Preparation method for photocatalytic material with strong adsorption and high visible light degradation of performance

A catalytic material and nano-light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of few application reports of LDHs derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of salt solution: add zinc nitrate, nickel nitrate and aluminum nitrate at a concentration ratio of 2:1:1 into deionized water, fully dissolve to form a solution, and its total metal ion concentration is 1.0 mol L -1 ;

[0027] (2) Preparation of alkaline solution: mix NaOH and Na 2 CO 3 respectively dissolved in deionized water to form [OH - ]=1.6 mol L -1 , [CO 3 2- ]=0.5 mol L -1 alkaline solution;

[0028](3) Preparation of mixed solution: heat the mixed salt solution prepared in step (1) to 80 °C in a magnetic water bath, and under rapid magnetic stirring, use a constant current pump to dissolve the alkali solution prepared in step (2) in 3 mL min -1 Add it into the mixed salt solution until the pH value of the mixed solution is equal to 9, and continue to stir at 80 °C for 1 h;

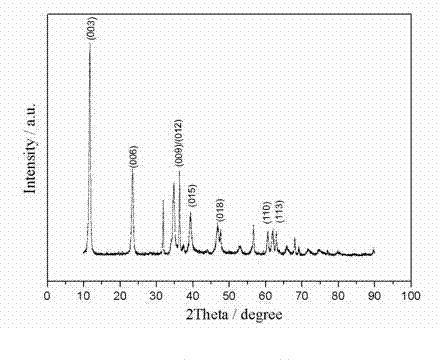

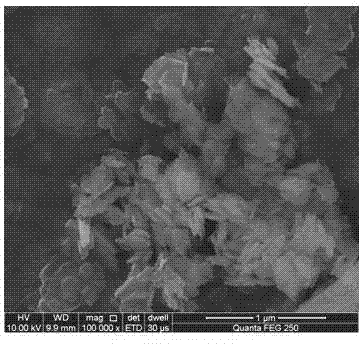

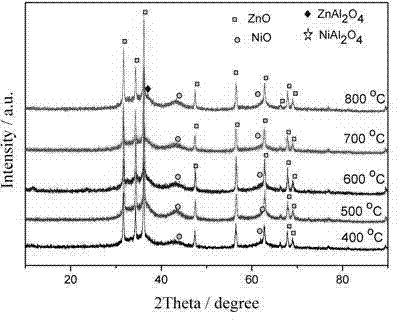

[0029] (4) Preparation of hydrotalcite-like: transfer the mixed solution prepared in step (3) to a hydrothermal reaction kettle lined with polytetrafluoroethyle...

Embodiment 2

[0033] (1) Preparation of salt solution: add zinc nitrate, nickel nitrate and aluminum nitrate at a concentration ratio of 3:1:1 into deionized water, fully dissolve to form a solution, and its total metal ion concentration is 0.8 mol L -1 ;

[0034] (2) Preparation of alkaline solution: a certain amount of NaOH and Na 2 CO 3 respectively dissolved in deionized water to form [OH - ]=1.3 mol L -1 , [CO 3 2- ]=0.6 mol L -1 alkaline solution;

[0035] (3) Preparation of mixed solution: heat the mixed salt solution prepared in step (1) to 80 °C in a magnetic water bath, and under rapid magnetic stirring, use a constant current pump to dissolve the alkali solution prepared in step (2) in 2 mL min -1 Add it into the mixed salt solution until the pH value of the mixed solution is 8, and continue to stir at 80 °C for 1 h;

[0036] (4) Preparation of hydrotalcite-like: transfer the mixed solution prepared in step (3) to a hydrothermal reaction kettle lined with polytetrafluor...

Embodiment 3

[0040] (1) Preparation of salt solution: Add zinc nitrate, nickel nitrate and aluminum nitrate at a concentration ratio of 1:1:1 into deionized water, fully dissolve to form a solution, and its total metal ion concentration is 1.2 mol L -1 ;

[0041] (2) Preparation of alkaline solution: a certain amount of NaOH and Na 2 CO 3 respectively dissolved in deionized water to form [OH - ]=1.9 mol L -1 , [CO 3 2- ]=0.8 mol L -1 alkaline solution;

[0042] (3) with step (3) in embodiment 1;

[0043] (4) Preparation of hydrotalcite-like: transfer the mixed solution prepared in step (3) to a hydrothermal reactor lined with polytetrafluoroethylene, and conduct hydrothermal treatment at 150 °C for 8 h. Cool the reaction kettle to room temperature naturally, pour it into a vacuum filtration device for suction filtration, filter and wash with deionized water for 3 times, put the obtained light green precipitate in a drying oven, dry at 70 °C for 3 h, and grind to obtain product; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com