Method for comprehensively treating copper nickel scrap

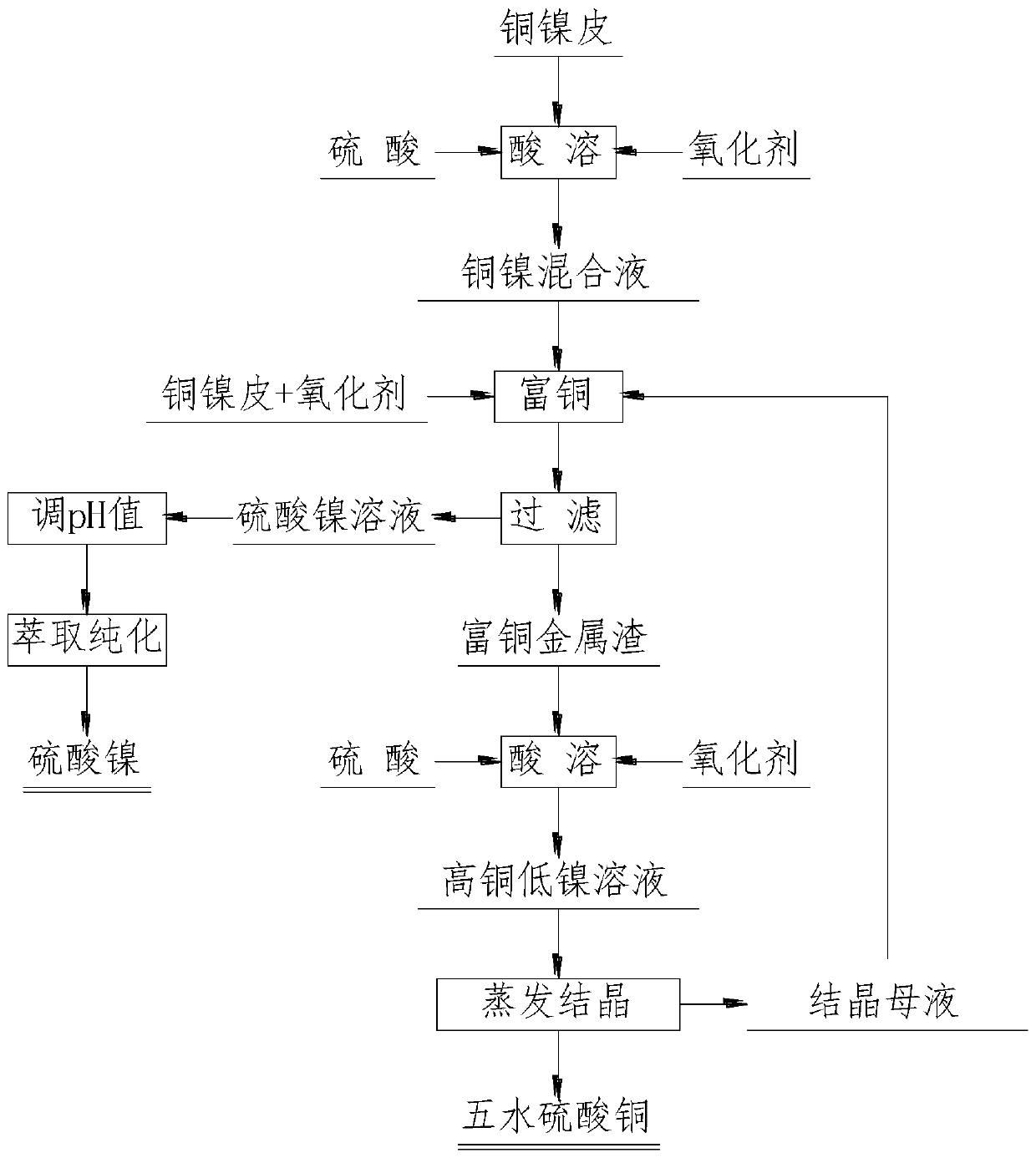

A comprehensive treatment, copper-nickel technology, applied in the preparation of copper sulfate, nickel sulfate, nickel compounds, etc., can solve the problems affecting the smooth progress of copper electrolysis process, high-temperature melting of copper-nickel alloy, and undesired economic benefits, and achieve good economic benefits. , The effect of less impurity removal auxiliary materials and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix 50g of copper-nickel skin waste with water at a mass ratio of 1:9, add 121g of sulfuric acid to obtain a mixture, heat the mixture to 80°C, and add 174g of hydrogen peroxide while stirring. The hydrogen peroxide addition time is 30min, and react under normal pressure. The waste copper-nickel skin is dissolved into a mixed solution containing copper and nickel. The dissolution rate of copper is 96.3%, and the dissolution rate of nickel is 98.6%.

[0026](2) Take 500 mL of the above copper-nickel mixed solution, add 126 g of copper-nickel skin waste, heat the copper-nickel-containing mixed solution and copper-nickel skin waste to 80 ° C, add 107.25 g of hydrogen peroxide while stirring, and add the hydrogen peroxide for 45 minutes. After the addition of hydrogen peroxide was completed, the reaction was continued for another 3 hours to obtain nickel sulfate solution and copper-rich metal slag. The copper concentration in the nickel sulfate solution is 0.34g / L, the...

Embodiment 2

[0033] (1) Mix 50g of copper-nickel skin waste with water at a mass ratio of 1:11, add 91g of sulfuric acid to obtain a mixture, heat the mixture to 120°C, and feed oxygen while stirring. The oxygen output pressure is 1.0MPa, and the reaction time is 3h . The waste copper-nickel skin is dissolved into a mixed solution containing copper and nickel. The dissolution rate of copper is 98.5%, and the dissolution rate of nickel is 98.8%.

[0034] (2) Take 500 mL of the above copper-nickel mixed solution, add 96 g of copper-nickel skin waste, heat the copper-nickel mixed solution and copper-nickel skin waste to 80 ° C, add 87.5 g of hydrogen peroxide while stirring, and add hydrogen peroxide for 45 minutes. After the addition of hydrogen peroxide was completed, the reaction was continued for another 3 hours to obtain nickel sulfate solution and copper-rich metal slag. The copper concentration in the nickel sulfate solution is 0.14g / L, the nickel concentration is 91.36g / L, and the p...

Embodiment 3

[0041] (1) Mix 50g of copper-nickel skin waste with water at a mass ratio of 1:10, add 91g of sulfuric acid to obtain a mixture, heat the mixture to 60°C, and add 154g of hydrogen peroxide while stirring. The hydrogen peroxide addition time is 30min, and react under normal pressure. The copper-nickel skin waste was dissolved into 640mL of copper-nickel mixed solution. The dissolution rate of copper is 95.1%, and the dissolution rate of nickel is 92.4%.

[0042] (2) Take 500 mL of the above-mentioned copper-nickel mixed solution, add 113 g of copper-nickel skin waste, heat the copper-nickel-containing mixed solution and copper-nickel skin waste to 60 ° C, add 98.75 g of hydrogen peroxide while stirring, and add the hydrogen peroxide for 45 minutes. After the addition of hydrogen peroxide was completed, the reaction was continued for another 3 hours to obtain nickel sulfate solution and copper-rich metal slag. The copper concentration in the nickel sulfate solution is 0.14g / L, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com