Copper sulfate pentahydrate crystal and preparation method thereof

A technology of copper sulfate pentahydrate and copper sulfate solution, which is applied in the direction of copper sulfate, copper compound preparation, chemical instruments and methods, etc., can solve the problems of complexity, low water content, and long preparation process, and achieve the method of environmental protection, method and , the efficient effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

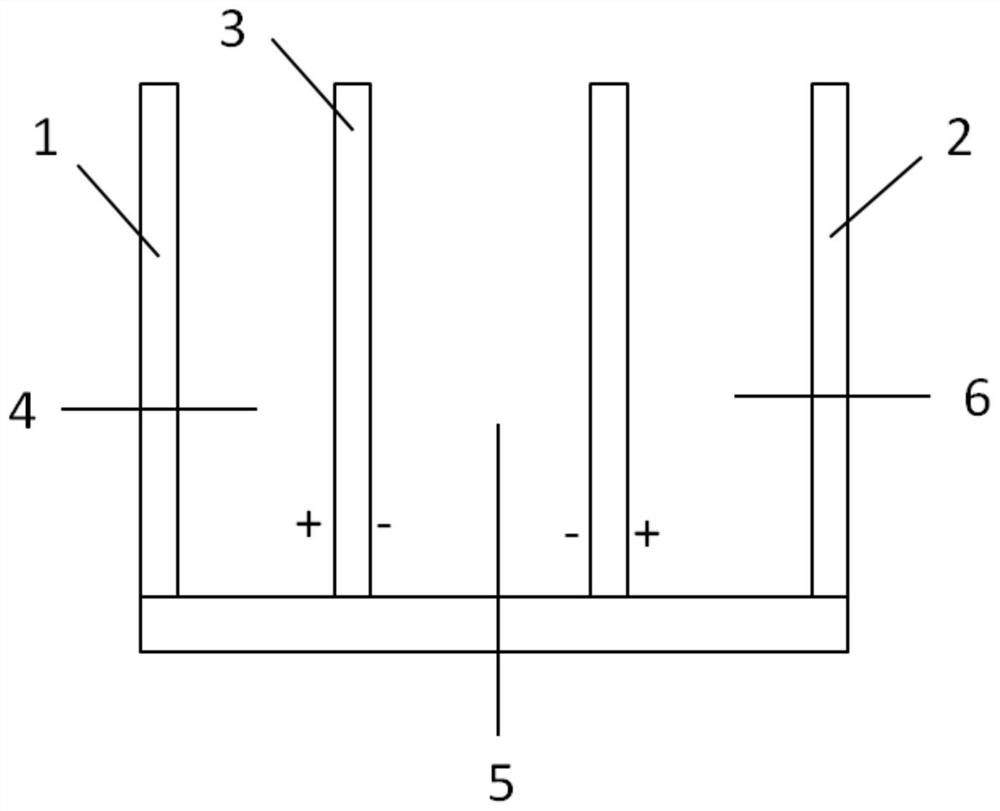

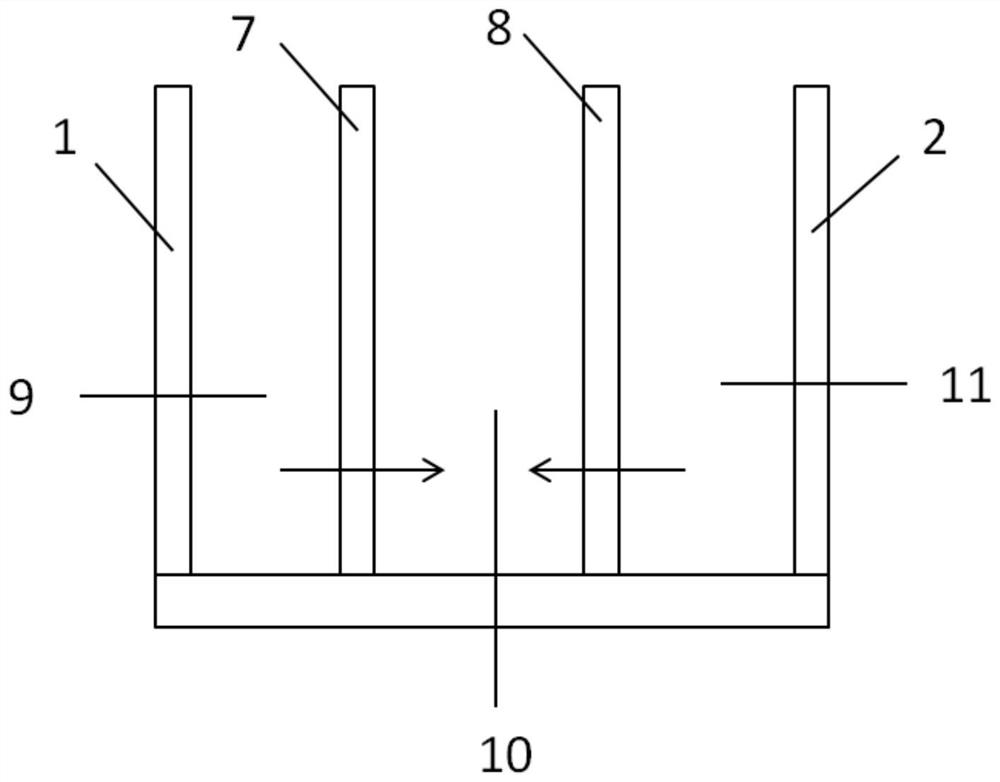

[0069] The present embodiment provides a kind of preparation method of copper sulfate crystal, and the structural schematic diagram of electrolyzer and electrodialyzer are respectively as follows figure 1 and figure 2 Shown, described preparation method comprises the steps:

[0070] (1) Before electrolysis, insert degreasing, deoxidized and cleaned electrolytic copper plate and 316L stainless steel plate as anode 1 and cathode 2 in electrolyzer and electrodialyzer respectively;

[0071] (2) Two unidirectional ionic membranes 3 are arranged in the electrolytic cell. The unidirectional cation membrane near the anode side only allows cations to pass through, and the unidirectional anion membrane near the cathode side only allows anion to pass through. The two unidirectional ion membranes The electrolytic cell is divided into a first compartment 4 of the electrolytic cell, a second compartment 5 of the electrolytic cell and a third compartment 6 of the electrolytic cell;

[007...

Embodiment 2

[0079] The present embodiment provides a kind of preparation method of copper sulfate crystal, and described preparation method comprises the steps:

