Patents

Literature

139results about How to "Elimination content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

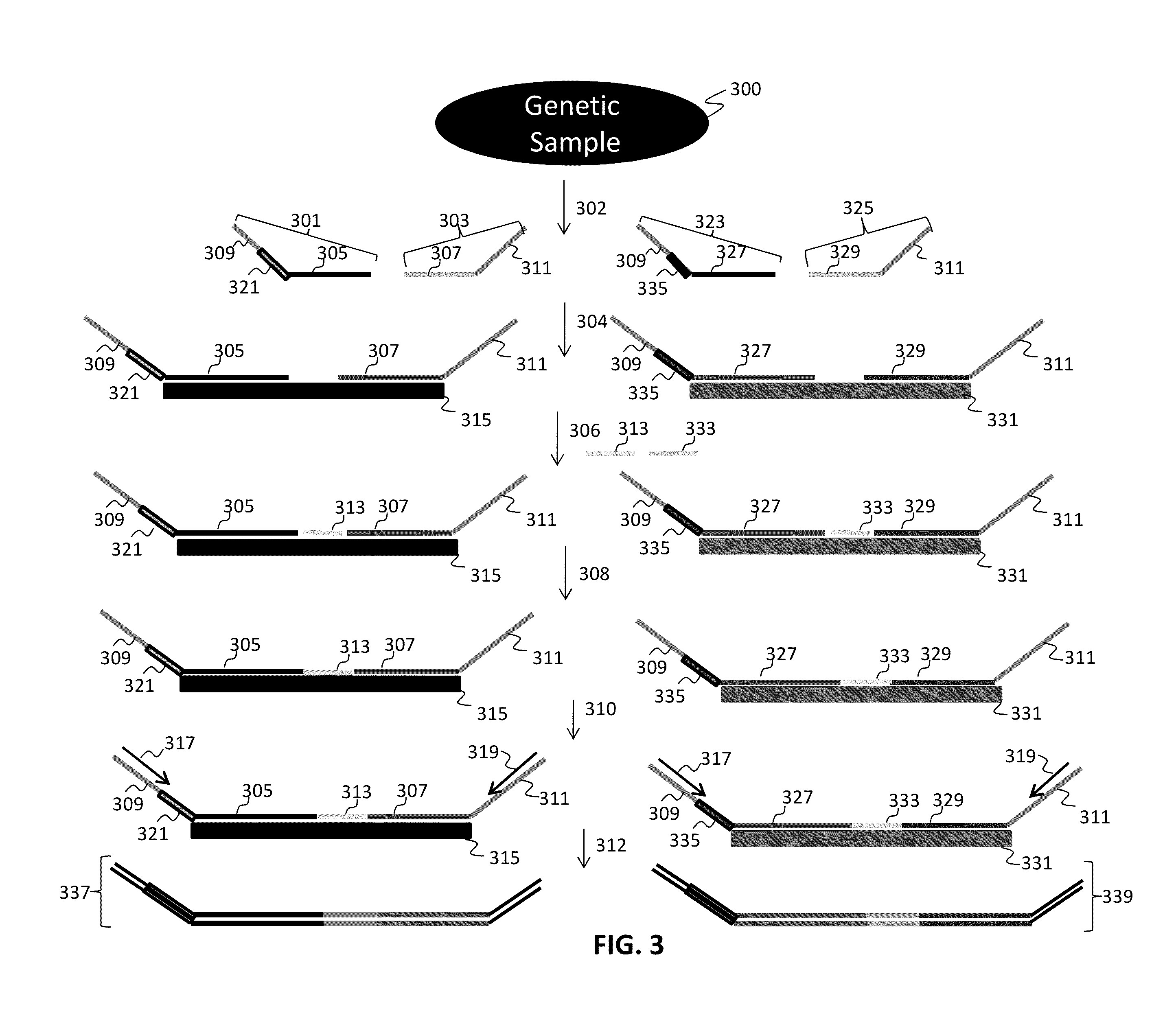

Ligation-based detection of genetic variants

InactiveUS20120034603A1Eliminate needElimination contentMicrobiological testing/measurementGeneticsOligonucleotide

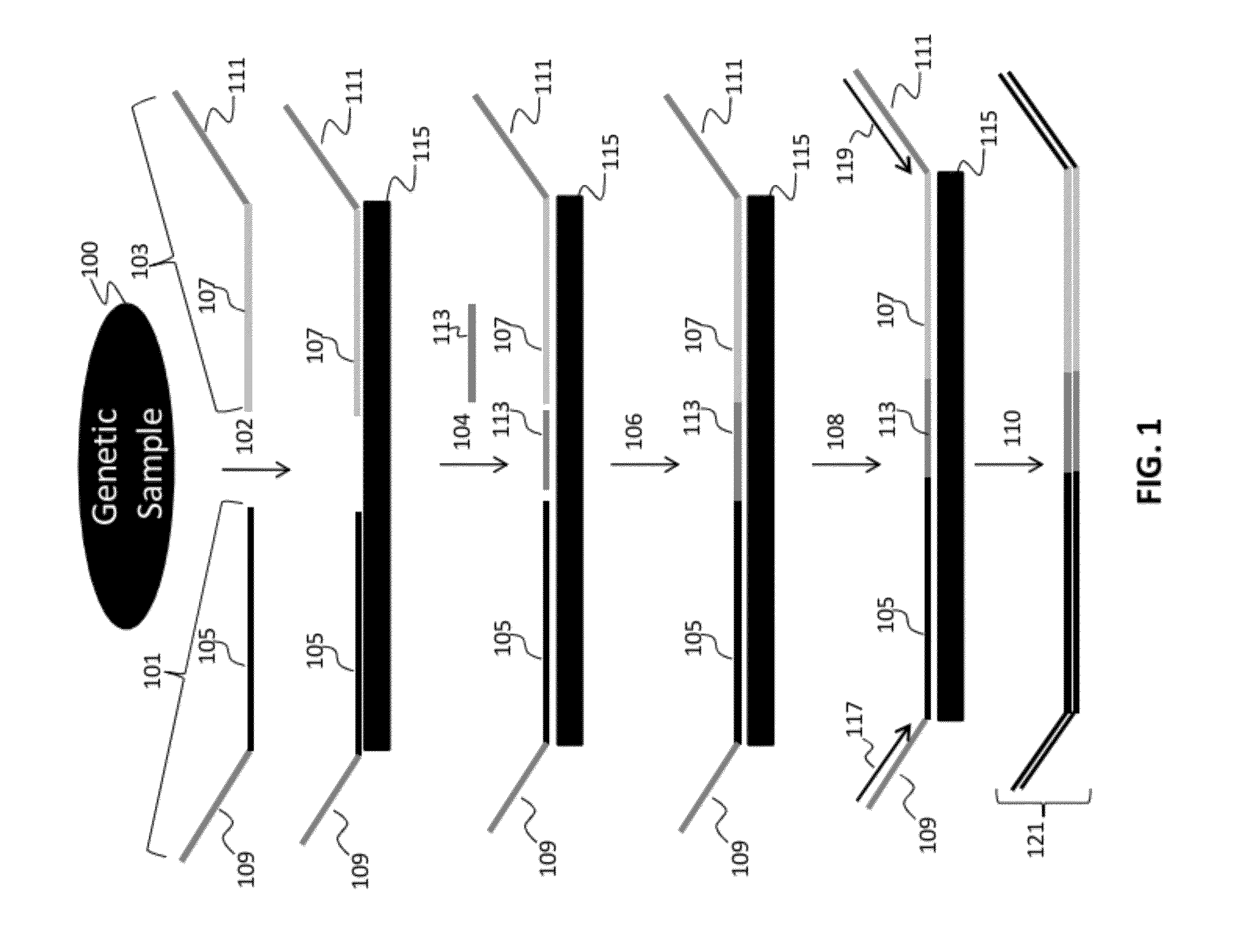

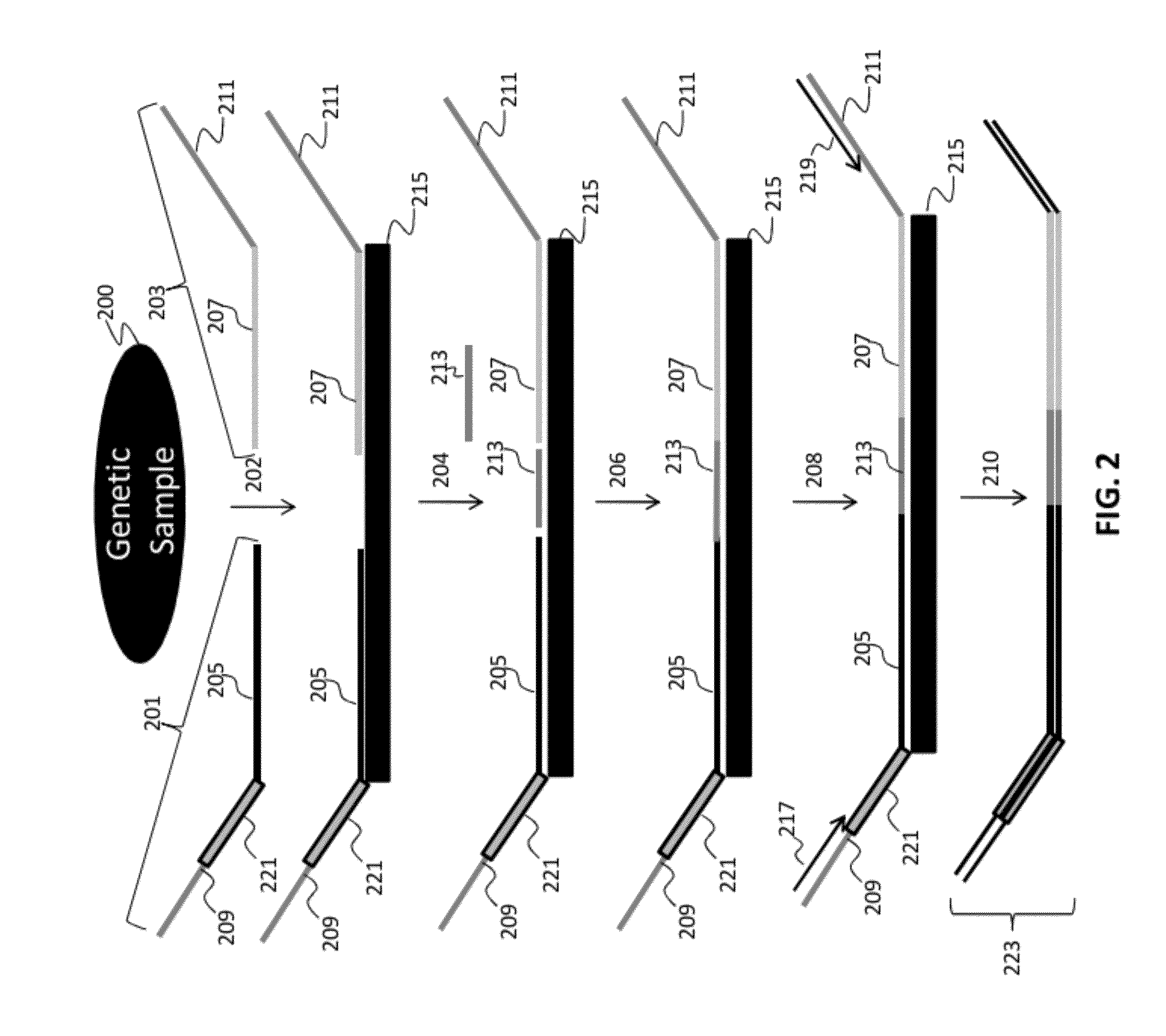

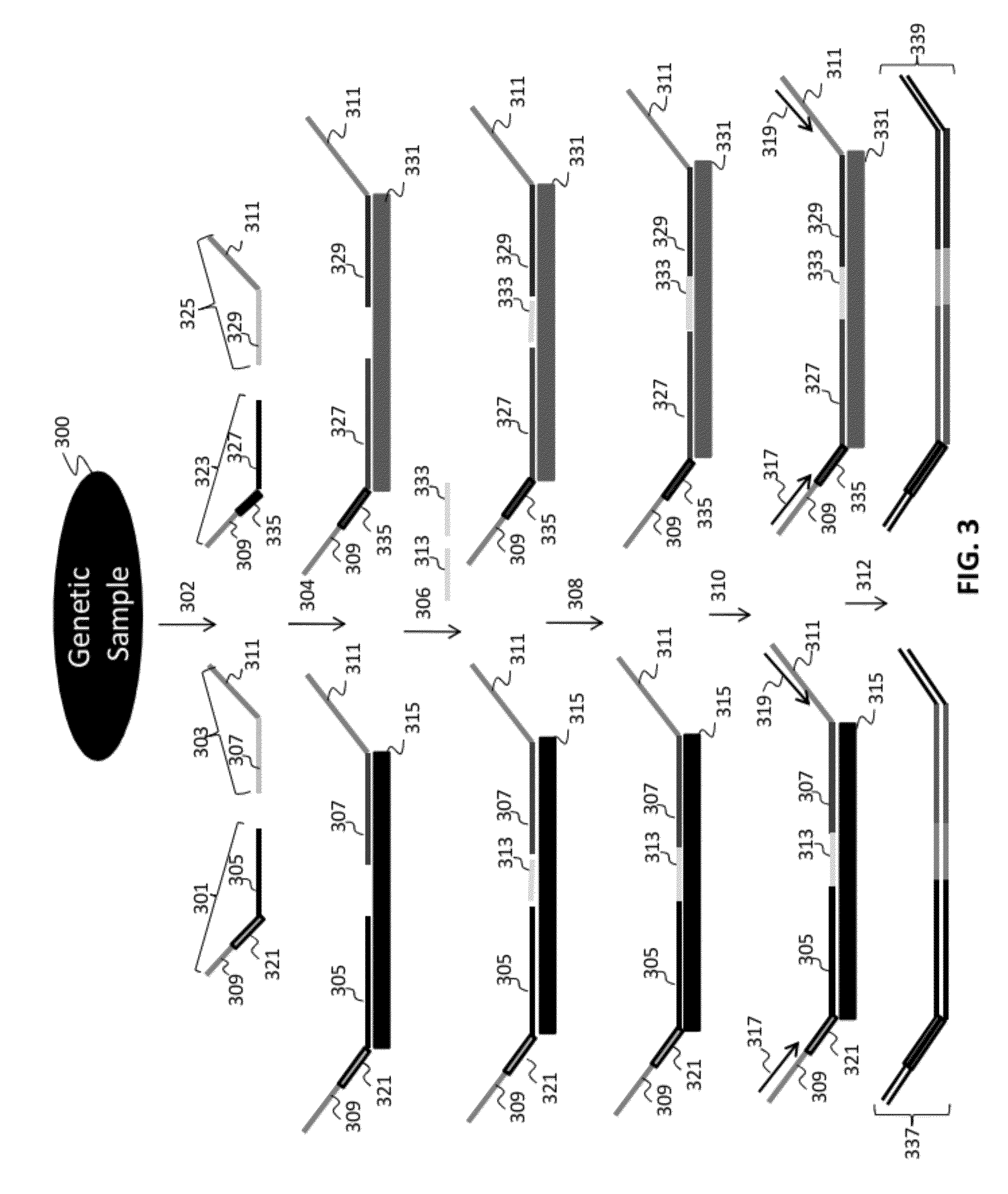

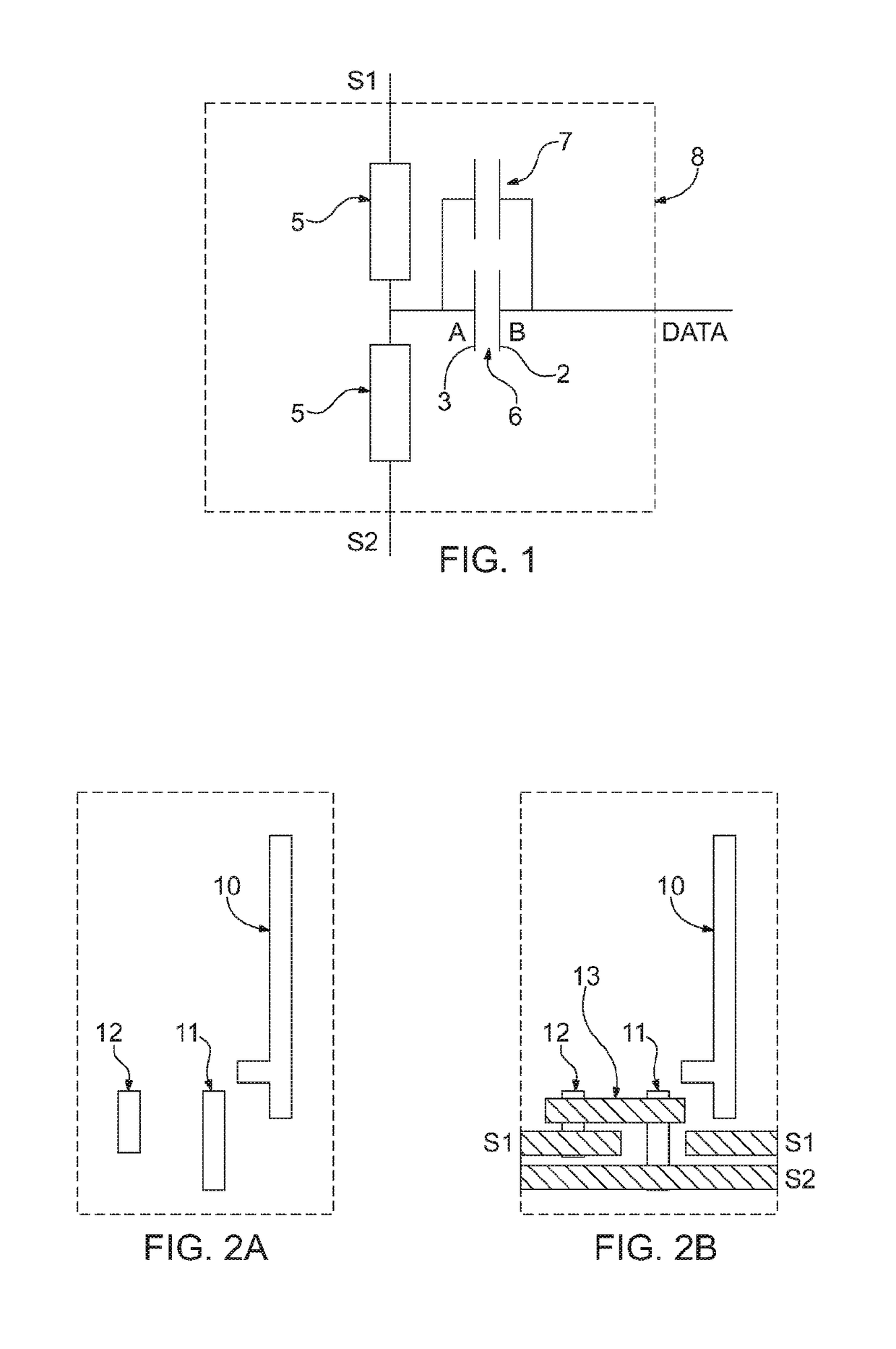

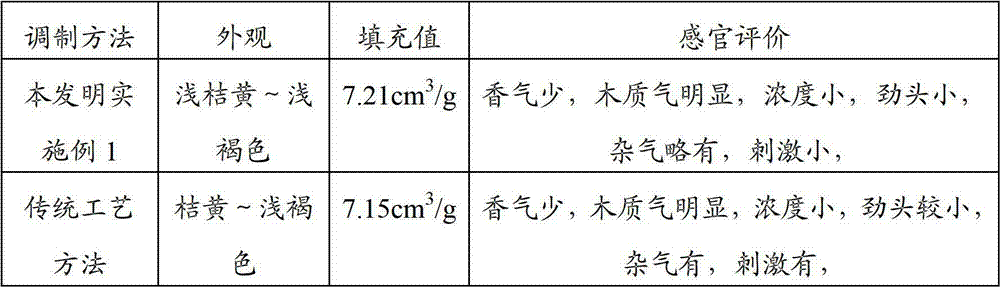

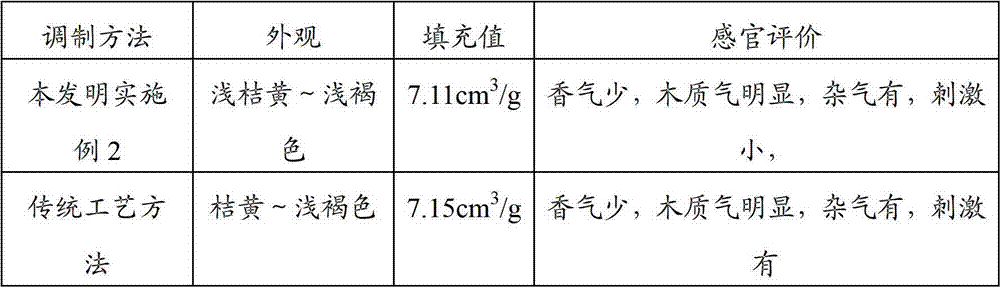

The present invention provides assays systems and methods for detection of genetic variants in a sample, including copy number variation and single nucleotide polymorphisms. The invention preferably employs the technique of tandem ligation, i.e. the ligation of two or more fixed sequence oligonucleotides and one or more bridging oligonucleotides complementary to a region between the fixed sequence oligonucleotides.

