Alkaline etching ammonia recycling system

An ammonia recovery and alkaline technology, applied in the field of alkaline etching ammonia recovery and utilization system, can solve the problems of environmental pollution, hazardous waste, high cost, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention provides such Figure 1-2 A kind of alkaline etching ammonia recycling system shown, comprises the following steps:

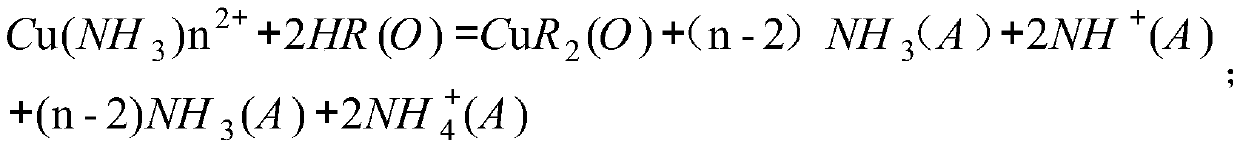

[0026] S1: Select an alkaline etching solution with a copper content of 120-180g / L, add it to the extraction tank, and add a hydrophobic β-diketone extractant with a concentration of 100mol / L for stirring, and add a separatory funnel inside, wait After standing for stratification, take out the water phase and the alkali phase in the separating funnel respectively, and set aside, the chemical reaction equation is as follows:

[0027]

