Preparation method of ternary anode material precursor

A cathode material and precursor technology, applied in the field of cathode material precursor preparation, can solve the problems of large irreversible capacity, large particle size and wide particle size distribution for the first time, and achieve low cost, high density and good layered crystal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

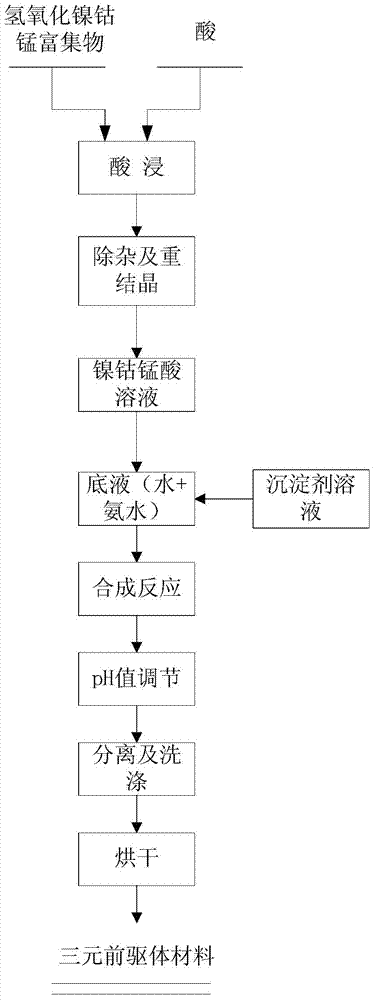

[0023] For a preparation method of a ternary cathode material precursor of the present invention, please refer to figure 1 , including the following process flow:

[0024] A. Acid leaching: use laterite nickel ore to produce electrolytic nickel intermediate product nickel manganese cobalt hydroxide enrichment as raw material, through acid leaching, the solid-liquid weight ratio is 1:1-1:4, to obtain nickel manganese cobalt acid solution;

[0025] B. Impurity removal and recrystallization: Add fluoride to the nickel-manganese-cobalt acid solution obtained in step A to remove calcium and magnesium impurities in the solution. The weight of the fluoride addition is the nickel-manganese-cobalt hydroxide concentrate in the A step 2% to 5% of the weight, and then filtered, concentrated, and crystallized to obtain a nickel-manganese-cobalt mixture;

[0026] C. Mixed salt preparation: Dissolve the nickel-manganese-cobalt mixture obtained in step B in water to form a nickel-manganese-c...

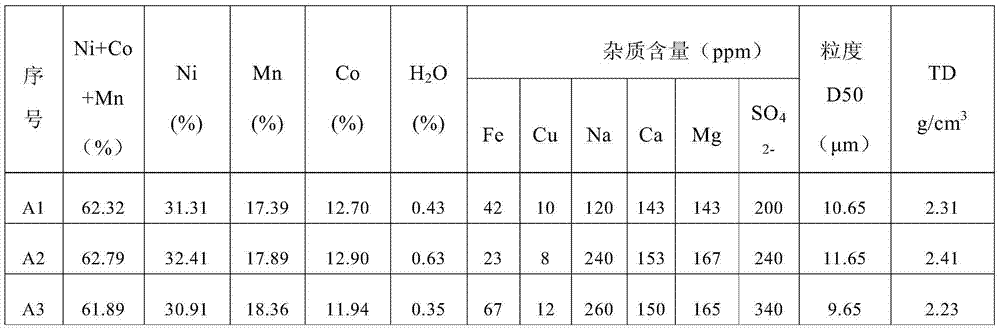

Embodiment 1

[0050] A. Acid leaching: Take 1000kg of laterite nickel ore to produce nickel hydroxide and cobalt concentrate, an intermediate product of electrolytic nickel, add 3000kg of sulfuric acid (98% by mass) for leaching, and stir vigorously for 30 minutes to obtain a nickel-manganese-cobalt acid solution;

[0051] B. Impurity removal and recrystallization: Add 50Kg sodium fluoride to the nickel-cobalt-manganese acid solution in step A to remove calcium and magnesium impurities in the solution, filter, concentrate, and crystallize to obtain 1268kg of nickel-cobalt-manganese mixture;

[0052] C. Mixed salt preparation: After the nickel-manganese-cobalt mixture obtained in step B is dissolved in 5072kg of water, the total volume of the solution is 5713L, and the concentration of Ni, Mn, and Co ions in the solution obtained by sampling analysis is 0.73mol / L and 0.16mol respectively / L, 0.08mol / L, then add 708.24KgNi to the mixed solution 2 SO 4 .6H 2 O, 714.5kg MnSO 4 .H 2 O, 807.7...

Embodiment 2

[0059] A. Acid leaching: Take 500kg of laterite nickel ore to produce nickel hydroxide and cobalt concentrate, an intermediate product of electrolytic nickel, add 2000kg of hydrochloric acid (36%) for leaching, and stir vigorously for 30 minutes to obtain nickel-cobalt-manganic acid solution;

[0060] B. Impurity removal and recrystallization: Add 10kg of sodium fluoride to the nickel-cobalt-manganese acid solution in step A and carry out chemical precipitation to remove calcium and magnesium impurities in the solution, filter, concentrate, and crystallize to obtain 716kg of nickel-cobalt-manganese mixture;

[0061] C. Mixed salt preparation: After the nickel-cobalt-manganese mixture obtained in step B is dissolved in 2148kg of water, the total volume of the nickel-manganese-cobalt mixture obtained is 2518L, and the concentration of Ni, Mn, and Co salt in the nickel-manganese-cobalt mixture is obtained by sampling analysis 1.01mol / L, 0.26mol / L, 0.10mol / L, then add 146.82Kg NiCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com