Method for comprehensively recovering waste FCC catalyst by using hydrochloric acid system

A catalyst and hydrochloric acid technology, which is applied in the preparation of nickel sulfide, nickel compound, aluminum hydroxide, etc., can solve the problems of complex process, high cost, and unsatisfactory separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

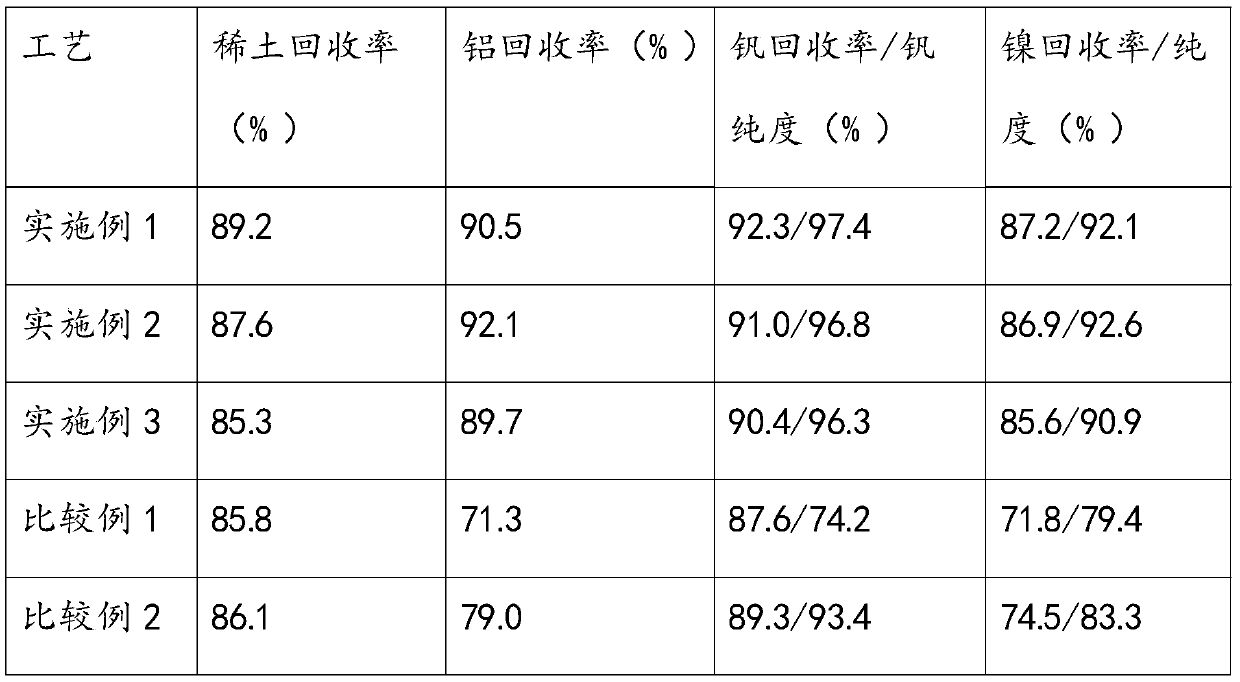

Embodiment 1

[0064] The spent FCC catalyst included the following components: 48 wt% alumina, 36 wt% silica, 4.1 wt% rare earth oxides, 1.2 wt% vanadium, 0.7 wt% nickel and 0.4 wt% iron. React it with hydrochloric acid solution and filter to obtain silicon slag and hydrochloric acid leaching solution; the reaction conditions are: hydrochloric acid concentration 8mol / L, reaction temperature 80°C, stirring time 16h, liquid-solid ratio 3:1.

[0065] The hydrochloric acid leaching solution was first adjusted to pH = 1.4 with sodium hydroxide solution, and hydrogen peroxide was added to carry out heating reaction; the reaction conditions were: temperature 60°C, reaction time 30 minutes. Use 50% (v / v) of two (2,4,4-trimethylpentyl) phosphinic acid heptane solution as extractant to extract; extraction condition is: the ratio of organic phase and aqueous phase (O / A) is 1:1, the extraction temperature is 25°C, and the extraction time is 45min; then the loaded organic phase is back-extracted with a...

Embodiment 2

[0070] The spent FCC catalyst included the following components: 48 wt% alumina, 36 wt% silica, 4.1 wt% rare earth oxides, 1.2 wt% vanadium, 0.7 wt% nickel and 0.4 wt% iron. React it with hydrochloric acid solution and filter to obtain silicon slag and hydrochloric acid leaching solution; the reaction conditions are: hydrochloric acid concentration 6mol / L, reaction temperature 85°C, stirring time 12h, liquid-solid ratio 4:1.

[0071] The hydrochloric acid leaching solution was first adjusted to pH = 1.6 with sodium hydroxide solution, then hydrogen peroxide was added, and the heating reaction was carried out; the reaction conditions were: temperature 50°C, reaction time 6h. Use 30% (v / v) of two (2,4,4-trimethylpentyl) phosphinic acid heptane solution to extract as extractant; extraction condition is: the ratio of organic phase and aqueous phase (O / A) is 2:1, the extraction temperature is 20°C, and the extraction time is 60min; then the loaded organic phase is back-extracted w...

Embodiment 3

[0076]The spent FCC catalyst included the following components: 48 wt% alumina, 36 wt% silica, 4.1 wt% rare earth oxides, 1.2 wt% vanadium, 0.7 wt% nickel and 0.4 wt% iron. React it with hydrochloric acid solution and filter to obtain silicon slag and hydrochloric acid leaching solution; the reaction conditions are: hydrochloric acid concentration 10mol / L, reaction temperature 75°C, stirring time 18h, liquid-solid ratio 2:1.

[0077] The hydrochloric acid leaching solution was first adjusted to pH = 1.2 with sodium hydroxide solution, and hydrogen peroxide was added to carry out heating reaction; the reaction conditions were: temperature 70°C, reaction time 10 minutes. Use 40% (v / v) of two (2,4,4-trimethylpentyl) phosphinic acid heptane solution to extract as extractant; extraction condition is: the ratio of organic phase and aqueous phase (O / A) is 0.5:1, the extraction temperature is 30°C, and the extraction time is 30min; then the loaded organic phase is back-extracted with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com