Preparation method and application of nitrogen-doped carbon supported metal nanoparticles electrocatalyst with uniform particle size for alkaline hydroxidation reaction

A metal nanoparticle, hydrogen oxidation reaction technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of using environmentally unfriendly, DMF toxic species and environment, organic reagents or surfaces The problem of high synthesis cost of active agent is achieved, and the effect of low synthesis cost, easy large-scale production, and simple and easy preparation process is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

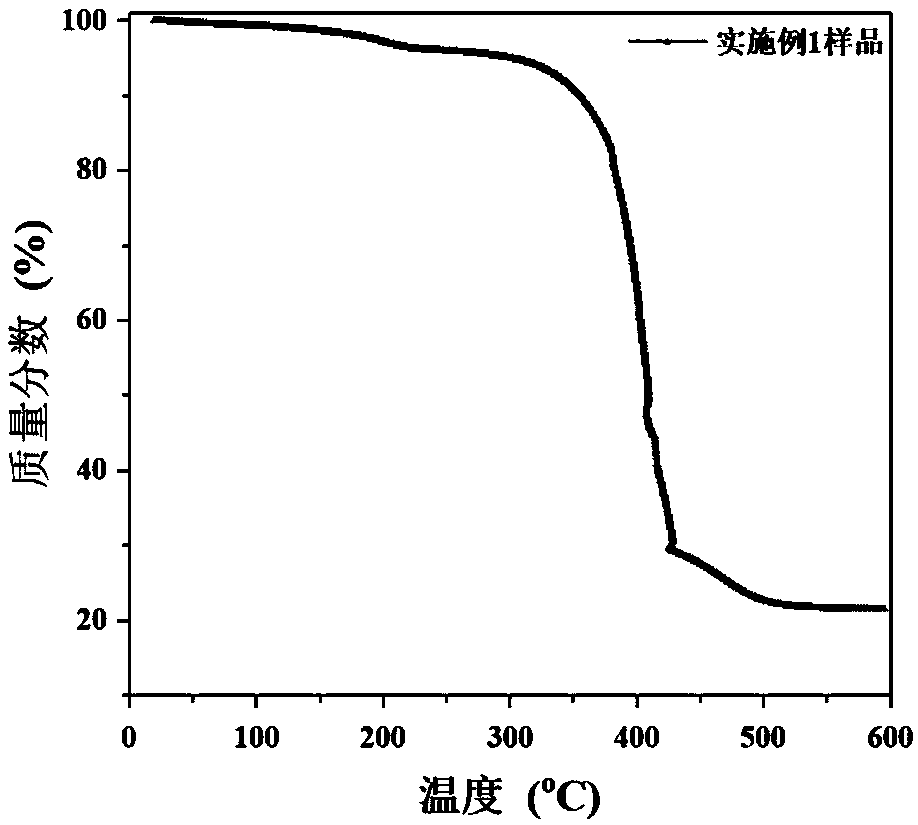

Embodiment 1

[0046] (1) Preparation of nitrogen-doped carbon support

[0047] Activated carbon (1.0g) and 2,2'-bipyridine (0.5g) were dispersed in ethanol (30ml), ultrasonicated for 40min; at 85°C, the ethanol reagent was evaporated with stirring to obtain a black mixture; dried in a vacuum oven, After grinding, carbonization was carried out at 1000° C. for 1 h in an argon atmosphere to finally obtain a nitrogen-doped carbon support.

