Method for preparing 6N-grade nickel sulfate by fractionally extracting P229 (bis(2-ethylhexyl)phosphonic acid)

A nickel sulfate extraction technology, which is applied in the preparation of nickel sulfate and nickel compounds, etc., to achieve the effects of short process flow, good working environment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

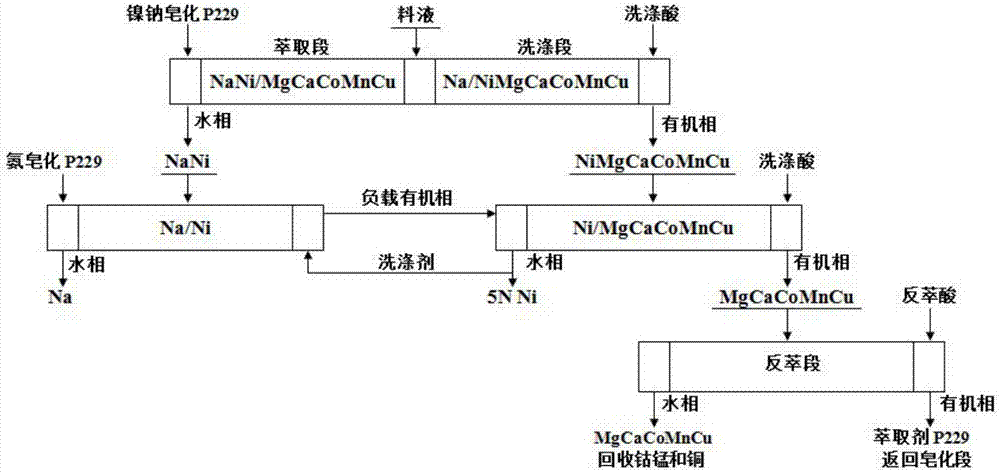

[0025] 1) Separation of NaNi / NiMgCaCoMnCu by fractional distillation

[0026] The organic phase of nickel-sodium saponification P229 is the sulfonated kerosene solution of extractant P229, and the concentration of extractant P229 is 1.0mol / L; when used, the first-stage outlet water phase of the NaNi / NiMgCaCoMnCu fractional distillation extraction system is used to obtain NiSO 4 and Na 2 SO 4 The aqueous solution of the mixture was saponified with nickel and sodium, and the saponification rate was 36%. 2N~3N industrial grade nickel sulfate aqueous solution is the aqueous solution containing nickel sulfate as the feed liquid, and its composition is: Ni110g / L, Na0.005g / L, Mg0.15g / L, Ca0.10g / L, Co0.03g / L, Mn0.02g / L, Cu0.01g / L, pH=4.0. Washing acid is 1.5mol / LH 2 SO 4 .

[0027] The organic phase of nickel sodium saponification P229 enters the NaNi / NiMgCaCoMnCu fractionation extraction system from the first stage, and the 2N~3N industrial grade nickel sulfate aqueous solution...

Embodiment 2

[0036] 1) Separation of NaNi / NiMgCaCoMnCu by fractional distillation

[0037] The organic phase of nickel-sodium saponification P229 is the sulfonated kerosene solution of extractant P229, the concentration of extractant P229 is 1.5mol / L; the first-stage outlet water phase of NaNi / NiMgCaCoMnCu fractional distillation extraction system is used to obtain NiSO 4 and Na 2 SO 4 The aqueous solution of the mixture was saponified with nickel and sodium, and the saponification rate was 30%. 2N~3N industrial grade nickel sulfate aqueous solution is the aqueous solution containing nickel sulfate as the feed liquid, and its composition is: Ni120g / L, Na0.01g / L, Mg0.25g / L, Ca0.15g / L, Co0.06g / L, Mn0.05g / L, Cu0.02g / L, pH=3.0. Washing acid is 1.5mol / LH 2 SO 4 .

[0038] The organic phase of sodium nickel saponification P229 enters the NaNi / NiMgCaCoMnCu fractionation extraction system from the first stage, and the 2N~3N industrial grade nickel sulfate aqueous solution enters the NaNi / NiM...

Embodiment 3

[0047] 1) Separation of NaNi / NiMgCaCoMnCu by fractional distillation

[0048] The organic phase of nickel-sodium saponification P229 is the sulfonated kerosene solution of extractant P229, the concentration of extractant P229 is 0.5mol / L; when used, the first-stage outlet water phase of the NaNi / NiMgCaCoMnCu fractional distillation extraction system is used to obtain NiSO 4 and Na 2 SO 4 The aqueous solution of the mixture was saponified with nickel and sodium, and the saponification rate was 40%. 2N~3N industrial grade nickel sulfate aqueous solution is the aqueous solution containing nickel sulfate as the feed liquid, and its composition is: Ni100g / L, Na0.001g / L, Mg0.025g / L, Ca0.015g / L, Co0.006g / L, Mn0.005g / L, Cu0.002g / L, pH=4.5. Washing acid is 1.5mol / LH 2 SO 4 .

[0049] The organic phase of sodium nickel saponification P229 enters the NaNi / NiMgCaCoMnCu fractionation extraction system from the first stage, and the 2N~3N industrial grade nickel sulfate aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com