Owner:TANDEM DIAGNOSTICS

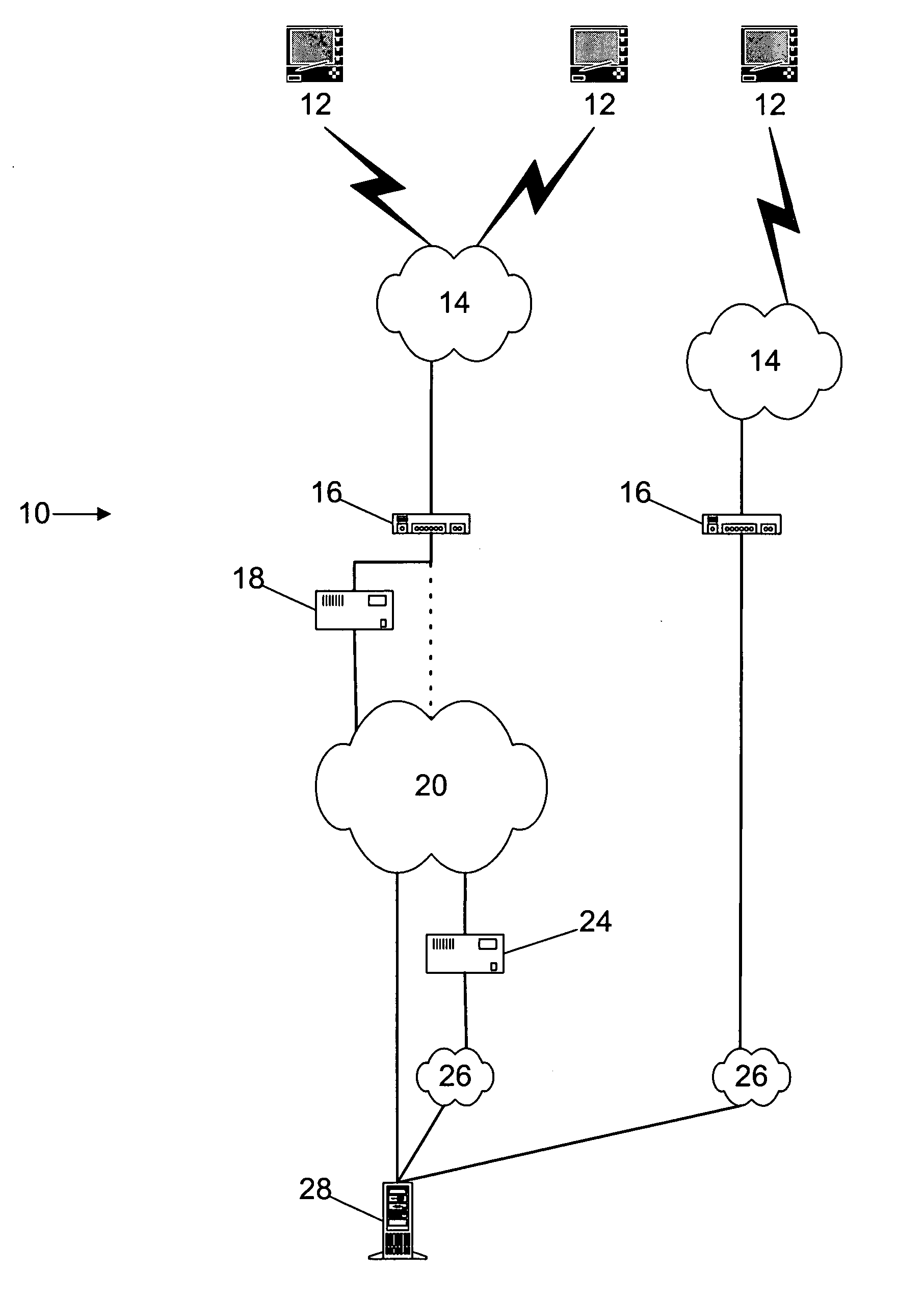

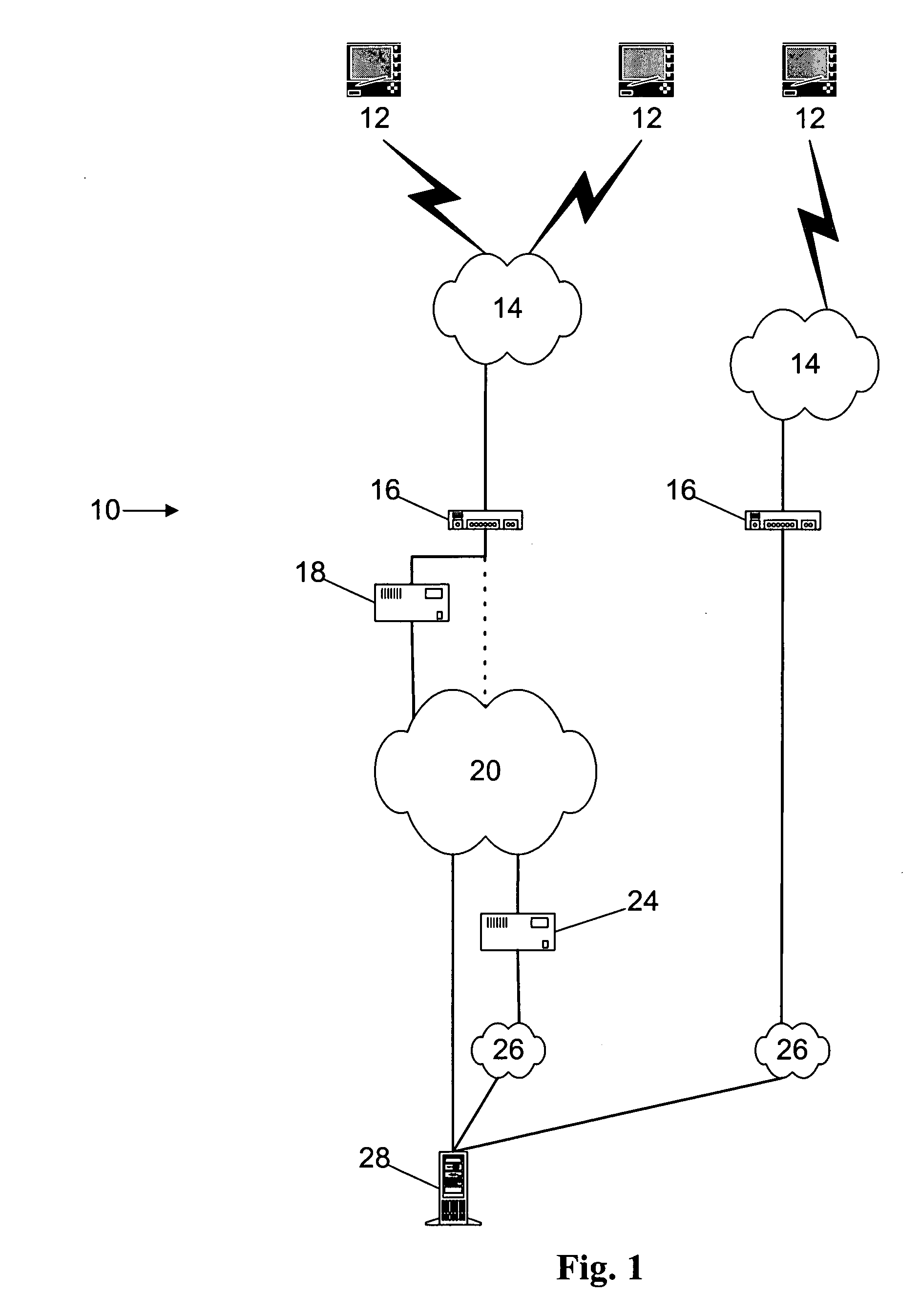

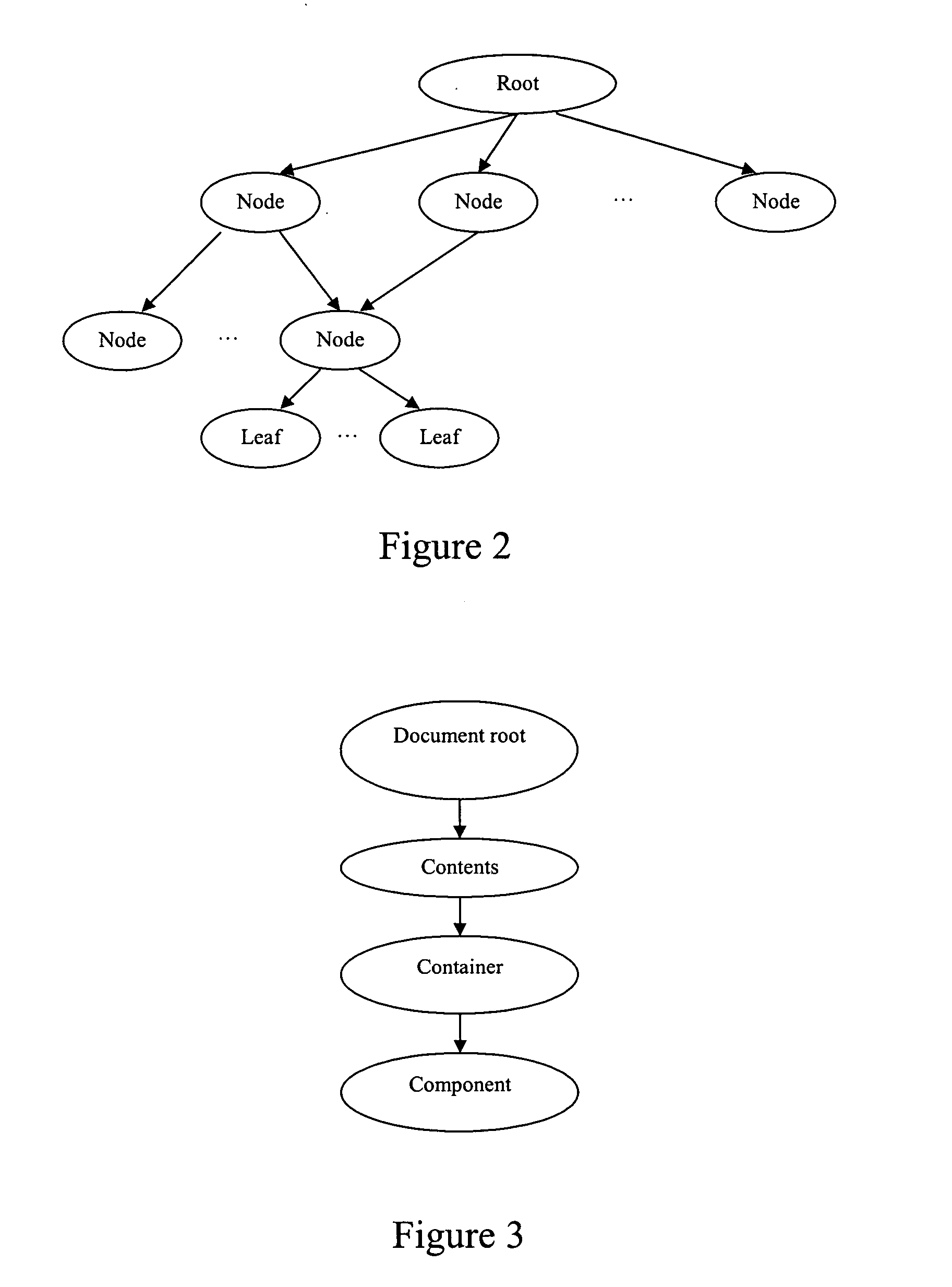

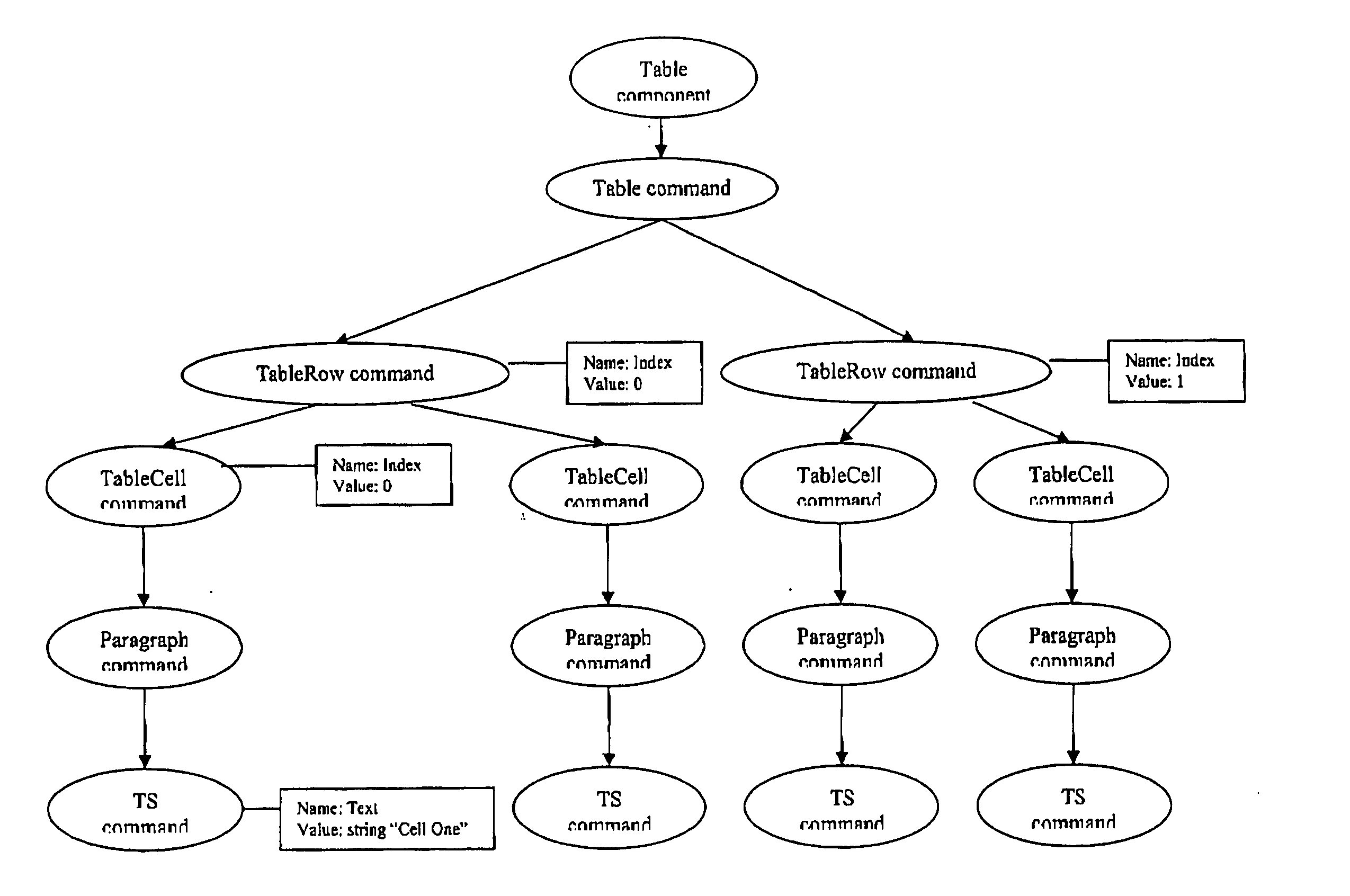

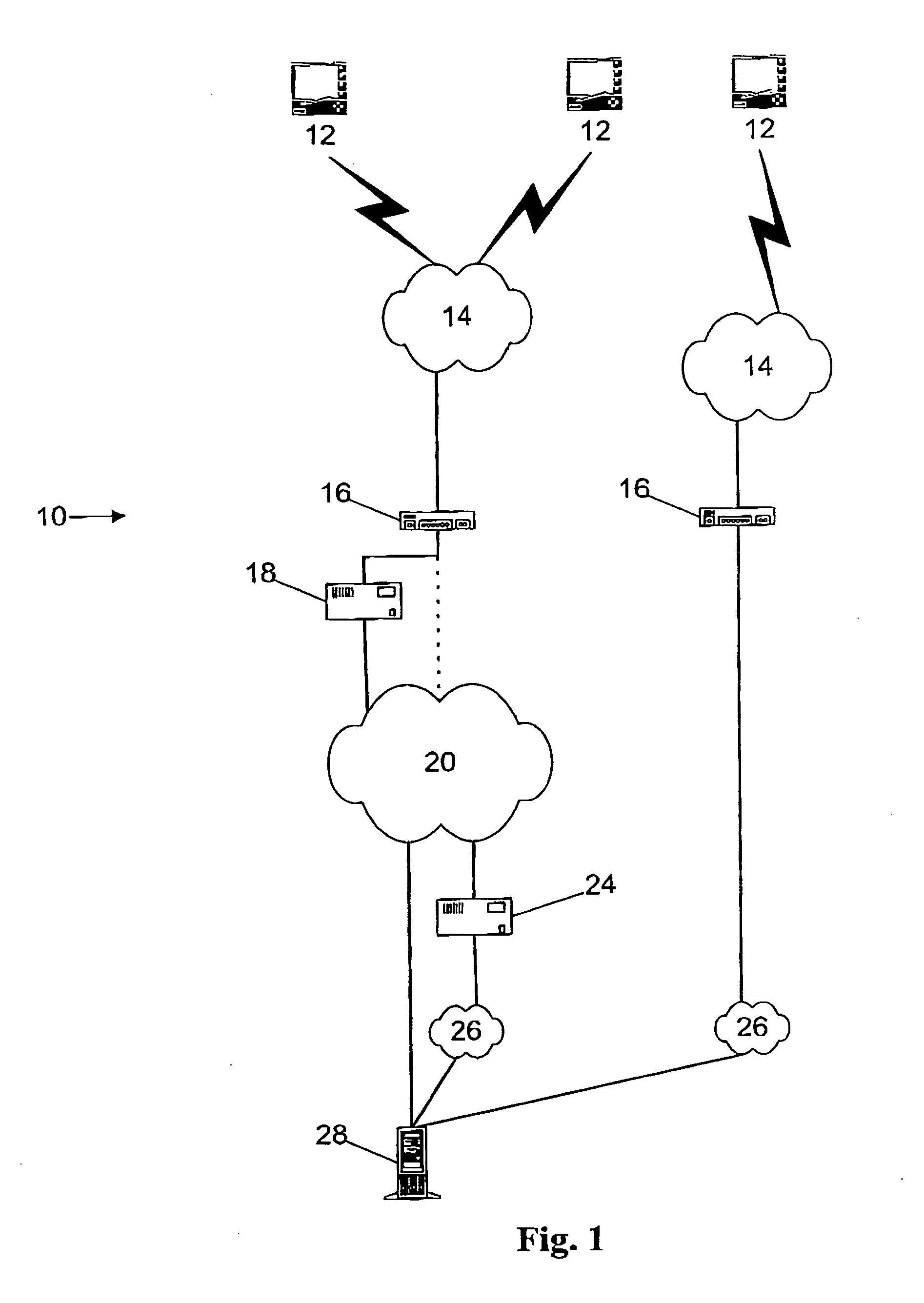

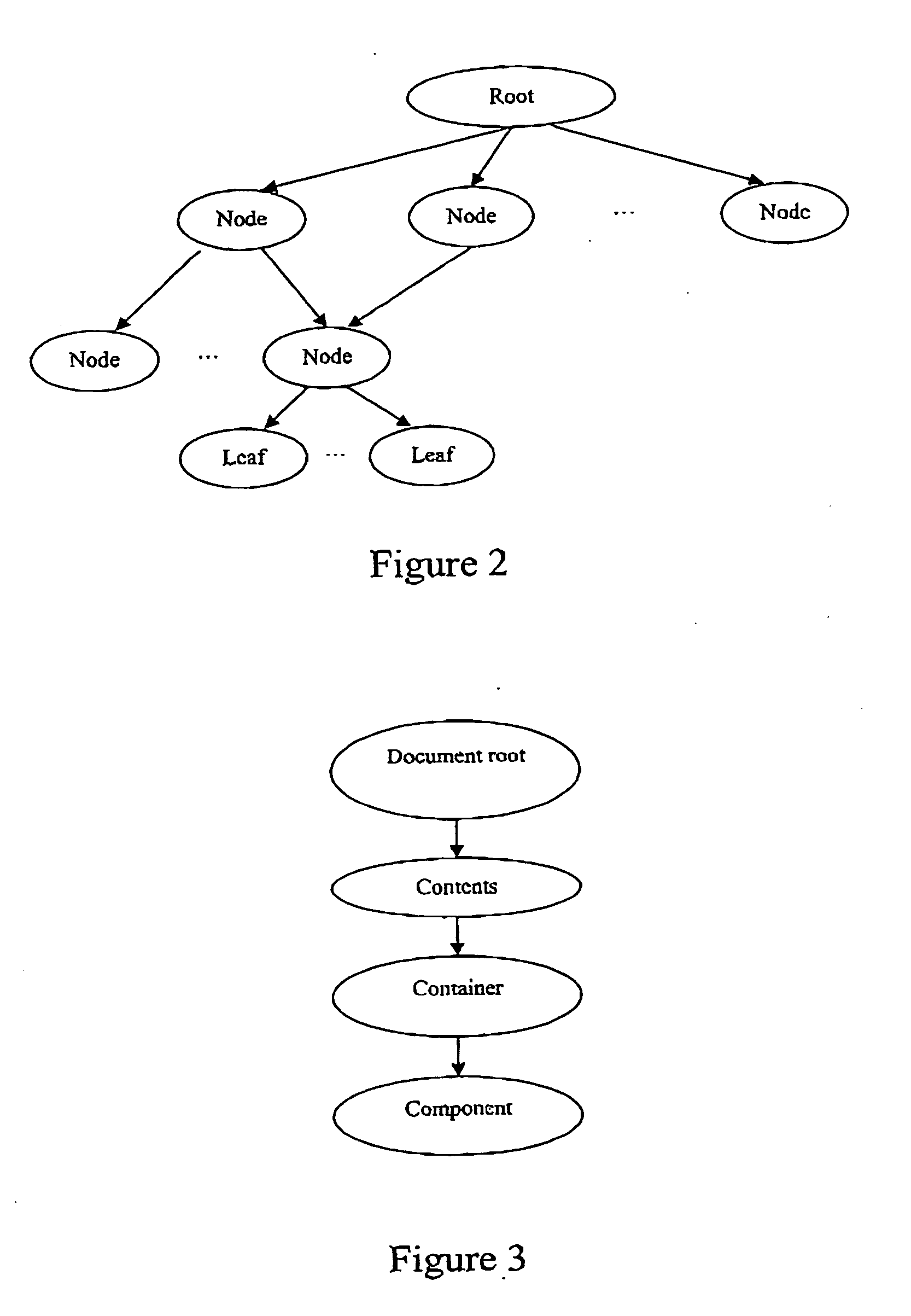

Method for paginating a document structure of a document for viewing on a mobile communication device

ActiveUS20060056334A1Bandwidth minimizedMinimize consumptionDigital data information retrievalNatural language data processingGraphicsPaper document

A process for transmitting a document from a server to a mobile device on a per page basis, comprising building a graph structure within the server representing a map of the document, transmitting a