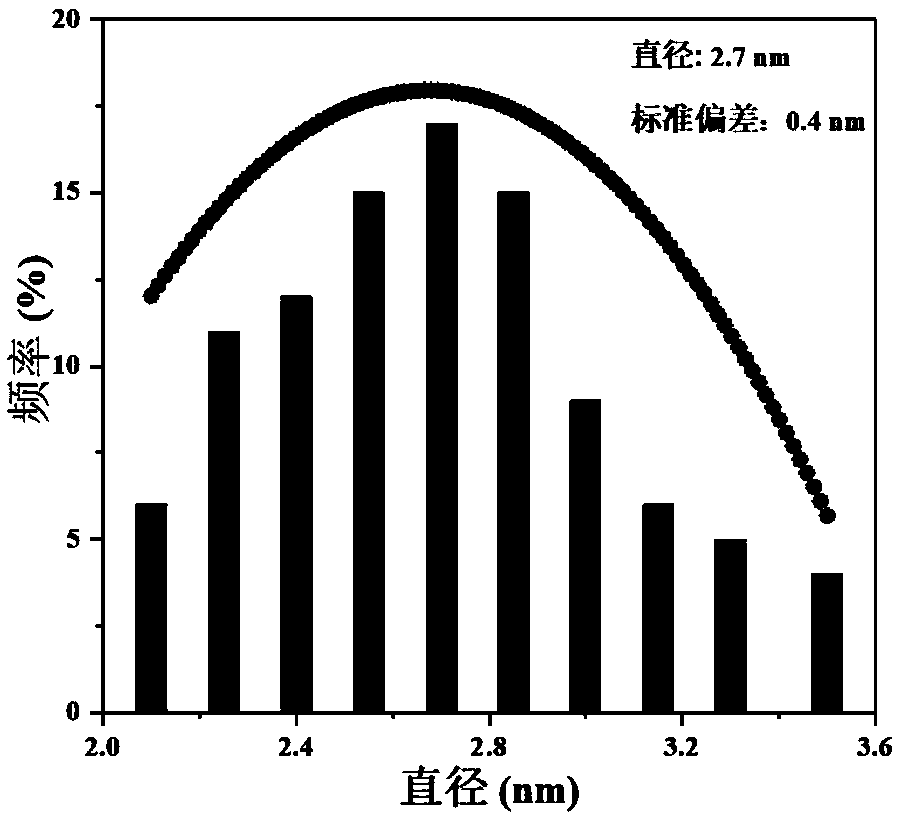

[0048] (2) Preparation of nitrogen-doped carbon-supported PdIr nanoparticles with uniform particle size electrocatalyst

[0049] Disperse the nitrogen-doped carbon carrier (160 mg) in an aqueous solution (20 ml), and sonicate for 40 min; place the suspension obtained above in a water bath, and add potassium chloropalladate (20 mM, 6.6 ml) and three Iridium chloride (20mM, 6.6ml) was stirred and adsorbed at constant temperature for 2h; then, the temperature was lowered to 10°C, and ascorbic acid solution (150mM, 20ml) was added and stirred at constant temper...

Embodiment 2

[0056] (1) Preparation of nitrogen-doped carbon support

[0057] Activated carbon (1.0g) and 2,2'-bipyridine (1.0g) were dispersed in ethanol (30ml), ultrasonicated for 40min; at 85°C, the ethanol reagent was evaporated with stirring to obtain a black mixture; dried in a vacuum oven, After grinding, carbonization was carried out at 600° C. for 1 h in an argon atmosphere to finally obtain a nitrogen-doped carbon support.

[0058] (2) Preparation of nitrogen-doped carbon-supported PtRu nanoparticle electrocatalyst with uniform particle size

[0059] Disperse the nitrogen-doped carbon carrier (160mg) in an aqueous solution (20ml) and ultrasonicate for 40min; place the suspension obtained above in a water bath, add chloroplatinic acid (20mM, 6.6ml) and ruthenium chloride at 25°C (20mM, 6.6ml) was stirred and adsorbed at constant temperature for 2h; then, lowered the temperature to 10°C, added ascorbic acid solution (150mM, 20ml) and stirred at constant temperature for 0.5h; filte...

Embodiment 3

[0065] (1) Preparation of nitrogen-doped carbon support

[0066] Activated carbon (1.0g) and 2,2'-bipyridine (0.5g) were dispersed in ethanol (30ml), ultrasonicated for 40min; at 85°C, the ethanol reagent was evaporated with stirring to obtain a black mixture; dried in a vacuum oven, After grinding, carbonization was carried out at 600° C. for 1 h in an argon atmosphere to finally obtain a nitrogen-doped carbon support.

[0067] (2) Preparation of nitrogen-doped carbon-supported Pd nanoparticle electrocatalyst with uniform particle size

[0068] Disperse the nitrogen-doped carbon carrier (160mg) in the aqueous solution (20ml) and ultrasonicate for 40min; place the suspension obtained above in a water bath, add potassium chloropalladate (20mM, 18.8ml) at constant temperature and stir at 40°C Adsorption for 2h; then, lower the temperature to 10°C, add ascorbic acid solution (150mM, 20ml) and stir at constant temperature for 0.5h; suction filter, wash, and dry to obtain a black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com