Recycling method and system of PCB (printed circuit board) etching waste liquid

A technology of PCB circuit board and treatment method, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc. The effect of low cost, low power consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

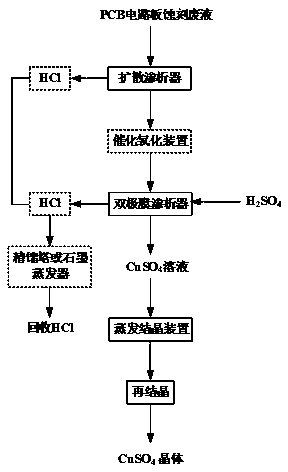

Image

Examples

Embodiment 1

[0044] The water quality of a circuit board wastewater is: copper 100g / L, hydrochloric acid concentration 3mol / L. During treatment, the raw waste water is transported to the diffusion dialyzer, and the recovered hydrochloric acid is 2.5mol / L, and the effluent of the diffusion dialysis device is pumped into the catalytic oxidation tower, and the effluent ensures that Cu 2+ Accounting for 95% of the total amount of Cu, the oxidized etching waste liquid is pumped to the bipolar membrane system, sulfuric acid is added to the bipolar membrane module through the dosing metering pump and pH interlock automatic control, and the output water of the bipolar membrane module is 260g / L of copper sulfate, two streams of 0.5mol / L hydrochloric acid, three streams of desalinated etching waste liquid, wherein the copper sulfate solution is sent to the evaporation crystallizer to recover industrial-grade copper sulfate, and the 0.5mol / L hydrochloric acid is passed through the evaporator or The ...

Embodiment 2

[0046] The water quality of a circuit board wastewater is: copper 150g / L, hydrochloric acid concentration 3.5mol / L. During treatment, the raw waste water is transported to the diffusion dialyzer, and the recovered hydrochloric acid is 3.3mol / L, and the effluent of the diffusion dialysis device is pumped into the catalytic oxidation tower, and the effluent ensures that Cu 2+ Accounting for 96% of the total amount of Cu, the oxidized etching waste liquid is pumped to the bipolar membrane system, sulfuric acid is added to the bipolar membrane module through the dosing metering pump and pH interlock automatic control, and the water output of the bipolar membrane module is 300g / L of copper sulfate, two streams of 0.8mol / L hydrochloric acid, three streams of desalinated etching waste liquid, wherein the copper sulfate solution is sent to the evaporation crystallizer to recover industrial-grade copper sulfate, and the 0.8mol / L hydrochloric acid is passed through the evaporator or Th...

Embodiment 3

[0048] The water quality of a circuit board wastewater is: the copper content is 180g / L, and the concentration of hydrochloric acid is 4mol / L. During treatment, the raw wastewater is sent to the diffusion dialyzer, and the recovered hydrochloric acid is 3.8mol / L, and the effluent of the diffusion dialysis device is pumped into the catalytic oxidation tower, and the effluent ensures that Cu 2+ Accounting for 94% of the total amount of Cu, the oxidized etching waste liquid is pumped to the bipolar membrane system, sulfuric acid is added to the bipolar membrane module through the dosing metering pump and pH interlock automatic control, and the output water of the bipolar membrane module is 330g / L of copper sulfate, two streams of 0.9mol / L hydrochloric acid, three streams of desalinated etching waste liquid, wherein the copper sulfate solution is sent to the evaporation crystallizer to recover industrial-grade copper sulfate, and the 0.9mol / L hydrochloric acid is passed through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com