page size limit from the mobile device to the server indicative of the size of a single page of the document to be displayed by the mobile device, traversing and paginating the graph structure into successive pages based on the page size limit, caching the pages within the server, and transmitting the successive pages from the server to said the mobile device for display by said the mobile device.

Owner:MALIKIE INNOVATIONS LTD

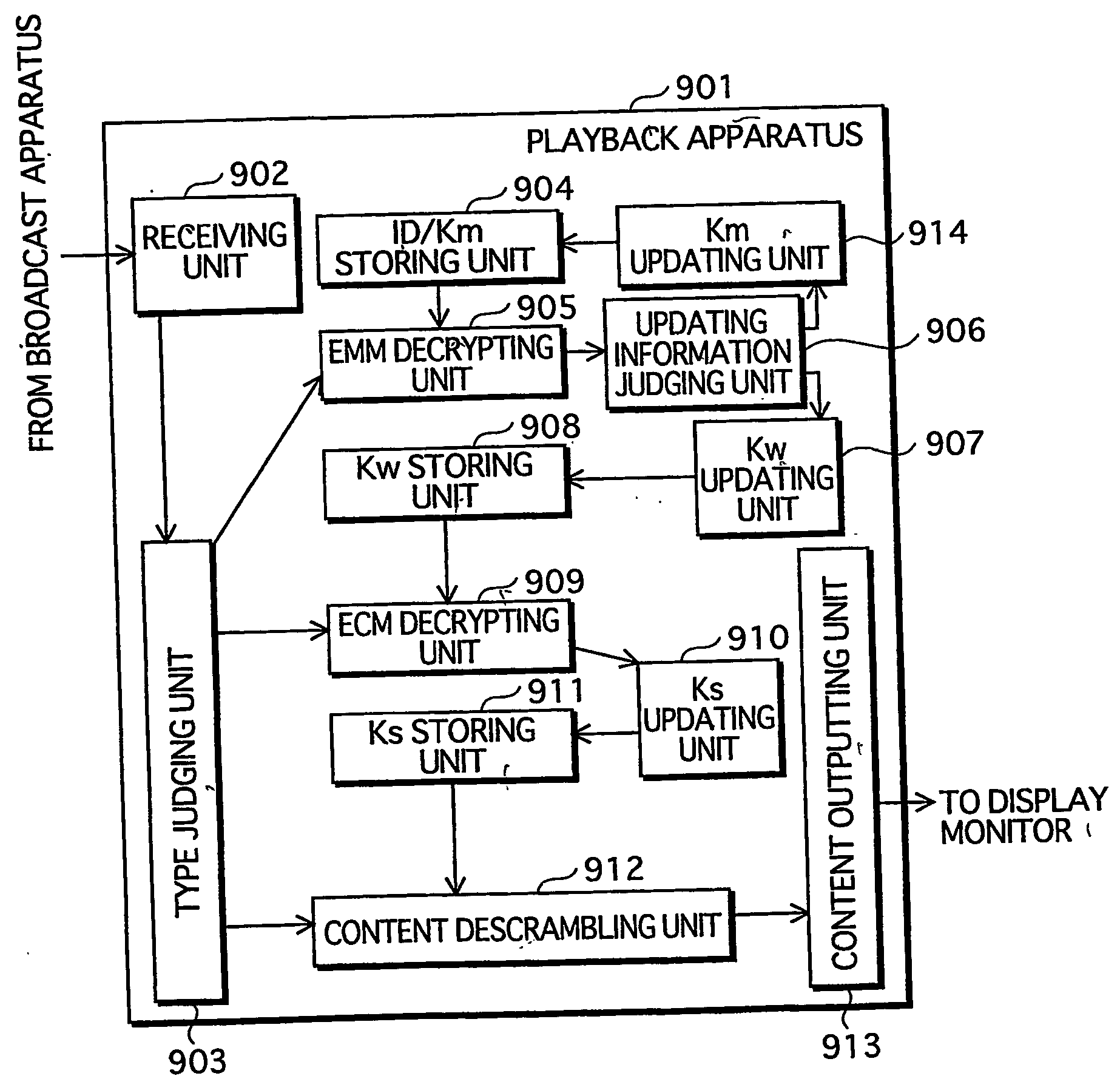

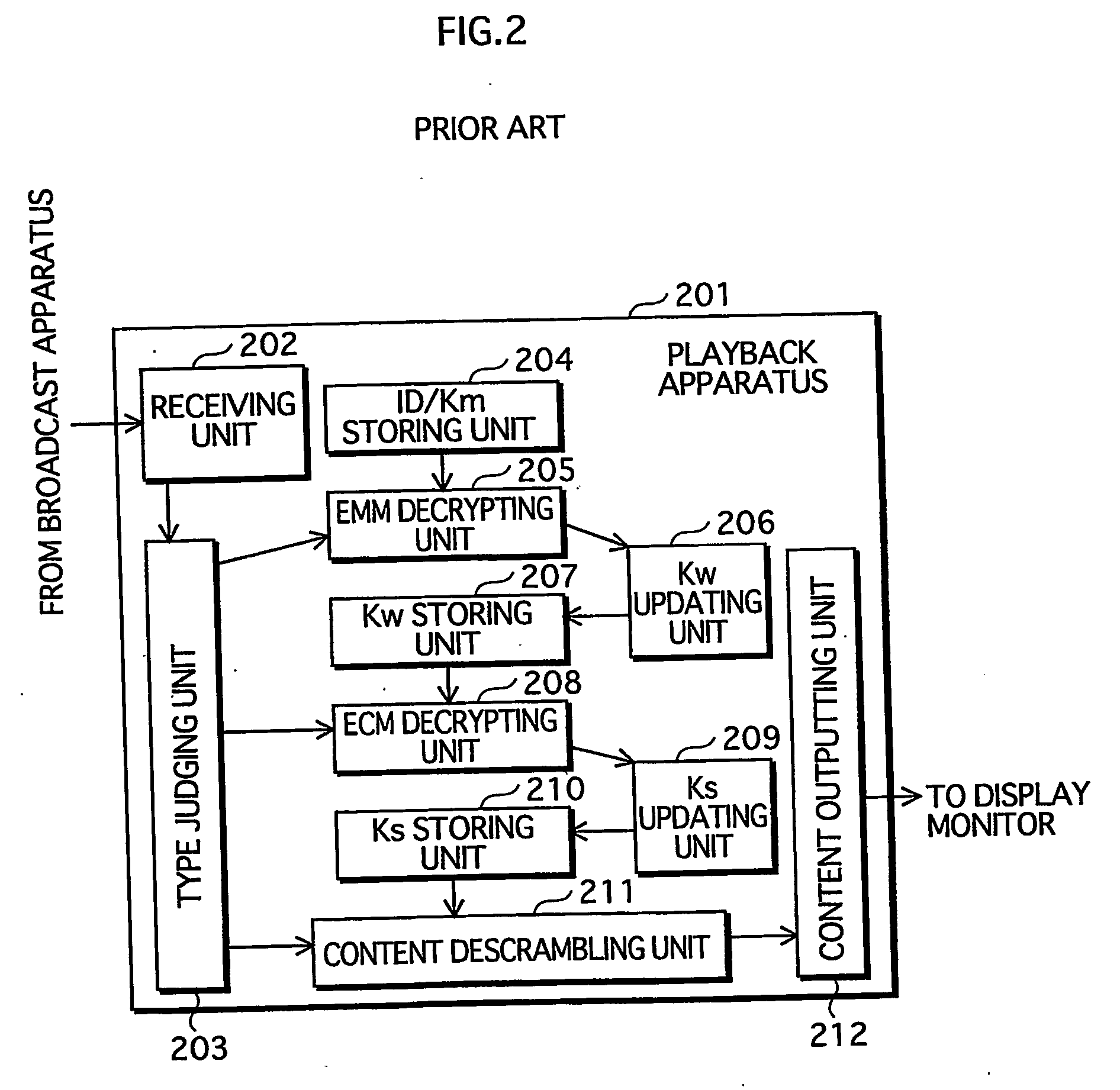

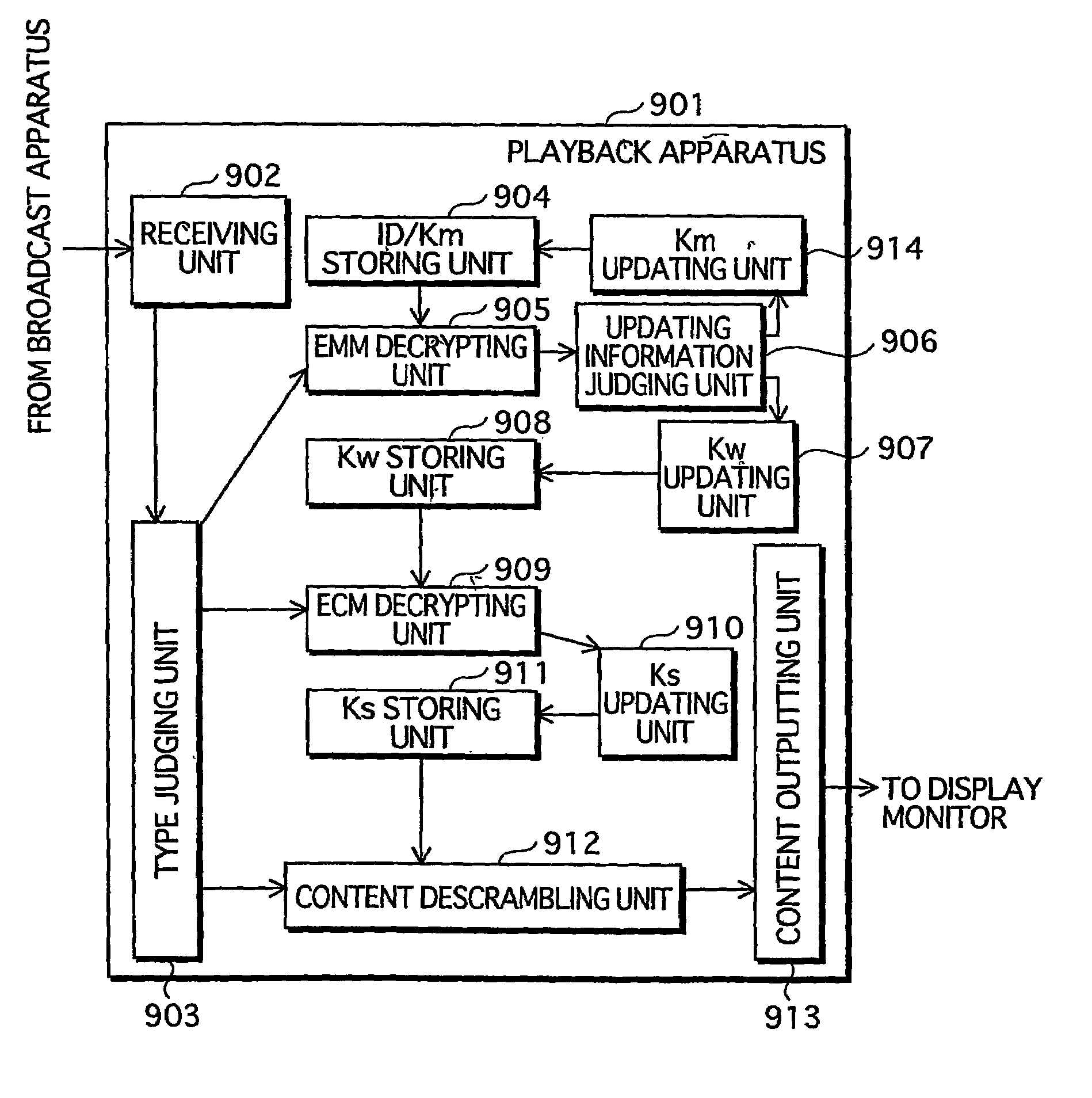

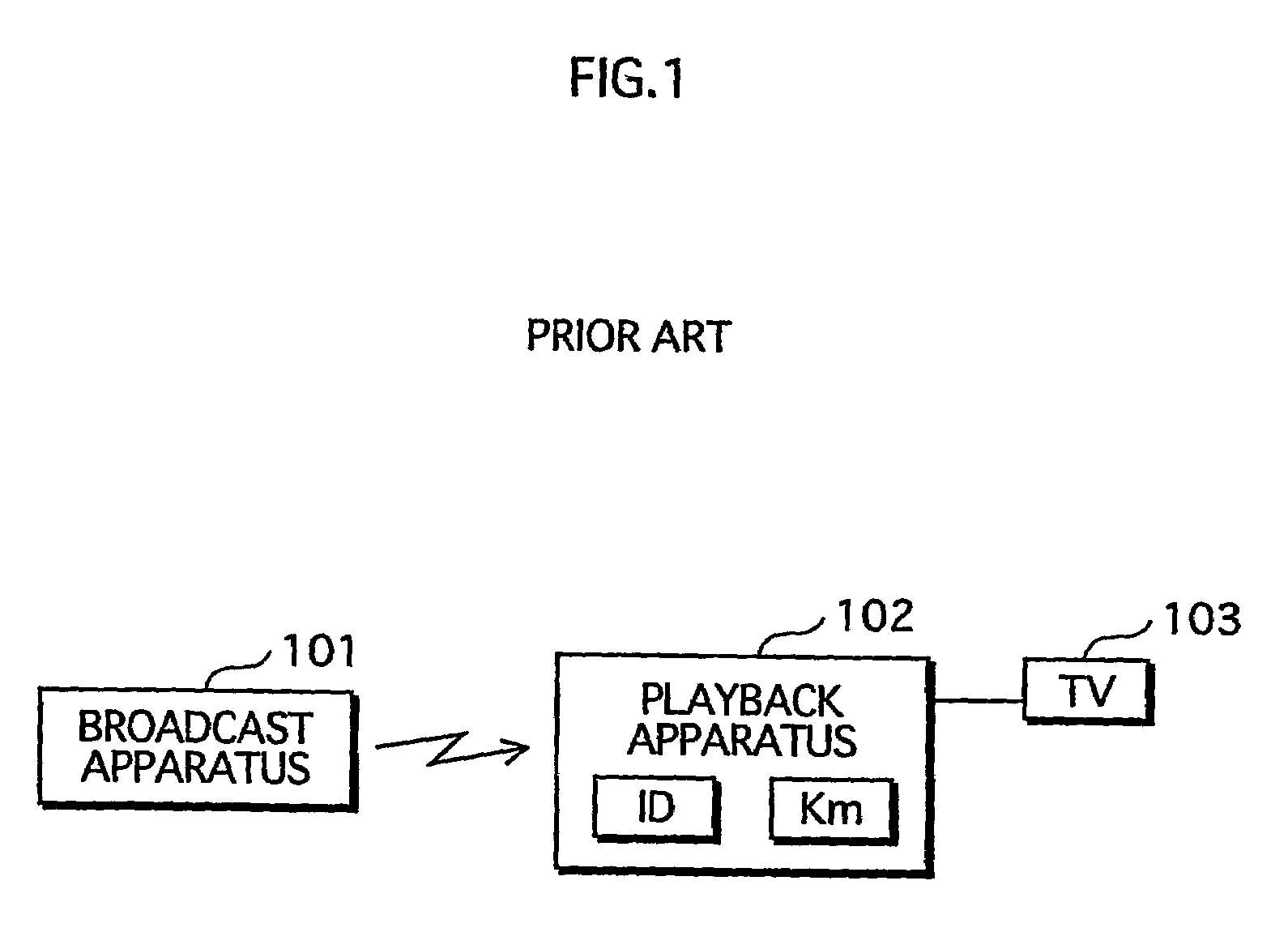

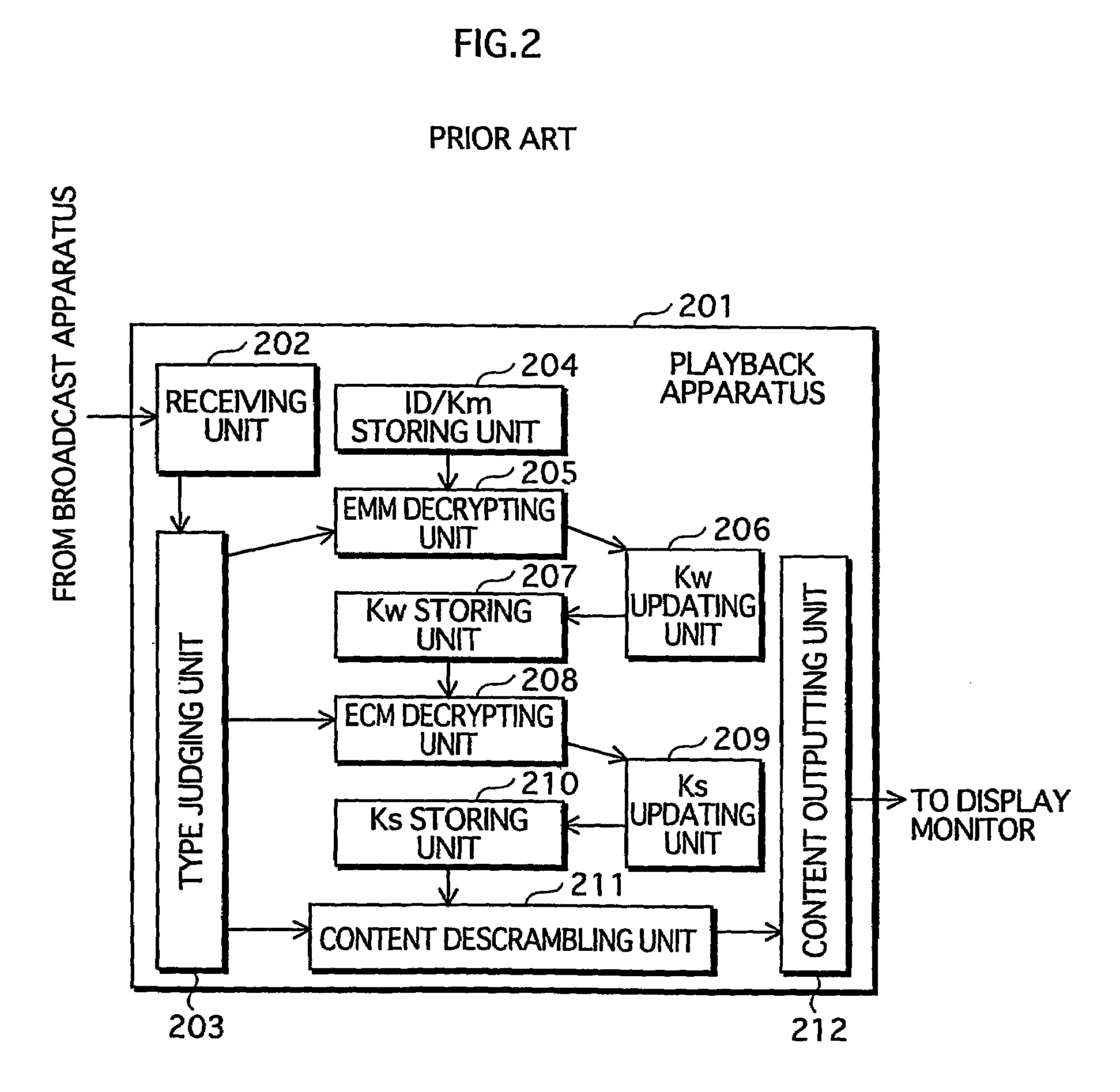

Content playback apparatus method and program and key management apparatus and system

