Patents

Literature

61results about How to "Facilitate interface reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing heavy metal ions in sewage by nanometer hydroxylapatite

InactiveCN101613135AWide variety of sourcesOvercome expensiveWater contaminantsWater/sewage treatment by sorptionWastewaterHydroxylapatite

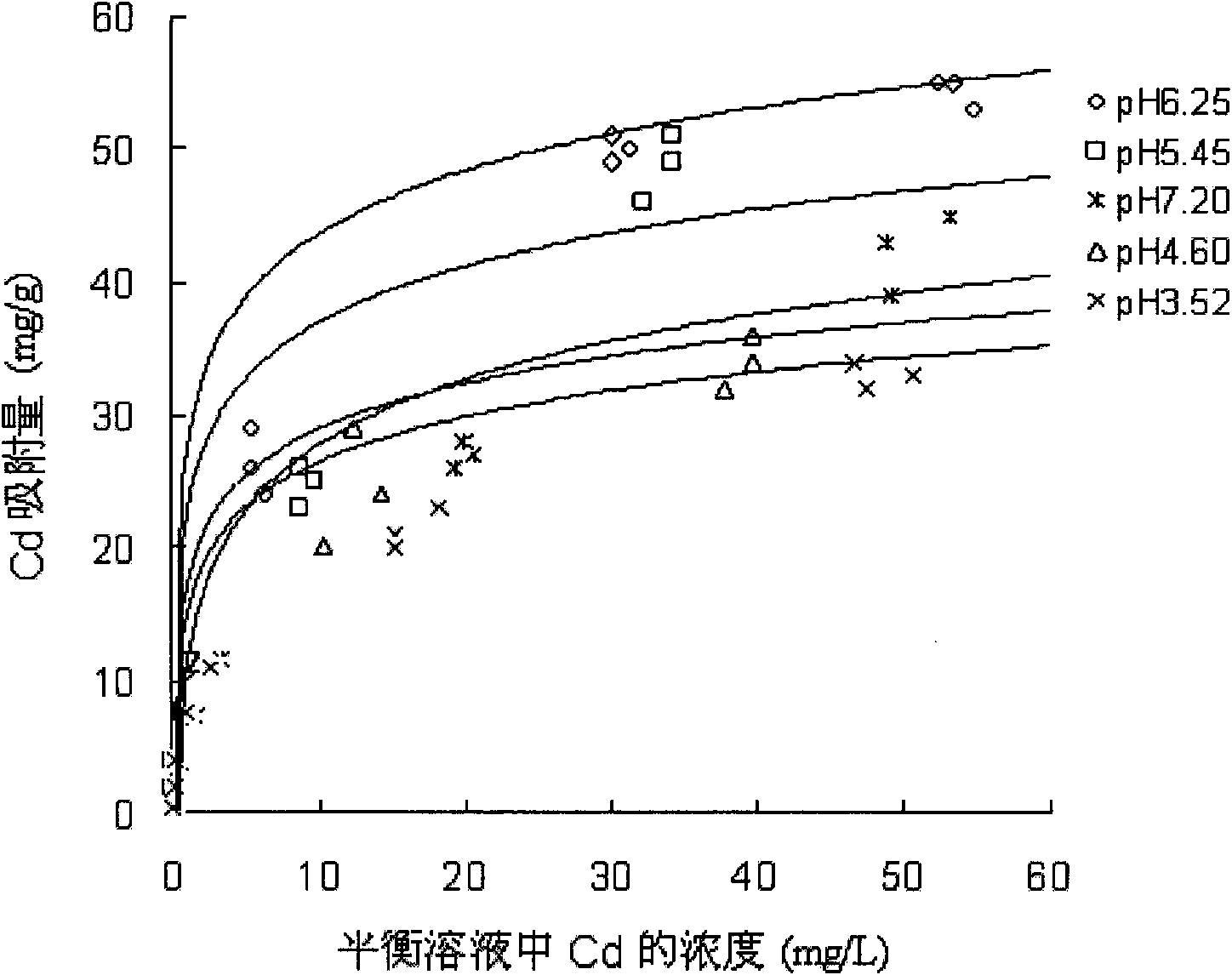

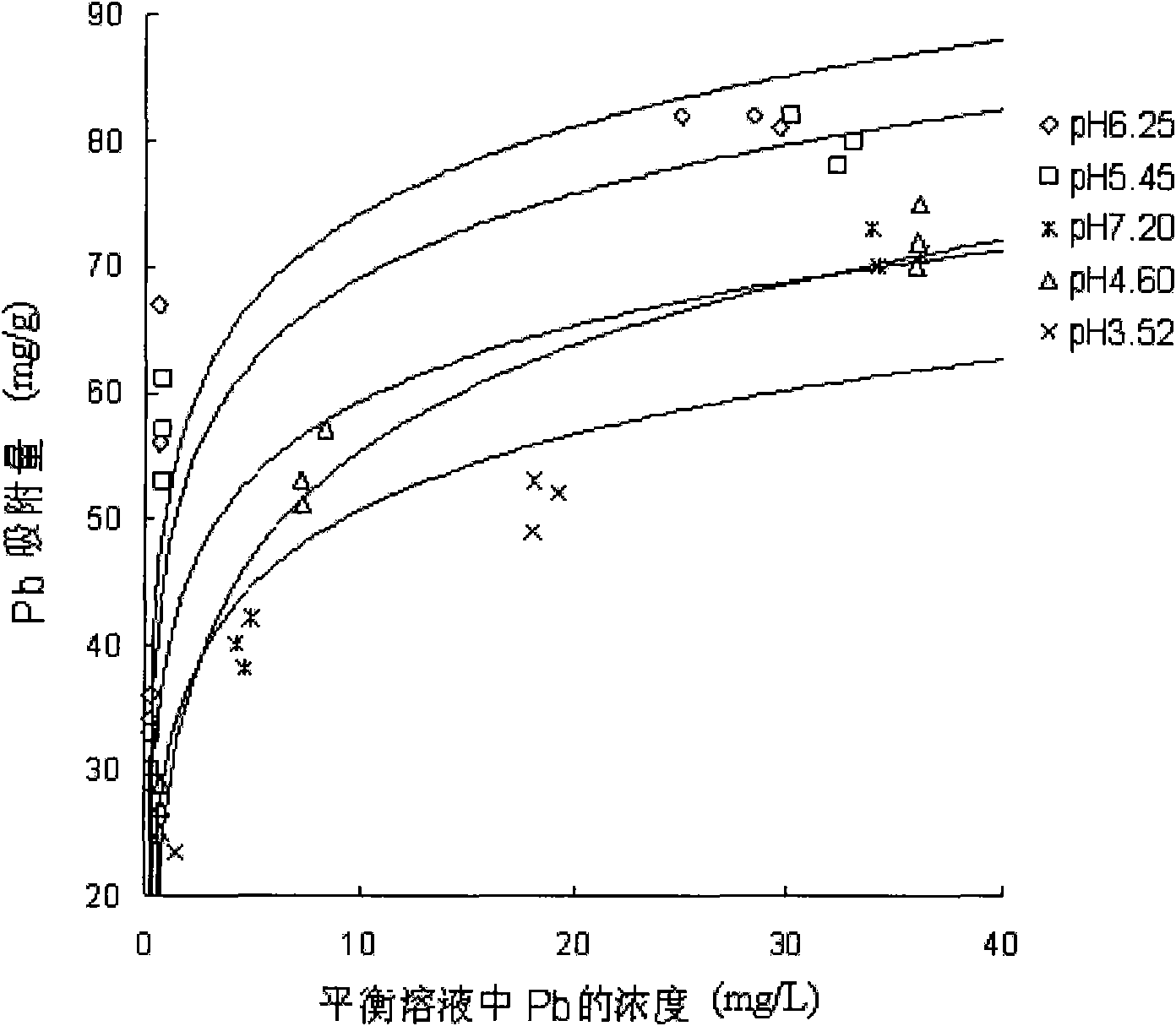

The invention discloses a method for removing heavy metal ions in sewage by nanometer hydroxylapatite, belonging to the technical field of heavy metal sewage treatment. The method comprises the following steps: adding nanometer grade hydroxylapatite powder in waste water containing heavy metal ions, wherein, the dosage of the hydroxylapatite powder is 6-8g / L; balancing the mixture for 12-48 hours at a temperature of 23-27 DEG C; and standing the mixture to remove the heavy metal ions in the waste water. The method uses the hydroxylapatite with relatively lower economic value to treat the heavy metal sewage, has high treatment efficiency, low treatment cost, strong field operability and small environment risk, and has heavy metal ion removal rate over 90 percent under conditions that concentration of Cd, Pb or Cu ions does not exceed 60mg / L.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

