Nickel salt production method

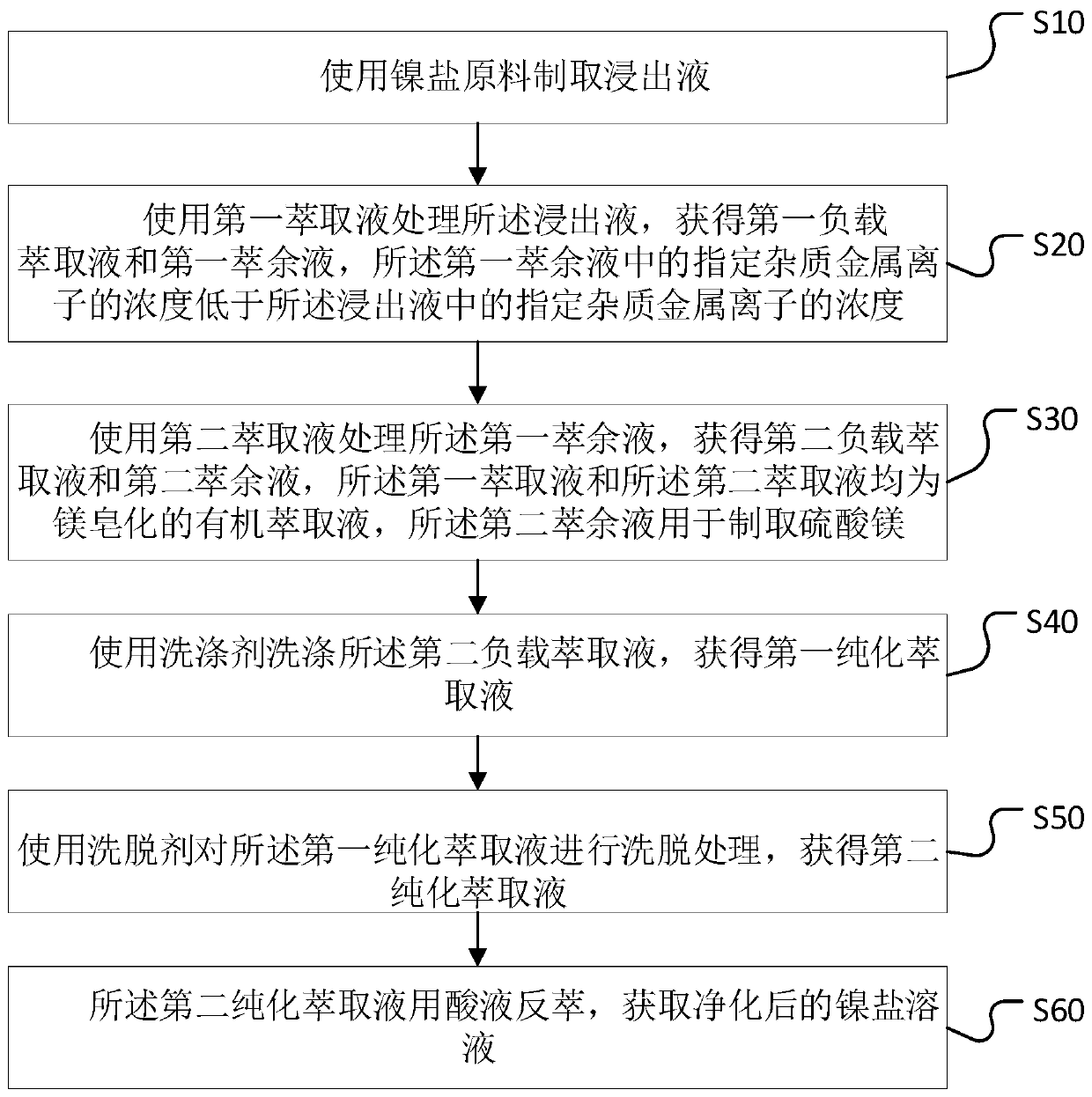

A production method and technology for nickel salts, which are applied in nickel sulfate, nickel compound preparation, liquid solution solvent extraction, etc., can solve problems such as rising salinity of external water bodies, and achieve the effects of automatic operation, high purity, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The crude nickel hydroxide (MHP) produced from laterite nickel ore was used to produce battery-grade nickel sulfate. The main components (mass fraction) of the samples are shown in Table 1.

[0078] The composition of table 1 embodiment 1 crude nickel hydroxide

[0079] element Ni% Co% Mn% Fe% Cu% Zn% Ca% Mg% Al% content 41.3 4.05 6.8 0.35 0.43 0.15 0.27 2.28 0.14

[0080] Put the above sample into the reaction kettle, control the solid-liquid ratio of 1:7, stir, add 98% concentrated sulfuric acid, pass in steam, keep the reaction temperature at 65°C, add hydrogen peroxide, react for 4 hours, and the final acid is controlled at pH 2.5 . The leaching liquid was separated from solid and liquid by a plate and frame filter press to obtain a nickel sulfate leaching liquid, the main components of which are shown in Table 2.

[0081] The main component of table 2 embodiment 1 nickel sulfate leaching solution

[0082] el...

Embodiment 2

[0095] The crude nickel carbonate produced from electroplating sludge was used to produce battery-grade nickel sulfate. The main components of the samples are shown in Table 6.

[0096] The composition of table 6 embodiment 2 nickel carbonate

[0097] element Ni co mn Fe Cu Zn Ca Mg content% 45.1 0.02 0.01 0.13 0.01 0.01 0.047 0.28

[0098] Add the above sample into the reaction kettle, control the solid-liquid ratio of 1:7, stir, add 98% concentrated sulfuric acid, feed steam, keep the reaction temperature at 65°C, react for 4 hours, and control the terminal acidity at pH 4.0. The leaching slurry was separated from solid and liquid by a precision filter to obtain a nickel sulfate leaching solution, the main components of which are shown in Table 7.

[0099] The main component of table 7 embodiment 2 nickel sulfate leaching solution

[0100] element Ni co mn Fe Cu Zn Ca Mg Contentg / L 64.8 0.027 0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com