InactiveUS20050021985A1Elimination contentTelevision system detailsKey distribution for secure communicationComputer hardwareKey management

Owner:SOVEREIGN PEAK VENTURES LLC

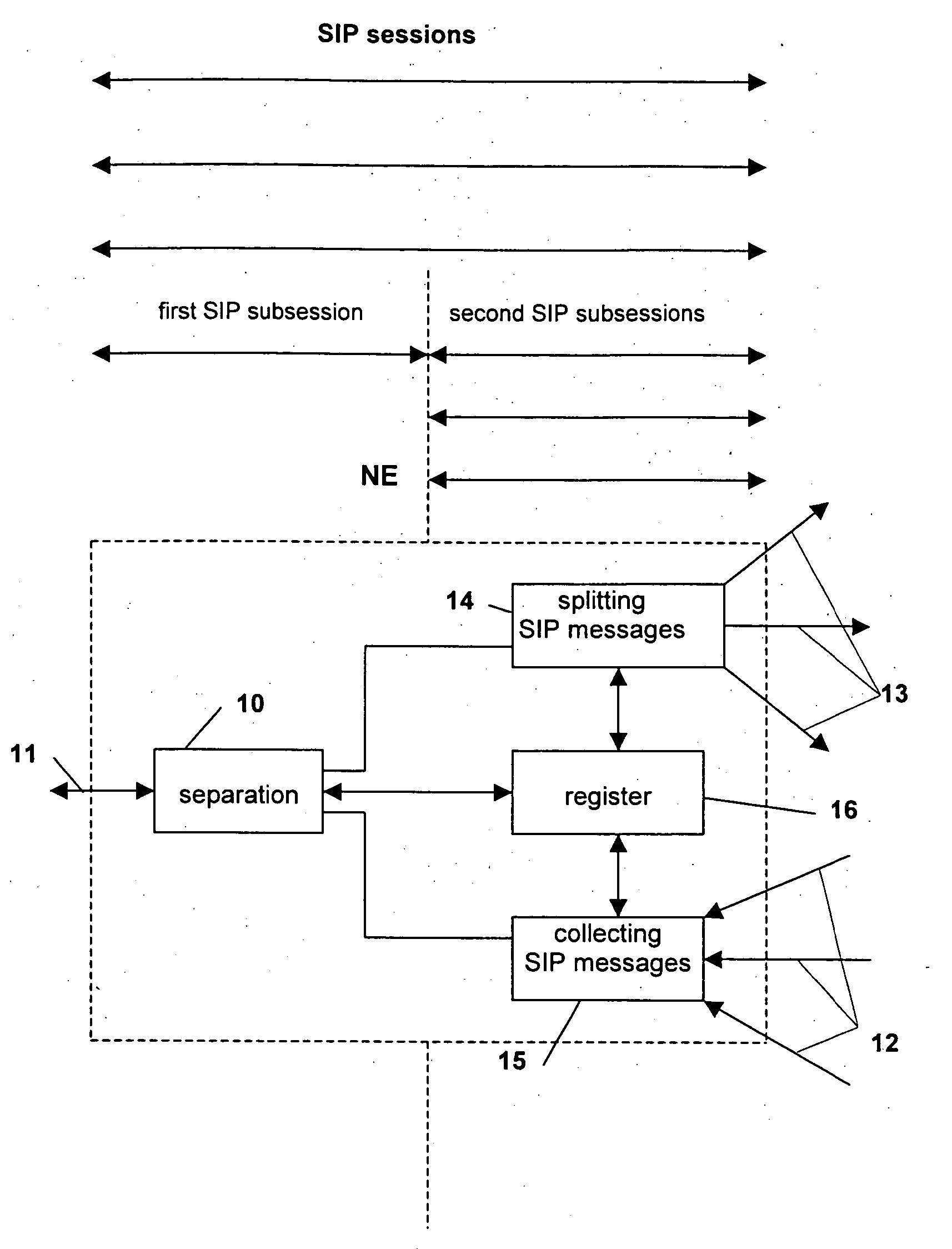

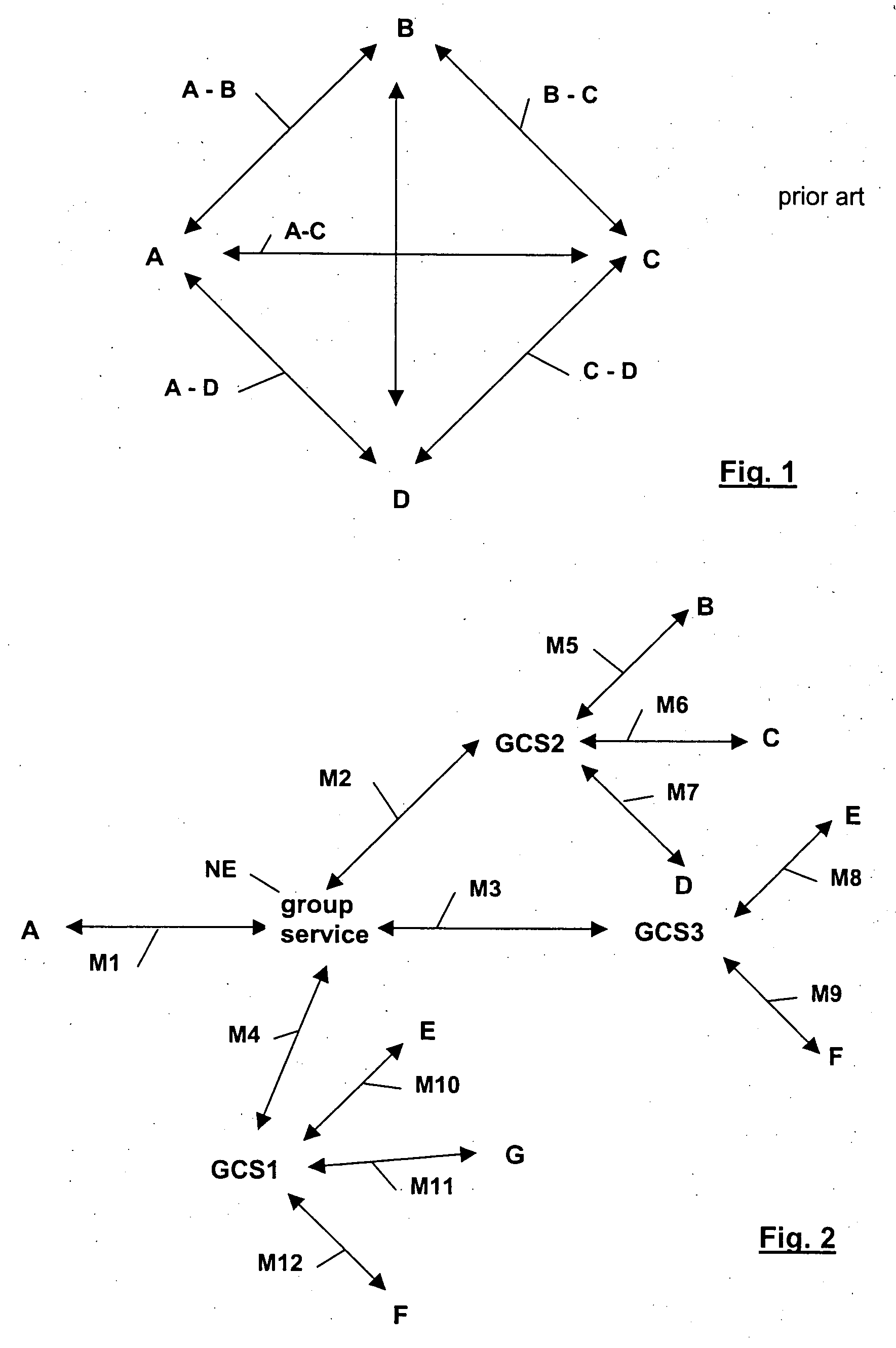

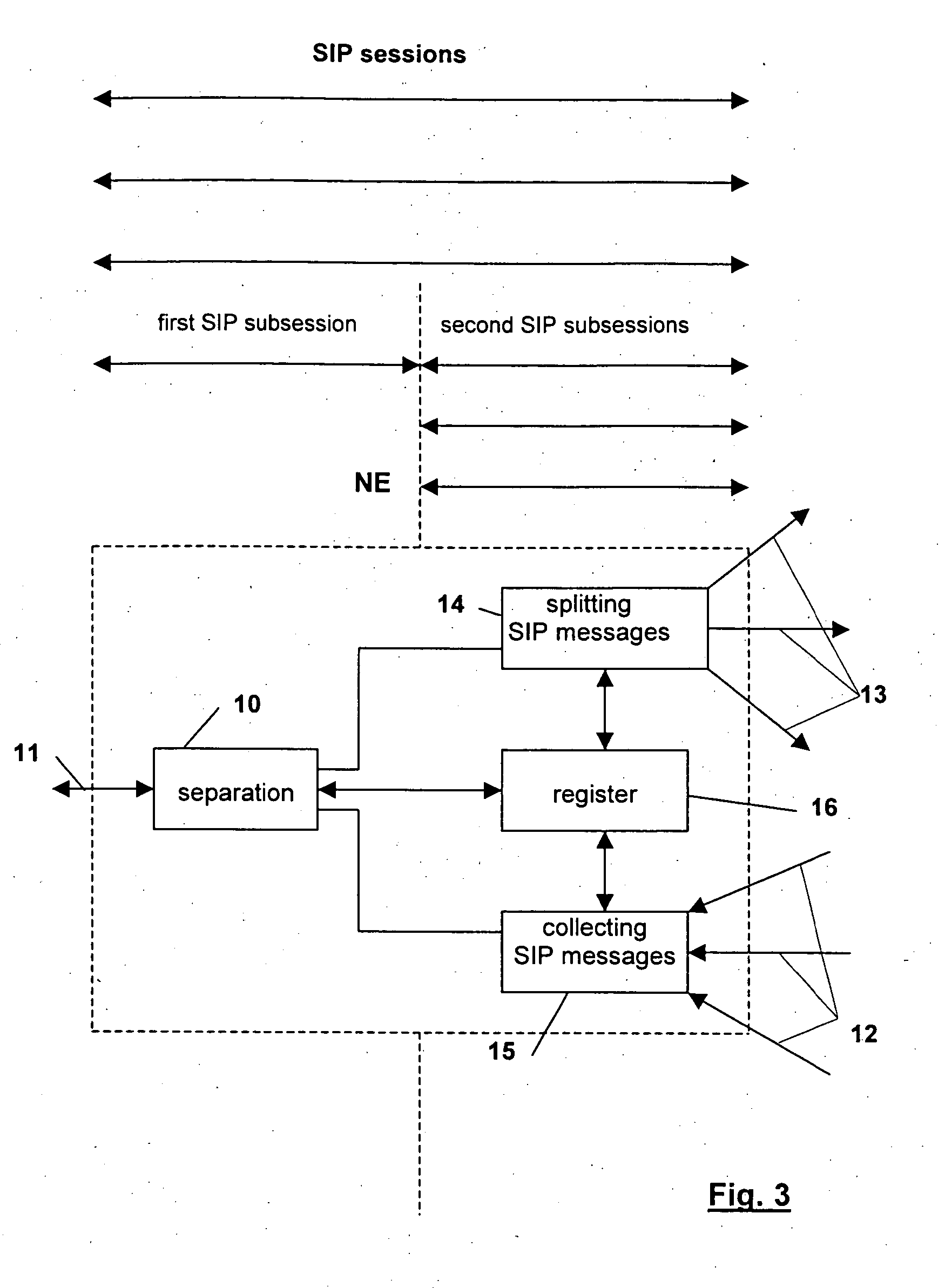

Method for managing sessions between network parties, methods, network element and terminal for managing calls

InactiveUS20050021616A1Save bandwidthNetwork capacity savedSpecial service provision for substationSpecial service for subscribersSession managementNetwork on

The invention relates to a management of sessions between parties being connectable with a network. Thereby a first party registers to the network and invites a second party to a session. It is determined from a session information whether said session is to be retained by the network. The retaining comprises storing at least part of the session information for a subsequent re-establishment or release of the session by the network on behalf of said first party, releasing said retained session by the network towards the second party on behalf of the first party, when the first party deregisters from the network or loses connection to the network, re-establishing the retained session by the network towards the second party on behalf of the first party, when the first party repeatedly registers to said network or re-establishes connection with said network. Furthermore, the invention relates to methods and a network element for managing multiple simultaneous sessions between parties participating in one or a plurality of calls and to a corresponding terminal.