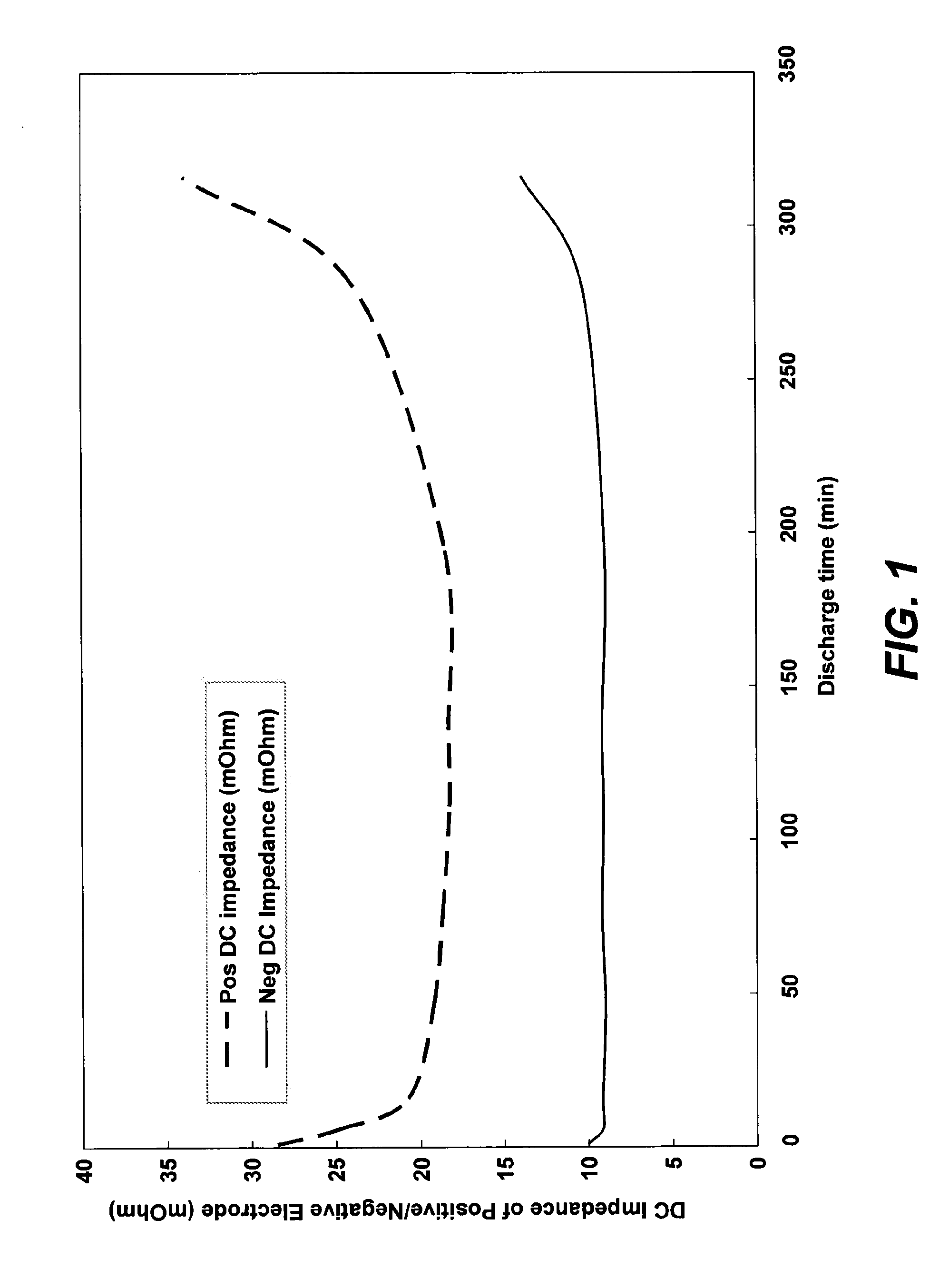

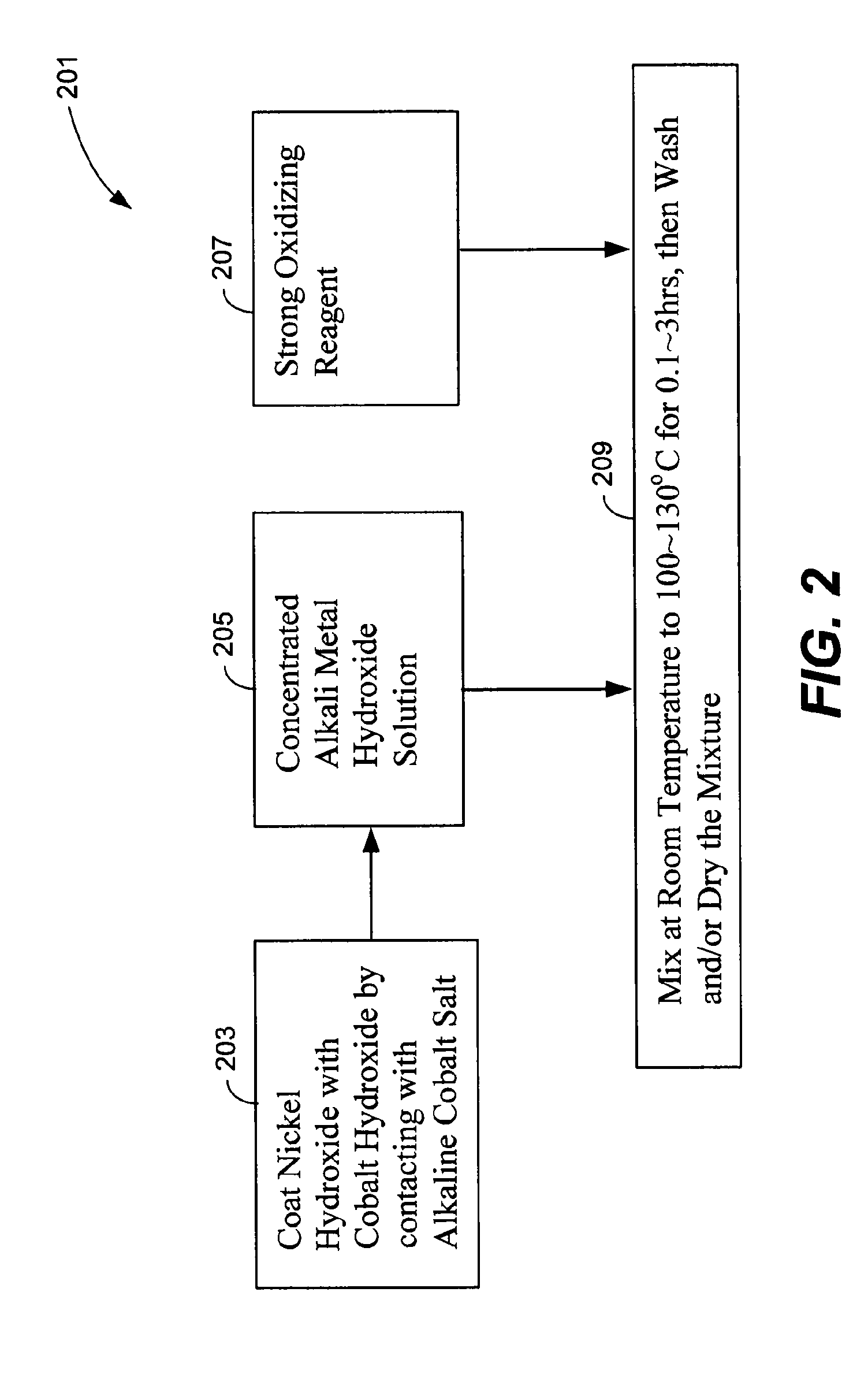

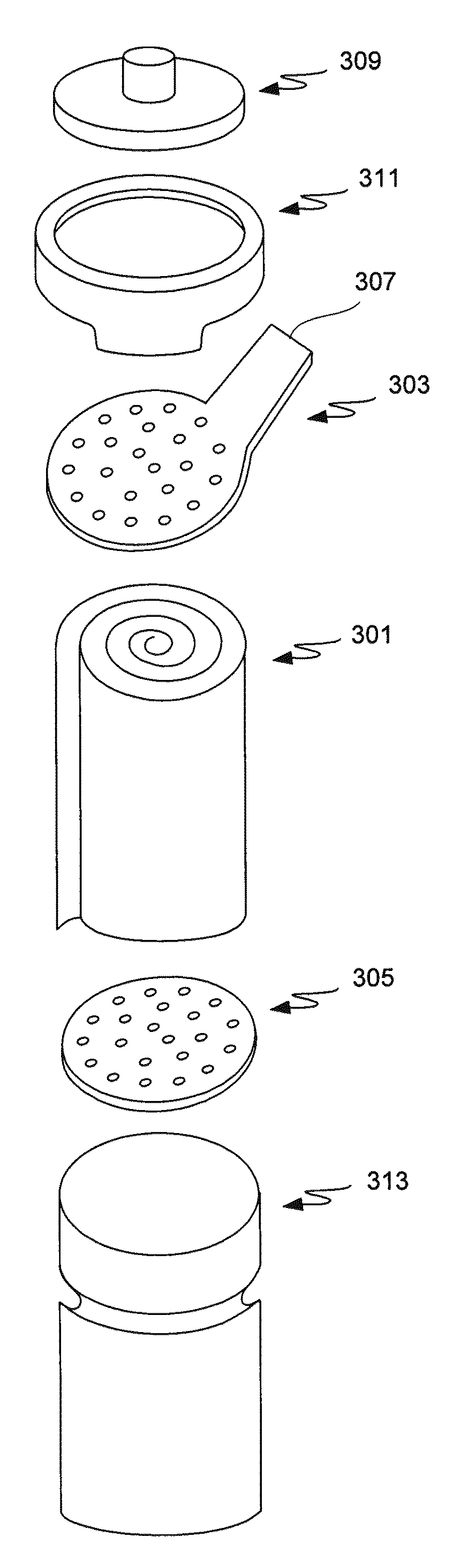

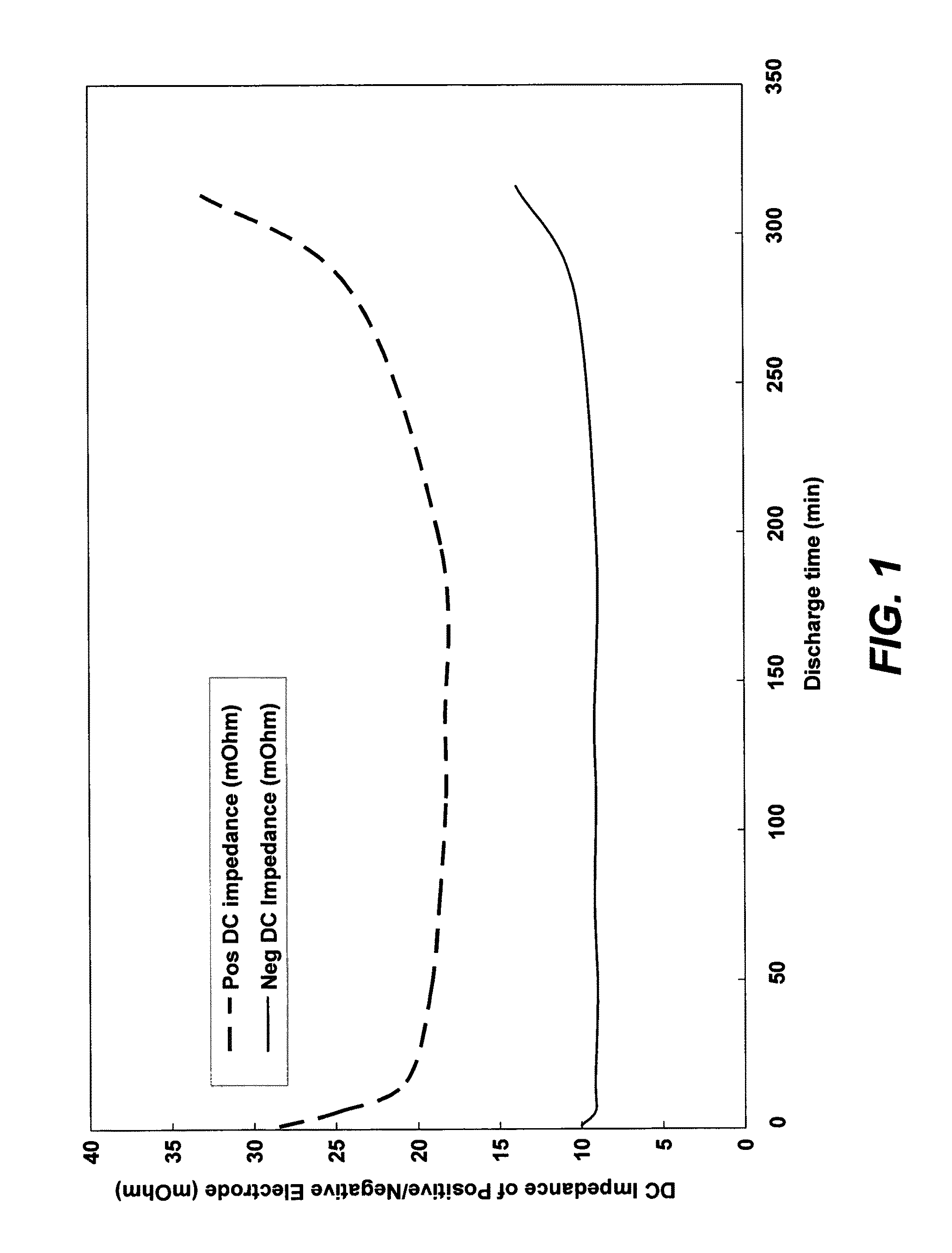

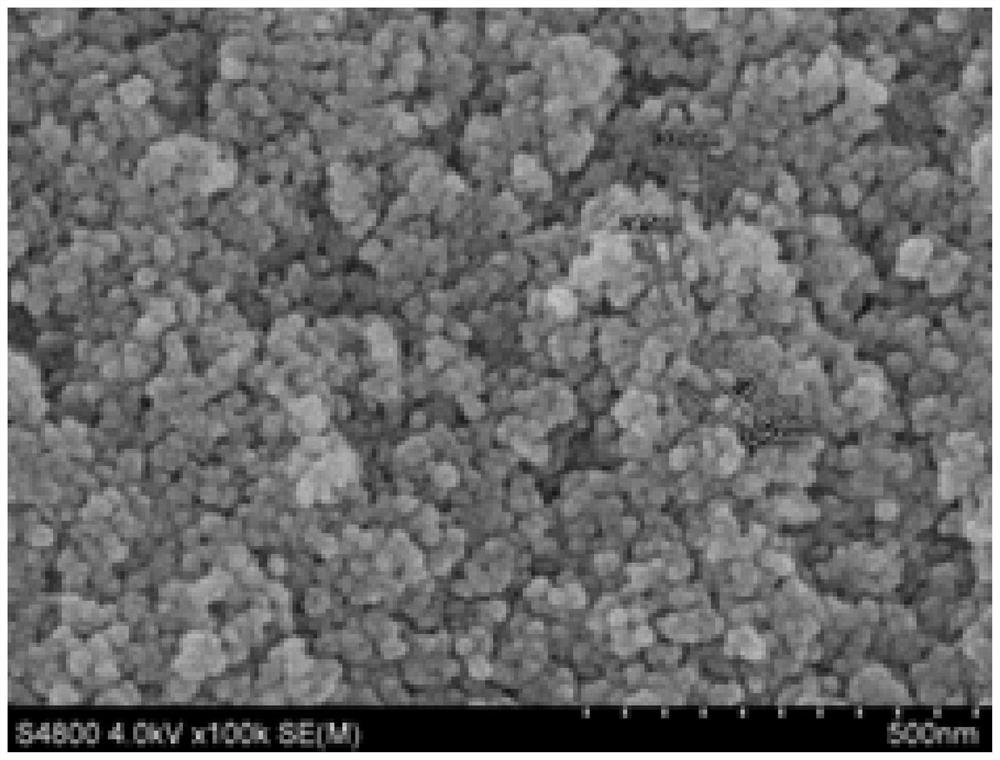

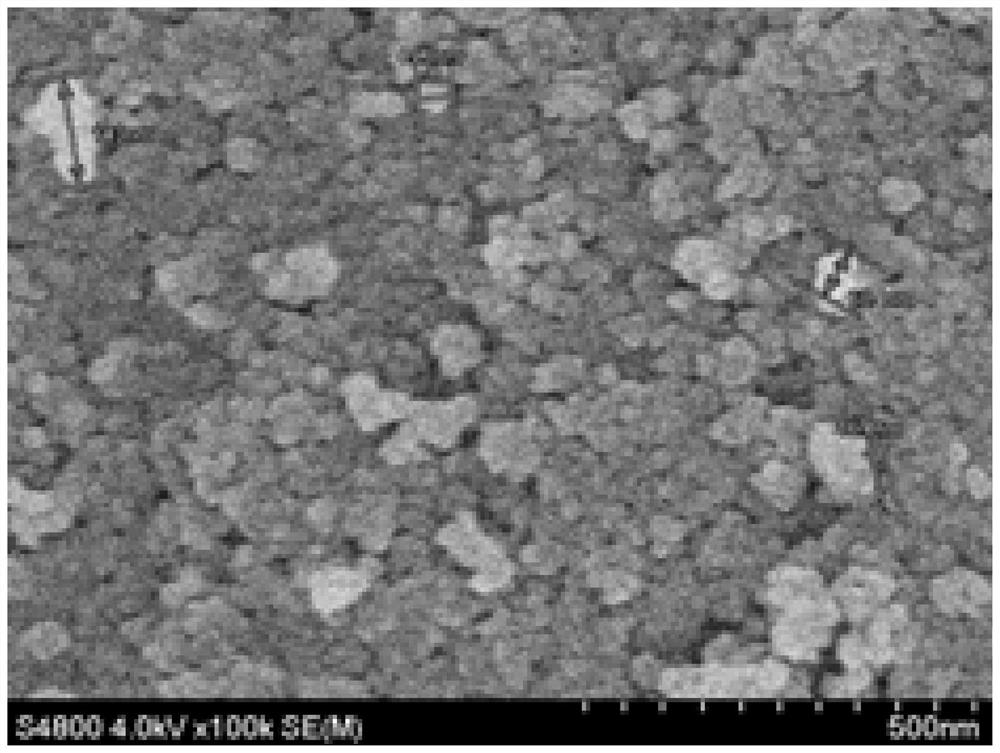

Nickel hydroxide electrode for rechargeable batteries

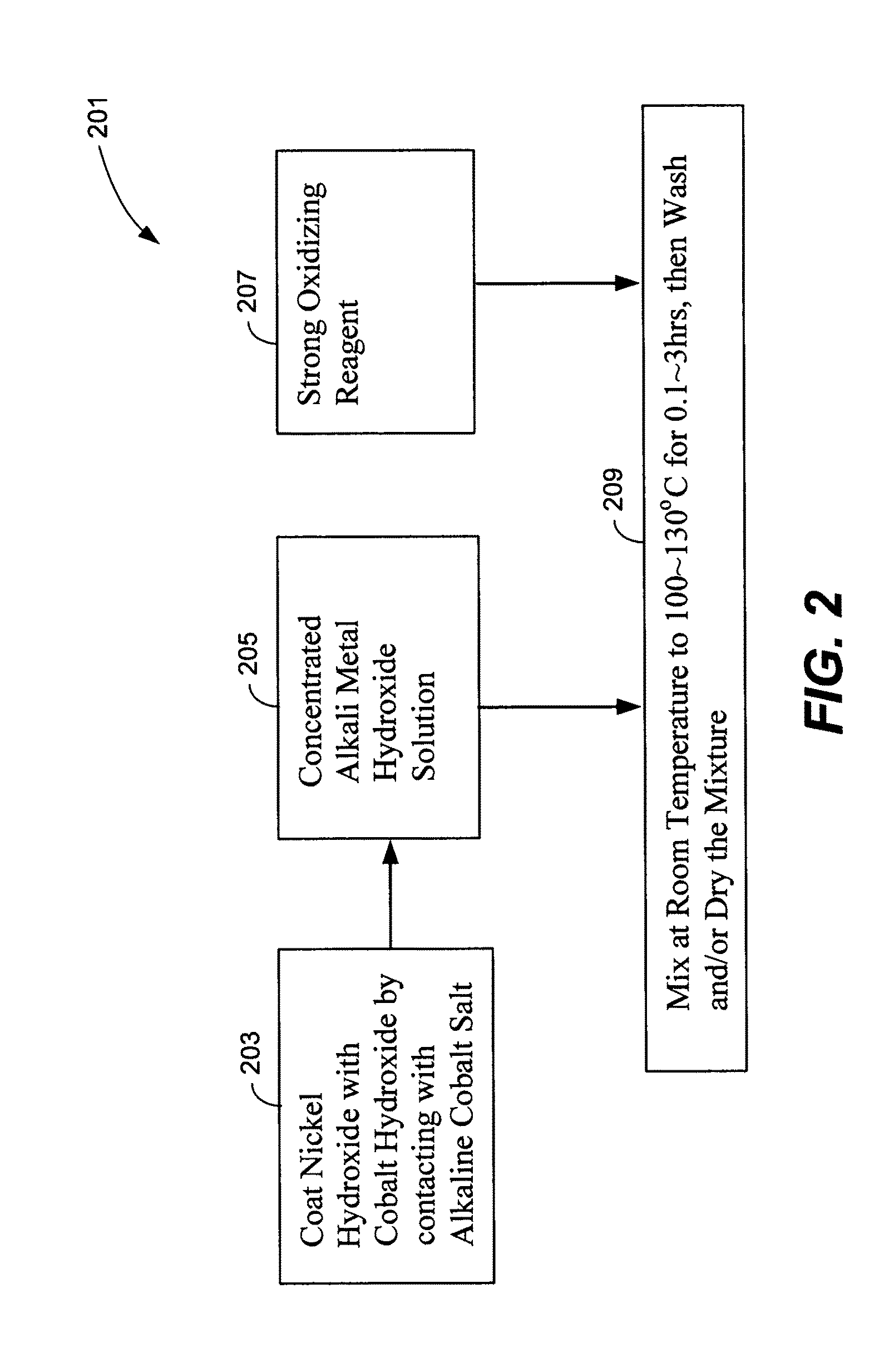

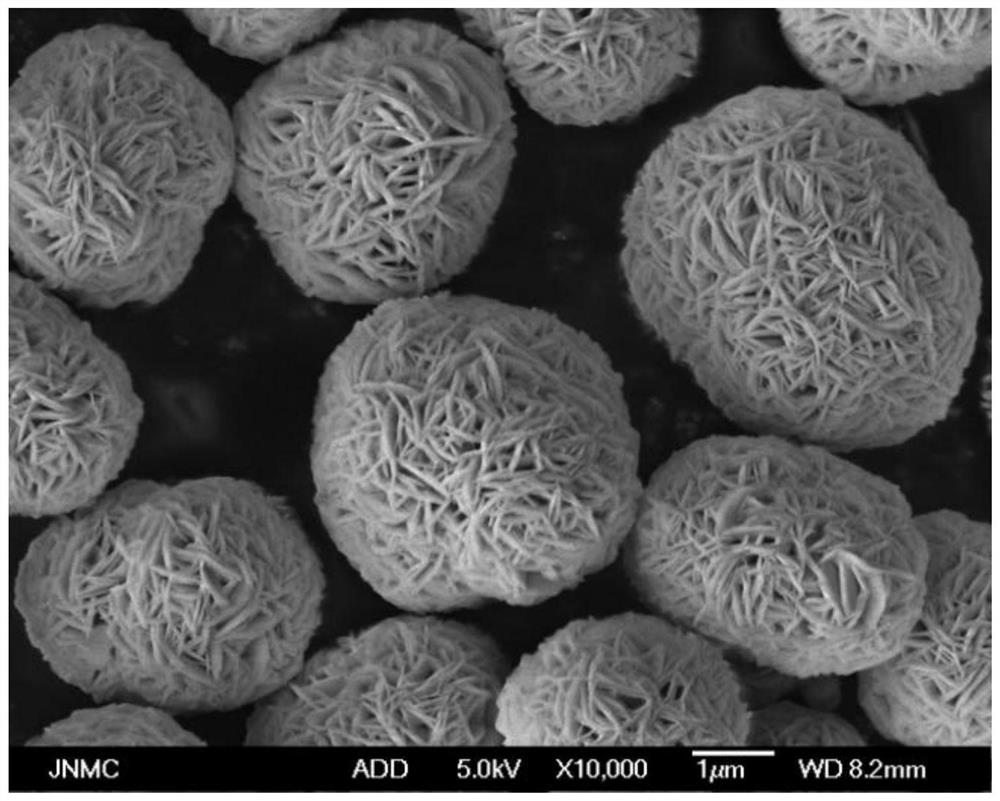

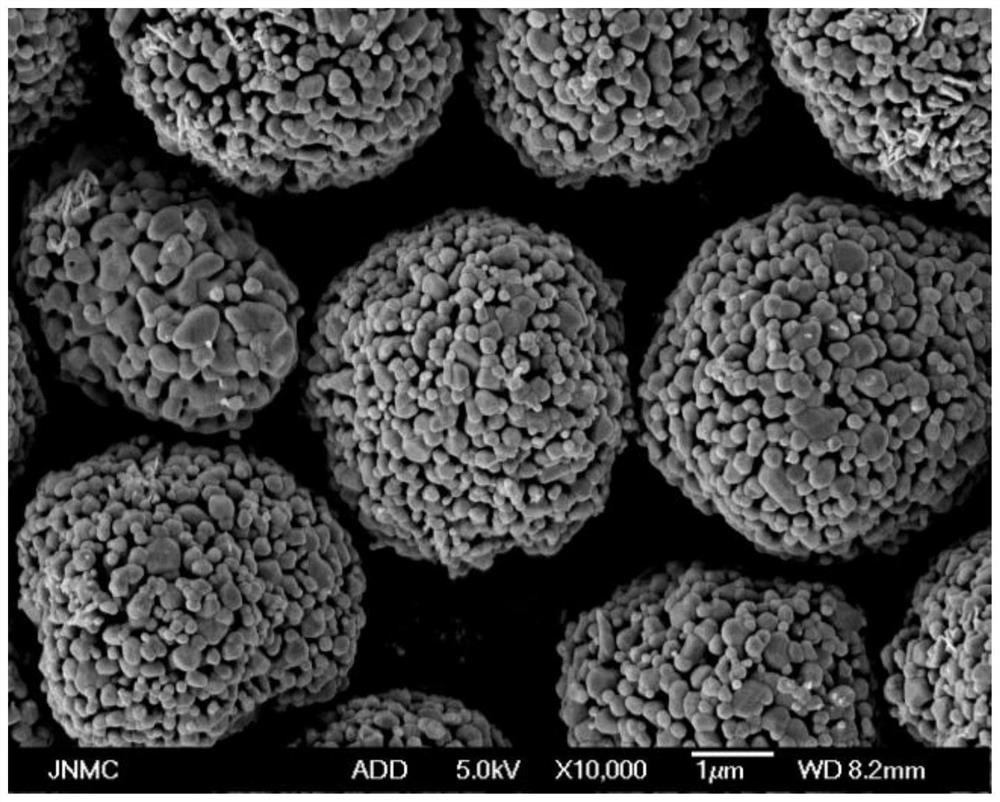

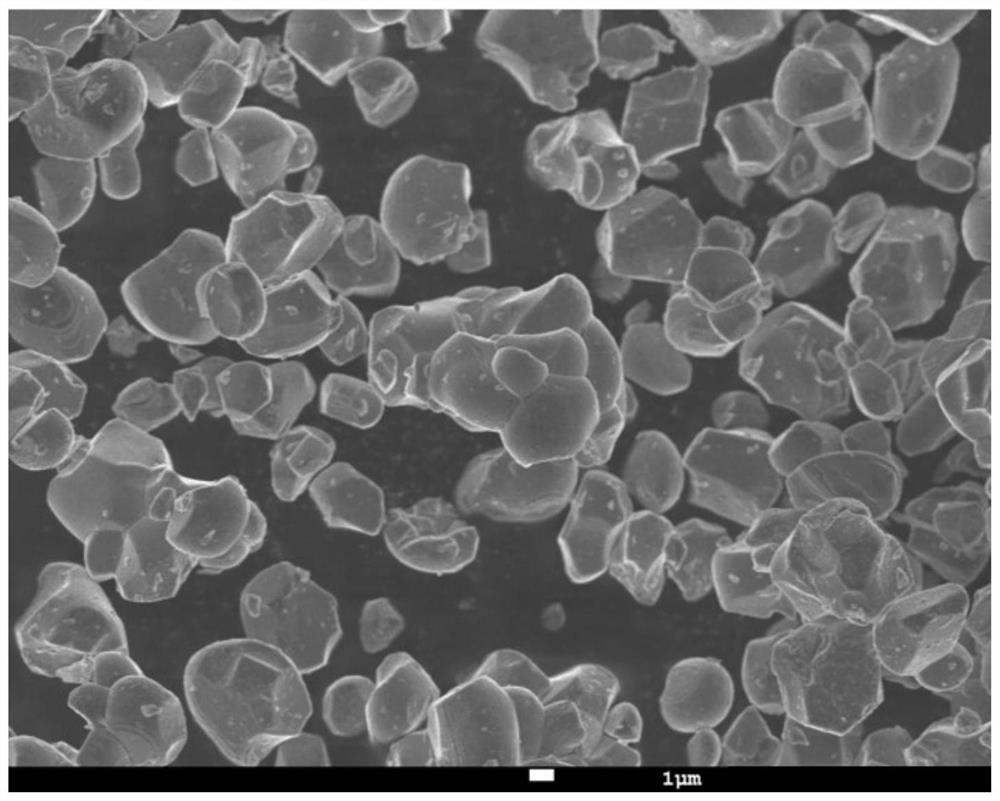

ActiveUS20090208839A1Facilitate interface reactionImprove reliabilityMaterial nanotechnologyHybrid capacitor electrodesPotassium persulfateNickel oxide hydroxide

The nickel hydroxide particles for a nickel hydroxide electrode may be treated using an alkaline solution of a strong oxidizing agent such as sodium or potassium persulfate to modify the surface nickel hydroxide structure. The resulting modified surface structure has been found to impart various benefits to electrodes formed from the nickel hydroxide. It is believed that the oxidation of cobalt compounds at the surface of the nickel hydroxide particles results in a highly conductive cobalt compound that plays an important role in the high reliability, high stability and high capacity utilization of nickel electrodes as described herein.

