Method for pretreating incineration ash of circuit board and recovering bromine

A recovery method and circuit board technology, which is applied in the direction of improvement of process efficiency, copper sulfate, lead sulfate, etc., can solve the problem that valuable metals cannot be completely recovered, and achieve the effect of no tail liquid discharge and high added value of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

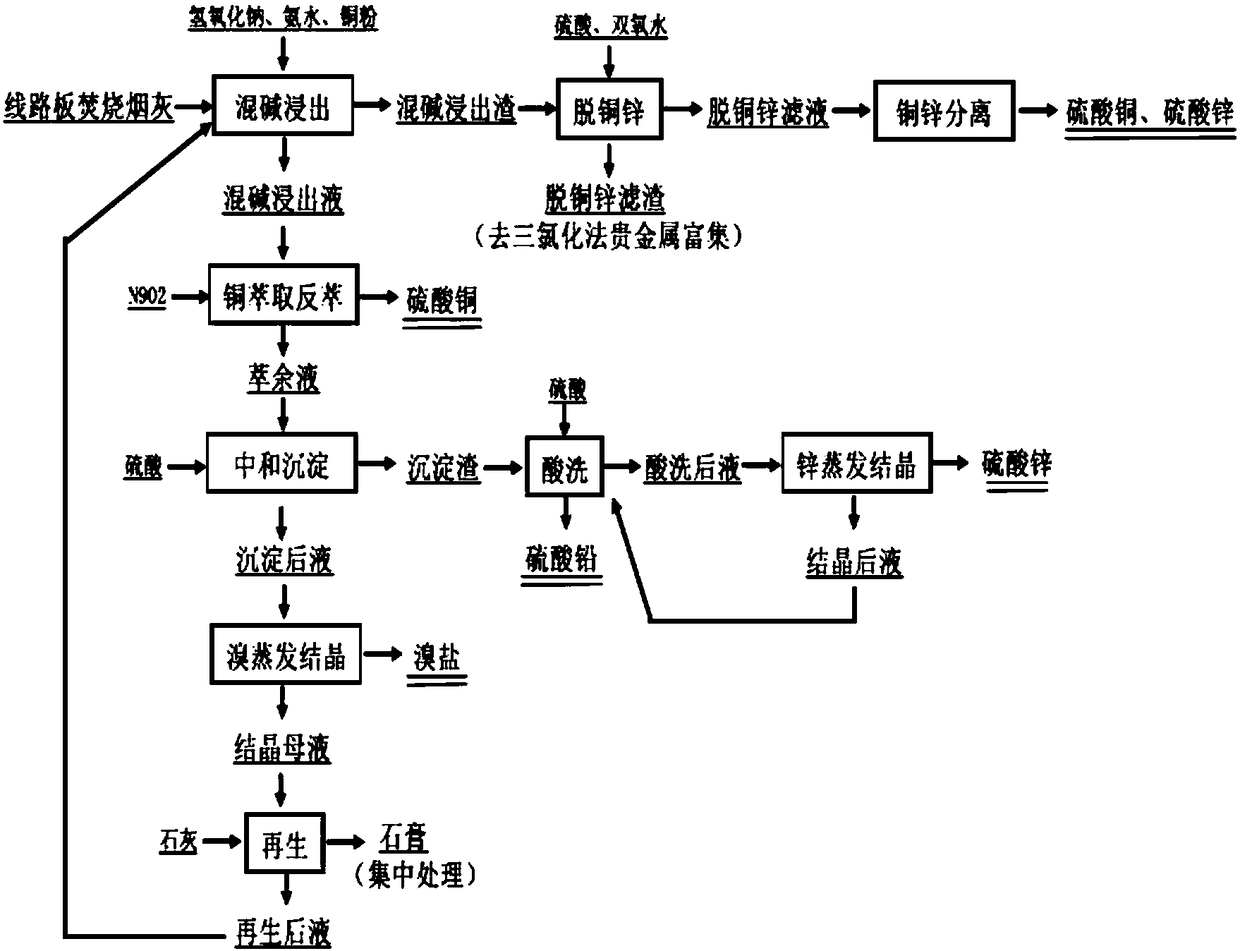

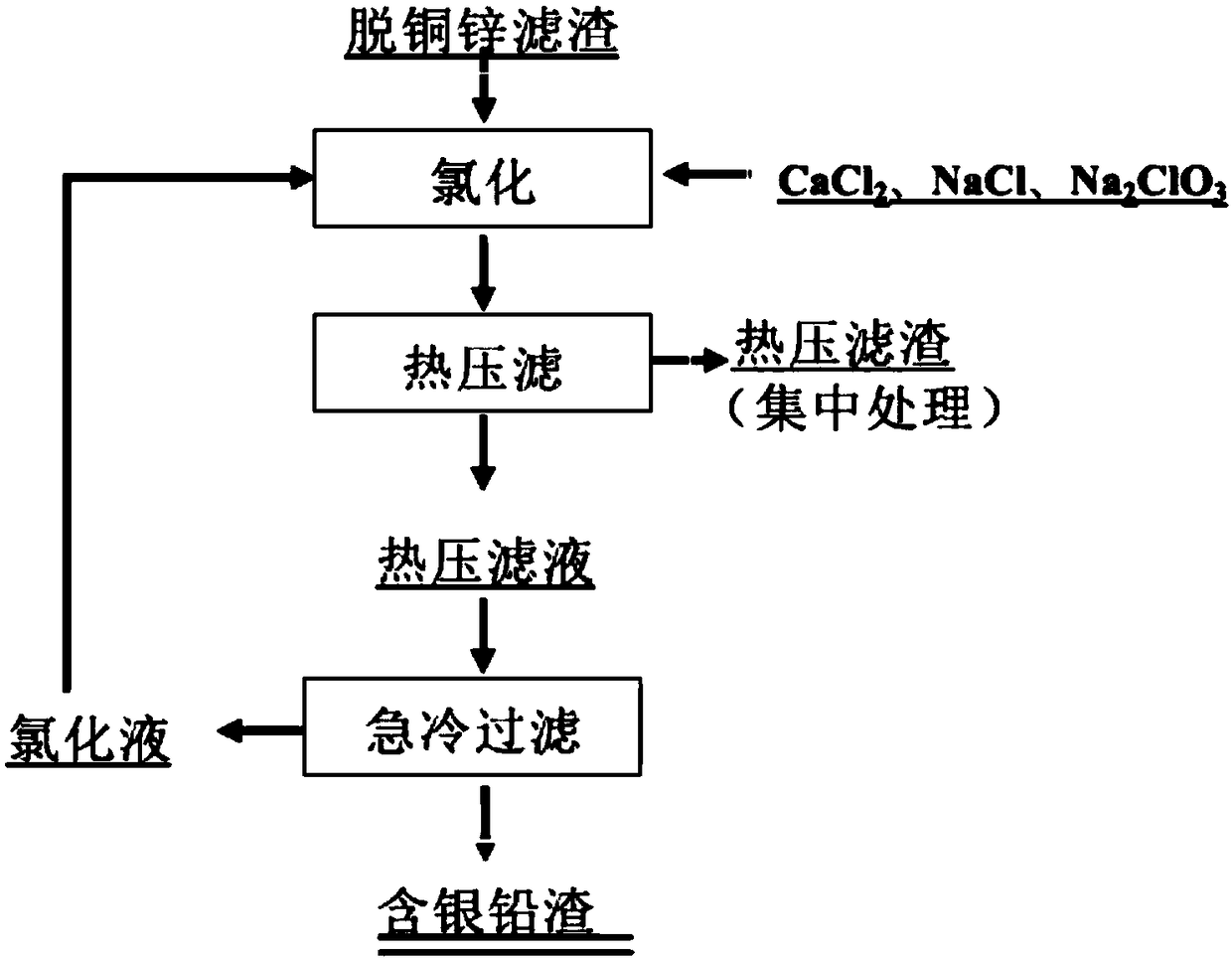

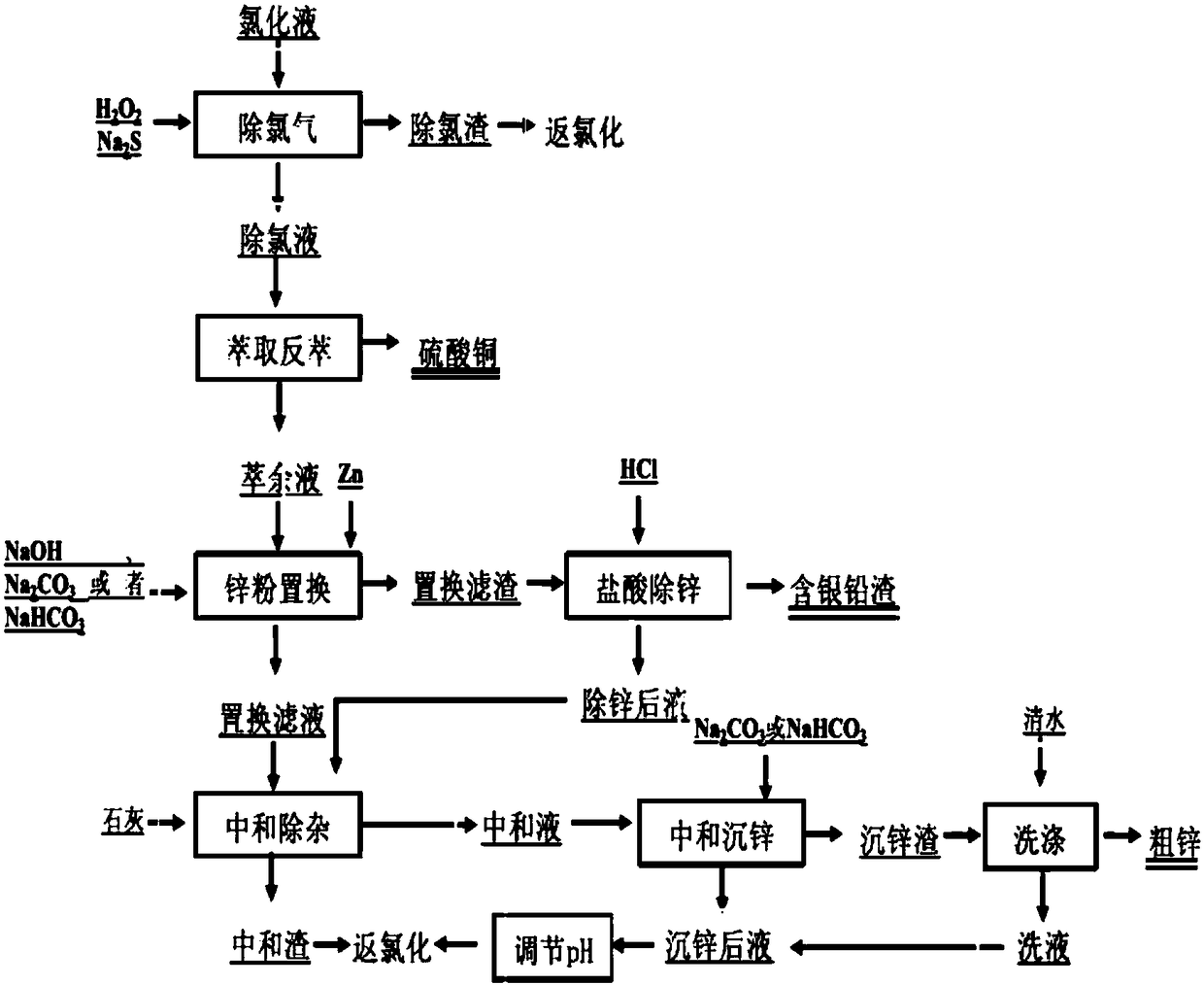

[0036] Follow the steps below to recycle:

[0037] (1) Mixed alkali leaching: carry out mixed alkali leaching with circuit board incineration smoke ash, leachate is made up of the mixed solution of sodium hydroxide and ammoniacal liquor, wherein the mass percent concentration of sodium hydroxide is 5%, the mass percent concentration of ammoniacal liquor is 5%, soot and The solid-to-liquid ratio of the leaching solution is 1:5 kg / liter, the leaching temperature is 35°C, stir and blow in air, the blowing air volume per cubic meter of leaching solution is 0.01 cubic meters per minute, after leaching for 1 hour, stop blowing in the air