Owner:VRINGO INFRASTRUCTURE +1

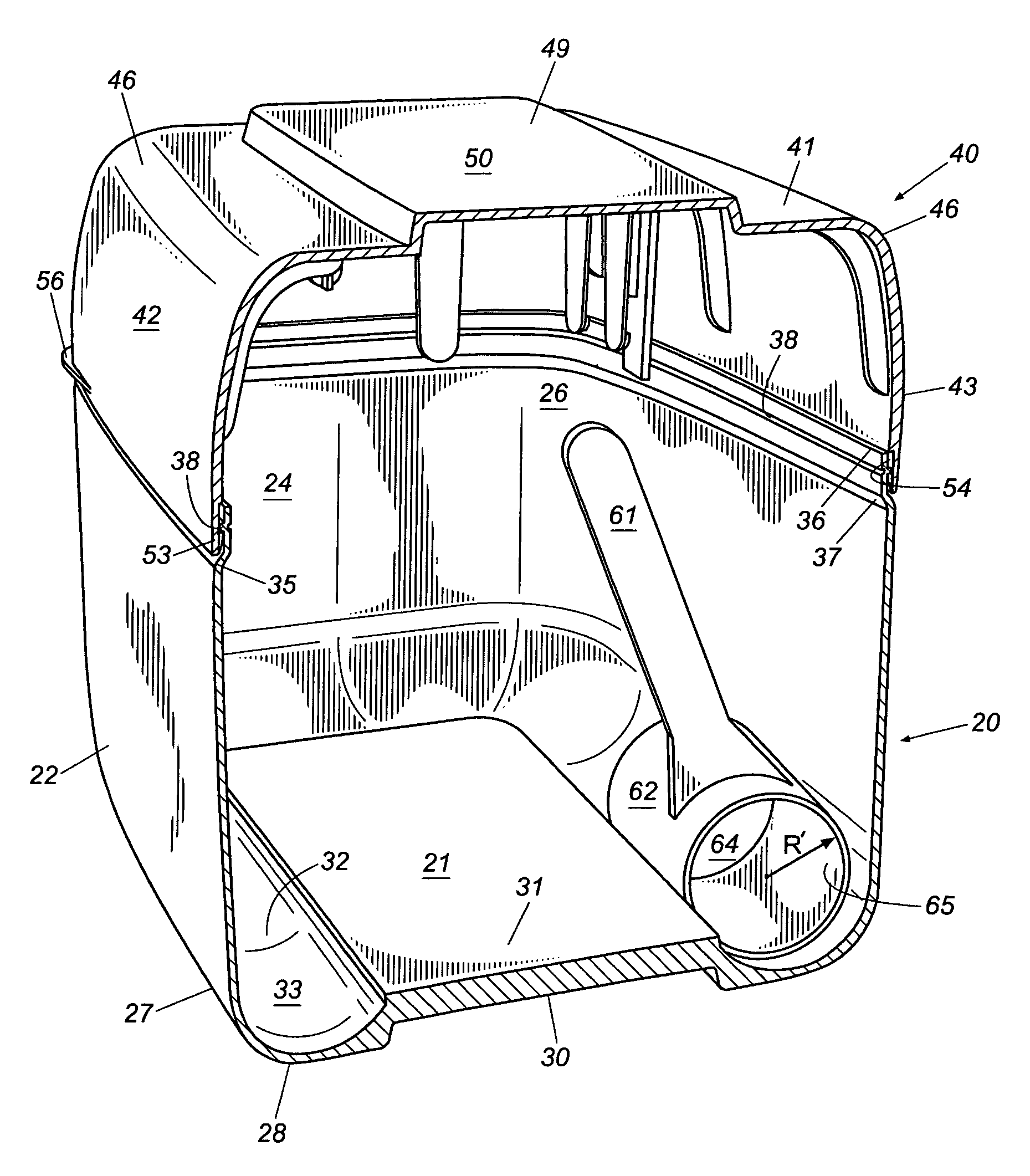

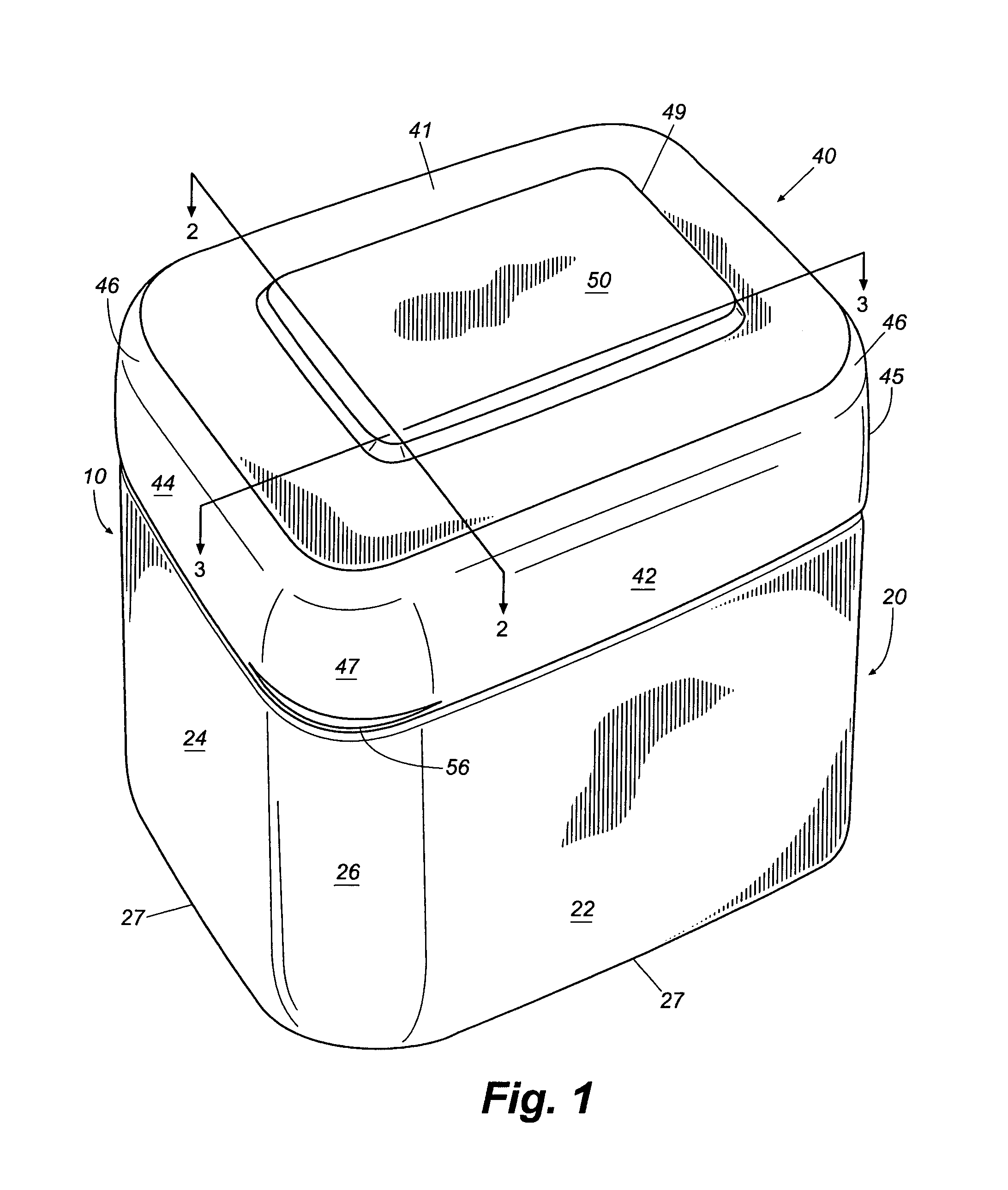

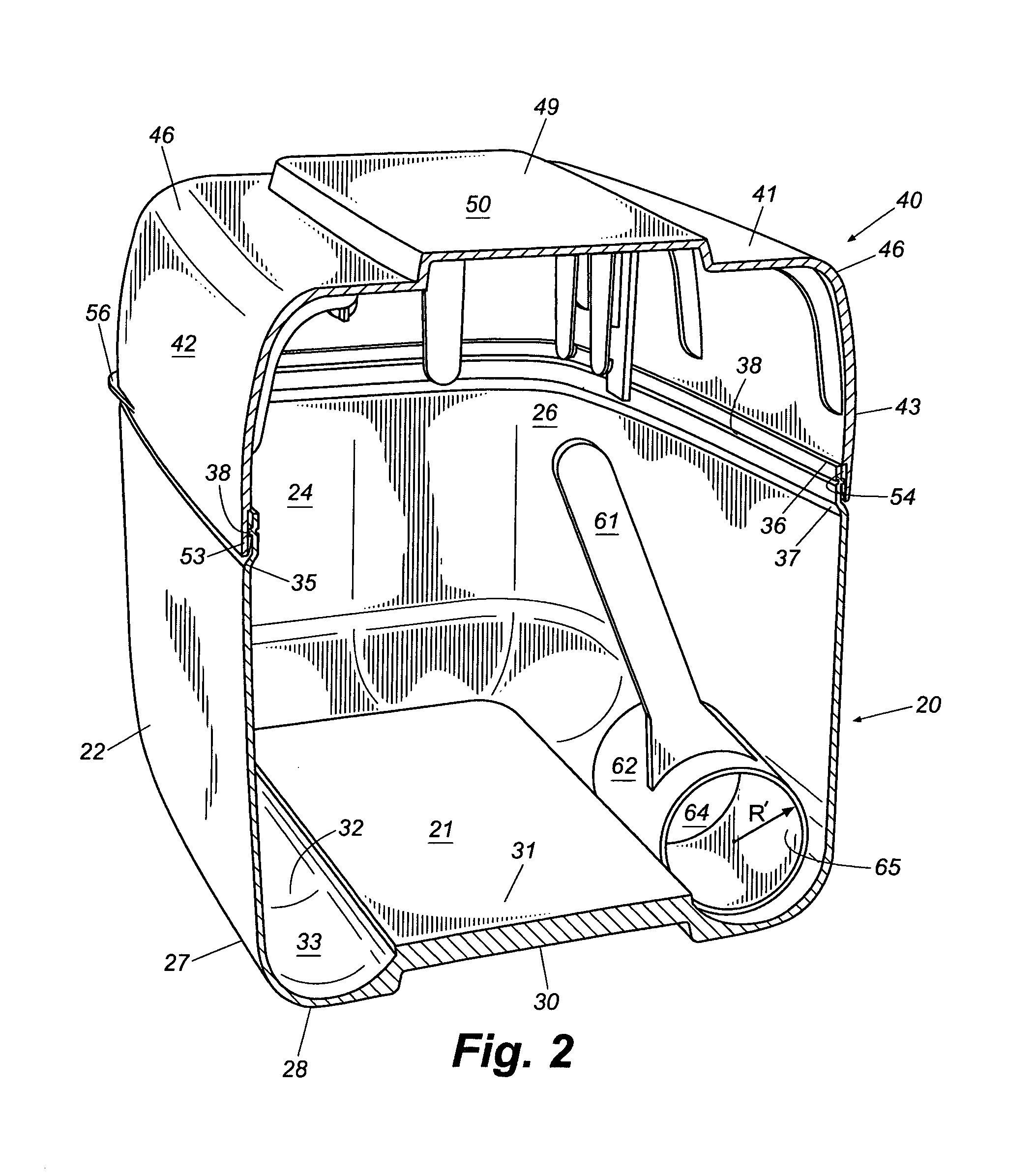

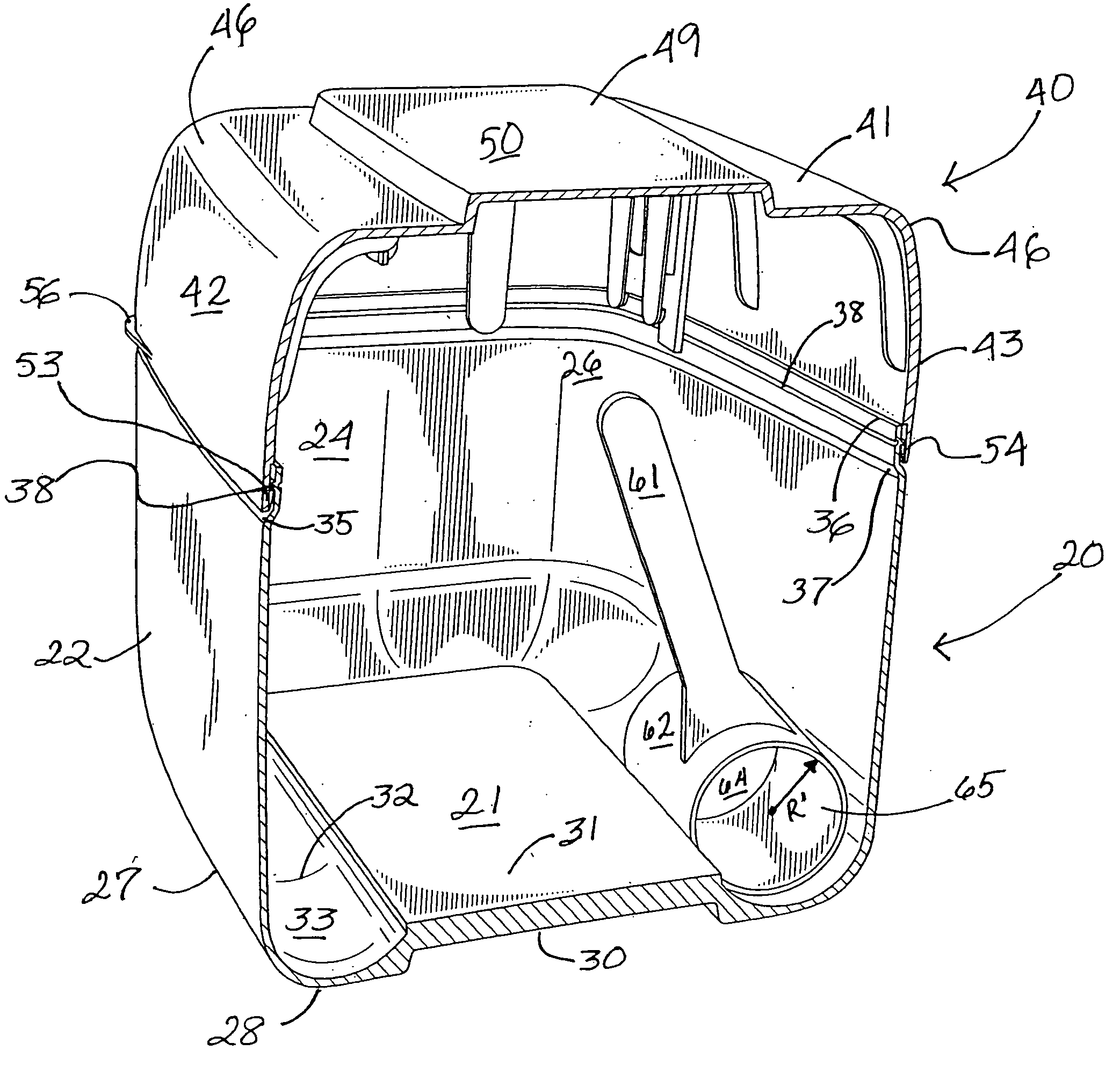

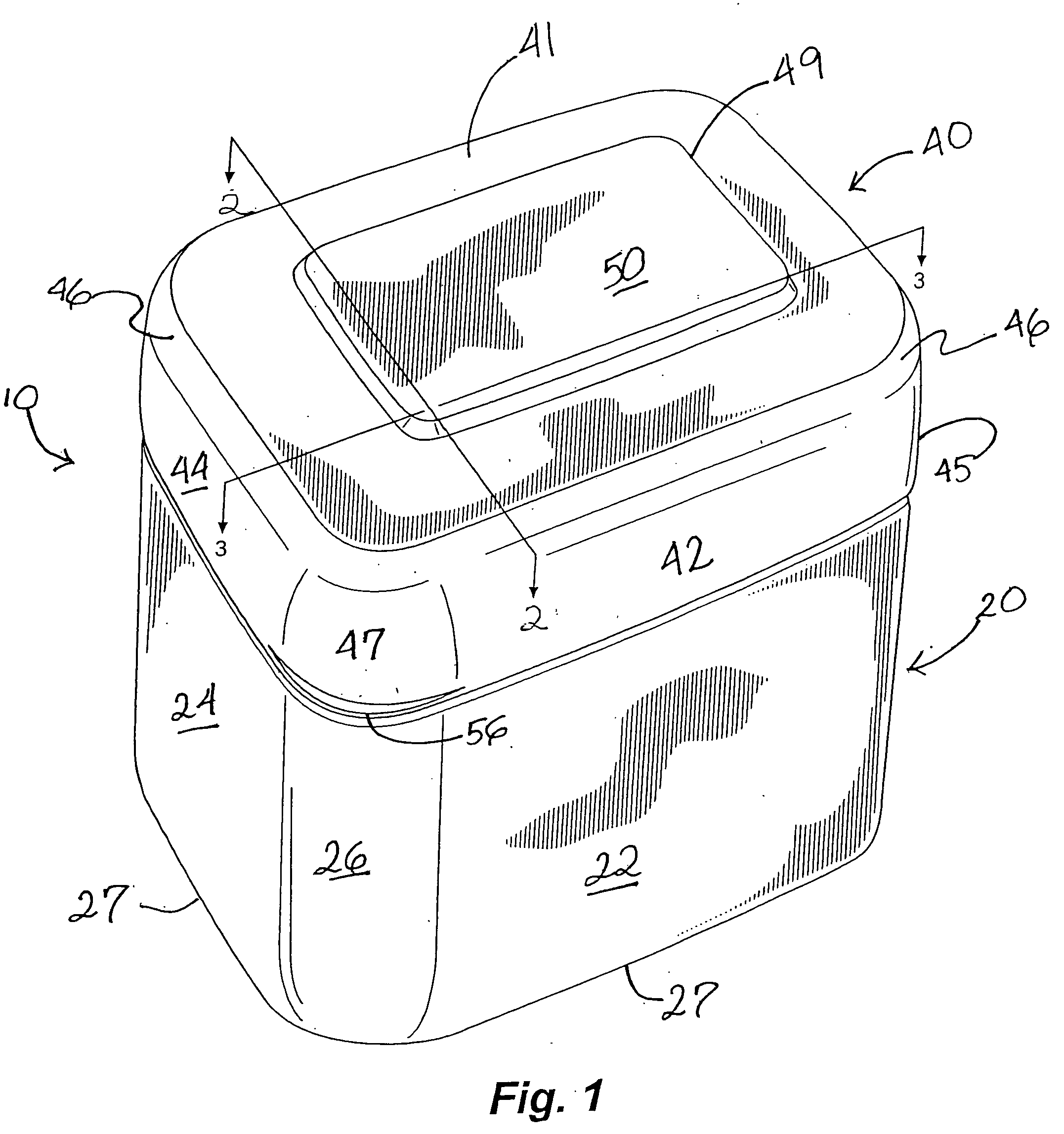

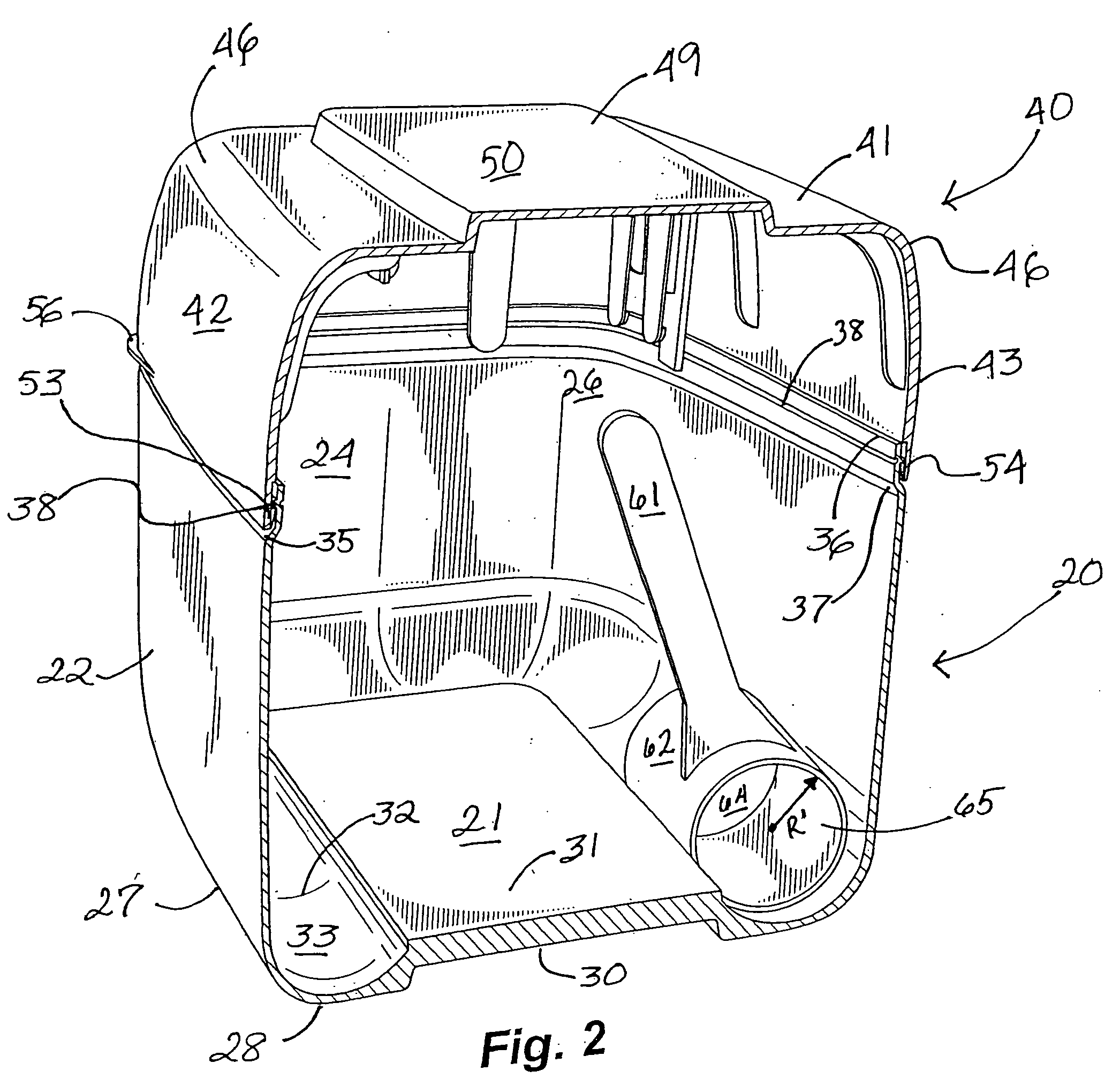

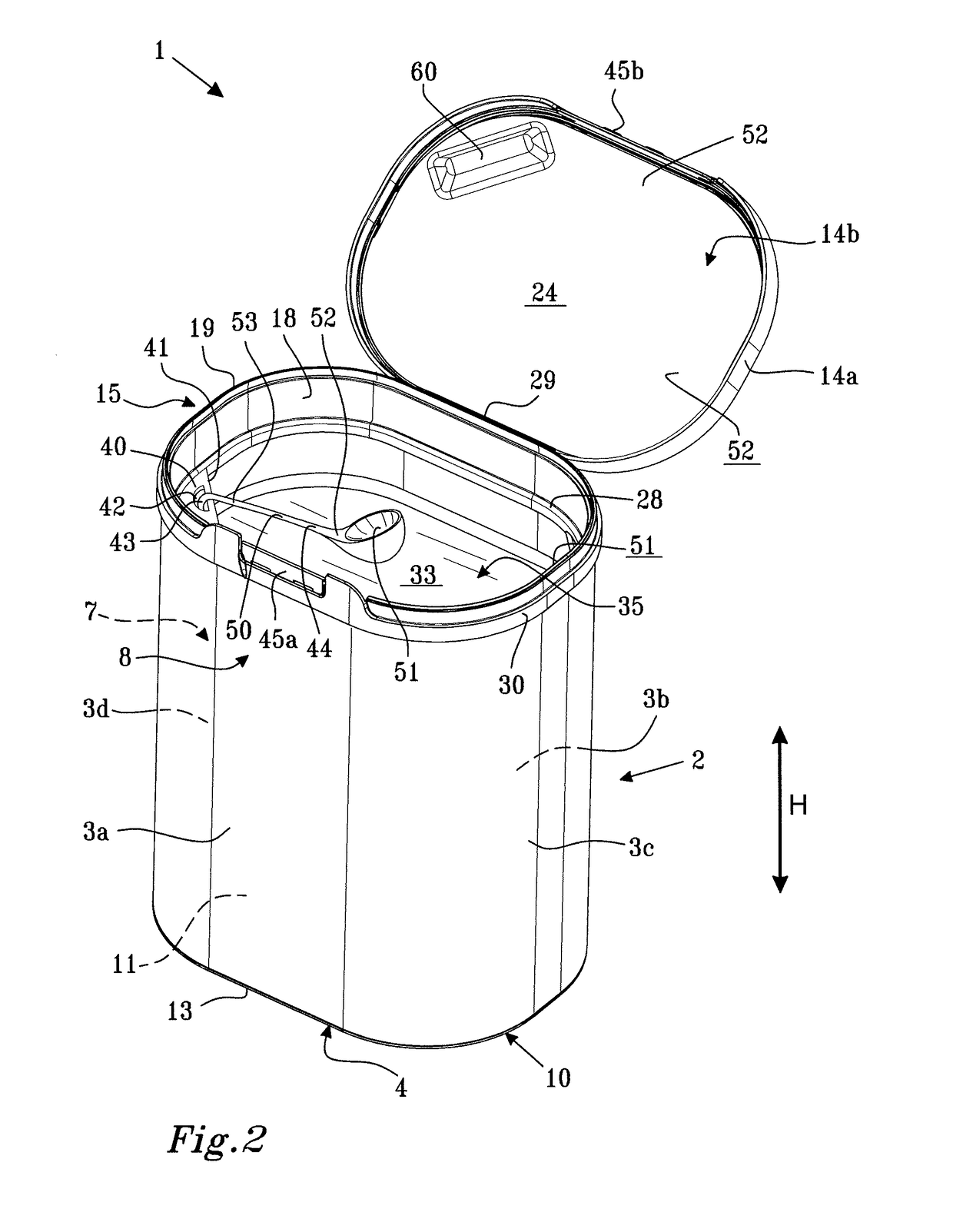

Container and scoop arrangement

Owner:MEAD JOHNSON NUTRITION

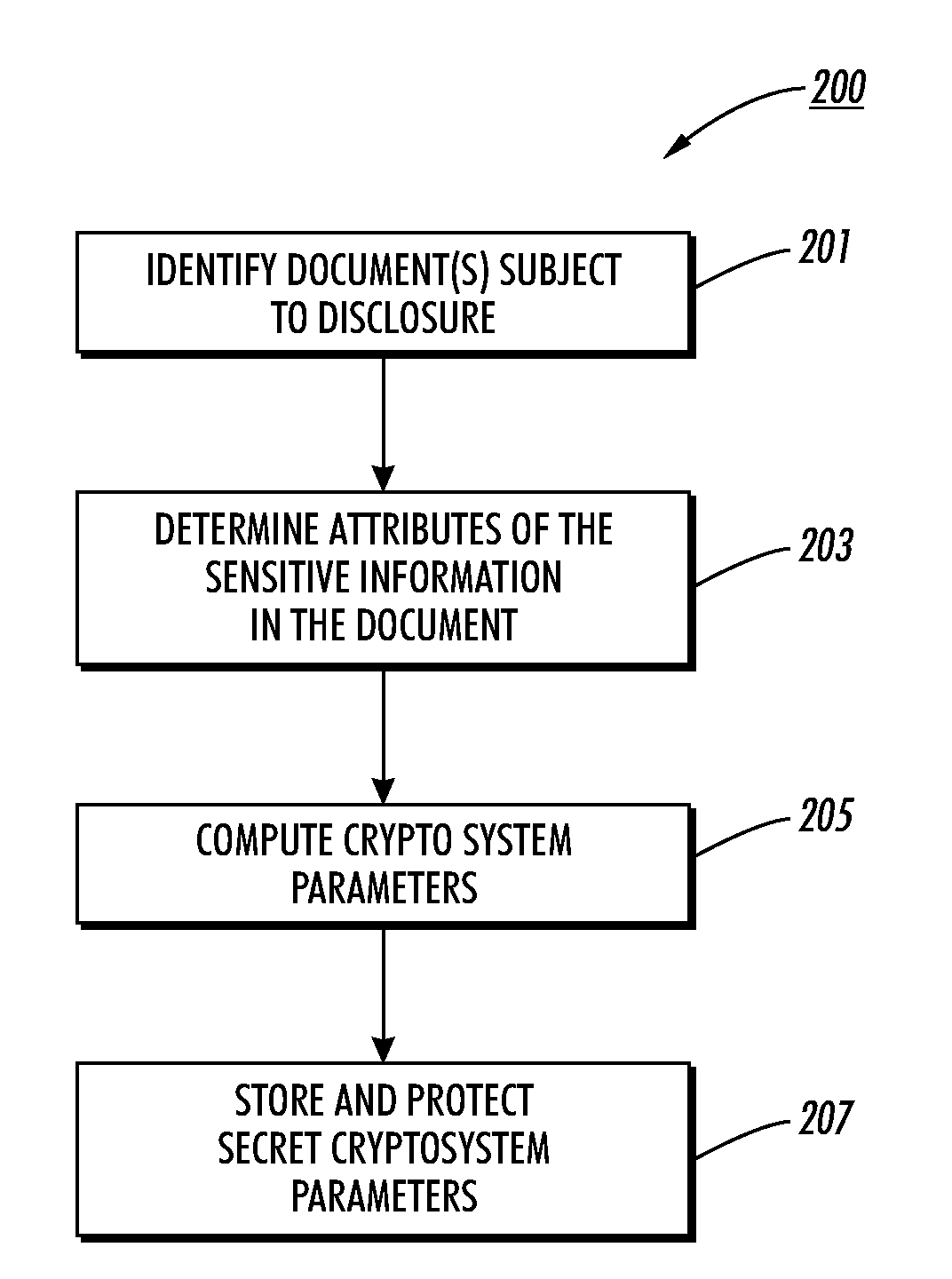

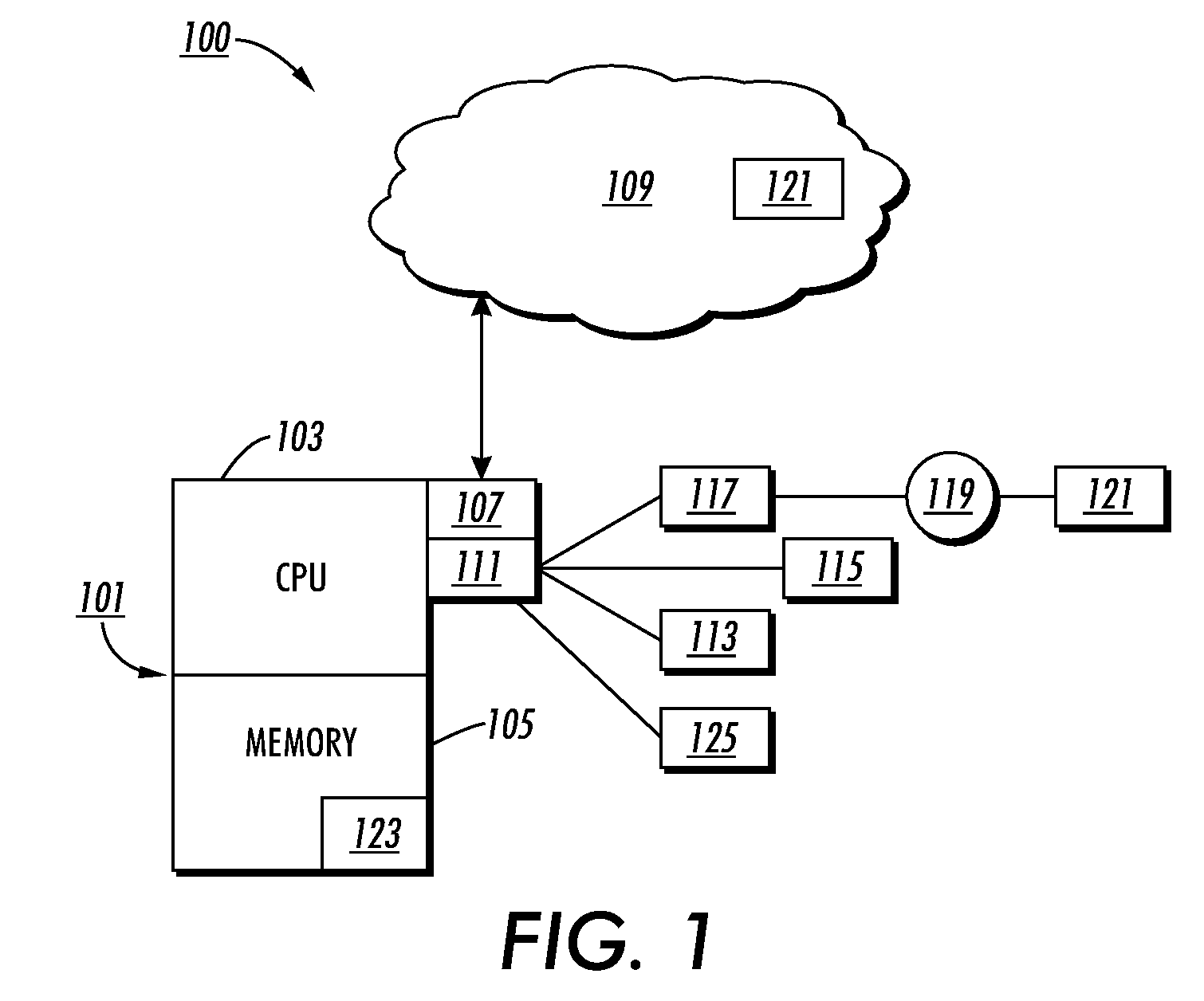

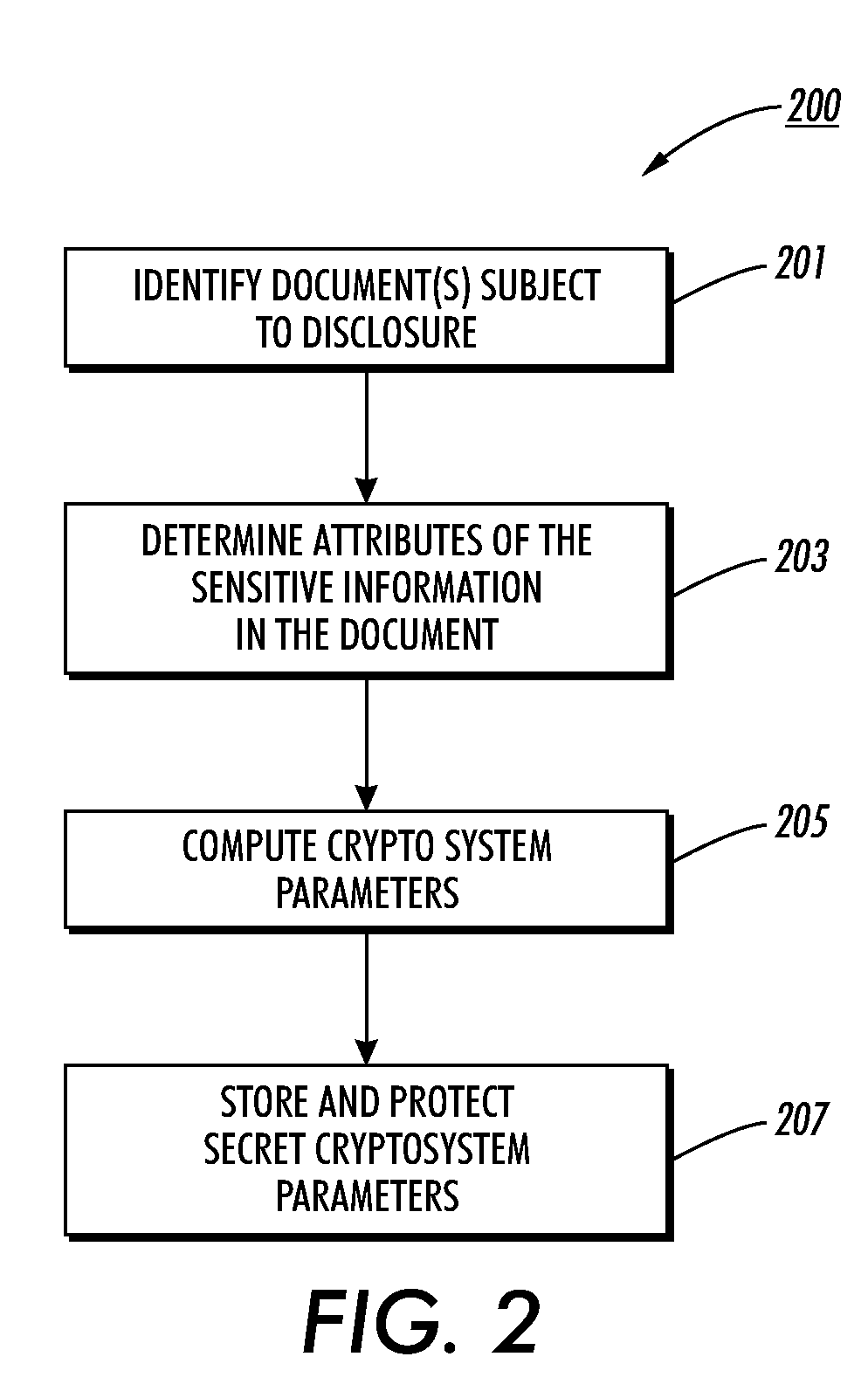

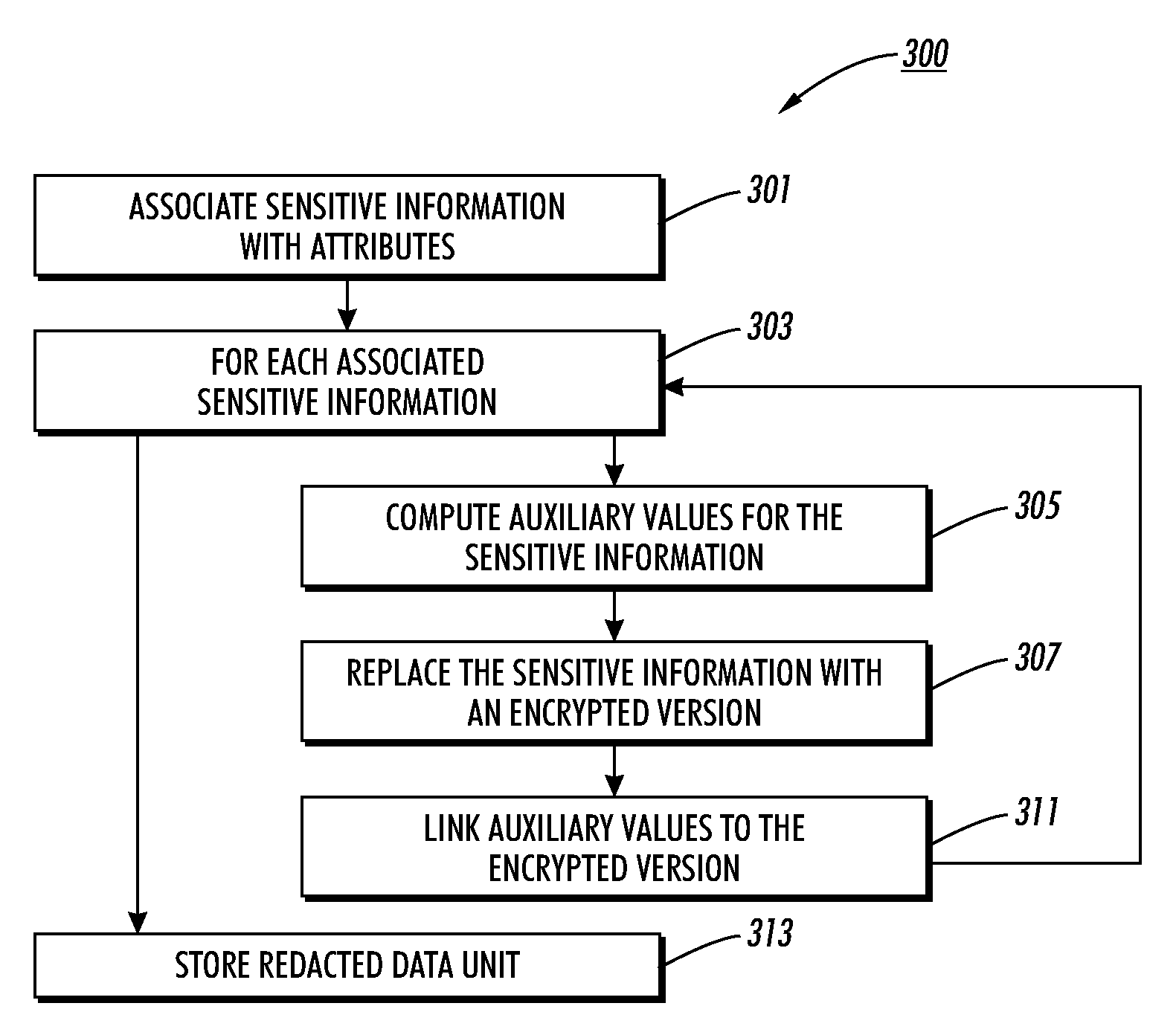

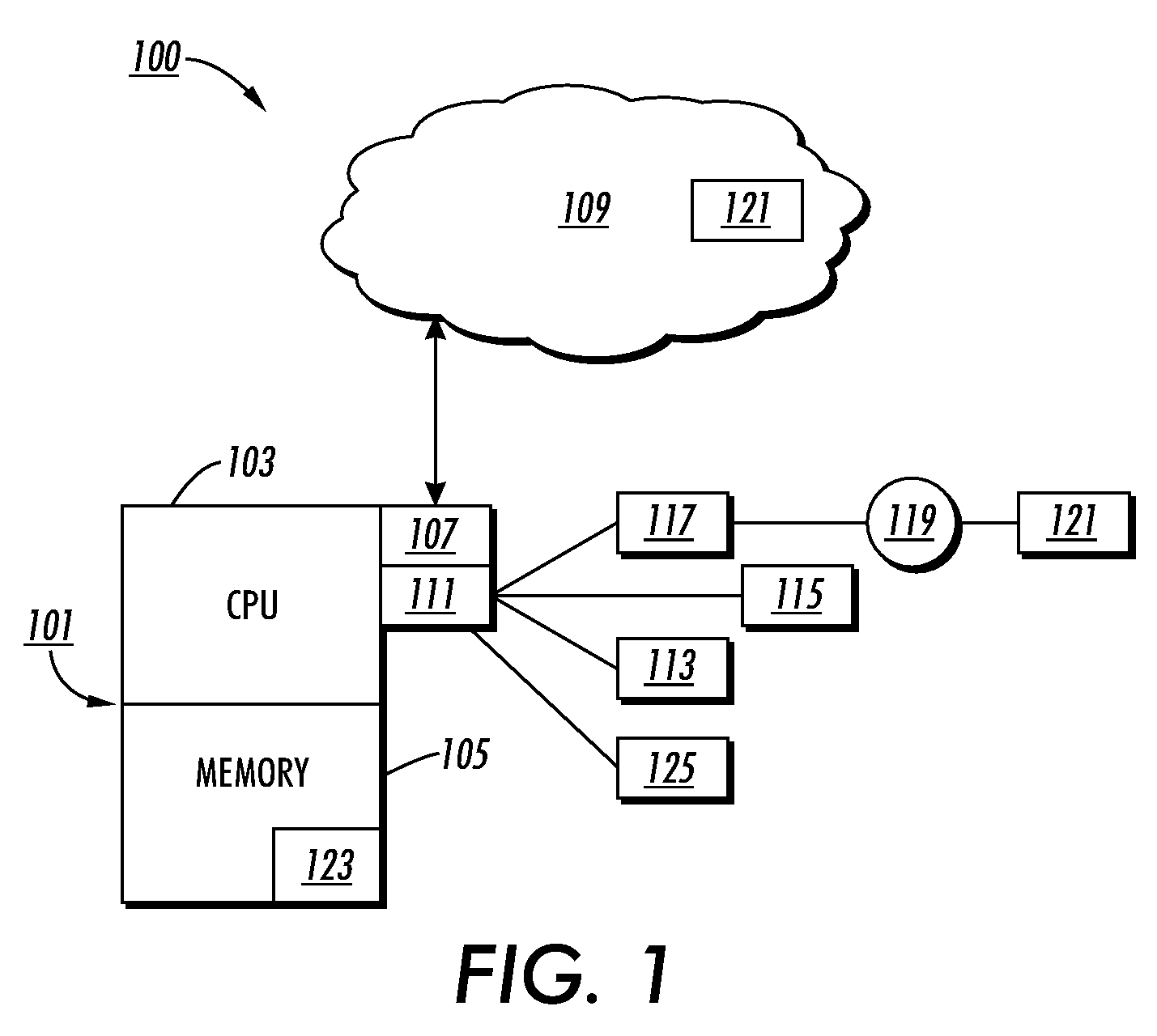

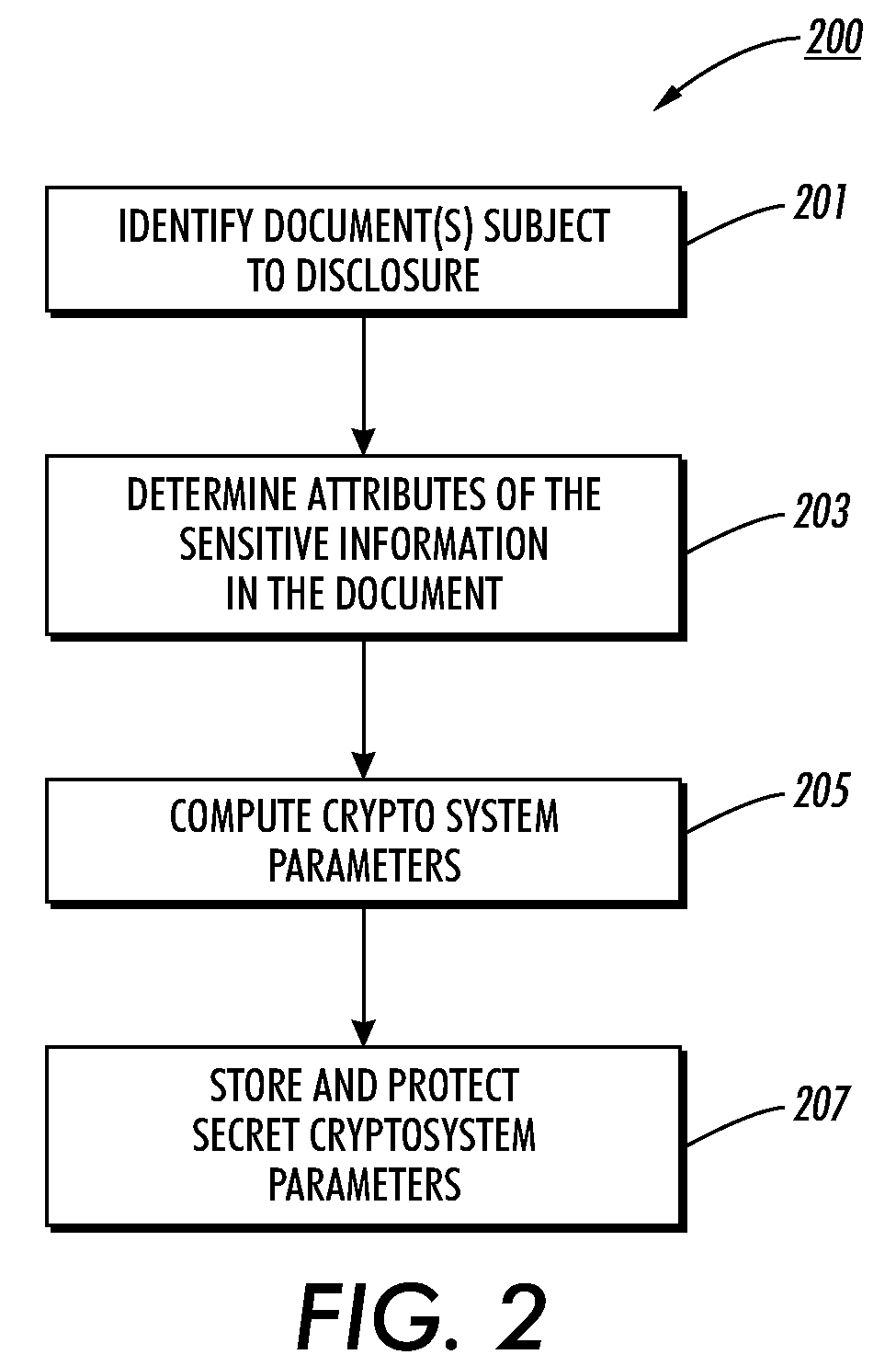

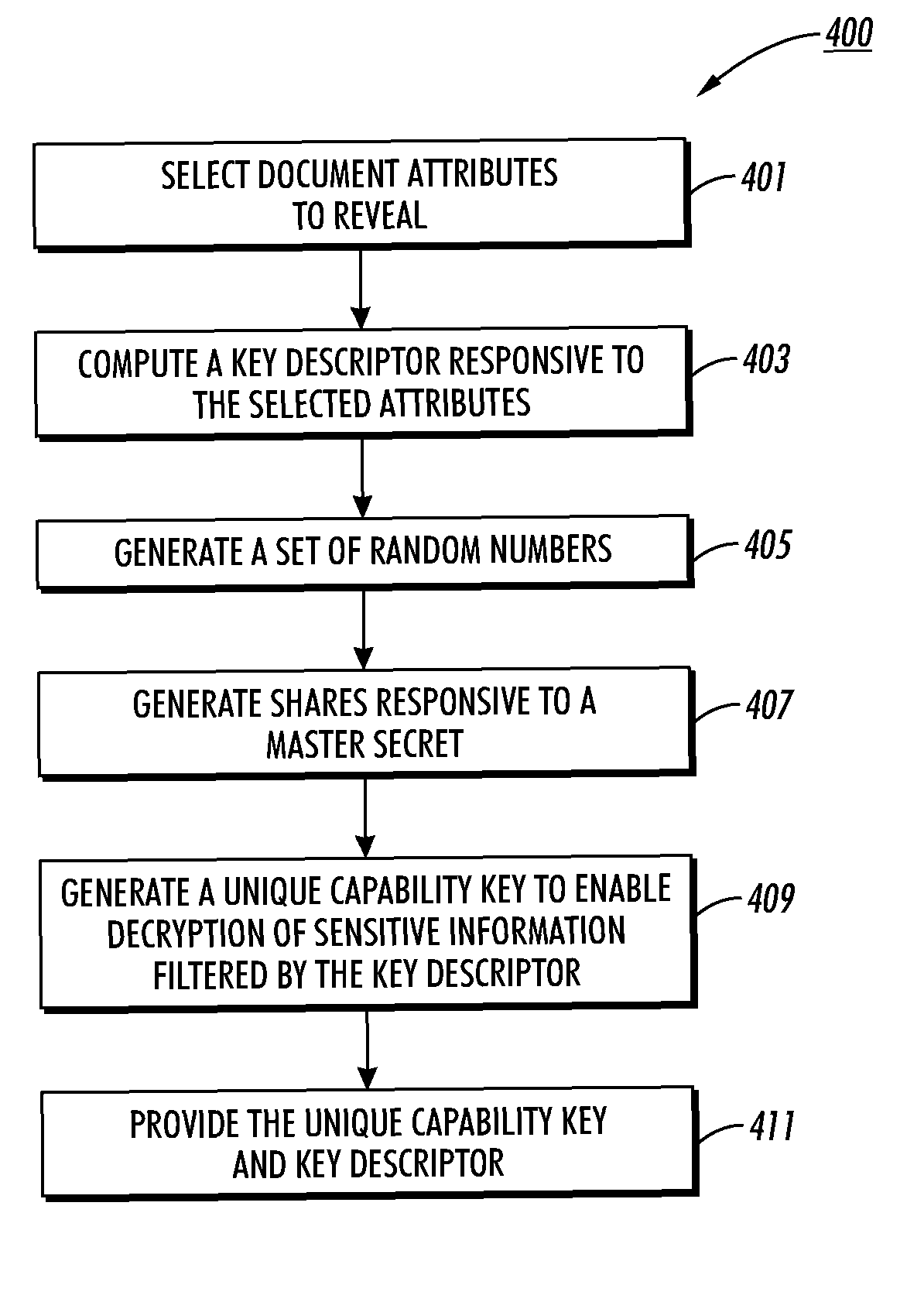

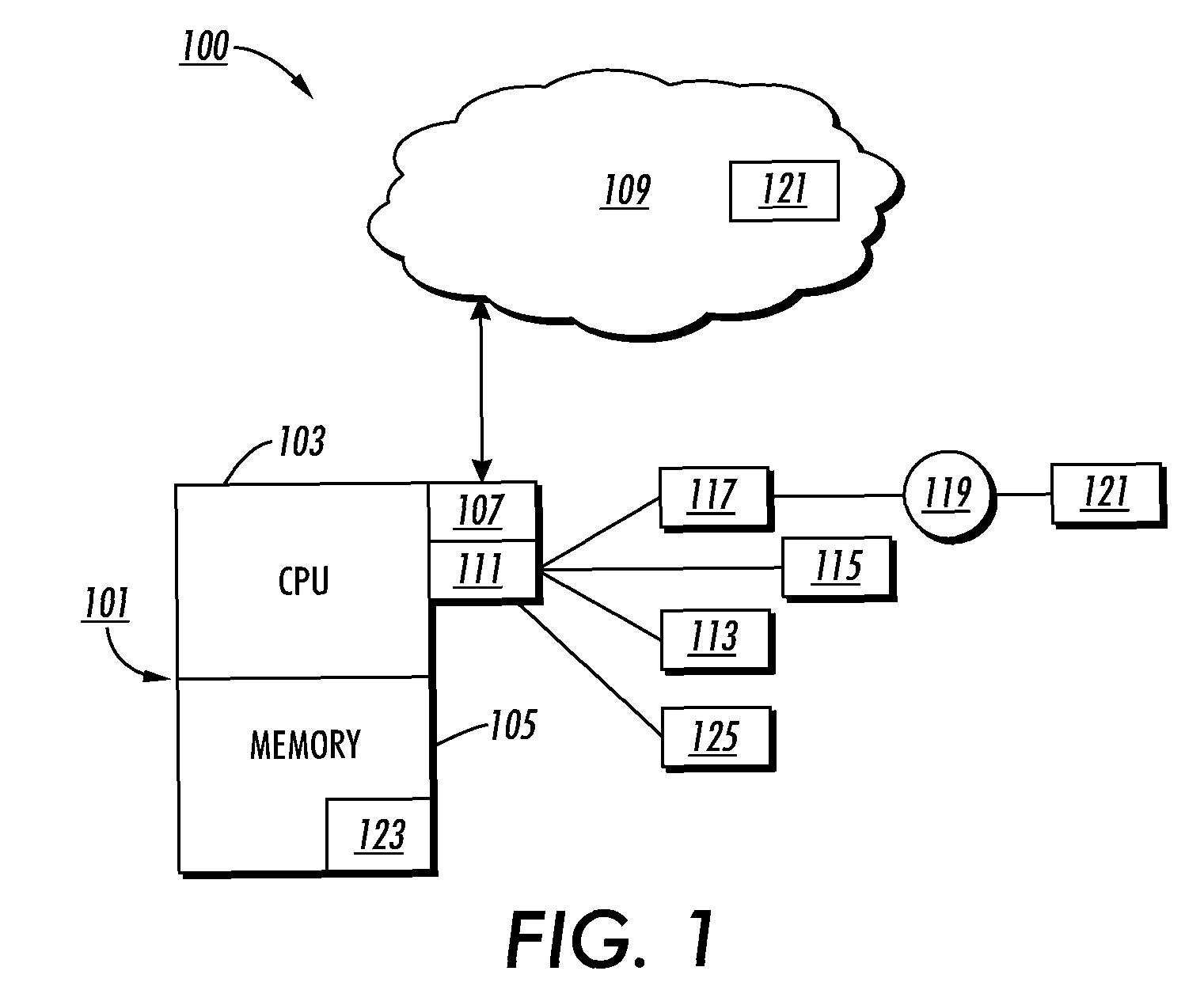

Method, apparatus, and program product for enabling access to flexibly redacted content

InactiveUS20080016341A1Shorten the timeFacilitate content indexingDigital data processing detailsUser identity/authority verificationCryptosystemComputer security

A capability key is generated that provides access to sensitive information within a selectively encrypted data unit created from an unencrypted data unit. A user specifies access rights as a monotone boolean relationship between a selection of a list of attributes related to the unencrypted data unit. This