Owner:ZINCFIVE POWER INC

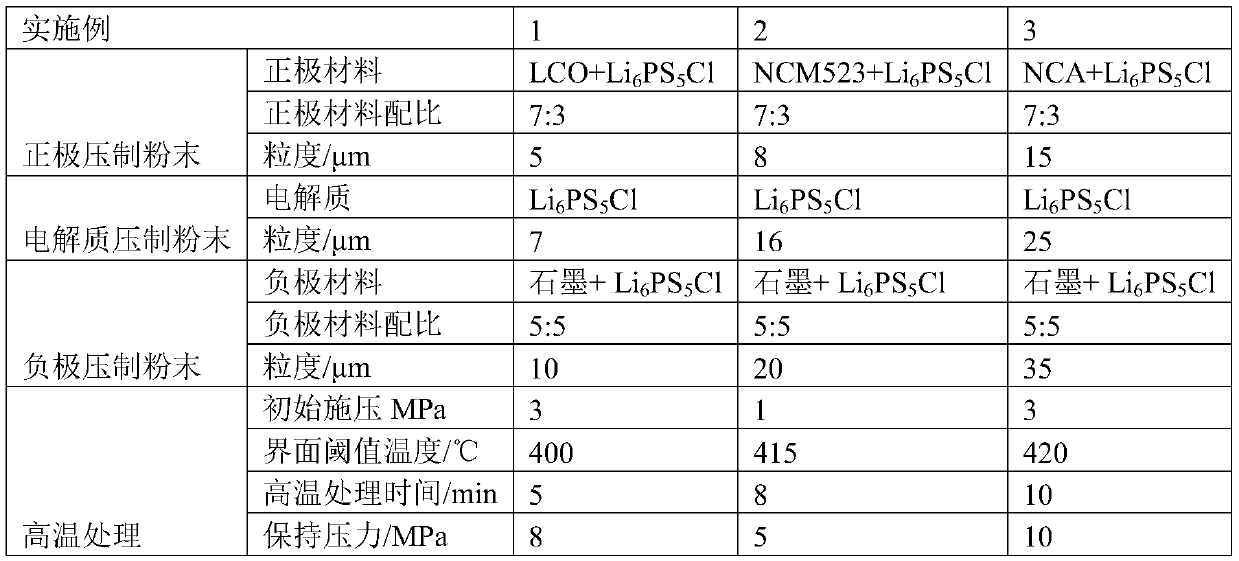

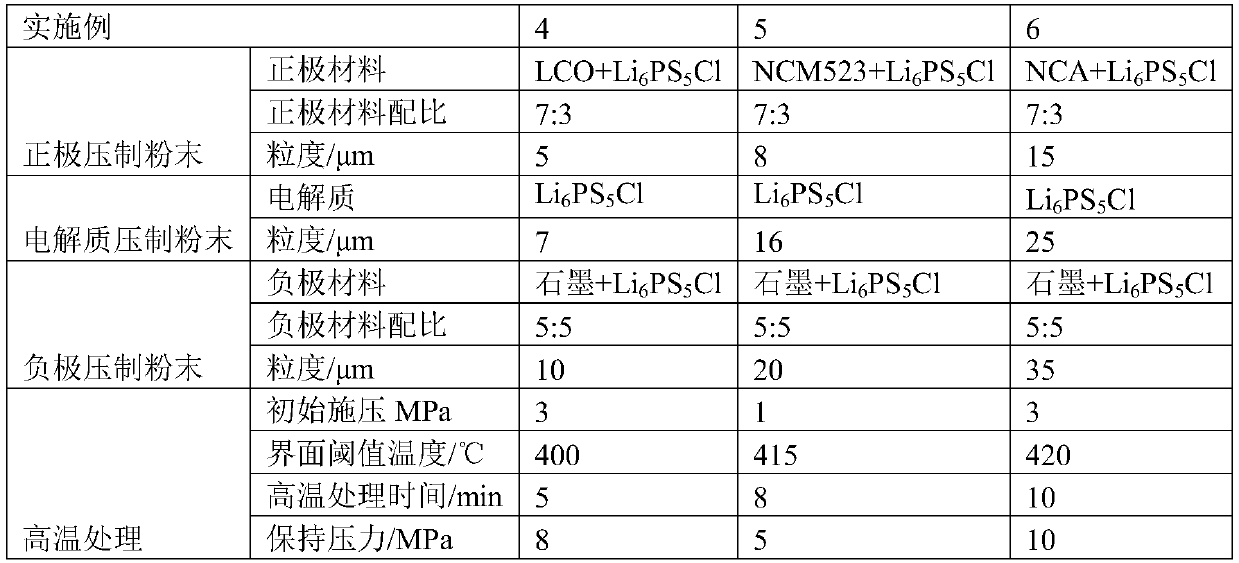

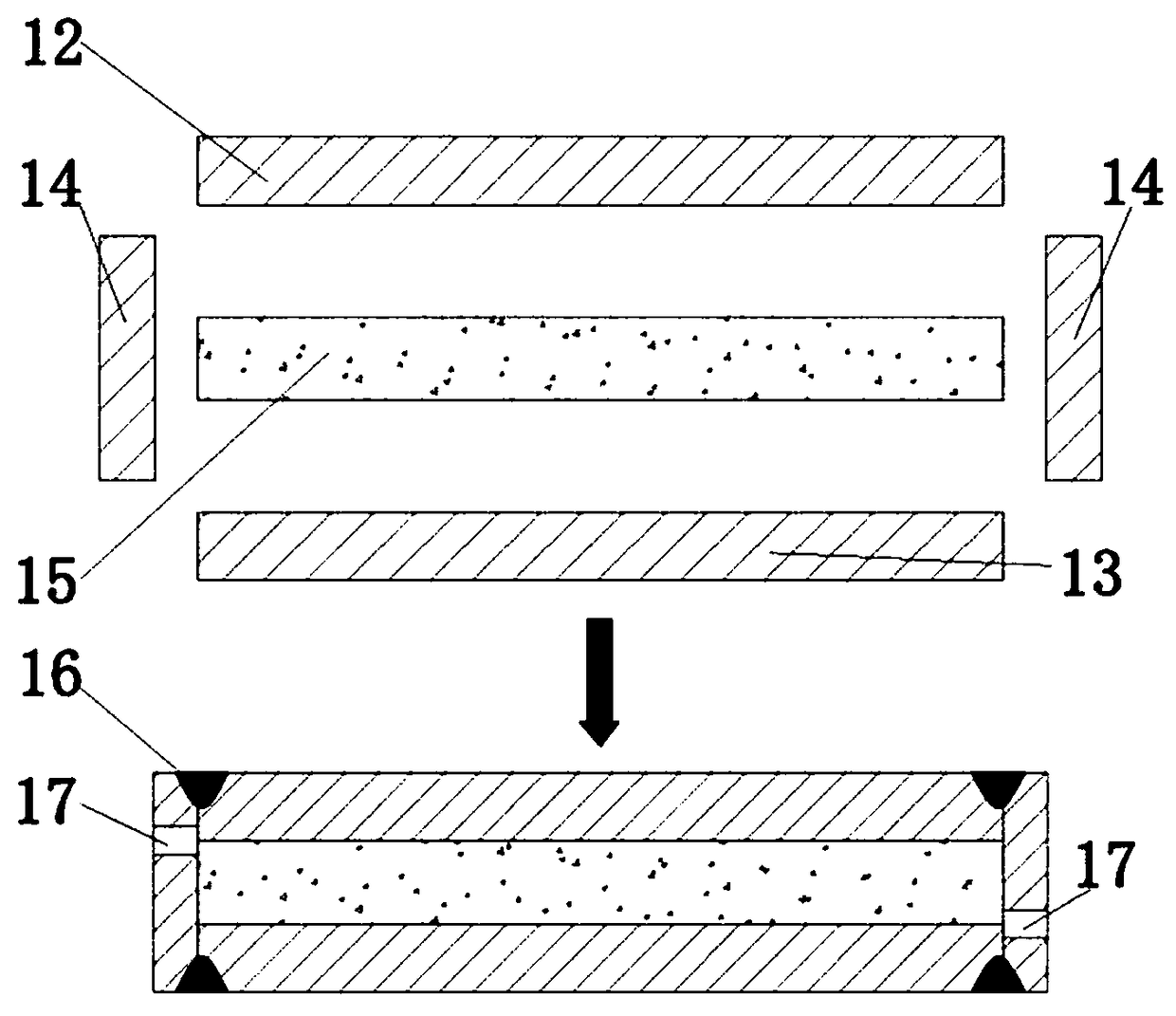

Low-internal-resistance solid sulfide electrolyte lithium battery cell, battery and preparation method thereof

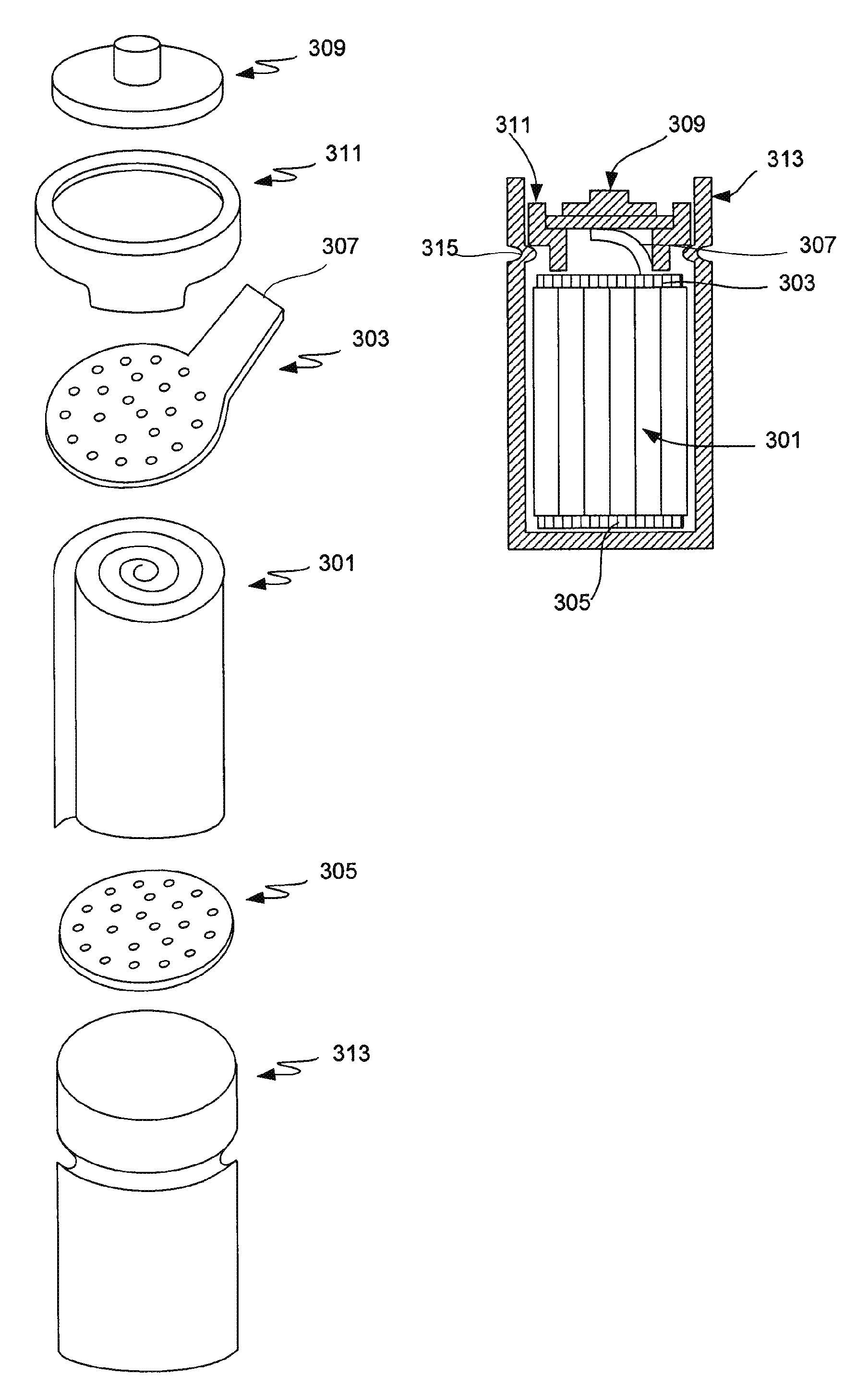

ActiveCN111313101AReduce feverReduce circulationElectrode rolling/calenderingFinal product manufactureAll solid stateElectrolysis

The invention relates to an all-solid-state lithium battery of a sulfide electrolyte, and discloses a low-internal-resistance solid sulfide electrolyte lithium battery cell, a battery and a preparation method thereof. Key points of the technical scheme of the low-internal-resistance solid sulfide electrolyte lithium battery cell are as follows: a positive electrode layer, an electrolyte layer anda negative electrode layer are formed by sequentially laminating and pressing powder of corresponding materials, a prefabricated battery cell is obtained, and the powder of the electrolyte layer is obtained by solid electrolysis of sulfide; a pressure is applied to the outer sides of the positive electrode layer and the negative electrode layer of the prefabricated battery cell in the direction ofthe electrolytic layer, and high-temperature treatment is performing for 5-10 minutes to obtain a finished battery cell; and tabs are installed on the finished battery cell, coating for the finishedbattery cell is performed by utilizing an aluminum-plastic film, and a battery shell is installed to obtain the solid sulfide electrolyte lithium battery with low internal resistance, and battery heating and cycle performance reduction caused by the internal resistance of the solid sulfide electrolyte lithium battery are slowed down.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

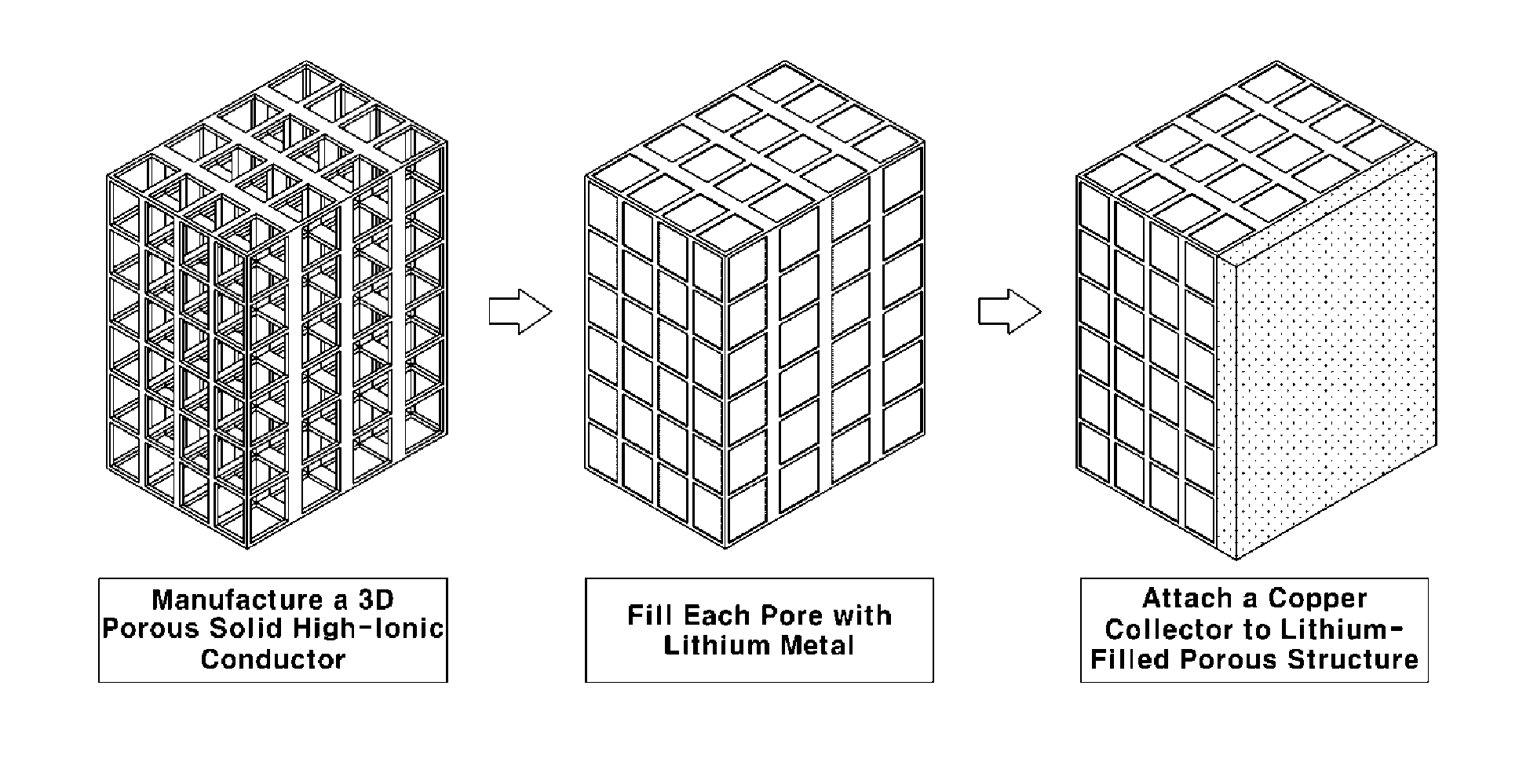

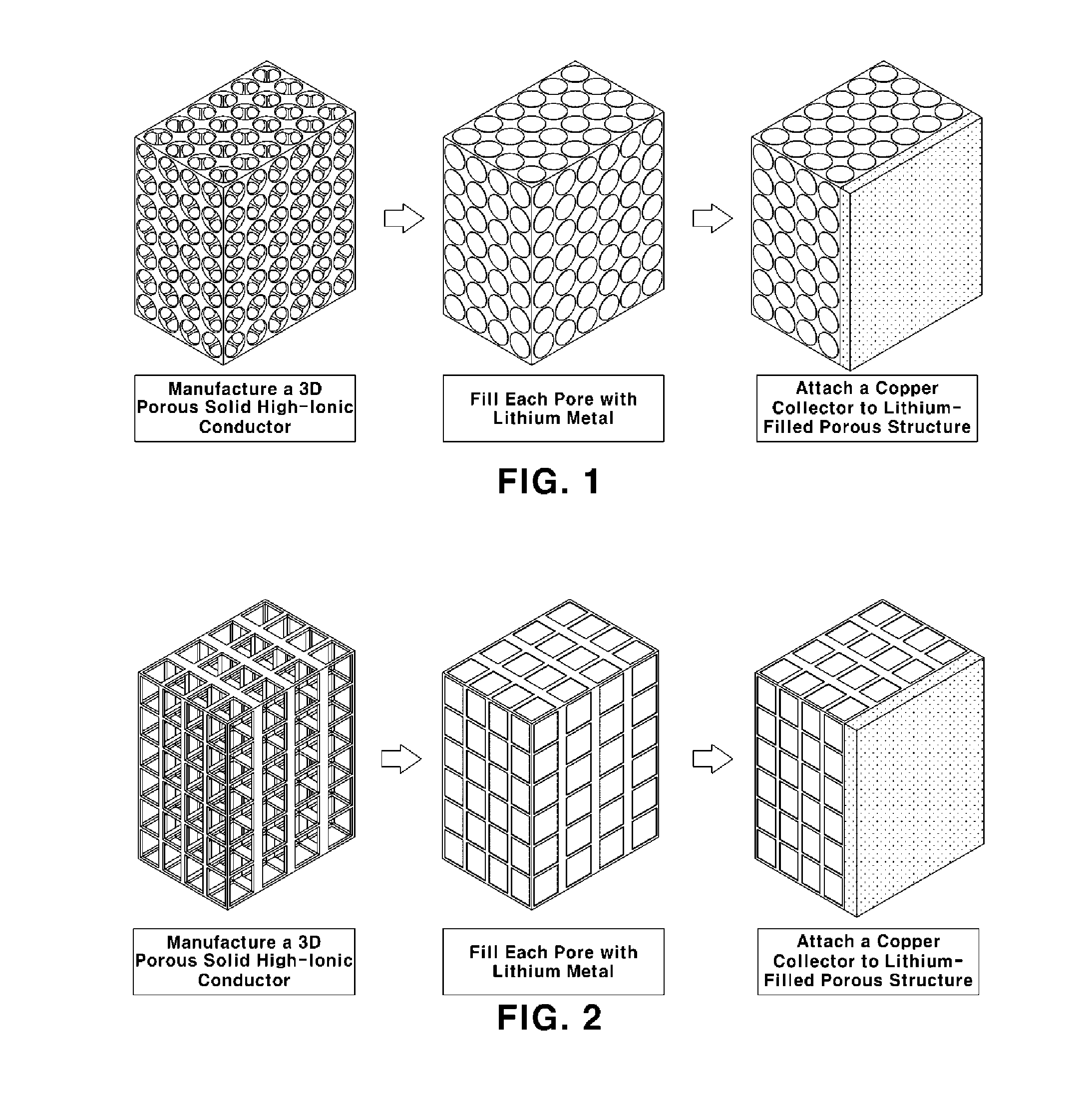

Lithium electrode for lithium metal battery and method of manufacturing the lithium electrode

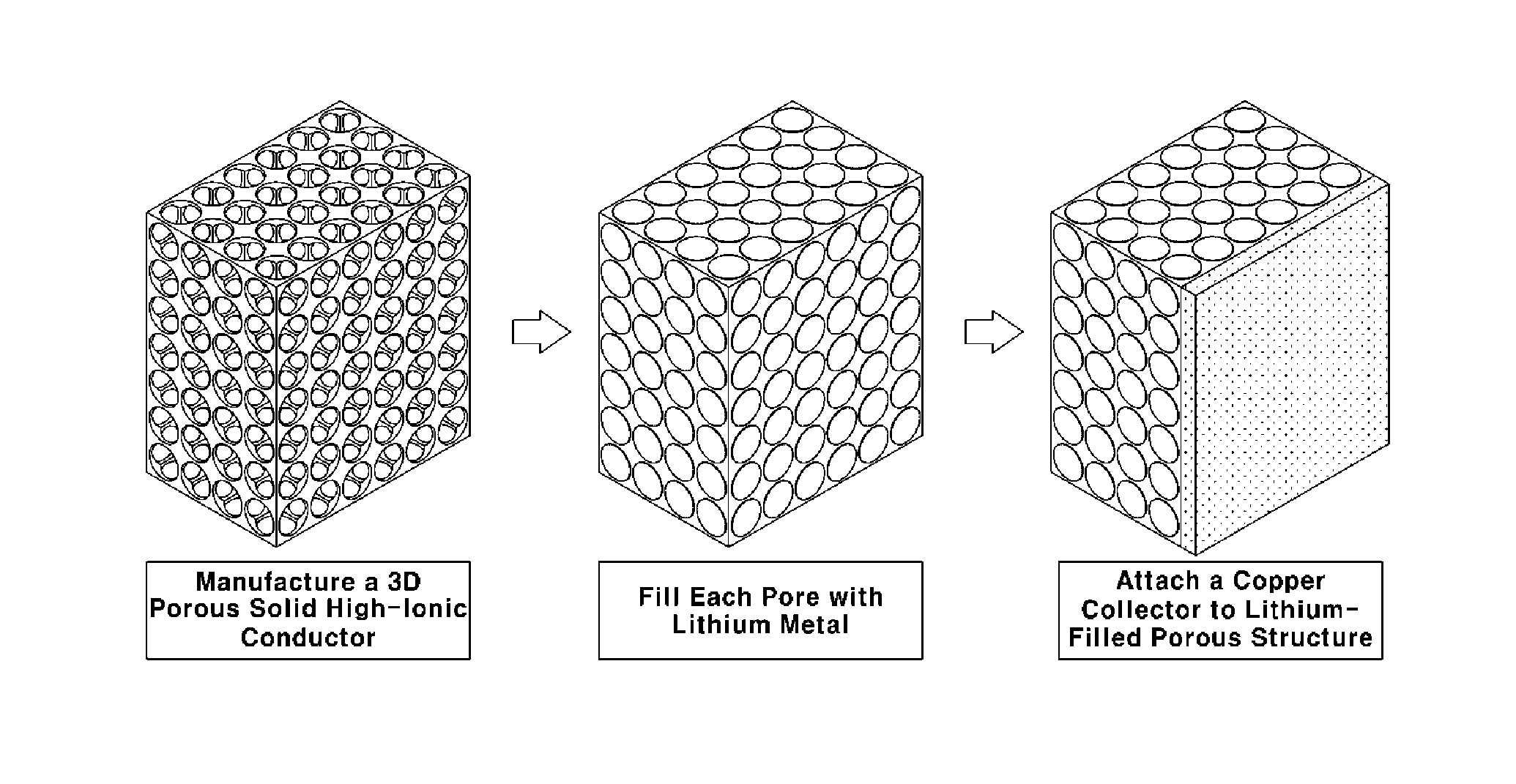

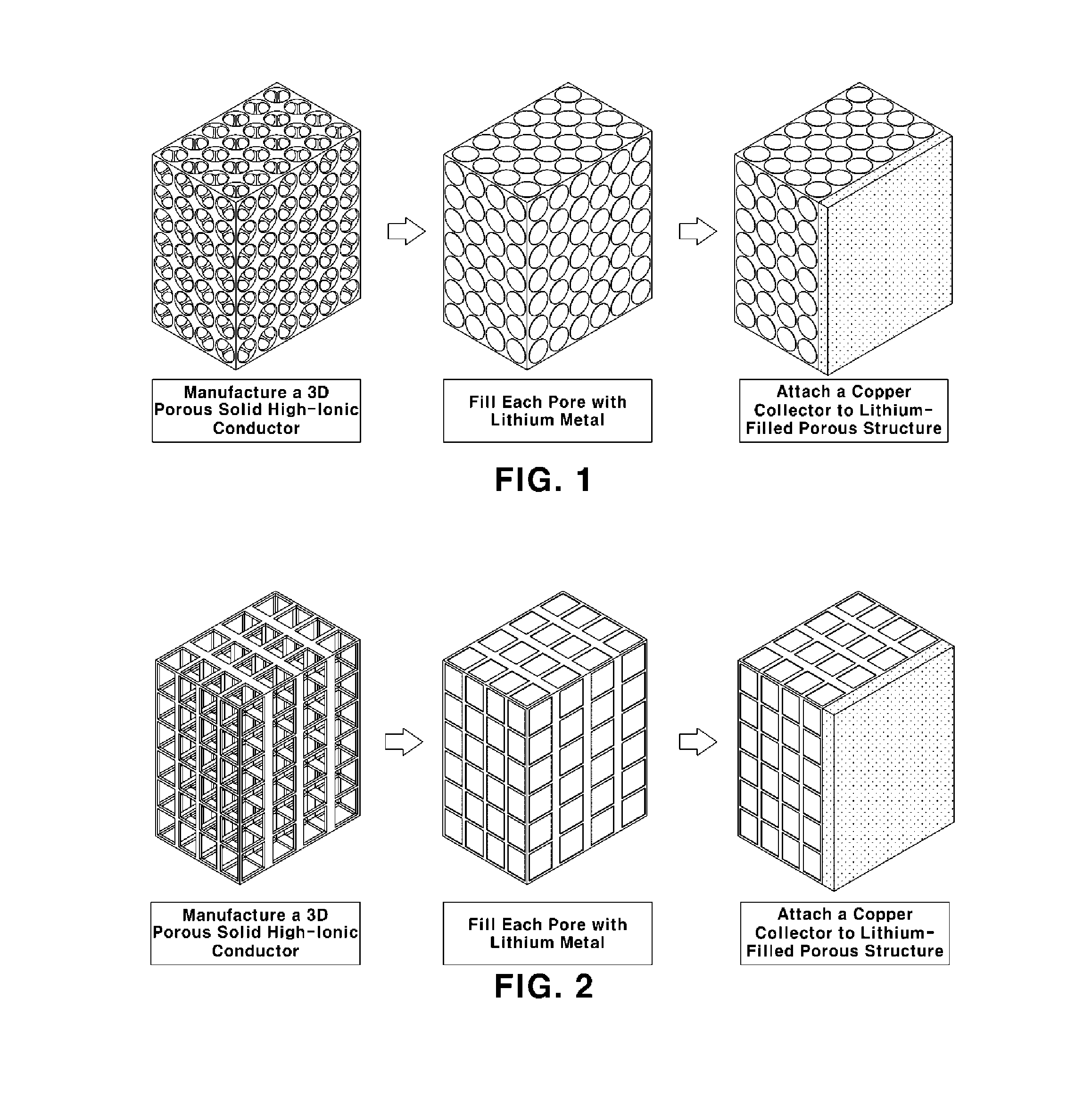

ActiveUS20130295452A1Extended shelf lifeFacilitate interface reactionSolid electrolytesElectrode manufacturing processesElectrochemical responseElectrical conductor

Disclosed are a lithium electrode for a lithium metal battery, which uses a solid high-ionic conductor having a three-dimensional (3D) porous structure, wherein a lithium metal or lithium alloy is filled into each pore and dispersed, and a method for manufacturing the lithium electrode. By applying a solid high-ionic conductor having a 3D porous structure, an ion conduction path is secured in the lithium electrode using the solid high-ionic conductor instead of a conventional liquid electrolyte, electrical-chemical reactivity in charging and discharging are further improved, and shelf life and high rate capability are enhanced.

