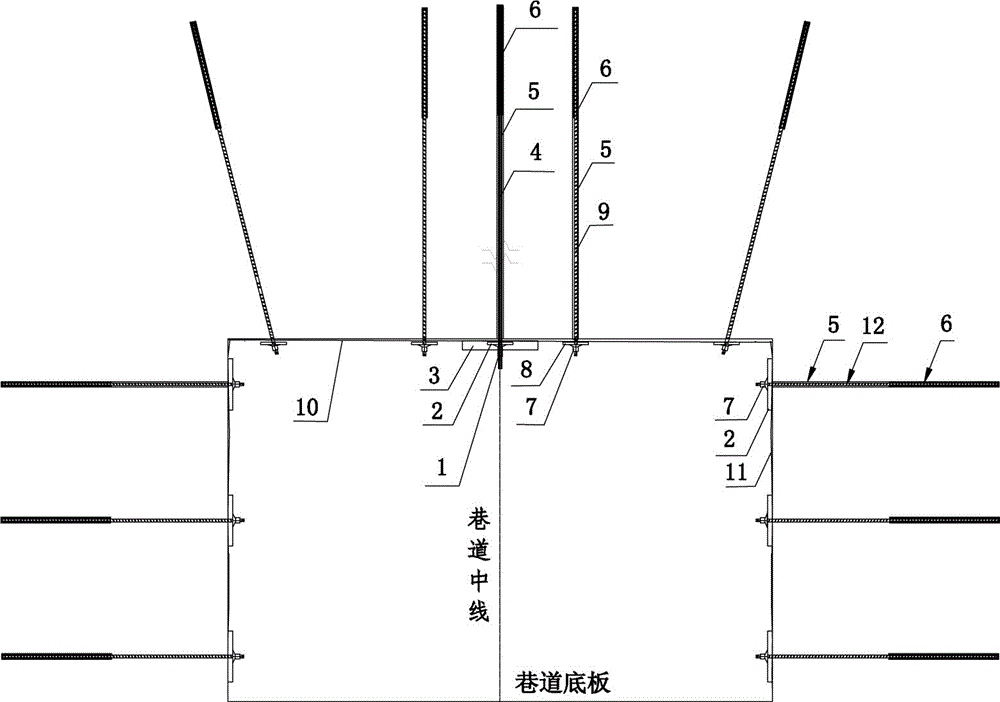

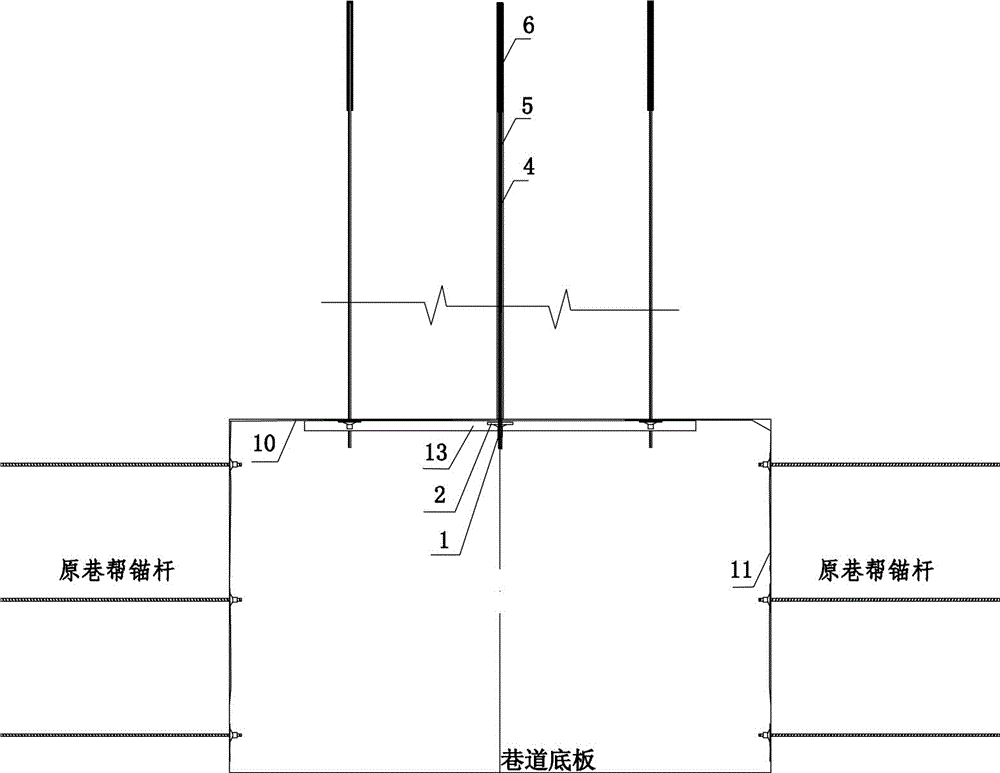

[0041] A mining support method for gob-side entry retaining, such as Figure 1 to Figure 8 shown, including the following steps:

[0042] The first step is to reinforce the mining roadway or dig the roadway and retain the roadway to strengthen the primary support.

[0043] (1) The roadway that has been constructed and is ready to be retained.

[0044] Before the mining of the working face, only the roof of the reserved roadway is reinforced and supported; the reinforcement is supported by anchor cable beams, one beam has three anchors, the distance between the beams and the anchor cables is 1 meter, and the length of the anchor cables is based on the mining height. 3-4 times more anchoring into the stable bedrock is not less than 2 meters, the length of the anchor beam is 0.8 meters less than the normal roadway width, and the anchor beam is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com