relationship is used to compute a key descriptor. Next one or more shares of a master secret is generated responsive to the monotone boolean relationship and a random number. Next a unique capability key is computed from one or more cryptosystem parameters, the one or more shares and the random number. The unique capability key and the key descriptor together enable decryption of sensitive information within a selectively encrypted data unit created from an unencrypted data unit. Finally, the unique capability key and the key descriptor are provided to allow decryption of sensitive information within the selectively encrypted data unit.

Owner:MAJANDRO LLC

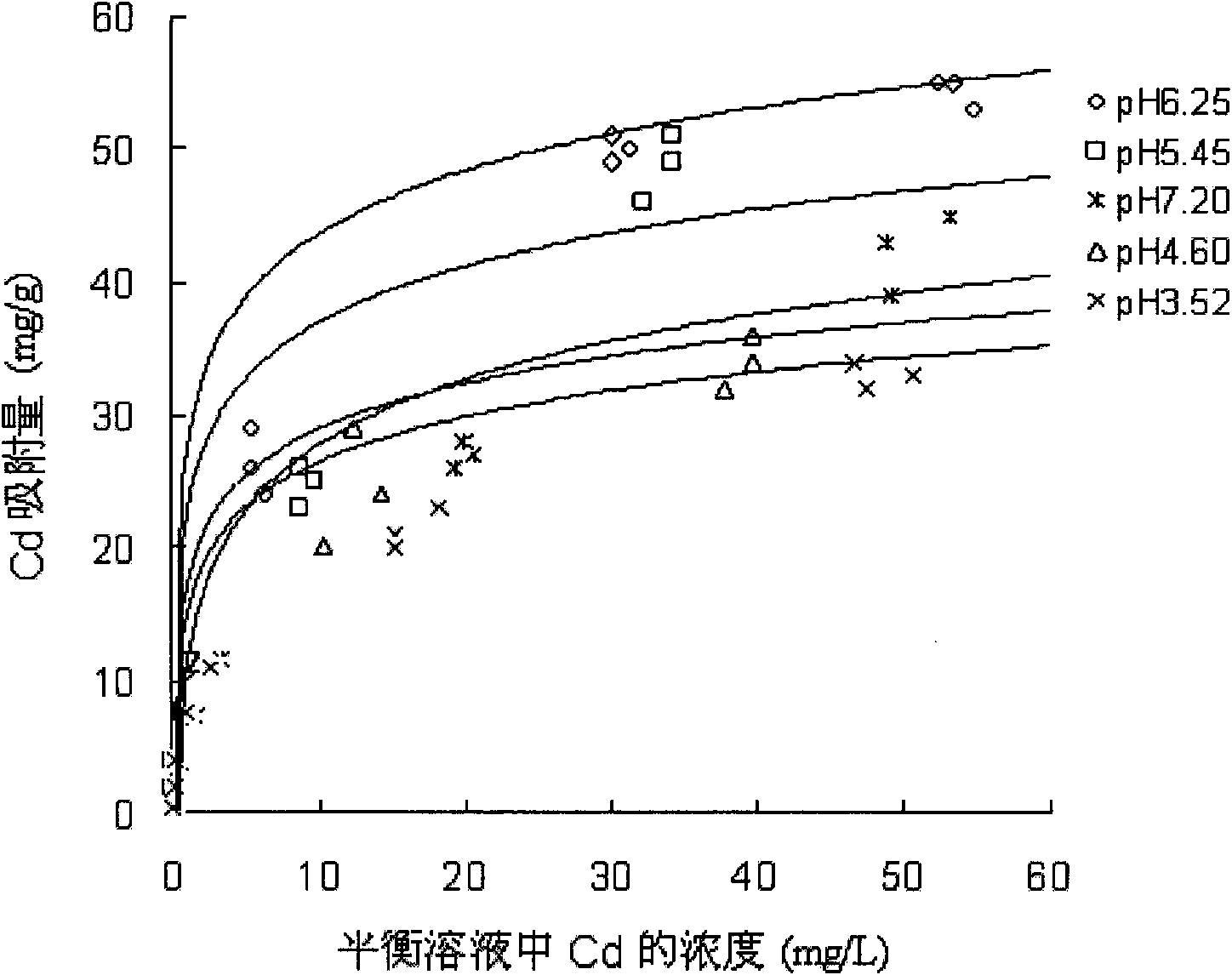

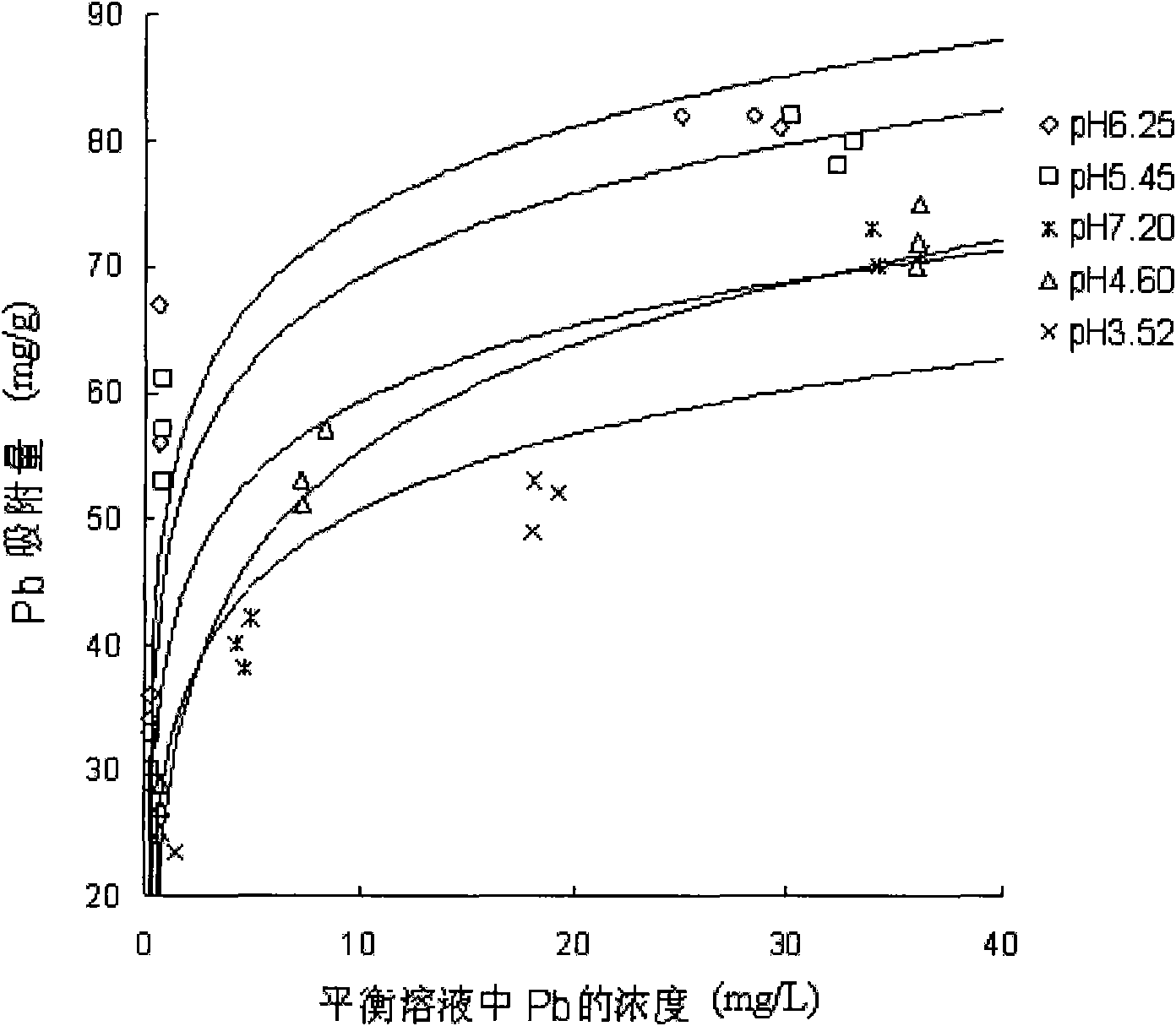

Method for removing heavy metal ions in sewage by nanometer hydroxylapatite

InactiveCN101613135AWide variety of sourcesOvercome expensiveWater contaminantsWater/sewage treatment by sorptionWastewaterHydroxylapatite

The invention discloses a method for removing heavy metal ions in sewage by nanometer hydroxylapatite, belonging to the technical field of heavy metal sewage treatment. The method comprises the following steps: adding nanometer grade hydroxylapatite powder in waste water containing heavy metal ions, wherein, the dosage of the hydroxylapatite powder is 6-8g / L; balancing the mixture for 12-48 hours at a temperature of 23-27 DEG C; and standing the mixture to remove the heavy metal ions in the waste water. The method uses the hydroxylapatite with relatively lower economic value to treat the heavy metal sewage, has high treatment efficiency, low treatment cost, strong field operability and small environment risk, and has heavy metal ion removal rate over 90 percent under conditions that concentration of Cd, Pb or Cu ions does not exceed 60mg / L.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Method for viewing document information on a mobile communication device

InactiveUS20060047729A1Minimize bandwidth usageMinimize power consumptionDigital data information retrievalSpecial data processing applicationsClient-sideRemote machine

A process for viewing document information on a mobile communication device without having to retrieve the full document onto the device. The solution is client—server based. The client is the mobile device attachment viewing application and the server is the document (attachment) handling process on a remote machine. The process comprises server document information construction and delivery, and document information display on the mobile device.