Owner:HYUNDAI MOTOR CO LTD

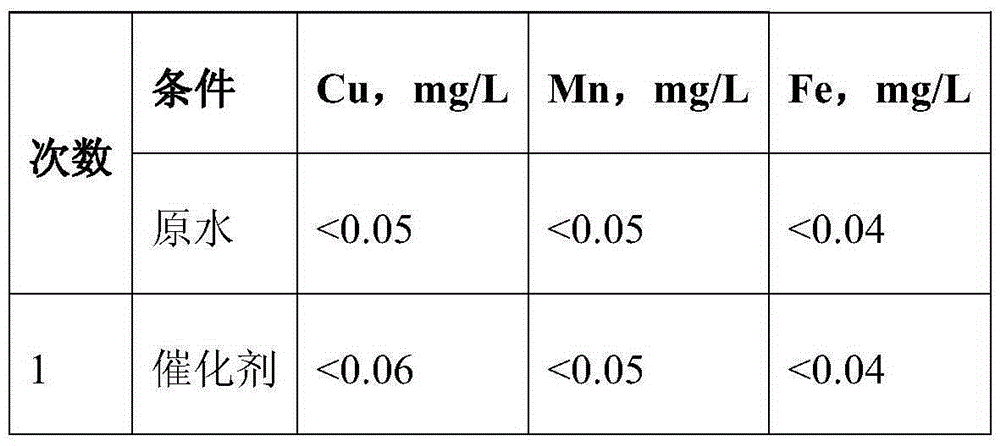

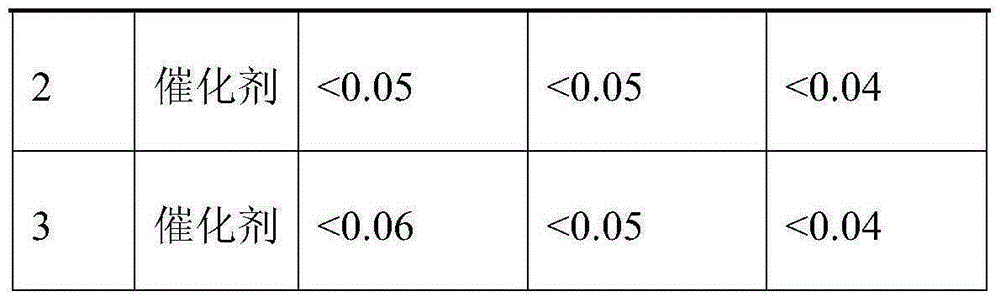

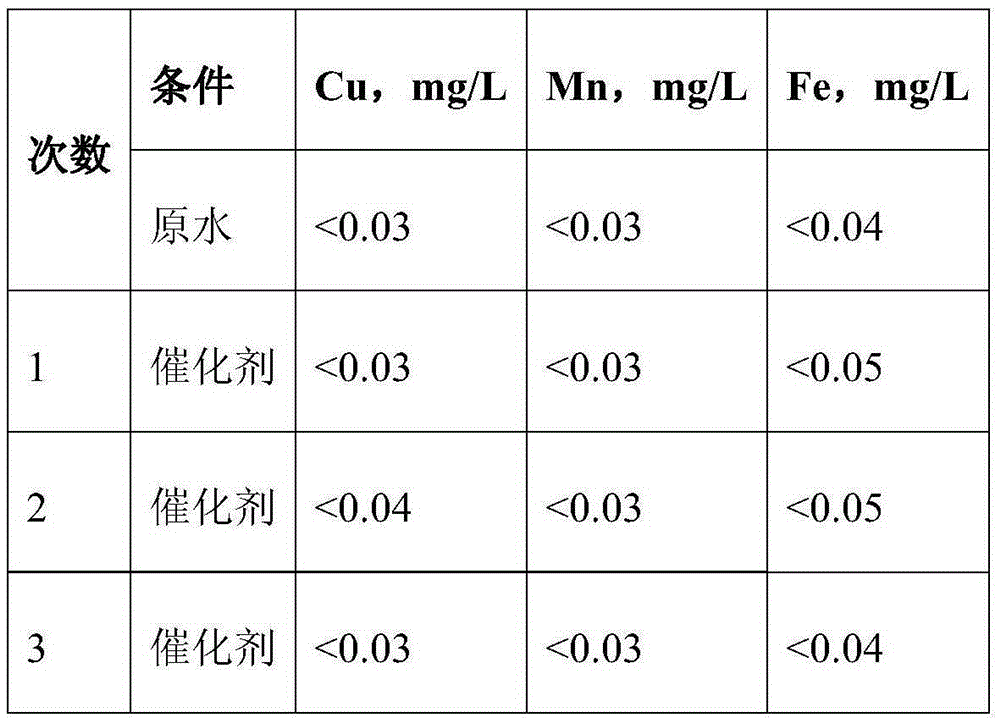

Preparation method of O3/H2O2 catalyst using activated bentonite as carrier, catalyst and application thereof

ActiveCN105233838AReduce usageReduce churnMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationCalcinationMetal salts

The invention provides a preparation method of an O3 / H2O2 catalyst using activated bentonite as a carrier, the catalyst prepared by means of the preparation method and application thereof. The activated bentonite is used as the carrier, and a part of the carrier is impregnated in a metal salt solution and then is loaded on the other unimpregnated part of the carrier to obtain the catalyst through drying and calcination. The catalyst obtained by means of the method is suitable for catalytic O3 / H2O2 oxidation water treatment and is suitable for large-scale production, and the manufacturing cost and operation cost are somewhat reduced.

Owner:GUANGDONG PROVINCIAL ACADEMY OF ENVIRONMENTAL SCI +1

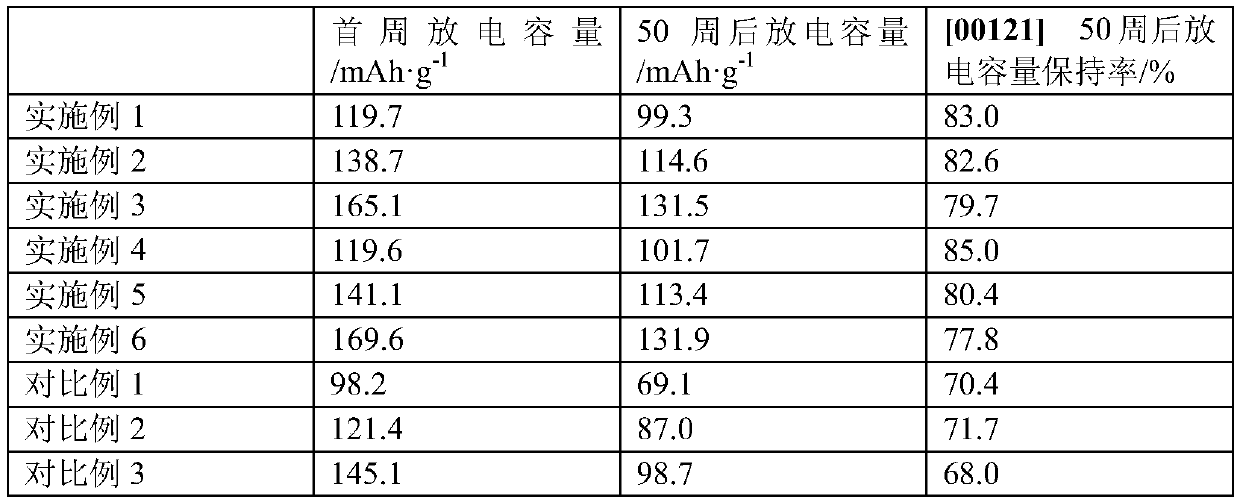

High-density graphite battery negative electrode material and preparation method thereof

ActiveCN106299258AImprove discharge capacityImprove stabilityCell electrodesSecondary cellsGraphite carbonHigh density

The present invention discloses a high-density graphite battery negative electrode material and a preparation method thereof. The graphite battery negative electrode material comprises the following raw materials: graphite carbon material supported modified quartz sand and a graphite carbon material, wherein a mass ratio of the graphite carbon material supported modified quartz sand to the graphite carbon material is 1:20-25. The preparation steps comprise: preparing modified quartz sand and graphite carbon material supported modified quartz sand, and adopting the graphite carbon material supported modified quartz sand and a graphite carbon material as raw materials to prepare the graphite battery negative electrode material. According to the present invention, the first discharge capacity is not less than 450 mAh / g (the irreversible capacity is less than 15 mAh / g), the first charge and discharge efficiency is more than 97.0%, and more than 90% of the first capacity is still retained after cycle 500 times; and the graphite battery negative electrode material has advantages of high capacitance, low irreversible capacity, stable cycle performance, high yield and simple process, and has broad application prospects in the applications in lithium-ion batteries and other negative electrode materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

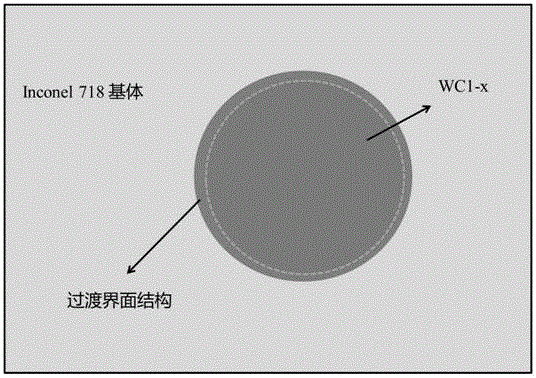

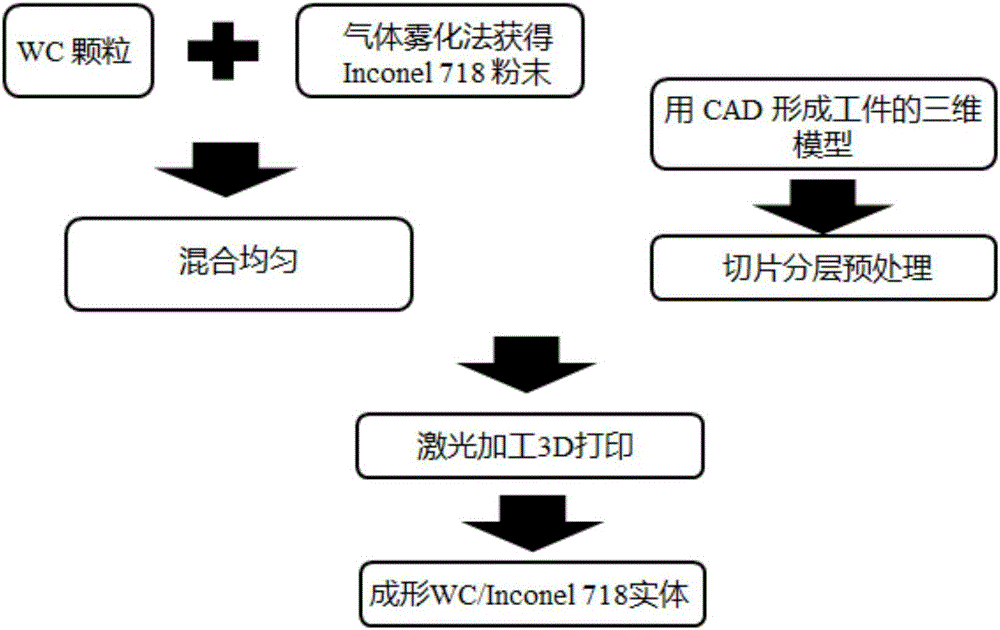

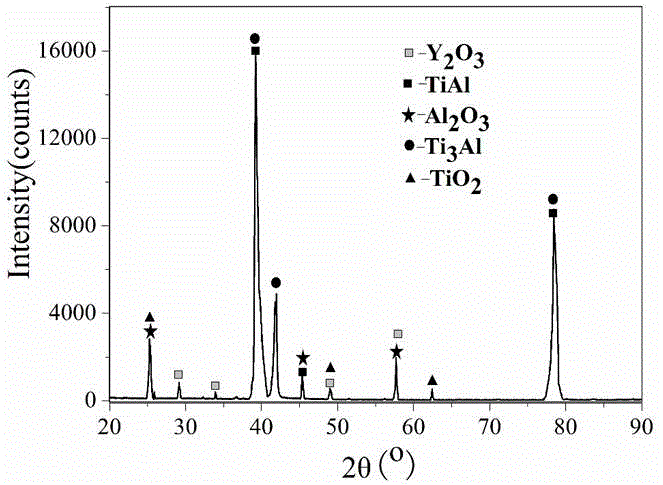

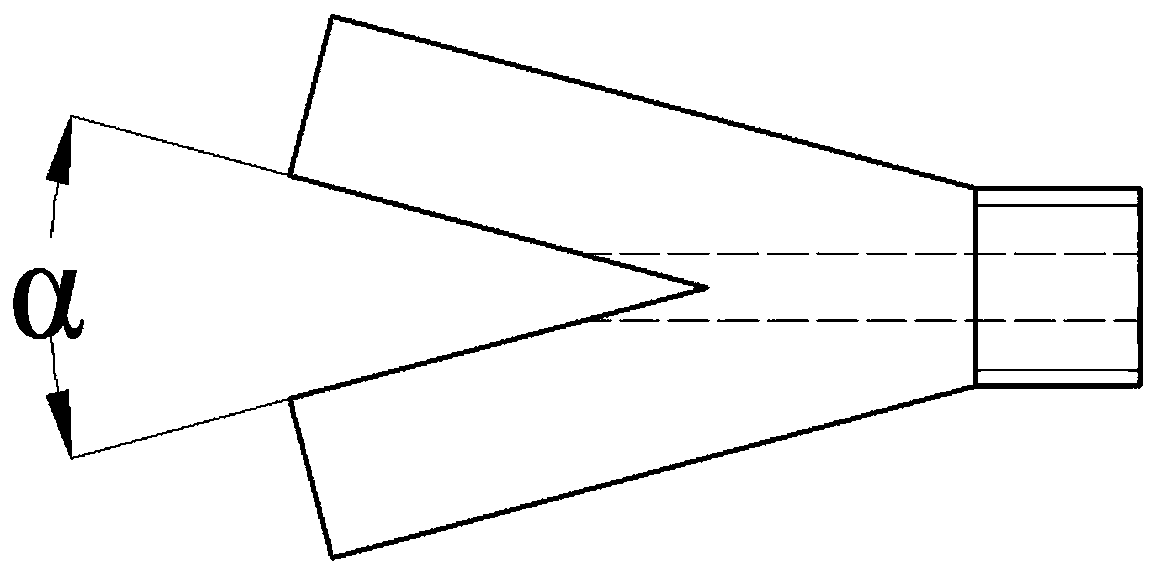

Method for preparing multielement transition interface cooperative-reinforced nickel base composite material by 3D printing

ActiveCN105728725AImprove bindingFacilitate interface reactionAdditive manufacturing apparatusIncreasing energy efficiencyThree dimensional shapeHardness

The invention discloses a method for preparing a multielement transition interface cooperative-reinforced nickel base composite material by 3D printing. A proper amount of WC particles is added in Inconel 718 powder; a 3D printing technology is processed through laser; when the linear density of laser energy is located in a range from 150 J / m to 250 J / m, a multielement transition interface is formed between a reinforced phase and a basal body; and the multielement transition interface and the added WC particles achieve an effect of cooperatively reinforcing an entity of the nickel base composite material. The method has the following advantages: parameters of the 3D printing technology are controllable, so that the manufacturing of parts with random three-dimensional shapes can be realized; through the cooperative reinforcing effect of the multielement transition interface and the reinforced particles, the plasticity and the toughness are improved when reinforcing the material strength and hardness; and the multielement transition interface between the reinforced phase and the basal body enables the reinforced phase and the basal body to be excellent in bonding performance, so that the crack initiation and expansion tendency is reduced, and the capacity of bearing a certain load is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

