Method for preparing nickel sulfate solution and battery grade ferric phosphate from nickel-containing pig iron

A technology of nickel pig iron and iron phosphate, which is applied in the field of nickel-containing pig iron to prepare nickel sulfate solution and battery-grade iron phosphate, can solve the problems of large consumption of auxiliary materials, difficult promotion, high energy consumption, etc., and achieve the goal of reducing processing costs and improving utilization value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

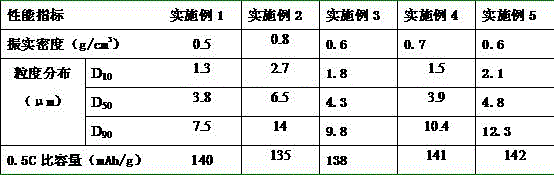

Embodiment 1

[0026] The invention discloses a method for preparing nickel sulfate solution and battery-grade iron phosphate from nickel-containing pig iron, which comprises the following steps:

[0027] (1) Pretreatment of raw materials, nickel-containing pig iron is dried, crushed into powder, and sieved for component detection;

[0028] (2) Acid leaching treatment, use mixed acid to carry out atmospheric pressure acid leaching on the undersize obtained in step (1), and obtain the filtrate after solid-liquid separation, the acid leaching temperature is 50-90°C, and the acid leaching time is 3-8 Hour;

[0029] (3) Precipitation treatment, under the condition of using a precipitating agent to maintain the pH value of the filtrate in step (2), add an oxidizing agent to oxidize the ferrous iron in the filtrate at the same time, use the controlled crystallization method to prepare iron phosphate precipitation, filter and wash after the reaction After obtaining nickel-containing filtrate and i...

Embodiment 2

[0035] The invention discloses a method for preparing nickel sulfate solution and battery-grade iron phosphate from nickel-containing pig iron, which comprises the following steps:

[0036] (1) Pretreatment of raw materials, nickel-containing pig iron is dried, crushed into powder, and sieved for component testing;

[0037] (2) Acid leaching treatment, use mixed acid to carry out atmospheric pressure acid leaching on the undersize obtained in step (1), and obtain the filtrate after solid-liquid separation, the acid leaching temperature is 50-90°C, and the acid leaching time is 3-8 Hour;

[0038] (3) Precipitation treatment, under the condition of using a precipitating agent to maintain the pH value of the filtrate in step (2), add an oxidizing agent to oxidize the ferrous iron in the filtrate at the same time, use the controlled crystallization method to prepare iron phosphate precipitation, filter and wash after the reaction After obtaining nickel-containing filtrate and iro...

Embodiment 3

[0044] The invention discloses a method for preparing nickel sulfate solution and battery-grade iron phosphate from nickel-containing pig iron, which comprises the following steps:

[0045] (1) Pretreatment of raw materials, nickel-containing pig iron is dried, crushed into powder, and sieved for component testing;

[0046] (2) Acid leaching treatment, use mixed acid to carry out atmospheric pressure acid leaching on the undersize obtained in step (1), and obtain the filtrate after solid-liquid separation, the acid leaching temperature is 50-90°C, and the acid leaching time is 3-8 Hour;

[0047] (3) Precipitation treatment, under the condition of using a precipitating agent to maintain the pH value of the filtrate in step (2), add an oxidizing agent to oxidize the ferrous iron in the filtrate at the same time, use the controlled crystallization method to prepare iron phosphate precipitation, filter and wash after the reaction After obtaining nickel-containing filtrate and iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com