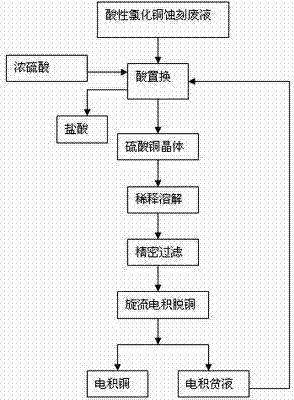

Process for recovering copper by processing acidic copper chloride etchant through rotational flow electrolysis

A swirl electrolysis, copper chloride technology, applied in the direction of photography process, photography auxiliary process, improvement of process efficiency, etc., can solve the problems of high consumption of reagents and poor economical type, and achieve less consumption of raw materials, low cost, and reduced cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Pour the 96% industrial concentrated sulfuric acid of 500ml into a 5L beaker, and then pour 3L of copper ion concentration of 100g / L and acidic copper chloride etching waste liquid of 200g / L into the separatory funnel Slowly add 1 drop / s into a 5L beaker, carry out acid displacement reaction at a reaction temperature of 180°C to obtain a solution containing copper sulfate crystals, add 1800ml of distilled water to dilute, and the diluted copper sulfate solution contains copper ions The concentration is 56g / L, and the concentration of chloride ion is 20g / L. Use suction filtration equipment to filter out suspended solids, organic matter and particulate impurities. The suction filtration speed is 1.1L / s. The obtained filtrate electrolyte flows from the circulation tank In the flow electrolysis device, copper is removed by swirl electrolysis, the volume of the electrolyte is 5.2L, and the current density is 1000A / m 2 , the flow rate of the electrolyte is 400L / h, electrolysi...

Embodiment 2

[0035] Pour 300ml of 98% industrial concentrated sulfuric acid into a 5L beaker, then pour 3L of acidic copper chloride etching waste liquid with a copper ion concentration of 130g / L and a chloride ion concentration of 180g / L into a separatory funnel Slowly add 3 drops / s into a 5L beaker, and carry out acid replacement reaction at a reaction temperature of 120°C to obtain a solution containing copper sulfate crystals, dilute with 1500ml of distilled water, and the diluted copper sulfate solution contains copper ions The concentration is 81g / L, and the concentration of chloride ion is 30g / L. Use suction filtration equipment to filter out suspended solids, organic matter and particulate impurities. The suction filtration speed is 0.9L / s. The obtained filtrate electrolyte flows from the circulation tank In the flow electrolysis device, copper is removed by swirl electrolysis, the volume of the electrolyte is 4.8L, and the current density is 800A / m 2 , the electrolyte flow rate is...

Embodiment 3

[0037] Pour 900ml of 98% industrial concentrated sulfuric acid into a 5L beaker, then pour 3L of acidic copper chloride etching waste liquid containing copper ion concentration of 120g / L and chloride ion concentration of 200g / L into the separatory funnel for 2 Slowly add dropwise into a 5L beaker at a rate of drop / s, and carry out acid replacement reaction at a reaction temperature of 150°C to obtain a solution containing copper sulfate crystals, dilute with 1500ml of distilled water, and the diluted copper sulfate solution contains copper ion concentration is 66.67g / L, and the chloride ion concentration is 10g / L. Use suction filtration equipment to filter out suspended solids, organic matter and particulate impurities. The suction filtration speed is 1.0L / s. The obtained filtrate electrolyte flows from the circulation tank In the flow electrolysis device, copper is removed by swirl electrolysis, the volume of the electrolyte is 5.3L, and the current density is 550A / m 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com