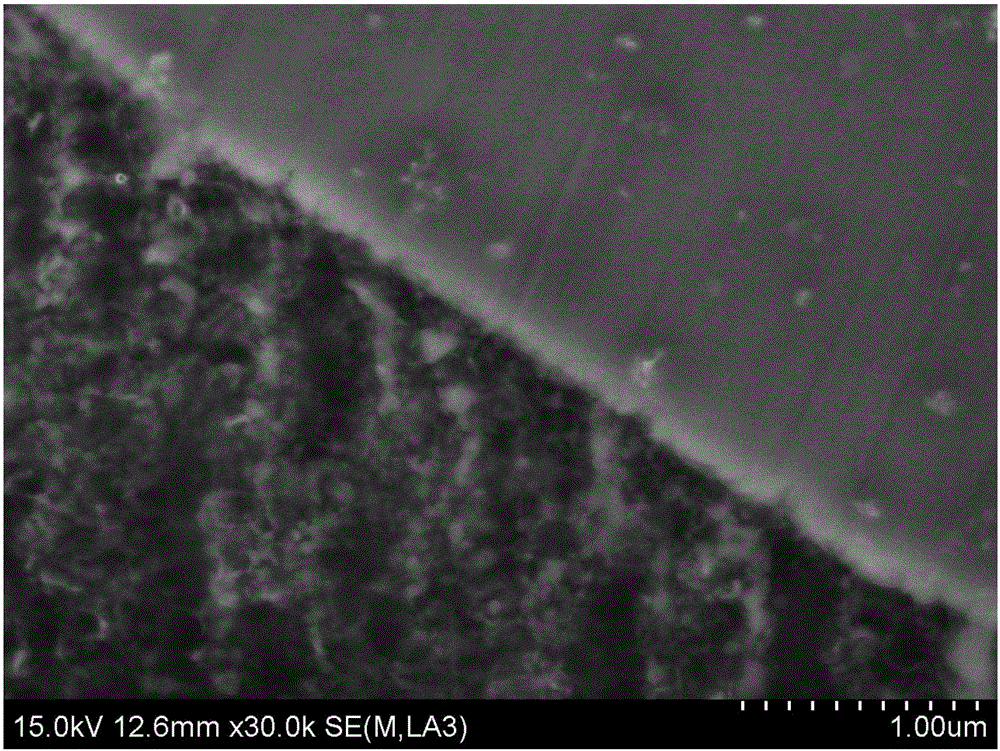

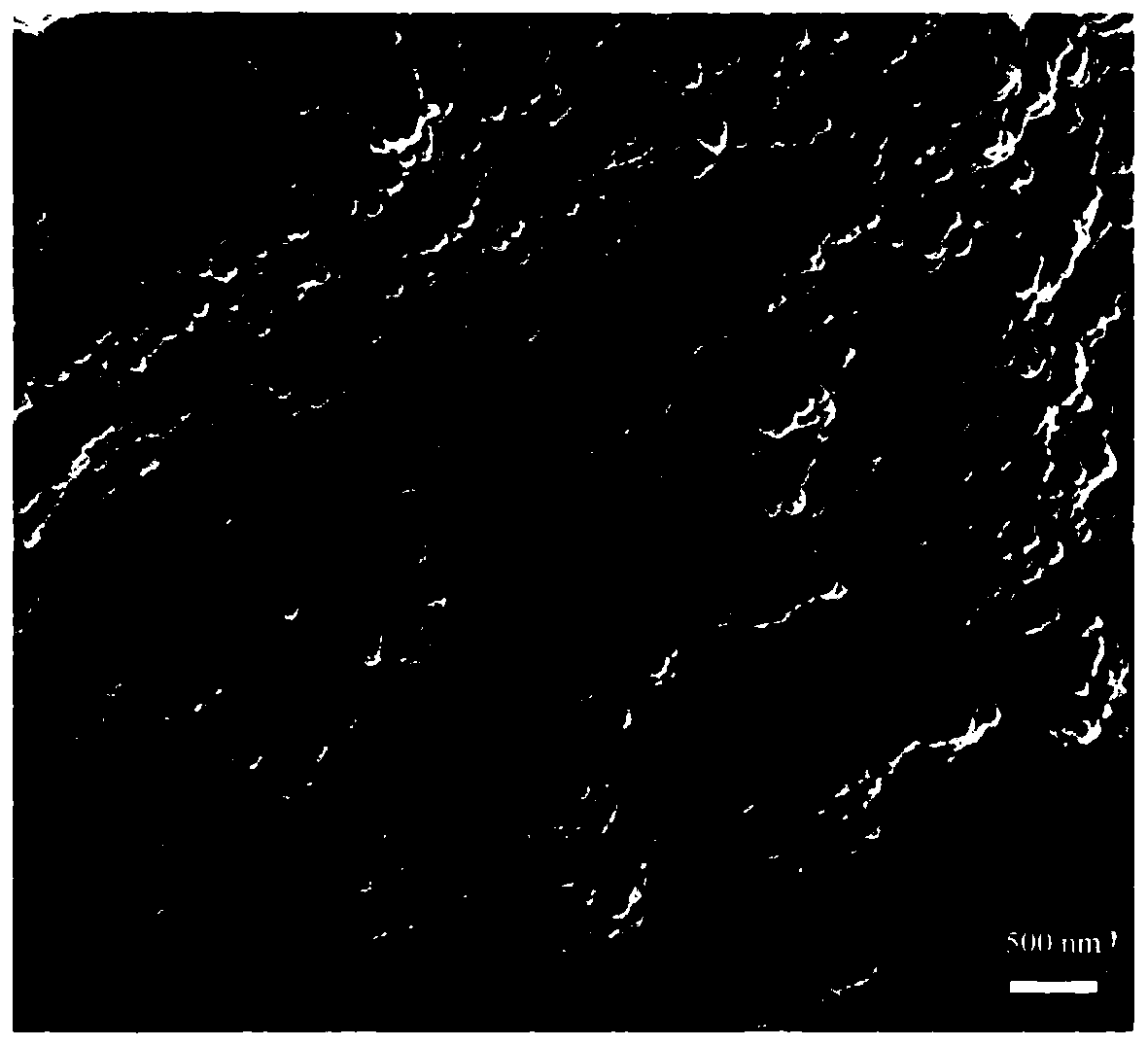

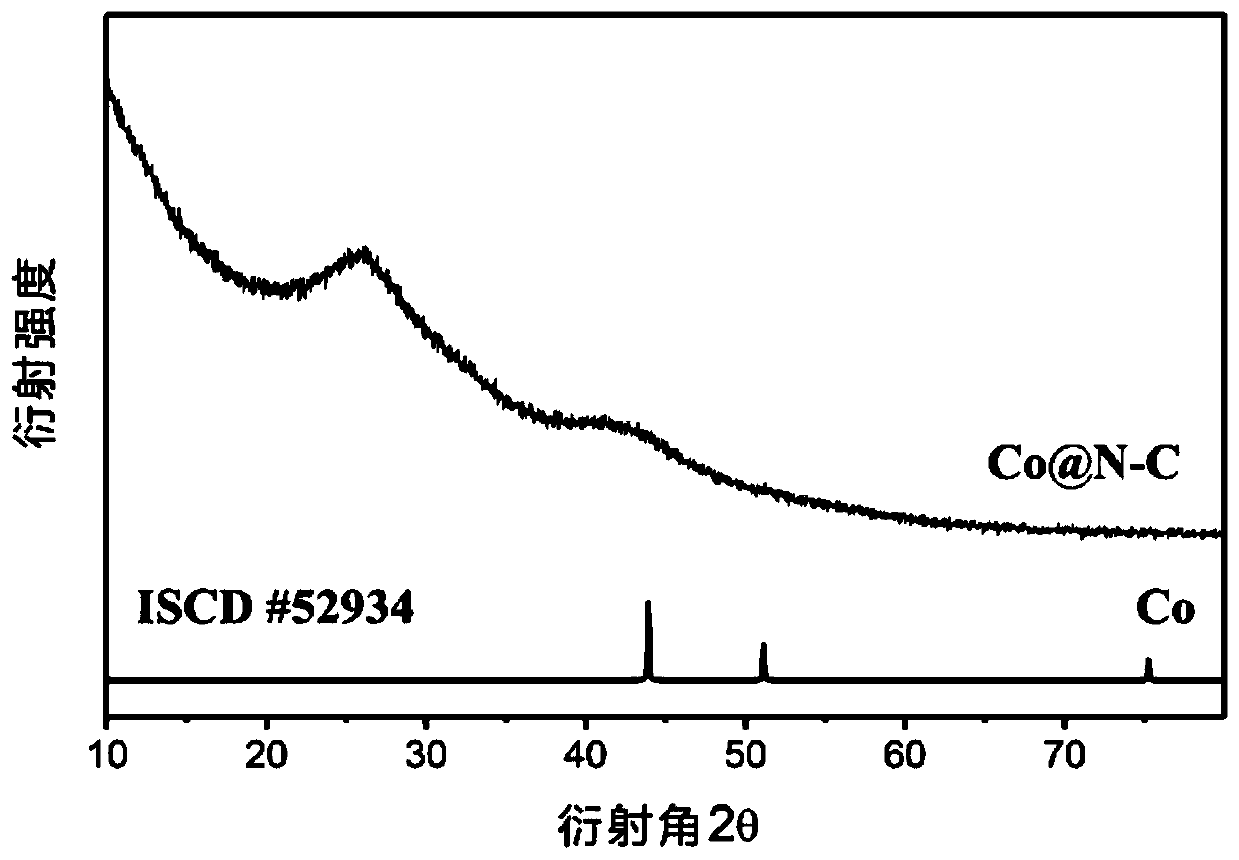

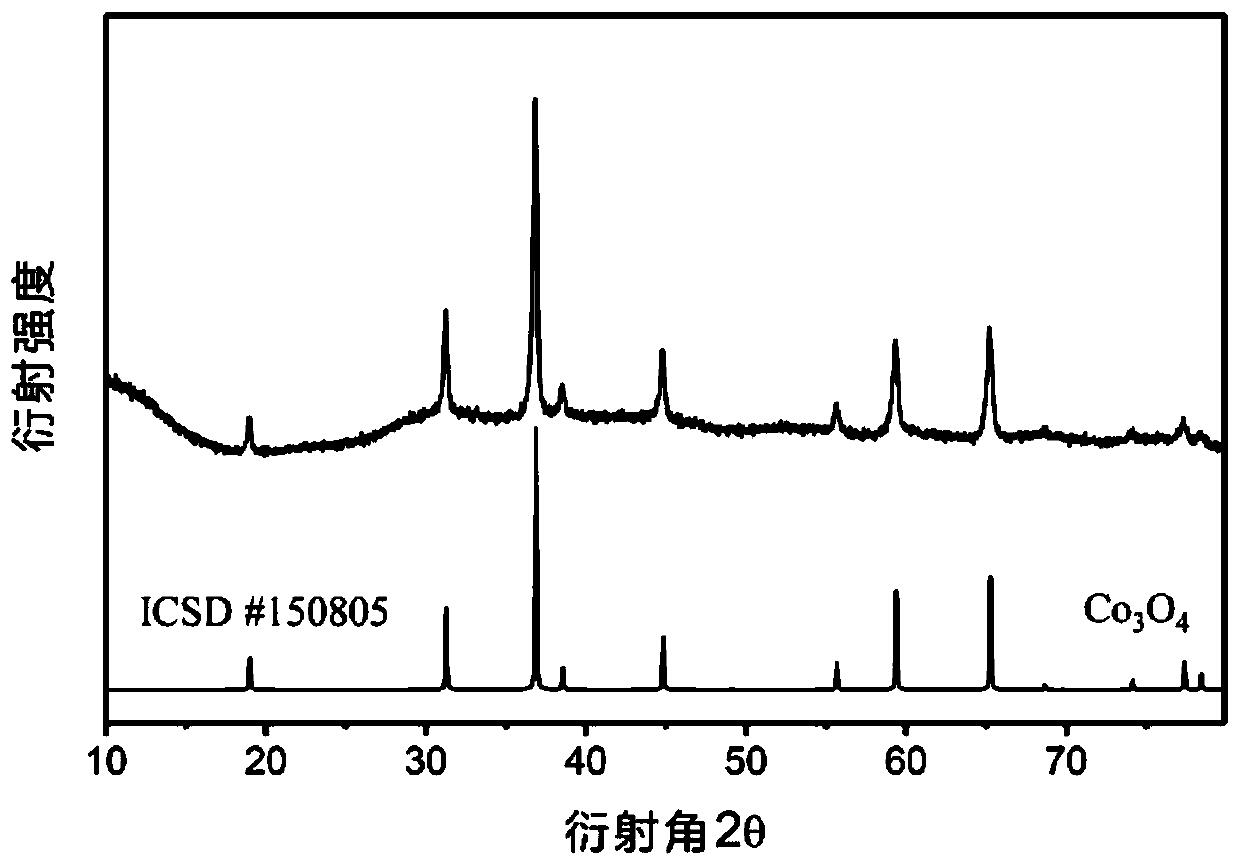

Transition metal cobalt single atom/cluster embedded nitrogen-doped carbon skeleton material, and preparation method and application thereof

InactiveCN110364705ACluster uniformEvenly dispersedCell electrodesSecondary cellsElectrolytic agentElectrical battery

The invention discloses a transition metal cobalt single atom / cluster embedded nitrogen-doped carbon skeleton material, and a preparation method and application thereof. The preparation method comprises the following steps: adding a cobalt source, a nitrogen-containing carbon source and silicon dioxide into a solvent, and carrying out ultrasonic stirring; carbonizing the obtained mixture in an inert atmosphere; carrying out pickling and etching on the obtained product in hydrochloric acid and hydrofluoric acid, and then washing and drying to obtain the transition metal cobalt single atom / cluster embedded nitrogen-doped carbon skeleton material. The method is simple in step and high in repeatability, and for the transition metal cobalt single atom / cluster embedded nitrogen-doped carbon skeleton, a mixed structure is endowed with enhanced electron conduction, and a large amount of uniformly dispersed N-C and Co-Nx active sites are introduced, thereby facilitating absorption of lithium ions and promotion of the interface reaction of the electrode material and the electrolyte. When being used as a lithium ion battery negative electrode material, the metal cobalt single atom / cluster embedded carbon hybrid material shows ultrahigh electrochemical activity and has very high potential application value.

Owner:SOUTH CHINA UNIV OF TECH +1

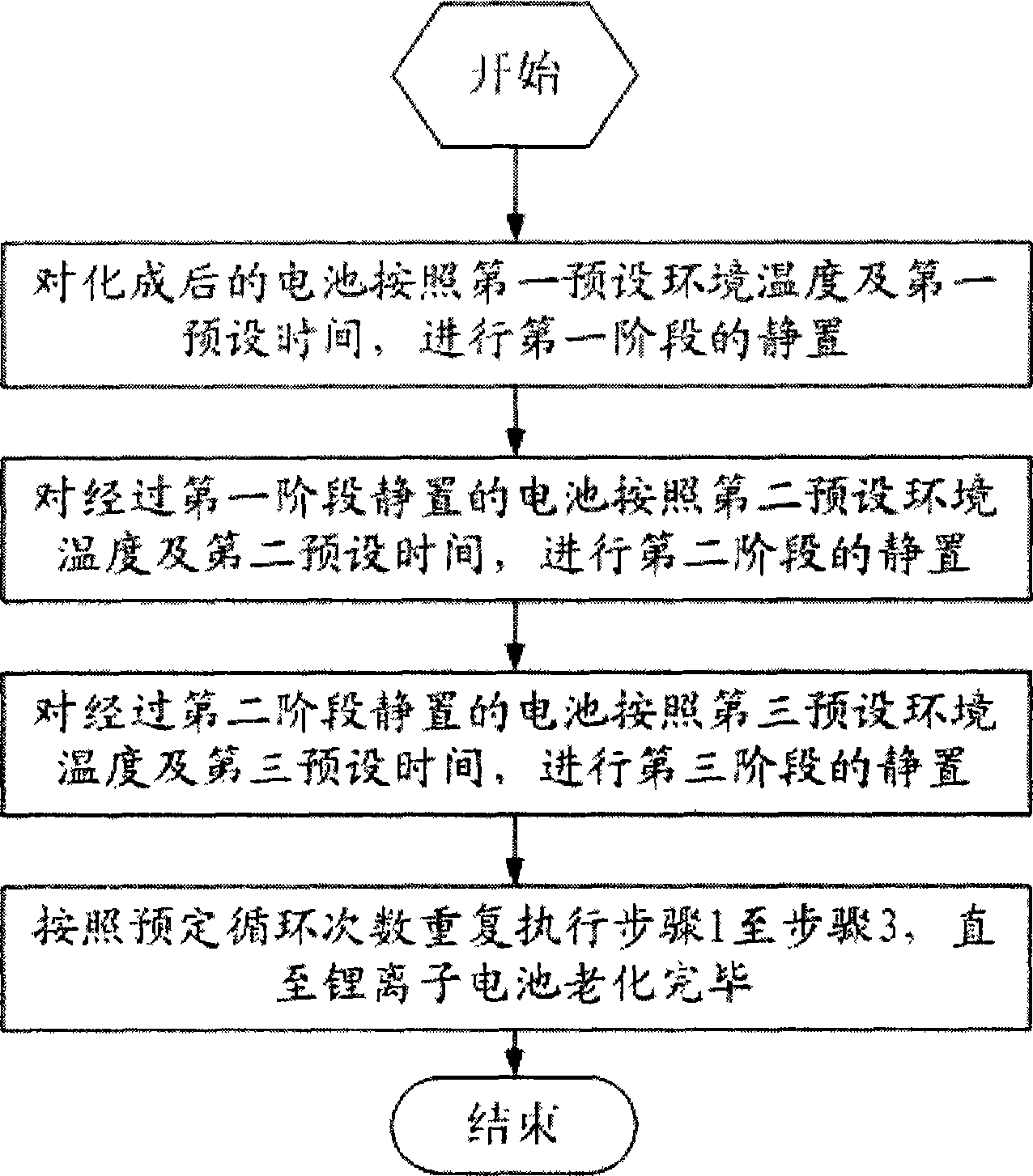

Lithium ion battery aging method

ActiveCN103985911ACompact formInhibit side effectsFinal product manufactureElectrolyte accumulators manufactureSecondary stageEngineering

The invention relates to a lithium ion battery aging method. The lithium ion battery aging method comprises the following steps: step one, standing at a first stage for an aged battery according to a first preset environment temperature and a first preset time; step two, standing at a second stage for the battery through standing at the first stage according to a second preset environment temperature and a second preset time; step three, standing at a third stage for the battery through standing at the second stage according to a third preset environment temperature and a third preset time; and step four, repeatedly carrying out the step one to the step three according to a preset cycle index until the aging of the lithium ion battery is finished. The method overcomes the defects of a conventional lithium ion battery aging method that the aging time is long and the battery performance after aging is low. The method can select batteries with low high-and-low temperature performance, so that the consistency of the batteries after being aged is ensured; meanwhile, the method is short in aging time, the production efficiency is improved, and the method is easy to operate and high in reliability.

Owner:JIANGSU ZHIHANG NEW ENERGY

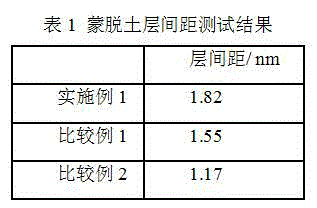

Inhibitor-loaded montmorillonite/epoxy self-healing coating

ActiveCN104098984AImprove corrosion resistanceIncrease spacingAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention provides an inhibitor-loaded montmorillonite / epoxy self-healing coating. The coating is prepared by the following steps: (1) dissolving montmorillonite with deionized water, and adding a blender subjected to acidizing treatment under fiercely stirring to obtain a modified montmorillonite; (2) dissolving the montmorillonite obtained in step (1) into a mixed solution of acetone and water, adding an inhibitor according to a certain rate to obtain an inhibitor-loaded montmorillonite; (3) adding the montmorillonite obtained in step (2) into epoxy resin, a mixed solvent, a dispersing agent, a flatting agent and the like to obtain an inhibitor-loaded montmorillonite / epoxy component I, then mixing the inhibitor-loaded montmorillonite / epoxy component I with an inhibitor-loaded montmorillonite / epoxy component II according to a certain rate to obtain the inhibitor-loaded montmorillonite coating. According to the invention, after the montmorillonite is subjected to loading, the distance between the two layers is increased, and the property of hydrophilicity of the montmorillonite is changed into lipophilicity, so that the compatibility of the montmorillonite with an organic phase is facilitated; the inhibitor-loaded montmorillonite / epoxy self-healing coating provided by the invention has excellent corrosion resistance.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of zirconium-plated diamond particle-reinforced aluminum matrix composite

ActiveCN108707770APrevent oxidationEvenly distributedVacuum evaporation coatingSputtering coatingEvaporationHeating temperature

The invention belongs to the technical field of composites and provides a preparation method of a zirconium-plated diamond particle-reinforced aluminum matrix composite. The preparation method specifically comprises the steps that the surfaces of diamond particles are plated with zirconium through magnetron sputtering or vacuum micro-evaporation; heat treatment is conducted on the zirconium-plateddiamond particles obtained through magnetron sputtering, wherein the heating temperature is 950-1050 DEG C, and the heat preservation time is 0.5-2h; a mold filled with the zirconium-plated diamond particles and a pure aluminum block is placed in an inductive heating area in a furnace; the mold is heated after a furnace body is vacuumized; high-purity argon is injected into the furnace, and the temperature and pressure are maintained; and the composite is obtained after the furnace is cooled to the room temperature. The diamond / aluminum composite prepared through the method has excellent heatconductivity and a small specific gravity, the heat conductivity of the composite can reach 622W / mK, the density of the composite is smaller than or equal to 3.3g / cm<3>, and the composite can meet the urgent requirement for high-conductivity lightweight heat management materials for heat dissipation of high-power devices in the aerospace field; and the generation of aluminum carbide boundary phases prone to hydrolysis is reduced, and the composite can be used and stored in a humid environment.

Owner:UNIV OF SCI & TECH BEIJING +1

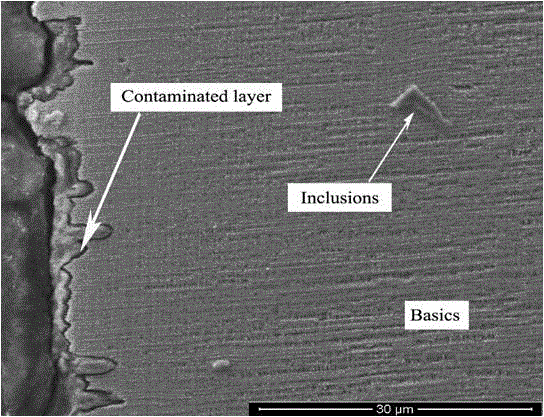

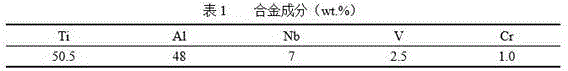

Process for reducing reaction of directional solidification titanium-aluminum alloy castings and casting mold coatings

ActiveCN105543618ADirectional solidification process optimizationHigh quality and precisionPolycrystalline material growthFrom frozen solutionsReaction layerMicrometer

The invention researches a process for reducing the reaction of directional solidification titanium-aluminum alloy castings and casting mold coatings, and belongs to a directional solidification casting method of a high-temperature structural alloy. The invention aims at providing optimal process parameters during titanium-aluminum alloy preparation achieved through directional solidification, the interface reaction between an alloy melt and casting mold materials is weakened to be minimum when the heat preservation time is 30 minutes and the drawing speed is 60 micrometers per second by means of design of directional solidification parameters of a Ti-48Al-7Nb-2.5V-1.0Cr alloy, the reaction layer thickness is reduced to be less than 10 micrometers, the surfaces of the castings are smooth, and internal contamination is little. The process is characterized in that the time of contact between the melt and casting molds is shortened, and the problems that when the drawing speed is high, the number of crystalline grains is increased and the deviation between the direction of the crystalline grains and the axial direction is large are solved. The process is reasonable and low in cost, can not influence the directional solidification structure orientation of a titanium-aluminum alloy, and can be applied to the directional solidification process of the titanium-aluminum alloy.

