Preparation method of high-cycle and high-rate carbon-based negative electrode energy storage composite material

A composite material, high-rate technology, applied in the field of materials science, can solve the problem of unstoppable capacity fading, and achieve excellent cycle stability, high lithium and sodium storage capacity, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

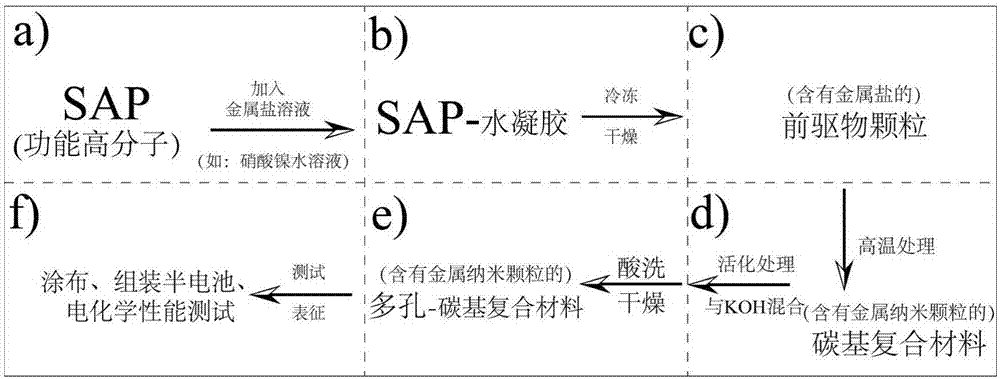

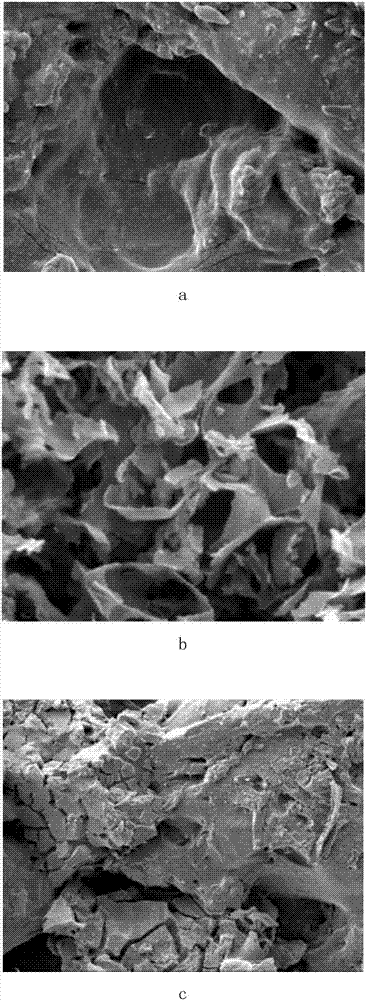

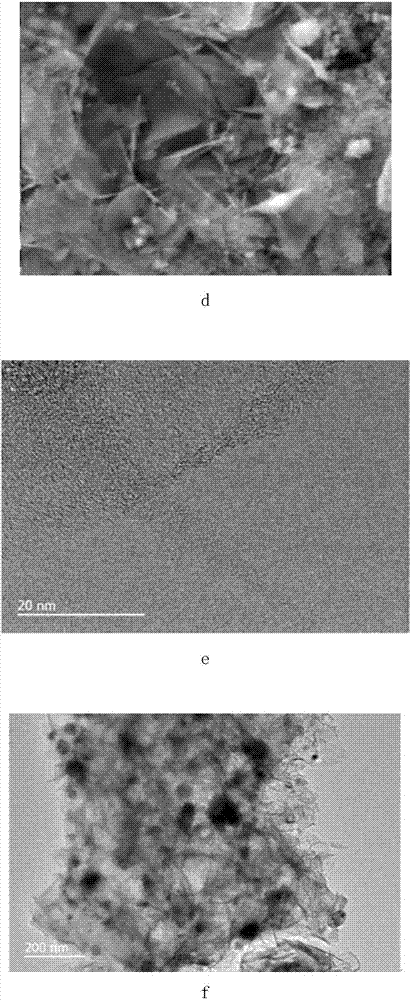

[0041] A method for preparing a high-cycle, high-rate carbon-based negative electrode energy storage composite material. The battery negative electrode material involves three main elements: Ni, C, and O. See the experimental procedure figure 1 , including the following steps:

[0042] (1) Collect polymer water-absorbent resin particles, weigh 1 g, weigh 0.1 g of nickel nitrate crystals, dissolve them in 10 ml of distilled water, then pour them into the polymer particles, mix well, and shake with a shaker.

[0043] (2) When the polymer is added to the nickel nitrate aqueous solution, a hydrogel is formed, and then the hydrogel is transferred to the refrigerator to freeze into an ice gel, and finally the solid ice is dried and sublimated by a freeze-drying machine (that is, the water in the original aqueous solution is removed. solvent) to obtain dry gel precursor particles.

[0044] (3) The precursor particles were transferred to a tube furnace and calcined at a high tempera...

Embodiment 2

[0054] A method for preparing a high-cycle, high-rate carbon-based negative electrode energy storage composite material. The battery negative electrode material involves three main elements: Ni, C, and O. Specifically include the following steps:

[0055] (1) Collect polymer water-absorbent resin particles, weigh 3 g, weigh 0.5 g of nickel nitrate crystals, dissolve in 30 ml of distilled water, then pour into polymer particles, and mix well. Shake using a shaker.

[0056] (2) When the polymer is added to the nickel nitrate aqueous solution, a hydrogel is formed, and then the hydrogel is transferred to the refrigerator to freeze into an ice gel, and finally the solid ice is dried and sublimated by a freeze-drying machine (that is, the water in the original aqueous solution is removed. solvent) to obtain dry gel precursor particles.

[0057] (3) The precursor particles were transferred to a tube furnace and calcined at high temperature. The calcination parameters were set as f...

Embodiment 3

[0063] A method for preparing a high-cycle, high-rate carbon-based negative electrode energy storage composite material. The battery negative electrode material involves three main elements: Ni, C, and O. Specifically include the following steps:

[0064] (1) Collect polymer water-absorbent resin particles, weigh 3 g, weigh 0.5 g of nickel nitrate crystals, dissolve in 30 ml of distilled water, then pour into polymer particles, and mix well. Shake using a shaker.

[0065] (2) When the polymer is added to the nickel nitrate aqueous solution, a hydrogel is formed, and then the hydrogel is transferred to the refrigerator to freeze into an ice gel, and finally the solid ice is dried and sublimated by a freeze-drying machine (that is, the water in the original aqueous solution is removed. solvent) to obtain dry gel precursor particles.

[0066] (3) The precursor particles were transferred to a tube furnace and calcined at high temperature. The calcination parameters were set as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com