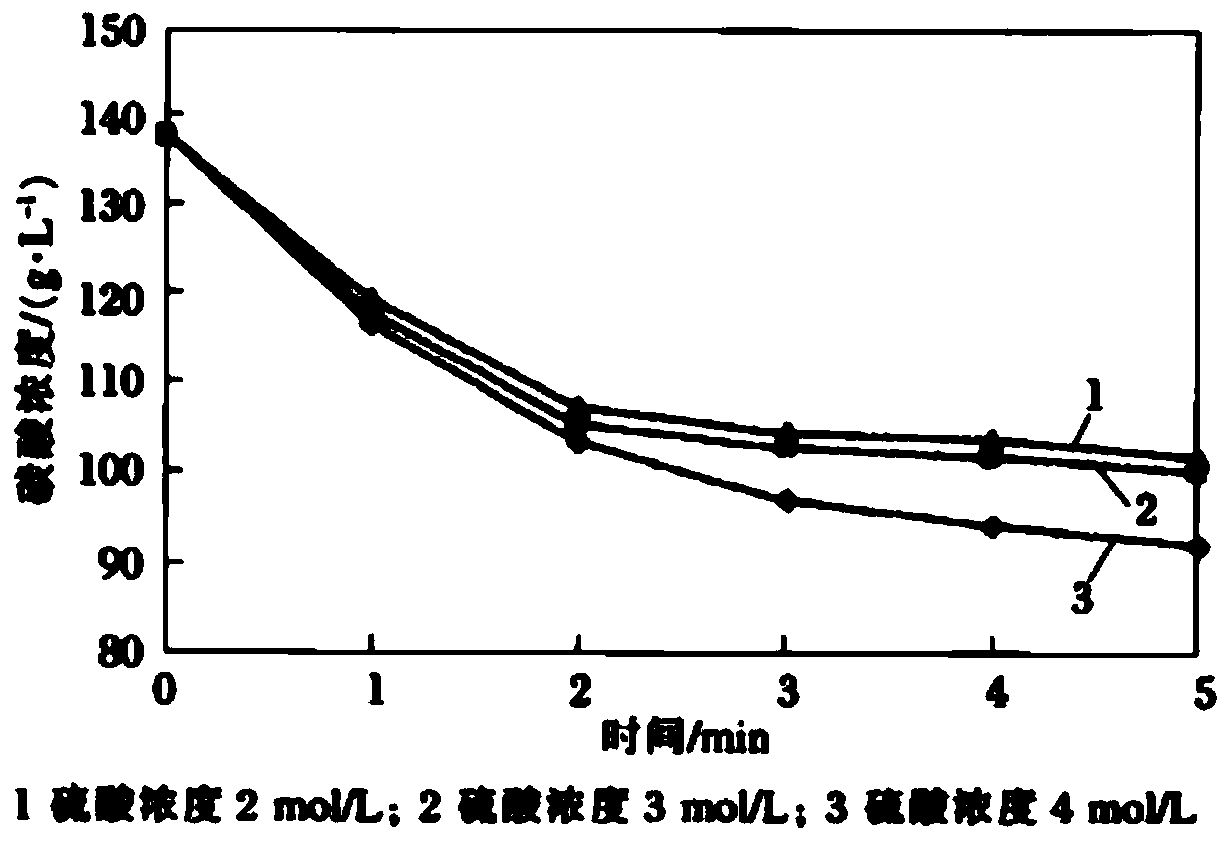

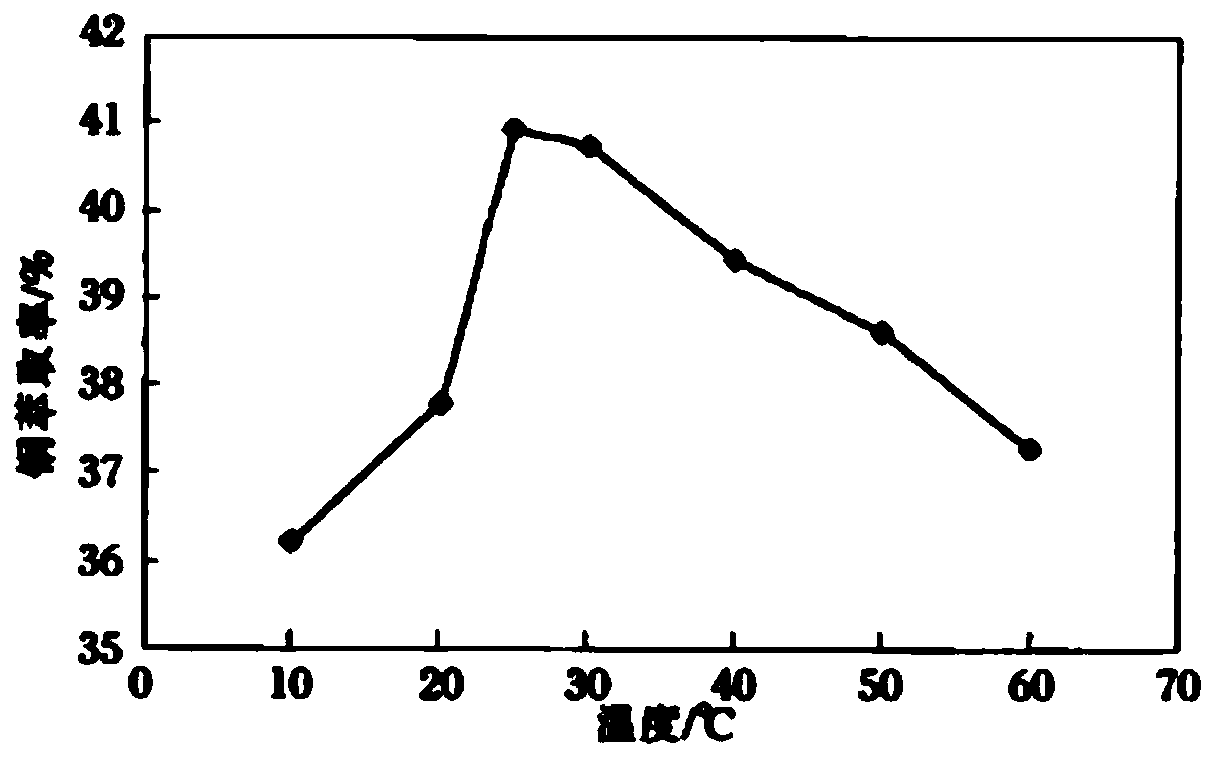

[0028] S2: Put the alkaline phase solution prepared in step S1 into the same container according to the same percentage, and add 2mol / L, 3mol / L and 4mol / L sulfuric acid solutions as stripping agents in the three containers respectively, Under the condition that the reaction temperature is 10 degrees, the alkali phase solutions added with different concentrations of sulfuric acid solutions are respe...

Embodiment 2

[0035] The invention provides a system for recycling alkaline etching ammonia, comprising the following steps:

[0036] S1: Select an alkaline etching solution with a copper content of 120-180g / L, add it to the extraction tank, and add a hydrophobic β-diketone extractant with a concentration of 100mol / L for stirring, and add a separatory funnel inside, wait After standing for stratification, take out the water phase and the alkali phase in the separating funnel respectively, and set aside, the chemical reaction equation is as follows:

[0037]

[0038] S2: Put the alkaline phase solution prepared in step S1 into the same container according to the same percentage, and add 2mol / L, 3mol / L and 4mol / L sulfuric acid solutions as stripping agents in the three containers respectively, Under the condition that the reaction temperature is 25 degrees, the alkali phase solutions added with different concentrations of sulfuric acid solutions are respectively reacted to generate copper ...

Embodiment 3

[0045] The invention provides a system for recycling alkaline etching ammonia, comprising the following steps:

[0046] S1: Select an alkaline etching solution with a copper content of 120-180g / L, add it to the extraction tank, and add a hydrophobic β-diketone extractant with a concentration of 100mol / L for stirring, and add a separatory funnel inside, wait After standing for stratification, take out the water phase and the alkali phase in the separating funnel respectively, and set aside, the chemical reaction equation is as follows:

[0047]

[0048] S2: Put the alkaline phase solution prepared in step S1 into the same container according to the same percentage, and add 2mol / L, 3mol / L and 4mol / L sulfuric acid solutions as stripping agents in the three containers respectively, Under the condition that the reaction temperature is 40 degrees, the alkali phase solutions added with different concentrations of sulfuric acid solutions are respectively reacted to form a copper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com