Owner:CHINA UNIV OF MINING & TECH

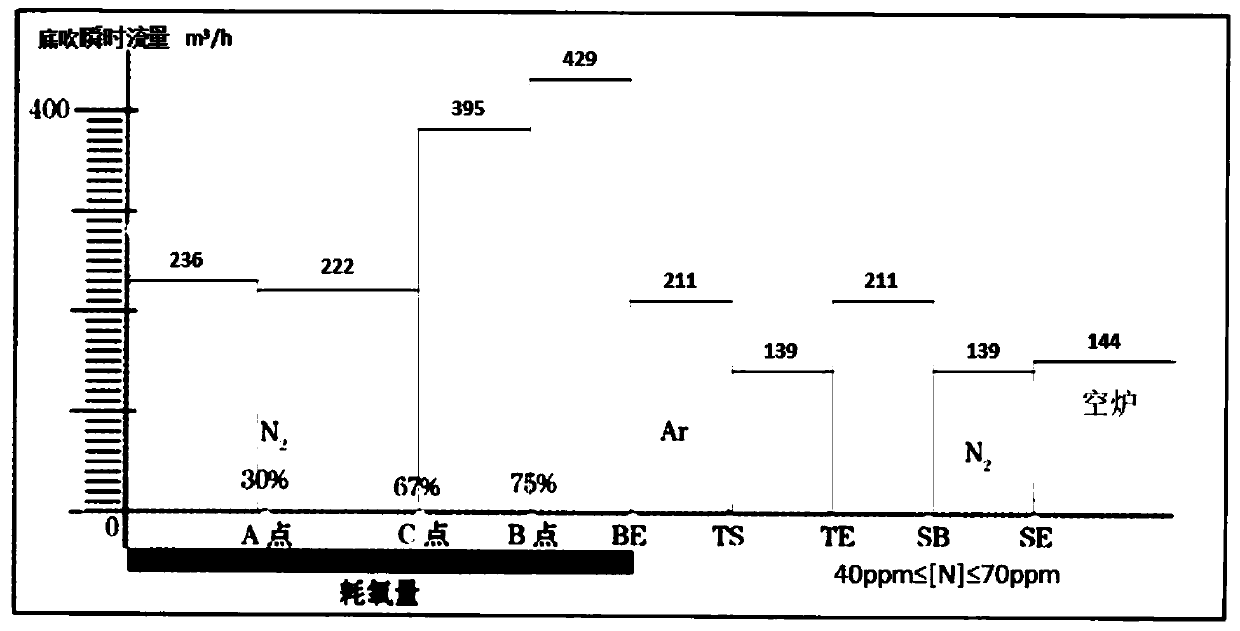

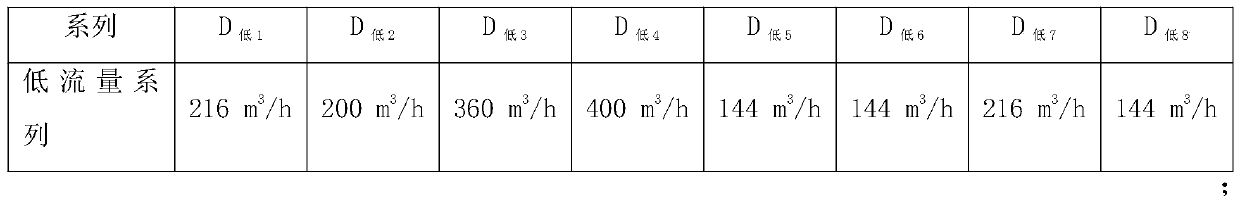

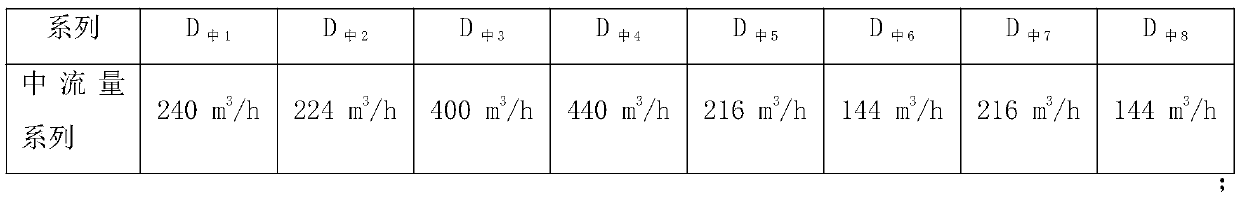

Bottom-blowing flow dynamic control method of top-bottom combined blowing converter

InactiveCN110157848ARealize dynamic controlSolve fixed problemsSteel manufacturing process aspectsIncreasing energy efficiencyEngineeringOxygen content

The invention provides a bottom-blowing flow dynamic control method of a top-bottom combined blowing converter. Firstly, three flow series composed of a high-flow series, a medium-flow series and a low-flow series are added based on three bottom-blowing air supply modes, three bottom blowing air supply modes and three flow series are permuted and combined into nine basic bottom-blowing curves, wherein the time coordinate axes of the basic bottom-blowing curves are provided with eight time intervals; in addition, the measured carbon content [C], the oxygen content [O], a molten pool liquid level a, and an end point temperature T of the converter blowing end point of the previous furnace as well as the furnace age of a next furnace to be blown are taken as variable parameters to be substituted into a formula, then the nine basic bottom blowing curves are dynamically corrected through formula calculation, thus the bottom blowing instantaneous flow after dynamic correction is the bottom blowing instantaneous flow of the actual blowing of the next furnace. According to the bottom-blowing flow dynamic control method of the top-bottom combined blowing converter, the problem that the bottom blowing flow is fixed is solved, the dynamic control of the bottom blowing flow is realized, thus reducing the carbon oxygen product at the blowing end point and improving the metallurgical effect of the bottom blowing as well as the quality of the molten steel.

Owner:山东钢铁集团有限公司

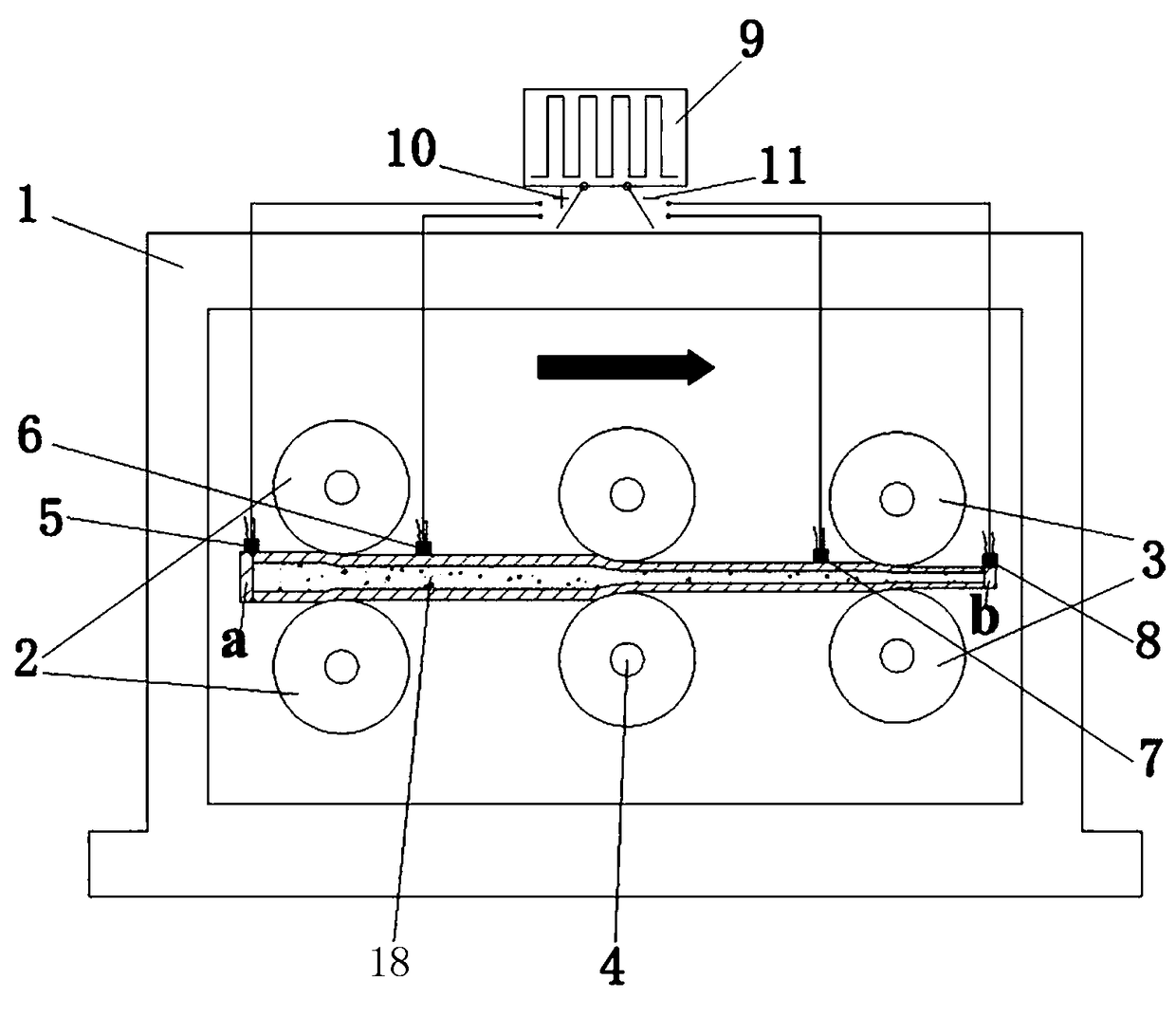

Method with pulsed electric field assisted adopting vacuum canning rolling to prepare metal-based composite material

ActiveCN109468480AReduce ambient temperatureImprove sintering efficiencyPulse power supplyPulse electric field

The invention discloses a method with a pulsed electric field assisted adopting vacuum canning rolling to prepare a metal-based composite material. The method comprises the following steps that firstly, composite powder is made into a blank is subjected to heat treatment, then the blank is overlapped with a metal-covered plate subjected to surface treatment, vacuum edge welding is carried out so that internal air can be exhausted, and a vacuum canning test piece structure is formed; and then, the canning test piece is placed into a rolling mill, on the basis of a canning rolling process, a pulse power supply is connected with electric brushes at different positions, a current is applied to the surface of a canning, and green blank plasma sintering and canning electro-plastic rolling are synchronously carried out. The current parameters, the rolling speed and the reduction rate are reasonably controlled, and thus a large-size metal-based composite sheet is obtained through multi-rollerrolling and reasonable sintering time. According to the method, the vacuum canning rolling is coupled with the pulsed electric field, the high-performance reinforced phase-containing metal-based composite sheet can be sintered and rolled in a short time period, wherein the sheet has the characteristics that the macroscopic size is large, the microscopic crystalline grains are fine, the reinforcedphases are uniformly dispersed and distributed; and the method has the characteristics of high efficiency, low consumption, being suitable for large-scale and intensive productions.

Owner:南京派拉斯曼工程技术有限公司

Nickel hydroxide electrode for rechargeable batteries

ActiveUS8048566B2Facilitate interface reactionImprove reliabilityMaterial nanotechnologyHybrid capacitor electrodesPotassium persulfateNickel oxide hydroxide

The nickel hydroxide particles for a nickel hydroxide electrode may be treated using an alkaline solution of a strong oxidizing agent such as sodium or potassium persulfate to modify the surface nickel hydroxide structure. The resulting modified surface structure has been found to impart various benefits to electrodes formed from the nickel hydroxide. It is believed that the oxidation of cobalt compounds at the surface of the nickel hydroxide particles results in a highly conductive cobalt compound that plays an important role in the high reliability, high stability and high capacity utilization of nickel electrodes as described herein.

Owner:ZINCFIVE POWER INC

Method for activating humic acid through physical and chemical combined solid-phase ball milling

InactiveCN106518532ALower requirementNo emissionsOrganic fertilisersFertilizer mixturesPhysical chemistryBall mill

The invention relates to a method for activating humic acid through physical and chemical combined solid-phase ball milling. The method comprises the following steps: firstly, smashing the weathered coal containing inactivated humic acid and filtering through a 60-mesh sieve, thereby acquiring powdered weathered coal A; adding a solid activating agent B and a synergist C into the weathered coal A and uniformly mixing; putting A, B and C into a ball mill; and setting a rotating speed at 60-80rpm and ball-milling for 60min-90min, thereby acquiring an activated product rich in humic acid. Compared with the traditional chemical activating method, the method has the advantages that more than 50% of energy consumption is saved and no dust or harmful gas is discharged; under the effect of the synergist, the humic acid with a micro-molecule structure is easily generated; the stimulation effect on crops and the improving effect on soil are further benefited; and the method is a low-cost, high-efficiency and environment-friendly activating method.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Monocrystal ternary positive electrode material and preparation method thereof

PendingCN113584590APromote growthReduce conventional sintering temperaturePolycrystalline material growthFrom solid stateDepolymerizationManganese

The invention provides a monocrystal ternary positive electrode material, which has a chemical formula of LiaNixCoyMnzMbO2, wherein a is greater than or equal to 1.02 and less than or equal to 1.25, x + y + z + b is equal to 1, the average valence state of Ni, Co and Mn is 3.0+ / -0.1, the molar ratio of Co is 0-20%, the molar ratio of Mn is greater than or equal to 20%, the molar ratio of Ni is 40-75%, the doped metal M is selected from at least one of Al, W, Ti, Mg, Zr, Ba and La, and the molar ratio of the doped metal M is less than 1%. The preparation method selects a medium-nickel low-cobalt ternary precursor,andcomprises the following steps: 1, mixing a lithium source, sintering to prepare a ternary positive electrode material with a large specific surface area and a single-crystal-like structure, and then crushing the ternary positive electrode material into primary monocrystal or monocrystal-like small particles which are relatively small in particle size and are uniformly dispersed; and 2, continuously mixing the primary small particles with a lithium source, carrying out element M doping, sintering at a higher temperature, and carrying out mechanical depolymerization to obtain the monocrystal-morphology positive electrode material with relatively good dispersibility. According to the invention, the problems that monocrystal particles of the low-cobalt and high-manganese-content ternary material are difficult to grow, Li / Ni mixed arrangement is high, and the rate capability is reduced are solved.

Owner:兰州金通储能动力新材料有限公司

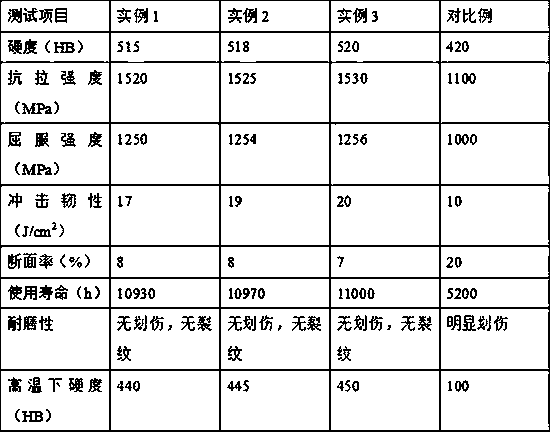

Preparation method of wear-resisting high-temperature-resisting metallic ceramic coating

InactiveCN108179405AImprove bindingMaintain densityLiquid/solution decomposition chemical coatingAlumina hydrateChemical plating

The invention relates to the technical field of metallic ceramic coatings, in particular to a preparation method of a wear-resisting high-temperature-resisting metallic ceramic coating. The preparation method comprises the steps of drying self-made metallic ceramic slurry to obtain dry metallic ceramic powder; conducting treatment on a self-made chemical plating solution to obtain a composite plating solution; dip-coating a self-made base plate with the composite plating solution to obtain a dip-coated plate; conducting high-temperature sintering on the dip-coated plate to obtain a metallic ceramic coating. Cerium oxide in glass powder enables active nickel atoms contained in ceramic powder bodies and metal in a base material form metallic bonds. The adherence of the metallic ceramic coating and the base material is improved, and the high-temperature-resistant performance of the metallic ceramic coating is improved. Alumina hydrate particles in the composite plating solution have positive charge, and the surface of the base plate has negative charge. The generated aluminum oxide particles are deposited on the surface of the base plate to form a high-density oxidized metallic film.The bonding force between the metallic ceramic powder bodies is increased. The wear-resisting high-temperature-resisting metallic ceramic coating is not likely to be abraded when applied to a cuttingtool. Accordingly, the abrasion resistance of the metallic ceramic coating is improved, and the wear-resisting high-temperature-resisting metallic ceramic coating has broad application prospects.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

High-temperature structure and function integrated Mg(Al)B2 and B4C co-enhanced aluminum-based neutron absorbing material and preparation method thereof

ActiveCN111349805AHigh strengthImprove high temperature strengthShieldingPhysical chemistryHigh heat

The invention discloses a high-temperature structure and function integrated Mg(Al)B2 and B4C co-enhanced aluminum-based neutron absorbing material and a preparation method thereof, and belongs to thetechnical fields of neutron absorbing materials and aluminum-based composite materials. According to the method, the components of a matrix alloy are optimized, the wettability of the alloy is improved through B4C particle pre-oxidation, densification is achieved through a process of heating, pressurizing to the specified density, slow heating control in-situ reaction and re-pressurizing, and thedensity obtained after two times of pressurizing and the heating speed in the in-situ reaction are specified, so that the content and uniform distribution of a liquid phase in the sintering process are controlled, and the high-temperature structure and function integrated neutron absorbing material is prepared. The content of the liquid phase in the hot-pressing sintering process is controlled byregulating and controlling the corresponding hot-pressing temperature and heating speed, so that the interface reaction is continuously, controllably and thoroughly carried out until the Mg element is exhausted and the liquid phase disappears finally, thereby completing the instantaneous liquid-phase reaction sintering process. In the obtained material, nano Mg(Al)B2 is dispersed and distributedin a matrix, so that the high-temperature performance of the material is remarkably enhanced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Lithium electrode for lithium metal battery and method of manufacturing the lithium electrode

ActiveUS9190658B2Extended shelf lifeFacilitate interface reactionSolid electrolytesFinal product manufactureElectrochemical responseElectrical conductor

Disclosed are a lithium electrode for a lithium metal battery, which uses a solid high-ionic conductor having a three-dimensional (3D) porous structure, wherein a lithium metal or lithium alloy is filled into each pore and dispersed, and a method for manufacturing the lithium electrode. By applying a solid high-ionic conductor having a 3D porous structure, an ion conduction path is secured in the lithium electrode using the solid high-ionic conductor instead of a conventional liquid electrolyte, electrical-chemical reactivity in charging and discharging are further improved, and shelf life and high rate capability are enhanced.