[0080] (1) Before electrolysis, insert degreasing, deoxidized and cleaned electrolytic copper plates and high-purity titanium plates as anodes and cathodes respectively in the electrolyzer and electrodialyzer;

[0081] (2) Two unidirectional ionic membranes are set in the electrolytic cell. The unidirectional cation membrane near the anode only allows cations to pass through, and the unidirectional anion membrane near the cathode side only allows anions to pass through. The two unidirectional ionic membranes will The electrolytic cell is divided into a first compartment of the electrolytic cell, a second compartment of the electrolytic cell and a third compartment of the electrolytic cell;

[0082] 5 electrolytic units are connected in parallel, inject sulfuric acid aqueous solution with a mass concentration of 10% into each com...

Embodiment 3

[0089] The present embodiment provides a kind of preparation method of copper sulfate crystal, and described preparation method comprises the steps:

[0090] (1) Before electrolysis, insert degreasing and deoxidized and cleaned electrolytic copper plates and 316L stainless steel plates as anodes and cathodes respectively in the electrolyzer and electrodialyzer;

[0091] (2) Two unidirectional ionic membranes 3 are set in the electrolytic cell. The unidirectional cation membrane near the anode side only allows cations to pass through, and the unidirectional anion membrane near the cathode side only allows anion to pass through. The two unidirectional ion membranes The membrane divides the cell into the first compartment of the cell, the second compartment of the cell and the third compartment of the cell;

[0092] 10 electrolytic units are connected in parallel, inject sulfuric acid aqueous solution with a mass concentration of 6% into each compartment of the electrolytic cell,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com