and continue stirring , adding 1 gram of copper powder per liter of leaching solution, and filtering after reacting for 10 minutes, to obtain mixed alkali leaching residue and mixed alkali leaching solution;

[0038] (2) Copper extraction and back extraction: the mixed alkali leach solution obtained in step (1) adopts N902 to carry out copper extrac...

Embodiment 2

[0059] Follow the steps below to recycle:

[0060] (1) mixed alkali leaching: carry out mixed alkali leaching with circuit board incineration soot, leachate is made up of the mixed solution of sodium hydroxide and ammoniacal liquor, wherein the mass percentage concentration of sodium hydroxide is 20%, the mass percentage concentration of ammoniacal liquor is 20%, soot and The solid-to-liquid ratio of the leaching solution is 1:10 kg / liter, the leaching temperature is 55°C, stir and blow in air, the blowing air volume per cubic meter of leaching solution is 0.1 cubic meters per minute, after leaching for 2 hours, stop blowing in the air and continue stirring , adding 3 grams of copper powder per liter of leaching solution, and filtering after 30 minutes of reaction to obtain mixed alkali leaching residue and mixed alkali leaching solution;

[0061] (2) Copper extraction and back extraction: the mixed alkali leach solution obtained in step (1) adopts N902 to carry out copper ext...

Embodiment 3

[0071] Follow the steps below to recycle:

[0072] (1) mixed alkali leaching: carry out mixed alkali leaching with circuit board incineration soot, leachate is made up of the mixed solution of sodium hydroxide and ammoniacal liquor, wherein the mass percentage concentration of sodium hydroxide is 15%, the mass percentage concentration of ammoniacal liquor is 10%, soot and The solid-liquid ratio of the leaching solution is 1:8 kg / liter, the leaching temperature is 40°C, stir and blow in air, the blowing air volume per cubic meter of leaching solution is 0.05 cubic meters per minute, after leaching for 1.5 hours, stop blowing in the air and continue stirring , adding 1 to 3 grams of copper powder per liter of leaching solution, and filtering after reacting for 10 to 30 minutes to obtain mixed alkali leaching residue and mixed alkali leaching solution;

[0073] (2) Copper extraction and back extraction: the mixed alkali leach solution obtained in step (1) adopts N902 to carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com