Owner:HYUNDAI MOTOR CO LTD

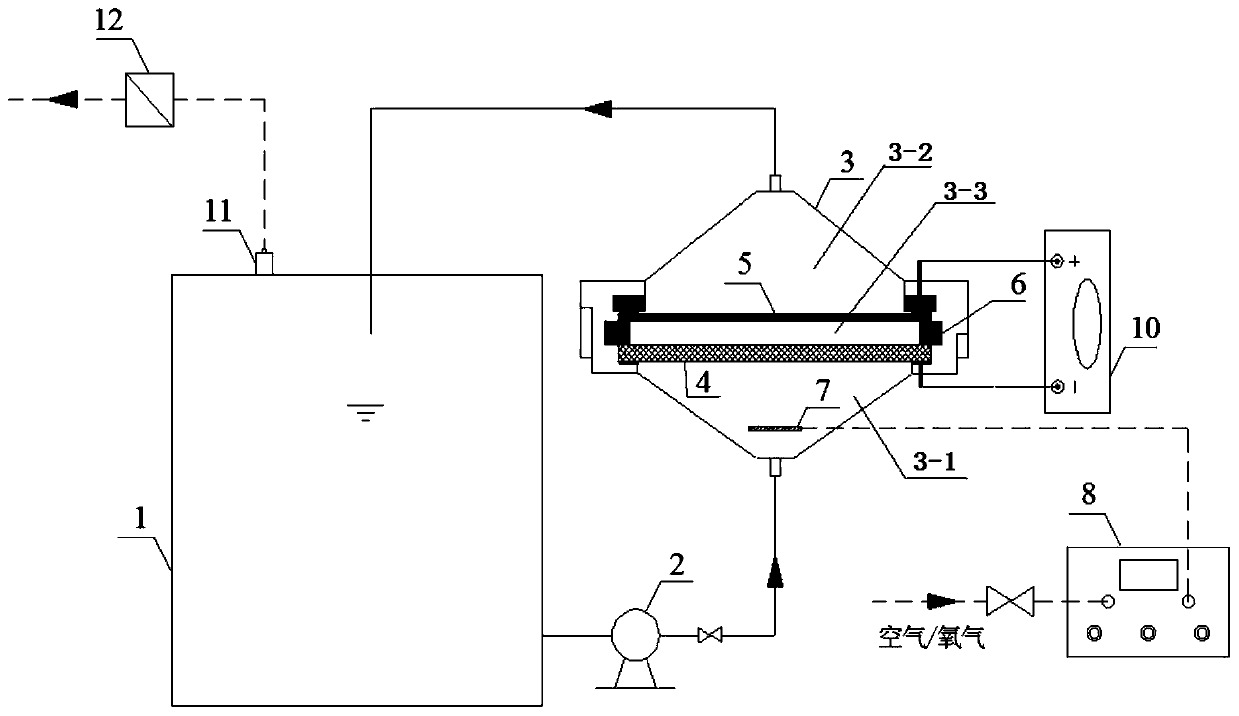

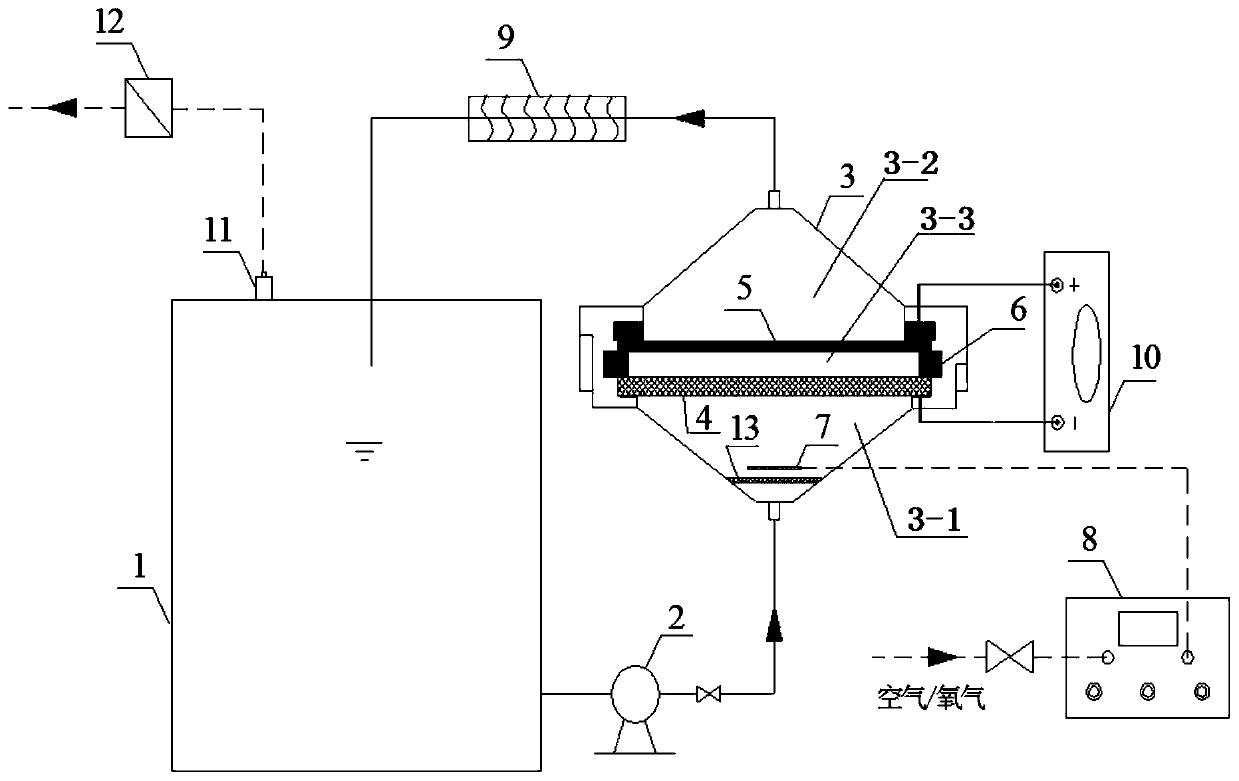

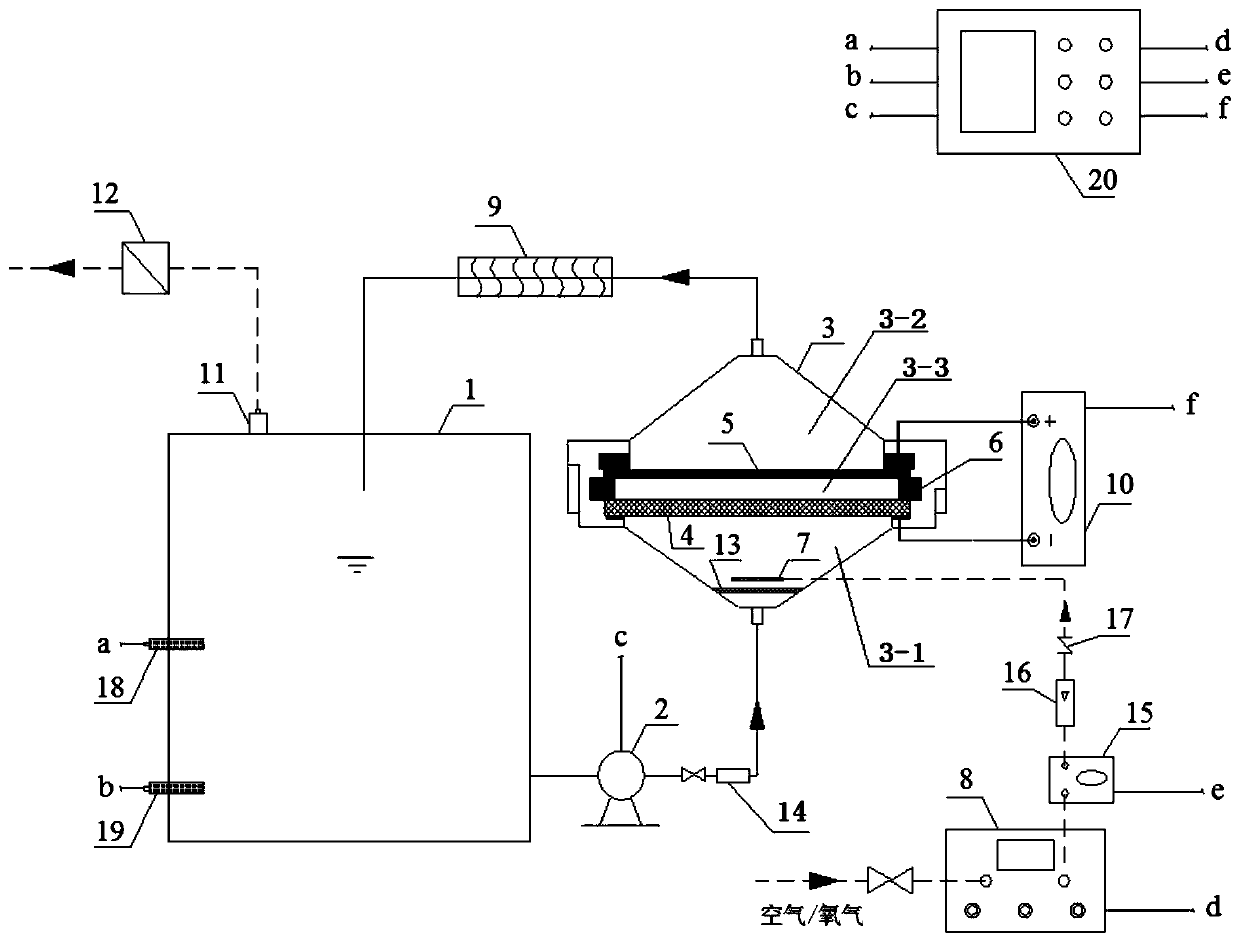

Circulating overflow type electric assisted ozone water treatment equipment as well as method for treating water thereby

ActiveCN110642340ACompact structureSimple and compactWater contaminantsWater/sewage treatment using germicide/oligodynamic-processElectrochemical responseEnvironmental chemistry

The invention provides circulating overflow type electric assisted ozone water treatment equipment as well as a method for treating water thereby. The equipment comprises a homogenous reactor, an electrochemical reaction device and an ozone generator, wherein the homogenous reactor and the electrochemical reaction device are mutually connected and form a circulating path; a cathode and an anode which are parallel with each other and are water-permeable and air-permeable are arranged in the electrochemical reaction device, and divide the internal space into a lower chamber positioned below thecathode, an upper chamber positioned above the anode and a middle chamber positioned between the two electrodes; the edges of the two electrodes and the inner wall of the electrochemical reaction device are in a sealed state; the water inlet end of the lower chamber is connected with the water outlet end of the homogenous reactor; the water outlet end of the upper chamber is connected with the water inlet end of the homogenous reactor; and a gas dispersing device is arranged in the lower chamber and is connected with the ozone generator outside. The equipment provided by the invention improvesreaction system mass transfer, reduces pollution of ozone tail gas, enables a homogeneous reaction system and an electrode interface reaction system to obtain favorable conditions respectively, and is efficient and environmentally-friendly.

Owner:HOHAI UNIV

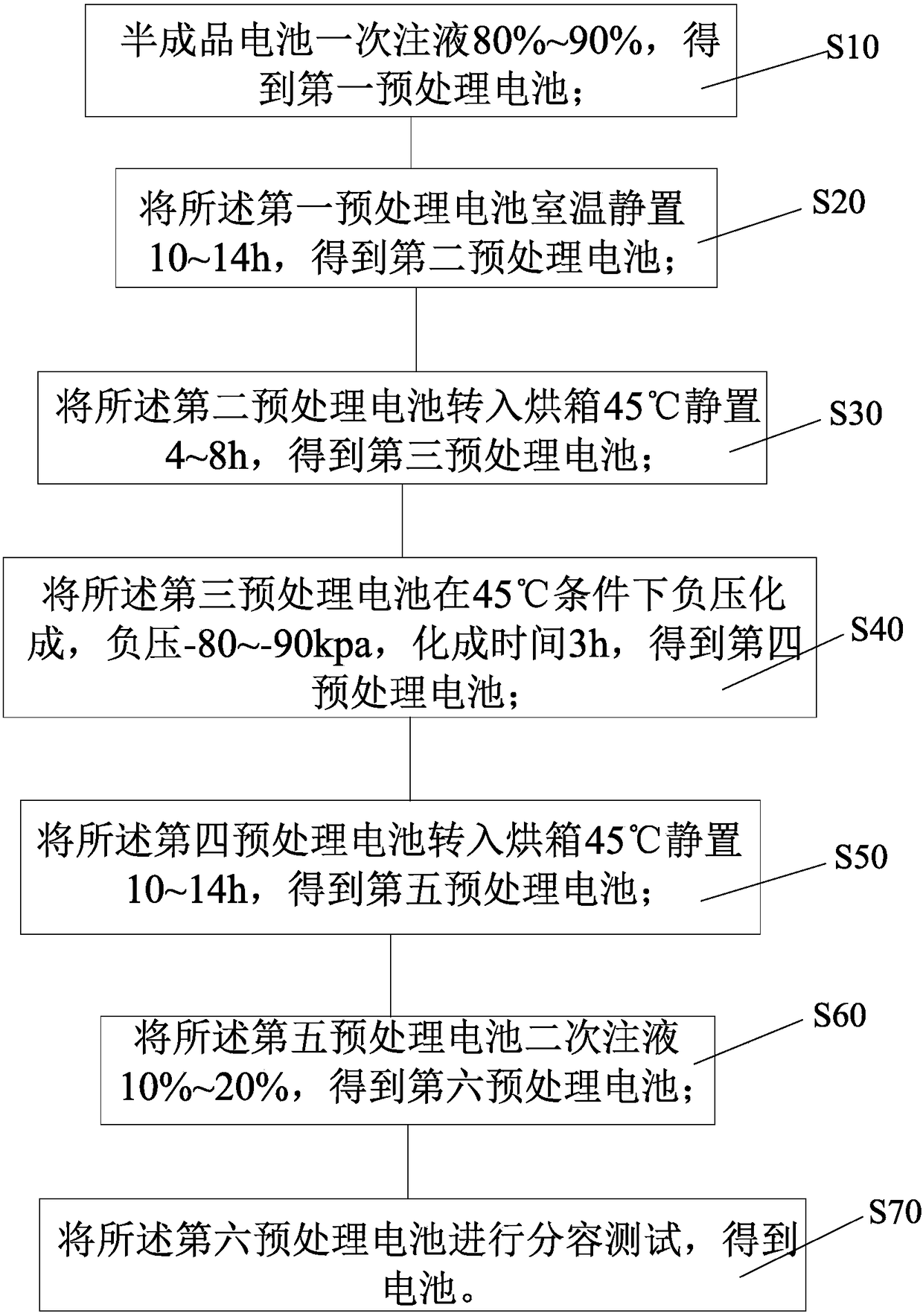

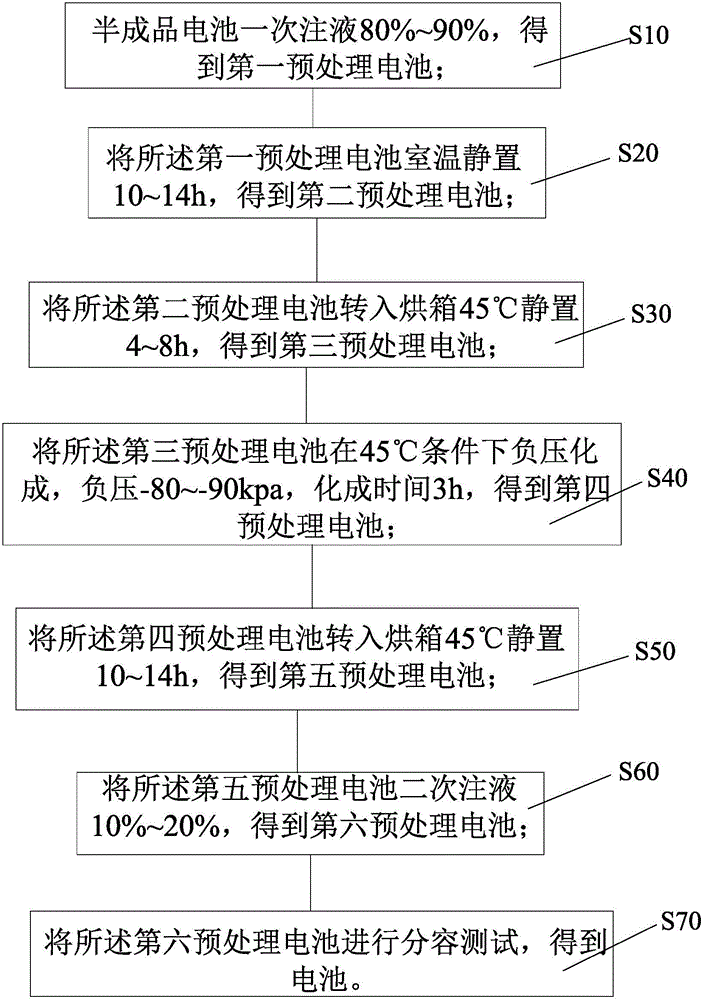

A Lithium-ion battery formation process

ActiveCN106067561BIncrease productivityIncreasing the thicknessFinal product manufactureElectrolyte accumulators manufactureEngineeringPre treatment

The invention discloses a lithium ion battery formation process, which comprises the following steps: injecting 80% to 90% of the semi-finished battery at one time to obtain a first pretreatment battery; leaving the first pretreatment battery at room temperature for 10 to 14 hours to obtain a second pretreatment battery 2. Pretreatment battery: transfer the second pretreatment battery into an oven at 45°C and let it stand for 4-8 hours to obtain the third pretreatment battery; form the third pretreatment battery under negative pressure at 45°C, the negative pressure ‑80~‑90kpa, the formation time is 3h, and the fourth pretreatment battery is obtained; the fourth pretreatment battery is transferred to an oven at 45°C for 10~14h, and the fifth pretreatment battery is obtained; the fifth pretreatment battery 10%-20% of liquid is injected into the battery for the second time to obtain a sixth pretreated battery; the sixth pretreated battery is subjected to a capacity separation test to obtain a battery. The formation process of the lithium-ion battery of the present invention solves the problem of gas generation in the formation process of the existing lithium-ion battery, controls battery swelling, optimizes the reaction interface, and improves battery performance.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Formation technology of lithium ion batteries

ActiveCN106067561AIncrease productivityIncreasing the thicknessFinal product manufactureElectrolyte accumulators manufactureRoom temperatureEngineering

The invention discloses formation technology of lithium ion batteries. The technology comprises the following steps: first liquid injection is carried out for 80-90% of a semi-finished product battery, and a first pretreated battery is obtained; the first pretreated battery is permitted to stand for 10-14 hours at room temperature, and a second pretreated battery is obtained; the second pretreated battery is transferred to a baking oven at 45 DEG C for 4-8 hours, and a third pretreated battery is obtained; formation is carried out for the third pretreated battery in a condition with a negative pressure at 45 DEG C, wherein the negative pressure is 80-90kpa, formation time is 3 hours, and a fourth pretreated battery is obtained; a forth pretreated battery is transferred to a baking oven at 45 DEG C for 10-14 hours, and a fifth pretreated battery is obtained; secondary liquid injection is carried out for 10-20% of a fifth pretreated battery, and a sixth pretreated battery is obtained; a capacity grading test is carried out for a six pretreated battery, and a battery is obtained. The formation technology of lithium ion batteries solves the problem that gas is generated in the prior formation technology of lithium ion batteries; swelling of batteries is controlled, reaction interfaces are optimized, and performance of batteries is improved.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

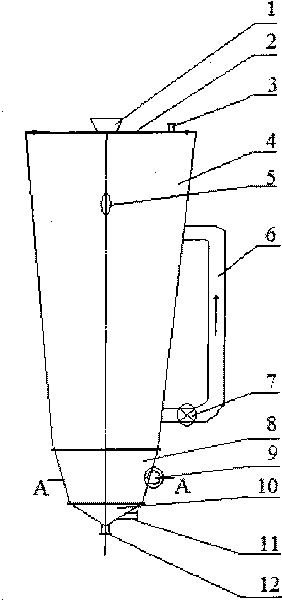

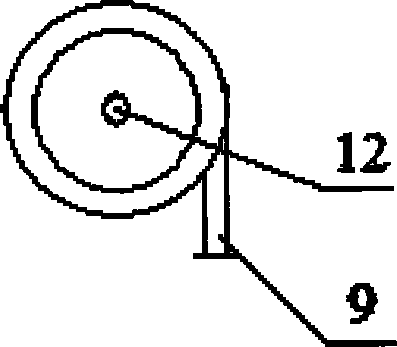

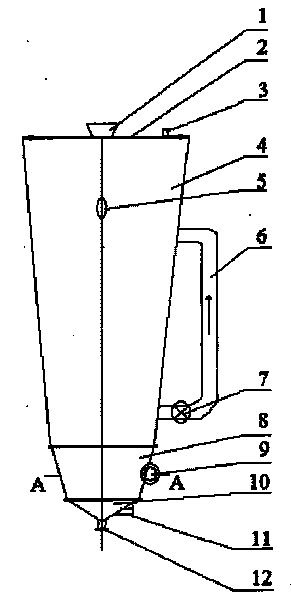

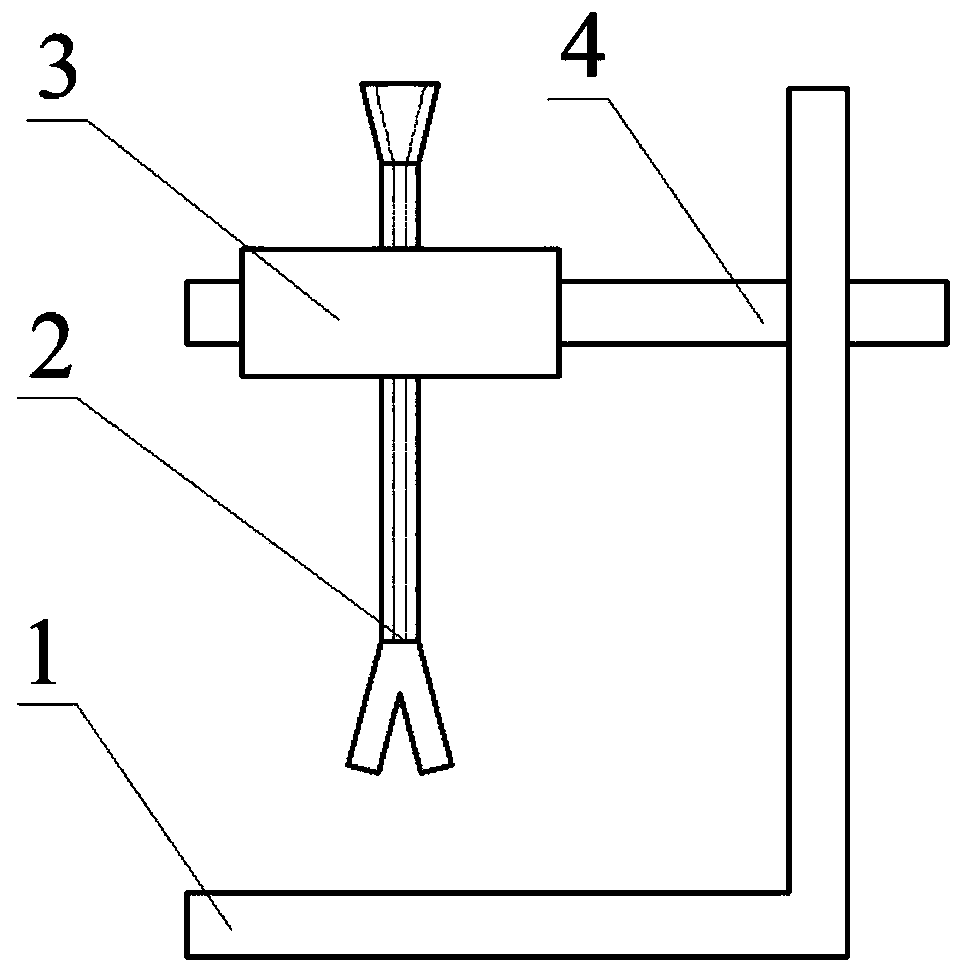

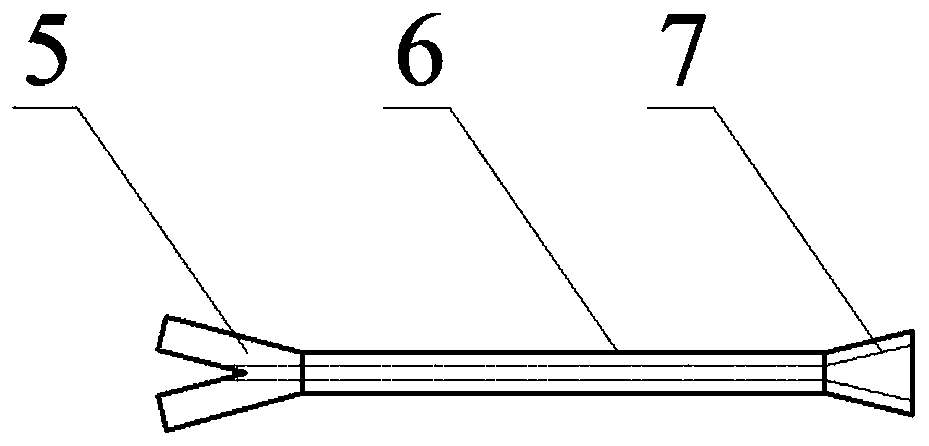

Leaching equipment

ActiveCN101721837AEffective shear agitationHeating up fastLiquid solutions solvent extractionGlass fiberEngineering

