Copper precipitation method by iron modification and copper precipitation and preparation apparatus used therefor

A manufacturing device and a technology for copper precipitation, which are applied in the preparation of copper compounds, chemical instruments and methods, copper compounds, etc., can solve the problems of complex process flow, etc., and achieve the effect of economy and reducing the cost of copper precipitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

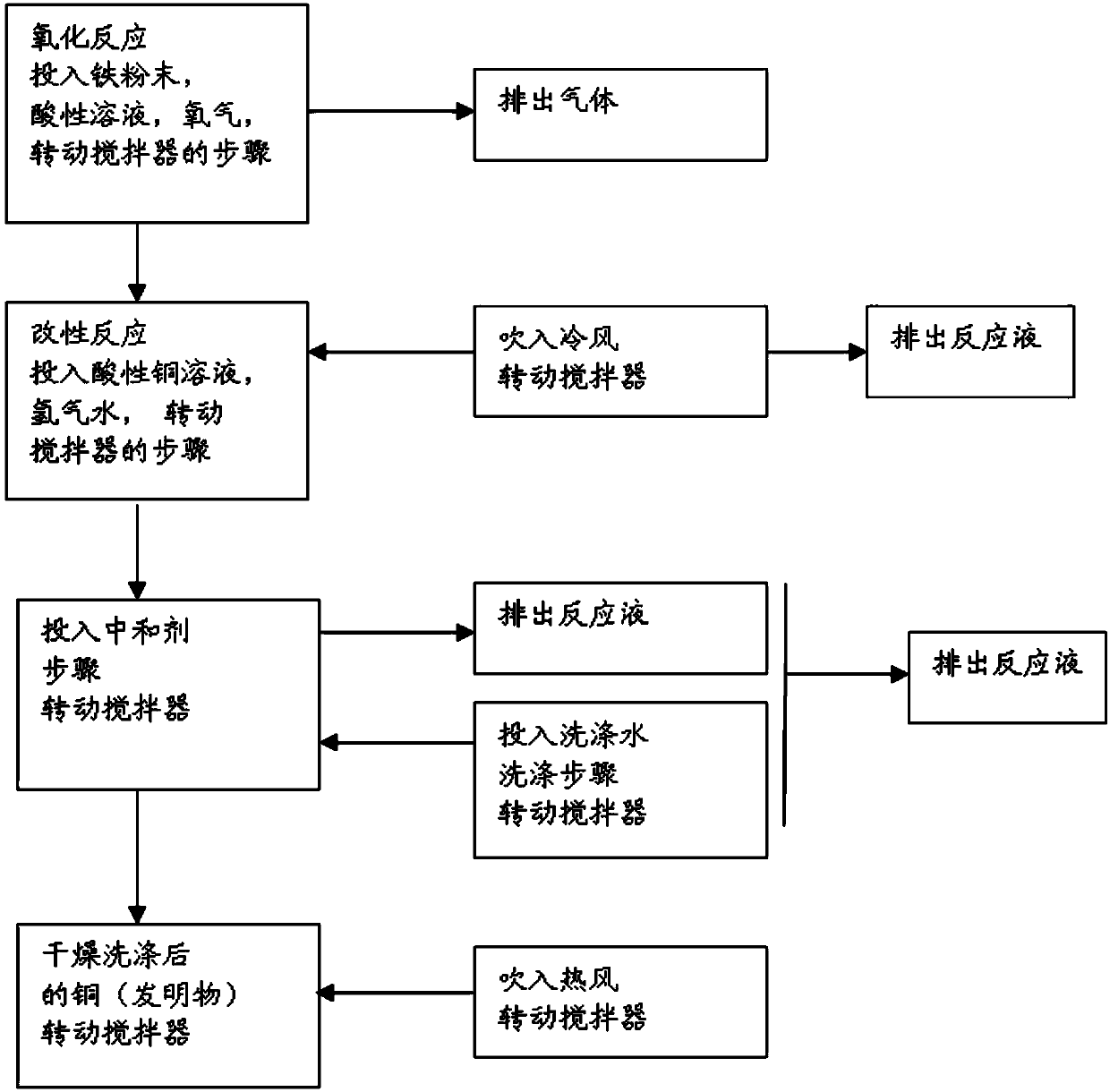

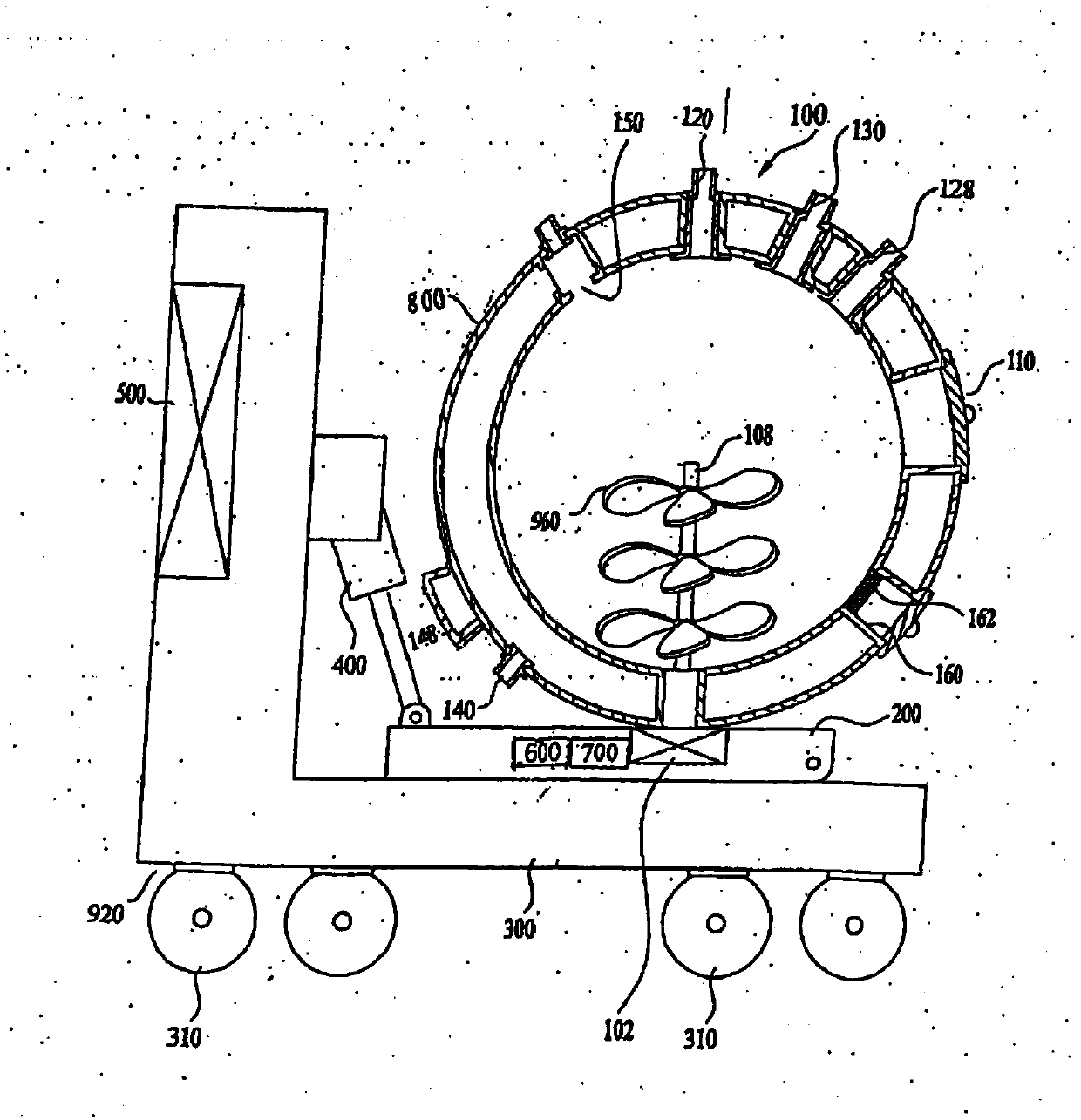

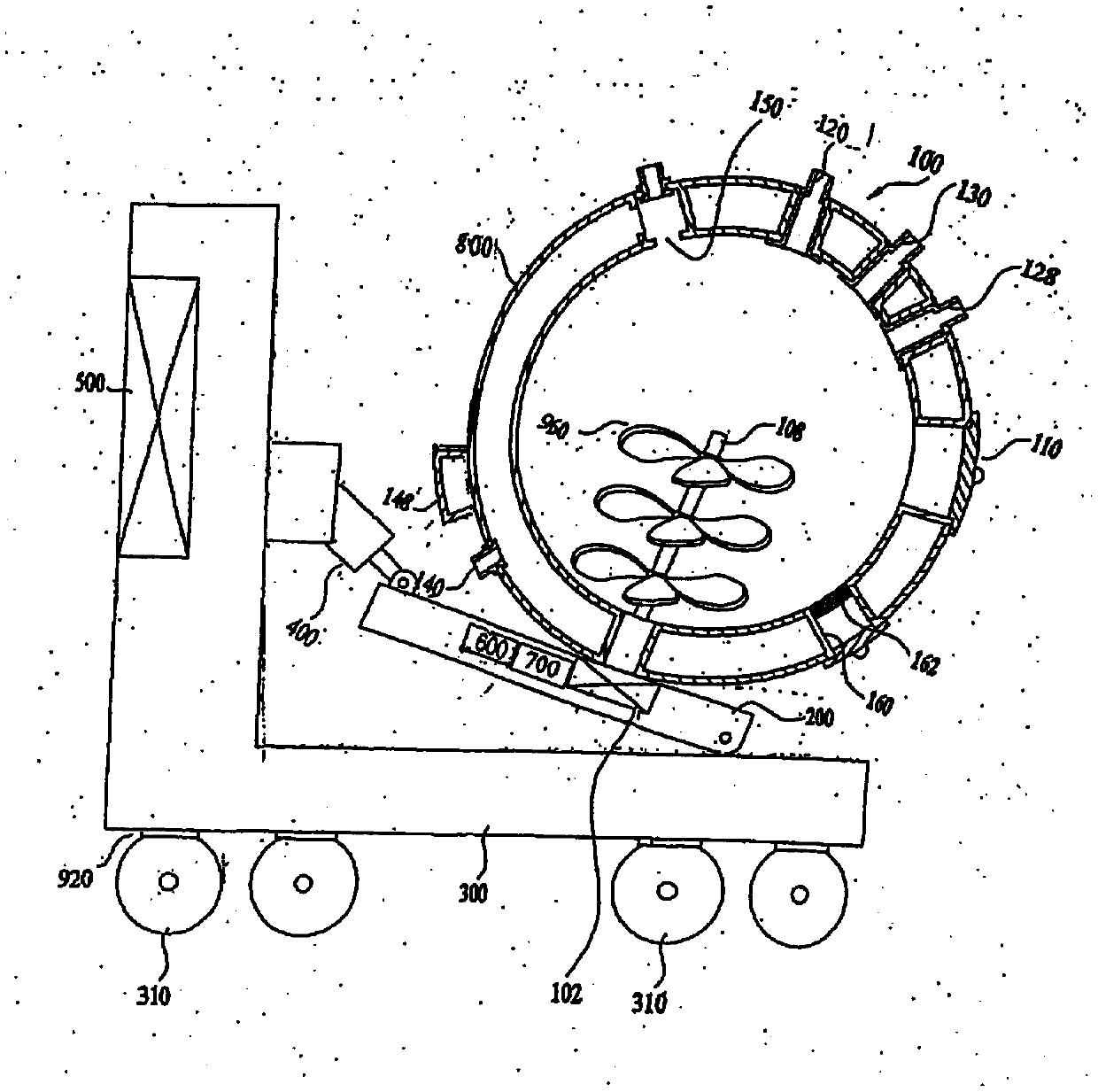

Method used

Image

Examples

Embodiment 1

[0137] 50ml of 10% sulfuric acid and 50ml of 10% hydrochloric acid were added into the reactor, and 45g of iron powder was added, and reacted at normal temperature for 48 hours to oxidize the iron powder. After the oxidation reaction is finished, only the oxidized iron powder remains in the reactor.

