Method for using copper sulfate waste liquid to prepare high-purity spherical copper oxide

A copper sulfate solution, copper sulfate technology, applied in copper oxide/copper hydroxide and other directions, can solve the problems of reduced purity of copper oxide, difficulty in stirring and heat transfer, etc., to ensure high purity, environmental friendliness, and less waste liquid. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below in conjunction with specific embodiments.

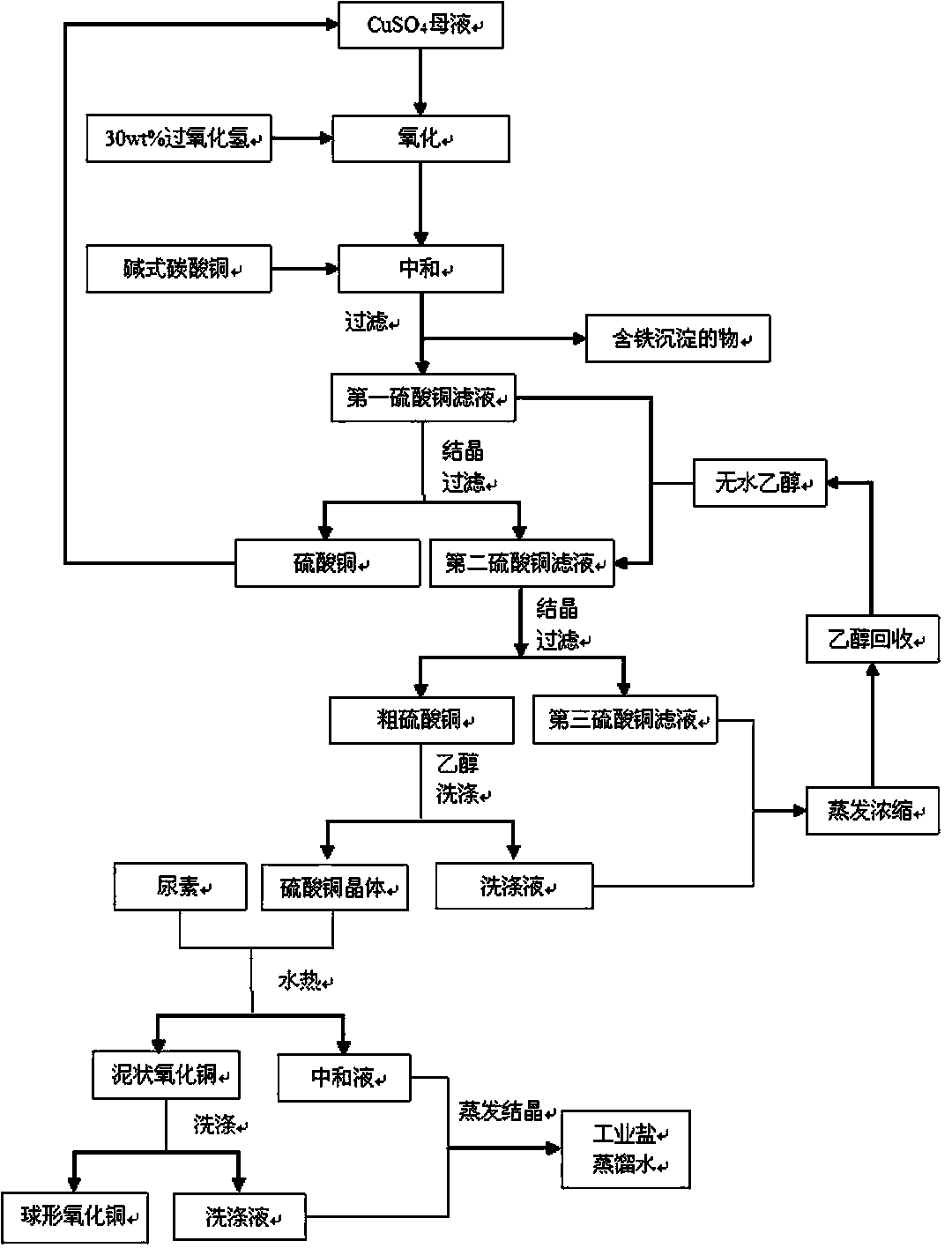

[0025] like figure 1 As shown, a method for preparing high-purity spherical copper oxide from copper sulfate waste liquid of the present invention comprises the following process steps:

[0026] a. Take 400mL copper sulfate waste liquid (see Table 1 for the composition of copper sulfate waste liquid), put it into a 500mL beaker, place it on a constant temperature magnetic stirrer, and add 1.0mL mass fraction to the solution at room temperature under low-speed stirring. It is a 30% hydrogen peroxide solution, and 23.8g Cu is added to the solution after 30min of reaction 2 (OH) 2 CO 3 After the solid powder adjusts the pH value of the solution to 3.5, continue stirring for 30min, stand for 12h, and filter;

[0027] b. Put the filtrate obtained in the above step into a 1L beaker, measure 10mL of absolute ethanol, add it to the solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com