The invention relates to leaching equipment which adopts the technical scheme: the upper end of an upper cone (4) is fixedly connected with a cover plate (2), and a feeding hole (1) is arranged in the center of the cover plate (2); an observation hole (5) is arranged at the upper part of a shell of the upper cone (4), the shell of the upper cone (4) is provided with a circulating tube (6), the circulating tube (6) is communicated with an inner cavity of the upper cone (4), and a pipeline of the circulating tube (6) is connected with a water pump (7); and a steam inlet (9) is arranged on a shell of a lower cone (8), and a discharge hole (12) is fixedly installed at the conical top part of a bottom cone (10). The shells of the equipment are both made of high temperature resistance glass fiber reinforced plastics, each inner wall is coated with acid resistance coatings, bolt connection is respectively used between the cover plate (2) and the upper cone (4), between the upper cone (4) and the lower cone (8), and between the lower cone (8) and the bottom cone (10), and a sealing ring is respectively padded at each connecting part. The invention has the advantages of simple structure, high leaching efficiency and long service life and can satisfy the requirements of temperature resistance and acid resistance.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method for nano aluminum oxide reinforced highly wear-resistant liner plate

InactiveCN108754462AImprove high temperature resistanceLower activation energyLiquid/solution decomposition chemical coatingAlumina hydrateWear resistant

The invention discloses a preparation method for a nano aluminum oxide reinforced highly wear-resistant liner plate and belongs to the technical field of metal material preparation. Cerium oxide in ceramic powder components is the oxide with the strongest activity among rare earth oxides, which can reinforce the interaction of atomic orbital between the ceramic powder and molecules of a coated base casting in a compound plating solution, so that the high-temperature resistance of the wear-resistant liner plate is improved. When the compound plating solution is used for dip-coating a substrateplate, alumina hydrate particles in the compound plating solution adsorb surrounding metal ions to be positively charged and migrate to the surface of the substrate plate continuously under the actionof electrostatic attraction. When the alumina hydrate particles are in contact with the surface of the substrate plate, a high density aluminum oxide membrane with ultrafine grain sizes can reduce the Akron abrasion volume dose of the wear-resistant liner plate, so that the binding force between metal ceramic powder and the substrate plate can be improved by means of the nano aluminum oxide particles. The nano aluminum oxide particles are unlikely to peel off and keep a high density, and are unlikely to wear, so that the wear resistance of the wear-resistant liner plate is improved and the wear-resistant liner plate has a wide application prospect.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Preparation method of metal ceramic composite material

The invention discloses a preparation method of a metal ceramic composite material. The method comprises the following steps: (1) sequentially carrying out crushing, ultrasonic cleaning and drying onfoamed SiC ceramic according to the procedures of primary crushing, secondary crushing and tertiary crushing to obtain an ellipsoidal SiC ceramic block with the size of 2 mm to 15 mm; (2) carrying outpre-oxidation, pre-corrosion and cleaning on the ellipsoidal SiC ceramic block obtained in the step (1) to obtain a foamed SiC ceramic reinforcement; and (3) mixing the foamed SiC ceramic reinforcement obtained in the step (2) with metal, putting the mixture into a mold, performing heating and applying pressure in a nitrogen atmosphere, performing cooling, solidifying, demolding and polishing toobtain the metal ceramic composite material.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

Preparation method of formaldehyde adsorption material

PendingCN113600144ALarge specific surface areaImprove adhesionGas treatmentOther chemical processesSodium carboxymethylcellulosePoly ethylene

The invention relates to a preparation method of a formaldehyde adsorption material. The preparation method is characterized by comprising the following steps of: (1) placing silica gel powder in a plasma reaction chamber so as to treat the silica gel powder, and taking out the treated silica gel powder; (2) dissolving polyethyleneimine in deionized water, performing uniform dispersing, adding an amine source, and performing uniform dispersing, forming a mixed solution; (3) adding plasma-treated silica gel powder into the mixed solution, performing dipping, dispersing and filtering, taking the effectively dipped silica gel powder, and drying the powder to obtain silica gel powder with the formaldehyde adsorption function; and (4) mixing the silica gel powder obtained in the step (3) with carboxymethyl cellulose and water, granulating and drying to obtain silica gel particles. The hydrophilic performance of the silica gel particles treated by the plasma is enhanced, and more ethylene urea can be loaded in the solution dipping process. Due to the existence of surface electrons, the amine source can be uniformly distributed inside and on the surface of silica gel channels during loading, and the formaldehyde adsorption performance of the material is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Casting anti-friction and abrasion-resistant high aluminum zinc-based composite material and preparation method thereof

The invention relates to a casting anti-friction and abrasion-resistant high aluminum zinc-based composite material and a preparation method thereof. The technical scheme is that the composite material takes zinc and aluminum as the base, and takes copper and magnesium as main alloy elements; trace alloy elements of strontium, titanium, boron, rare earth lanthanum and the like, and micron siliconcarbide and micron graphite non-metallic ceramic reinforcement particles are added, smelting is carried out, and thus substrate molten liquid is obtained; and the substrate molten solution is subjected to the deep processing technology of powder spraying, stirring and ultrasonic combined treatment so that the silicon carbide particles with abrasion-resistant performance and the graphite particleswith anti-friction performance can be well immersed in the substrate molten liquid and be uniformly dispersed and distributed in the composite material accordingly, and thus the fine-grained casting anti-friction and abrasion-resistant high aluminum zinc-based composite material obtained. The casting anti-friction and abrasion-resistant high aluminum zinc-based composite material has the characteristics of simple technology and low preparation cost. The reinforcement particles of the prepared product are uniformly distributed, and the composite material are excellent in plasticity, toughness and abrasion resistance, and stable in quality.

Owner:WUHAN UNIV OF SCI & TECH

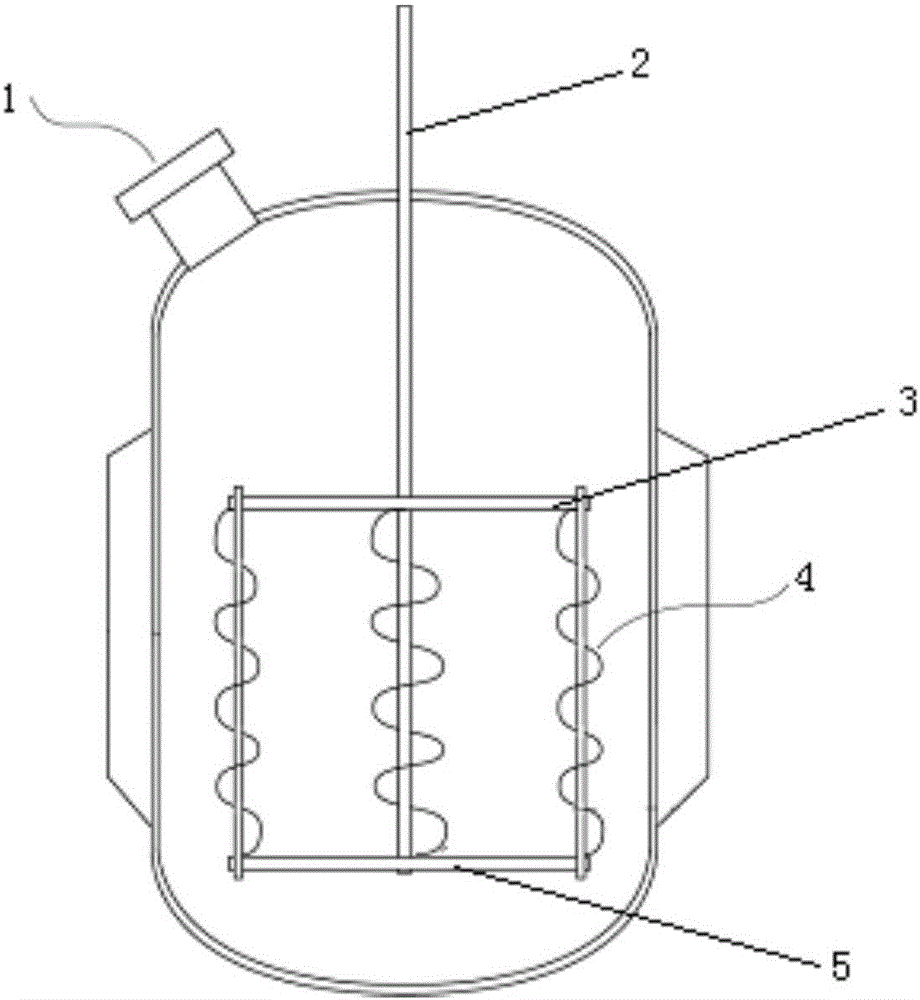

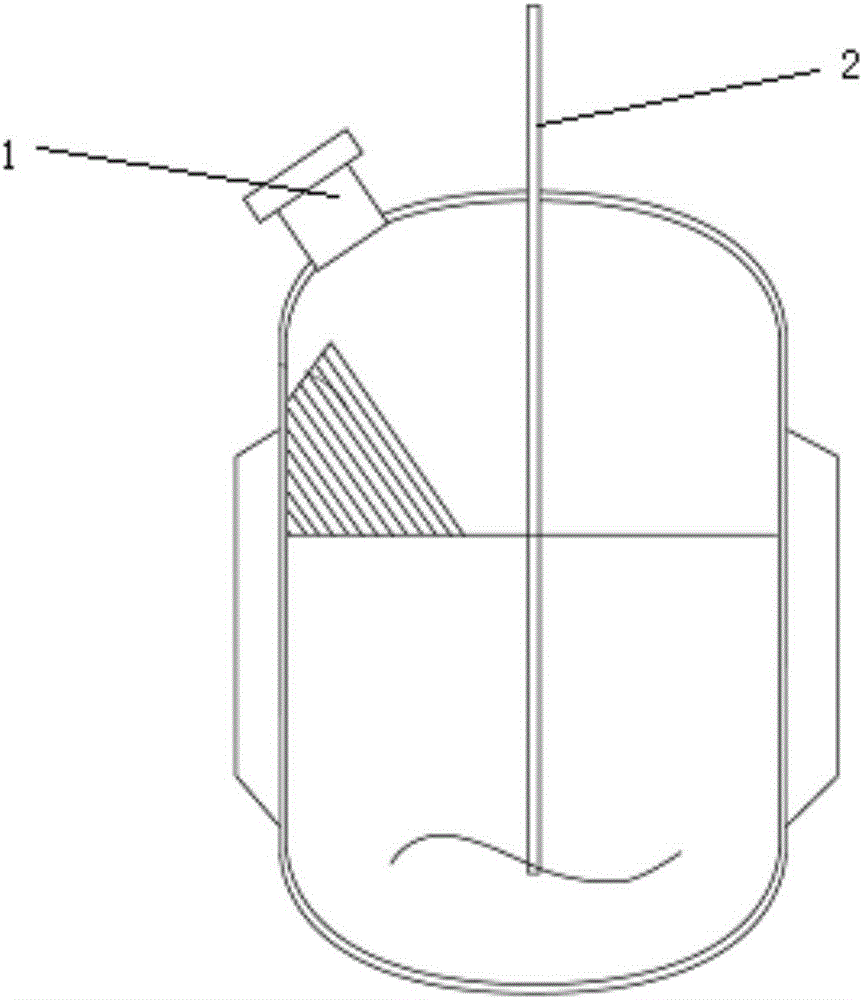

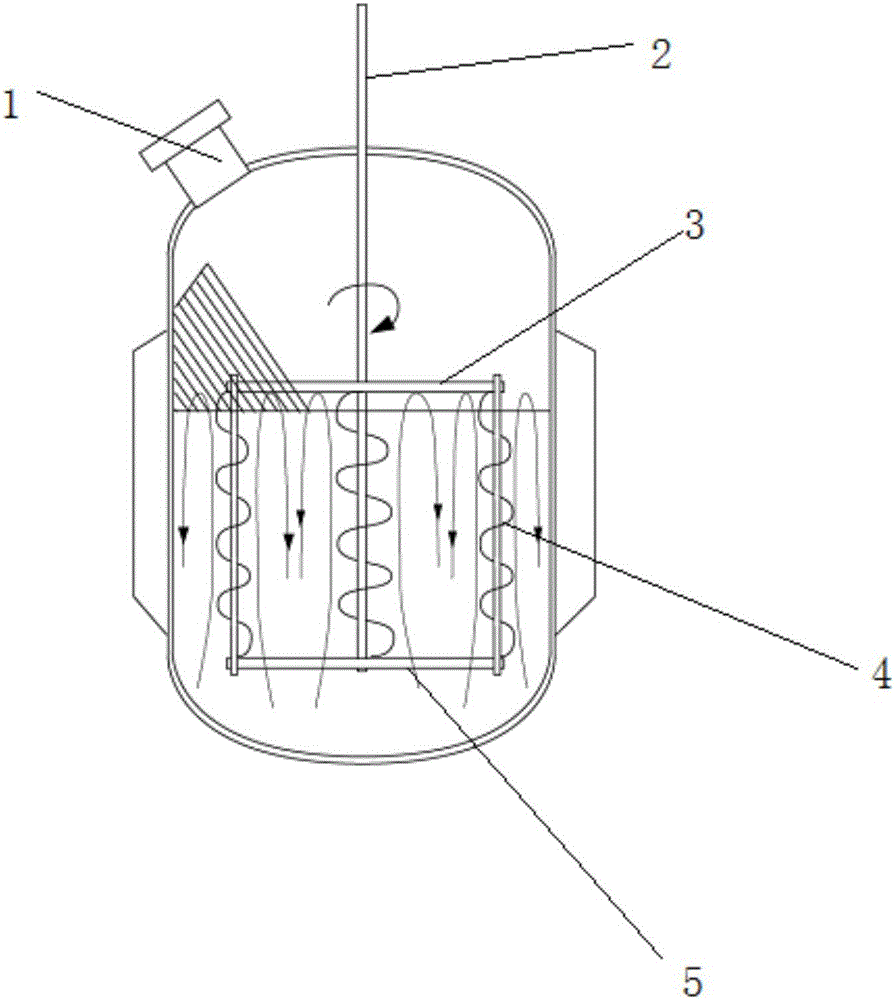

Reactor preventing accumulation of solid material

InactiveCN106179165AEliminate potential safety hazardsStir wellChemical/physical/physico-chemical stationary reactorsInterfacial reactionEngineering

The invention provides a reactor preventing accumulation of solid material, comprising a body and a stirrer; the top of the body is provided with a feed port; the stirrer includes a stirring bar, the top end of the stirring bar extends out of the top of the body and connects with a handle, the lower middle of the stirring bar is provided with a fixture, a plurality of releasable belt spiral stirring blades are evenly arranged on the fixture, and the length directions of the belt spiral stirring blades are parallel to that of the stirring bar. The stirrer according to the invention can provide top-bottom and circular stereoscopic circulation in reaction liquid so that materials are quickly merged in the reaction liquid, safety hazards are eliminated, and sufficient stirring can be provided to promote interfacial reaction and improve efficiency.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

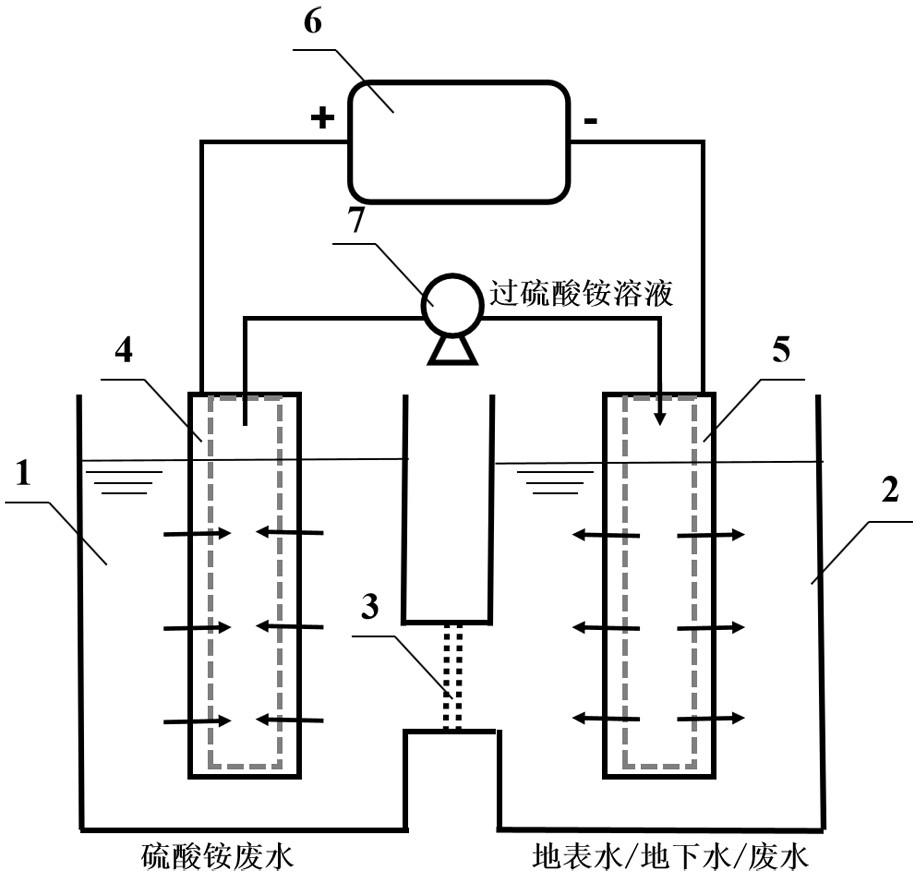

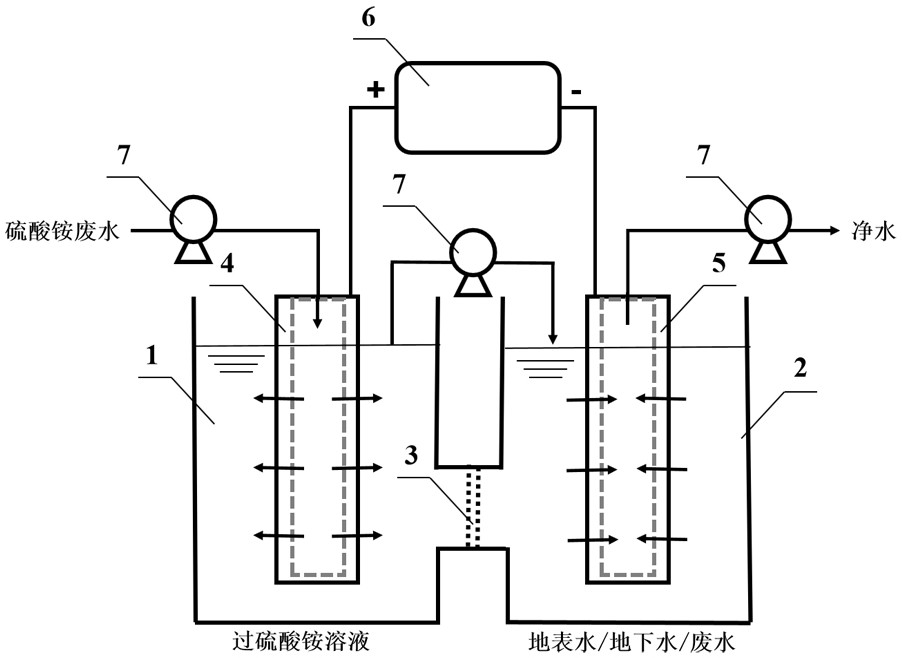

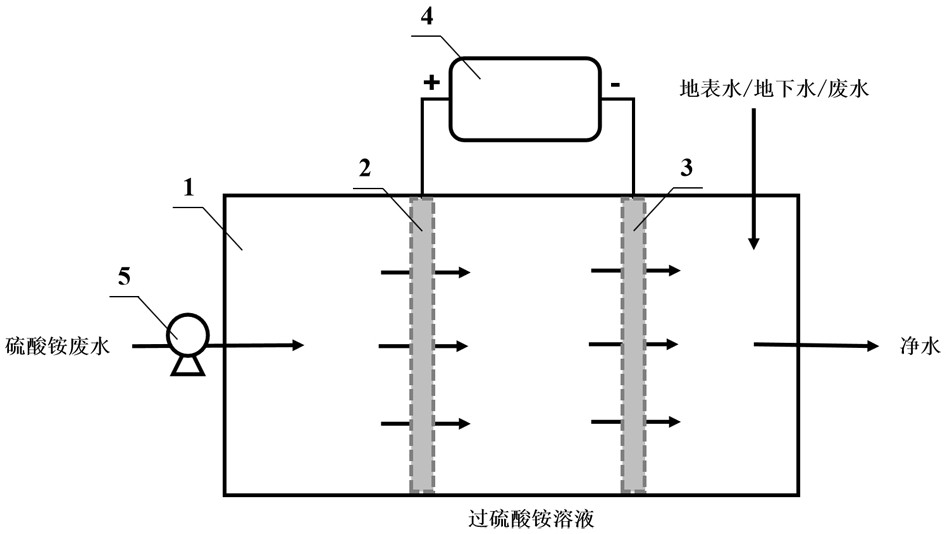

Device and method for synchronous electrolysis/membrane separating/advanced oxidation cooperative treatment of ammonium sulfate-containing wastewater and organic wastewater

PendingCN112321034AIncrease profitFacilitate interface reactionWater contaminantsWater/sewage treatment bu osmosis/dialysisAmmonium sulfateEnvironmental chemistry

The invention discloses a device and method for synchronous electrolysis / membrane separating / advanced oxidation cooperative treatment of ammonium sulfate-containing wastewater and organic wastewater,the device comprises an ammonium sulfate wastewater treatment chamber, an organic wastewater treatment chamber, an anode membrane electrode, a cathode membrane electrode and a power supply system, themethod comprises the following steps: the ammonium sulfate-containing organic wastewater is introducedinto the ammonium sulfate wastewater treatment chamber; large-particle suspended substances in the wastewater are intercepted under the action of membrane separating, organic matters in the wastewater are removed through interception, direct oxidation and indirect oxidation under the synergisticaction of membrane separating and anodic oxidation, and ammonium sulfate in the wastewater is electrolyzed on the surface of the anode membrane electrode and in pore passages to generate ammonium persulfate; then, the ammonium persulfate solution is electrically activated on the surface of the cathode membrane electrode and in pore channels to generate free radicals such as SO4. <-> and.OH, so that the organic matters in the wastewater are subjected to multiple treatment such as free radical oxidation, electrochemical oxidation reduction and membrane separating to obtain purified water.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com