[0138] 22.5 g of the copper sulfate pentahydrate (copper content 5.71 g) was dropped into and dissolved in 100 ml of distilled water. Carry out the modification reaction of 48 hours in the reactor then, after the reaction finishes, filter and remove reaction solution and impurity by reaction solution outlet, drop into 1% copper sulfate aqueous solution 200ml (copper content 0.31g / 100ml, The total was 0.62 g), and after further reacting for 1 hour, the 2nd reaction liquid and impurities were removed by the same method. The above-mentioned copper modification process is a heat dissipation reaction, which generates a large amount of heat, so no additional heating process is require...

Embodiment 2

[0143] Put 20% hydrochloric acid solution and 45g of iron powder into the first reactor, then add accelerator oxygen water (dissolved amount is 0.001%-0.01% / Liter), and turn the mixer, at 3°C-25°C The reaction was performed for 3 hours to produce iron oxide from the iron powder.

[0144] After the iron oxidation reaction finishes, drop into cupric chloride solution (copper content is 7.3g) in the first reactor that is built-in with described ferric oxide after reacting, in described first reactor, add hydrogen water ( After the dissolved amount is 0.001%-0.01% / Liter), the agitator is rotated for 2 hours to carry out the modification reaction. After the reaction is completed, the reaction liquid and impurities are filtered and removed through the reaction liquid outlet. The copper modification process as described above performs heat dissipation reaction while generating bubbles, so a large amount of heat is generated, so no additional heating process is unnecessary.

[0145] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com