Owner:BLACKBERRY LTD

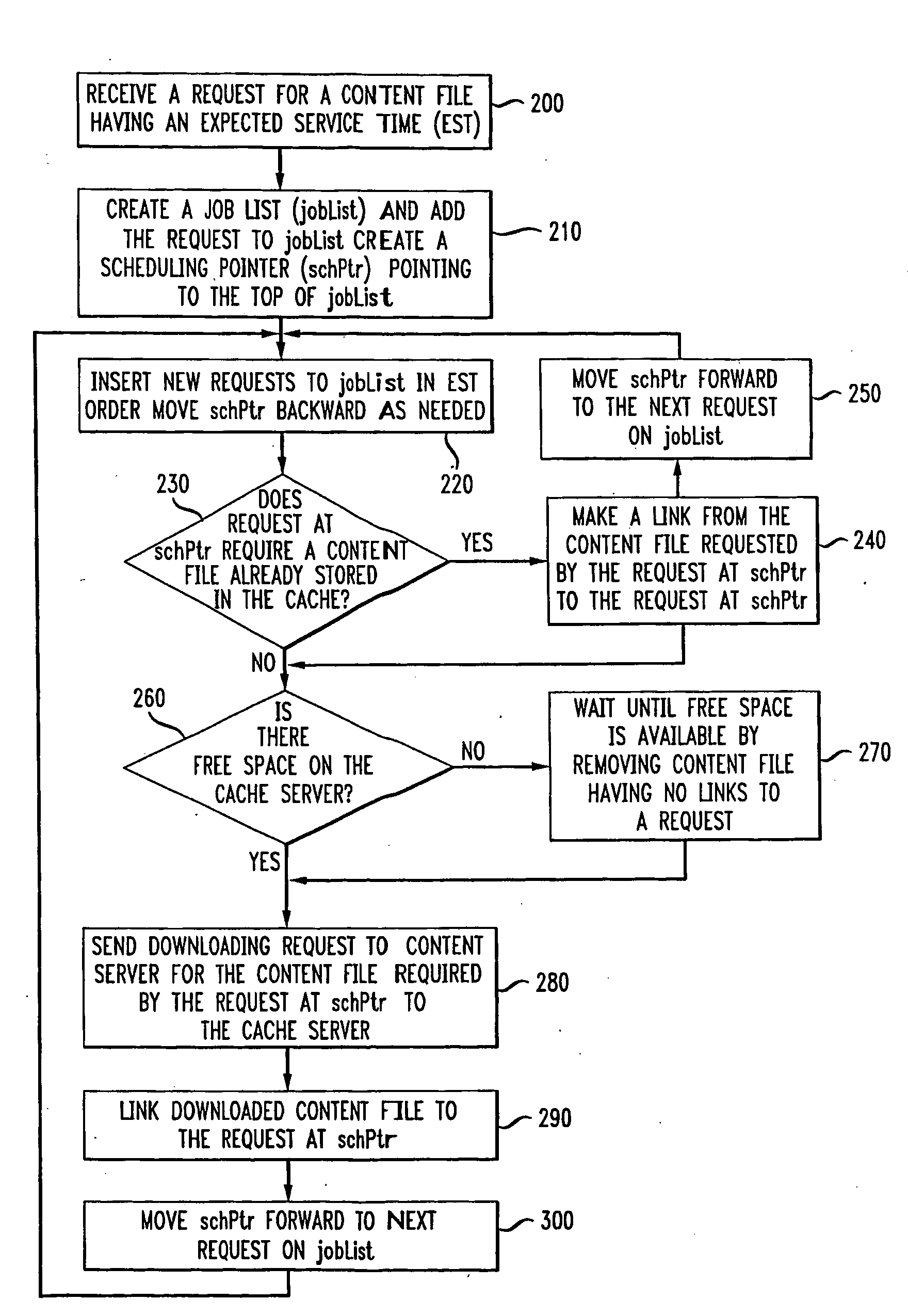

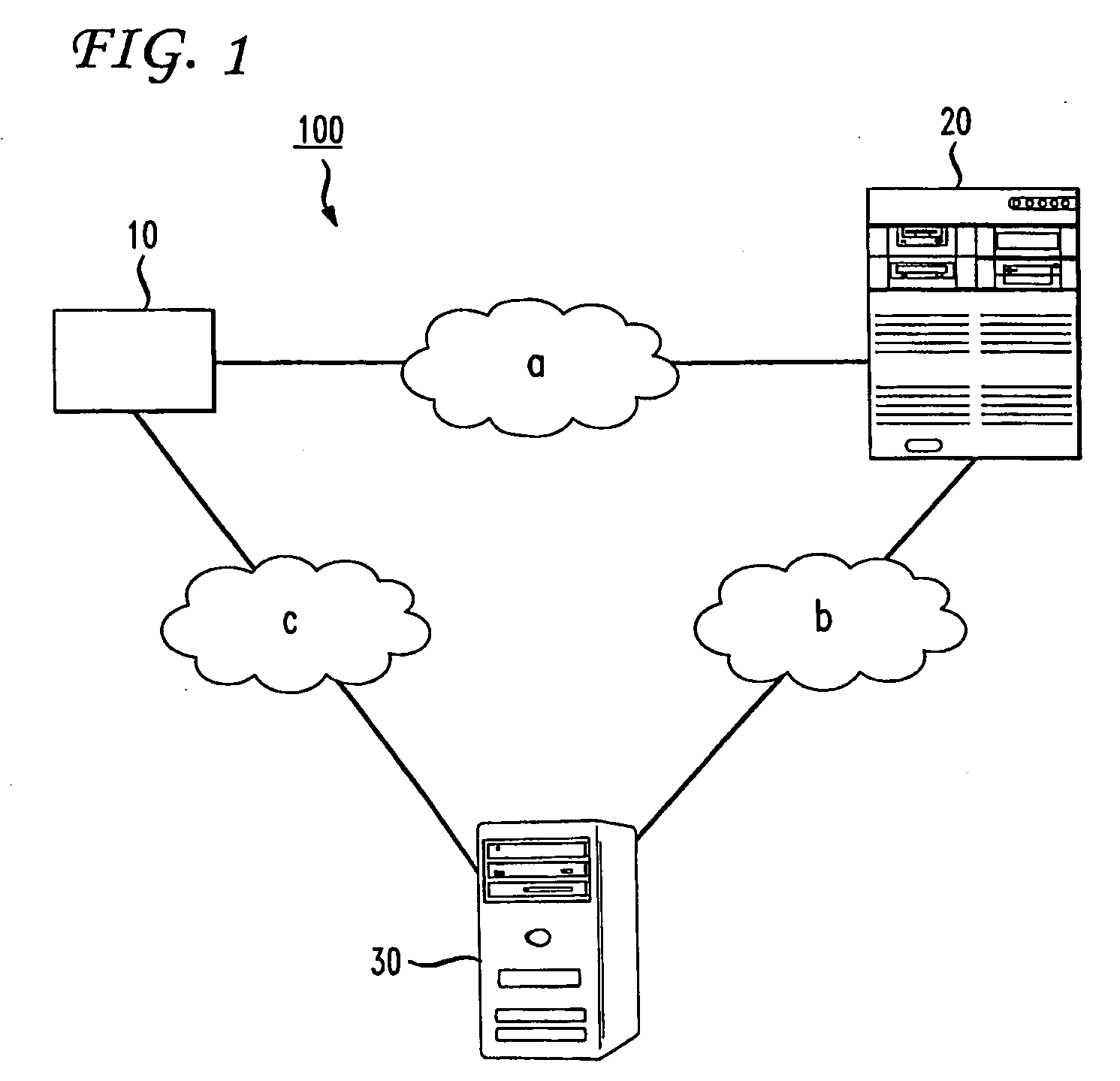

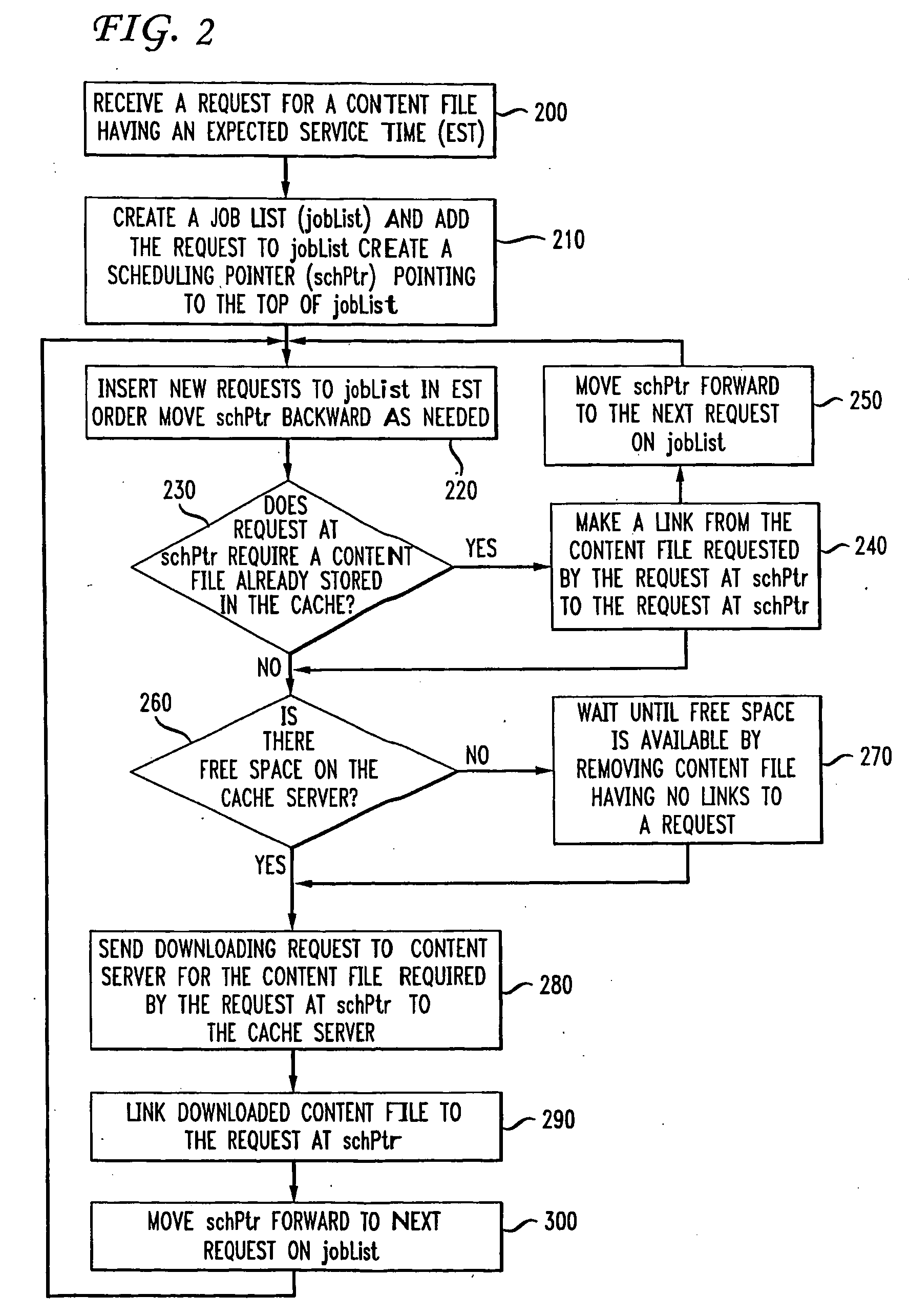

System and Method for Scheduling Downloading in a Cached Network Environment

InactiveUS20080235360A1Eliminate the problemMaximizing cache server storage utilizationDigital data information retrievalMultiple digital computer combinationsCache serverClient-side

A system and method schedules downloading of content files from a content server to a client through a cache server. A user can request a content file for future delivery at a certain service time at a certain location such as a hotspot. A cache server receives these requests and sorts them in an order which depends on the relative service times, and eliminates redundancies by only downloading content files not already stored in the cache server. A scheduling algorithm minimizes the instances of tardiness under the constraint of cache storage capacity.

Owner:THOMSON LICENSING SA

Content playback apparatus method and program and key management apparatus and system

InactiveUS7401232B2Elimination contentTelevision system detailsKey distribution for secure communicationComputer networkEngineering

A key management apparatus which can be used to encrypt / decrypt content data in a content playback device includes a storing unit for storing a secret key, a key information decrypting unit for decrypting encrypted key information and an updating unit operable to update the secret key with an algorithm stored therein, when the decrypted key information is key-updating information. Seed information can be received for use with the algorithm to provide a new secret key, and preliminary trigger information can be used to poll a group of appliances to request key information to determine any duplication of appliances.

Owner:SOVEREIGN PEAK VENTURES LLC

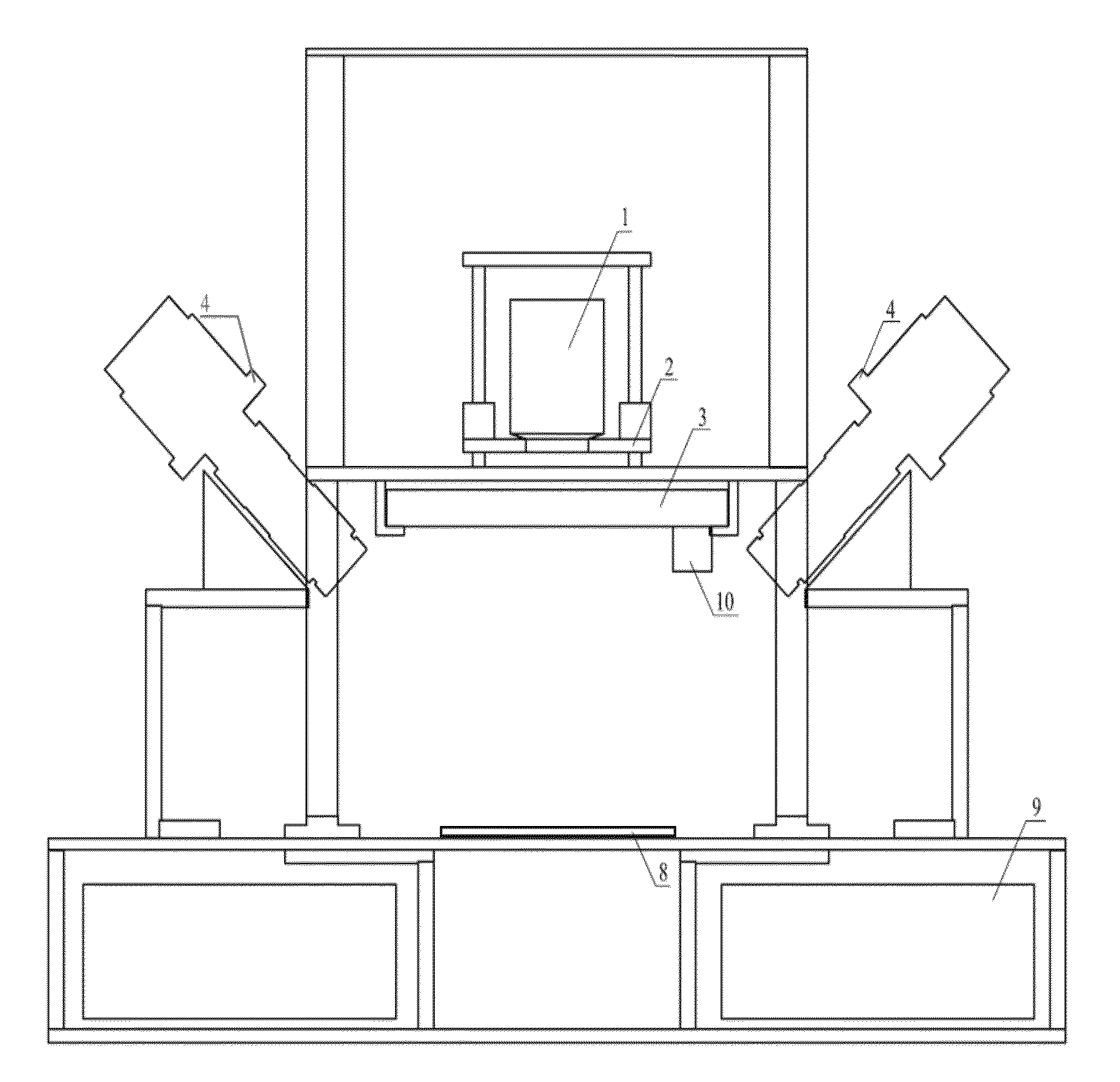

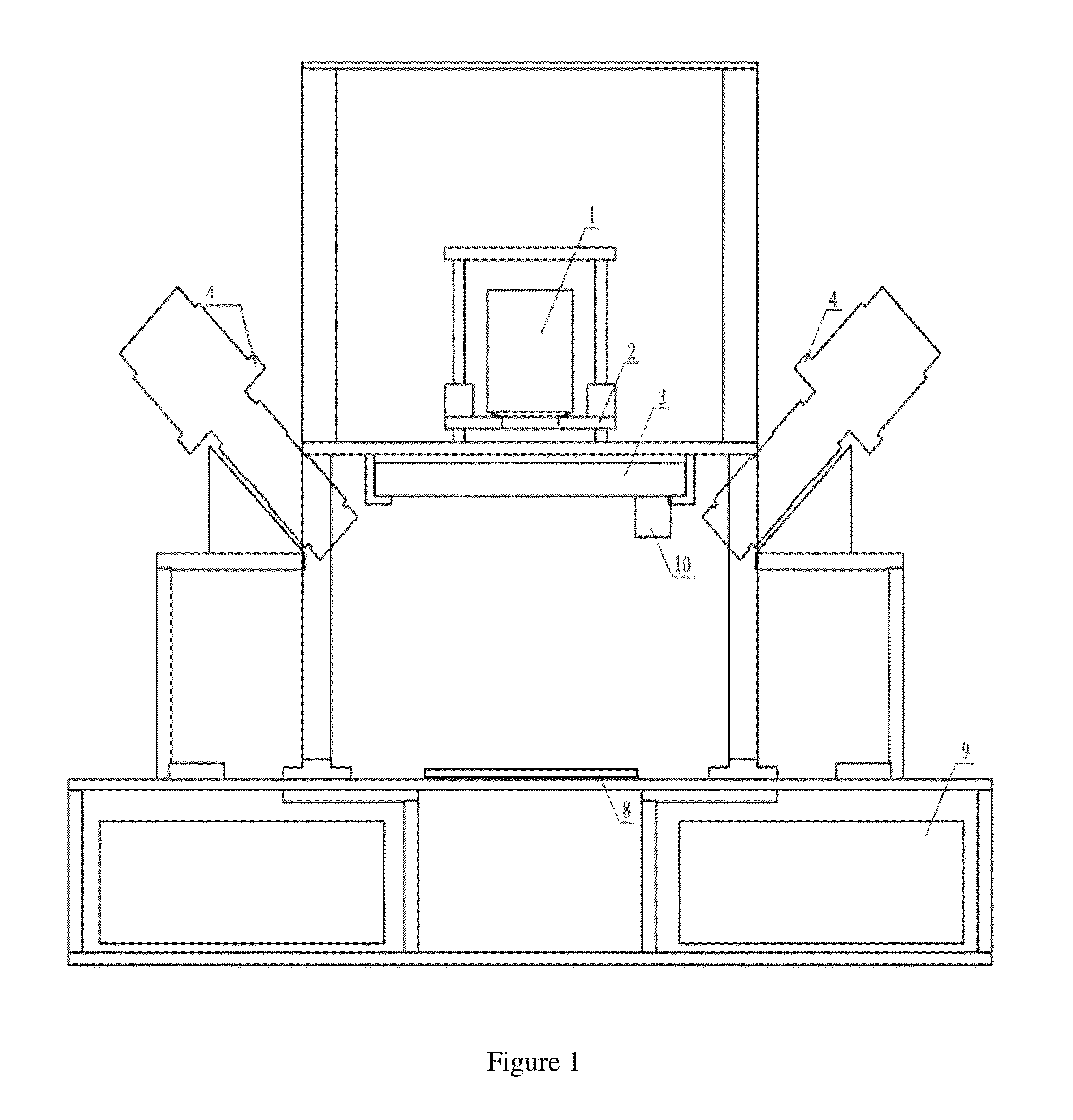

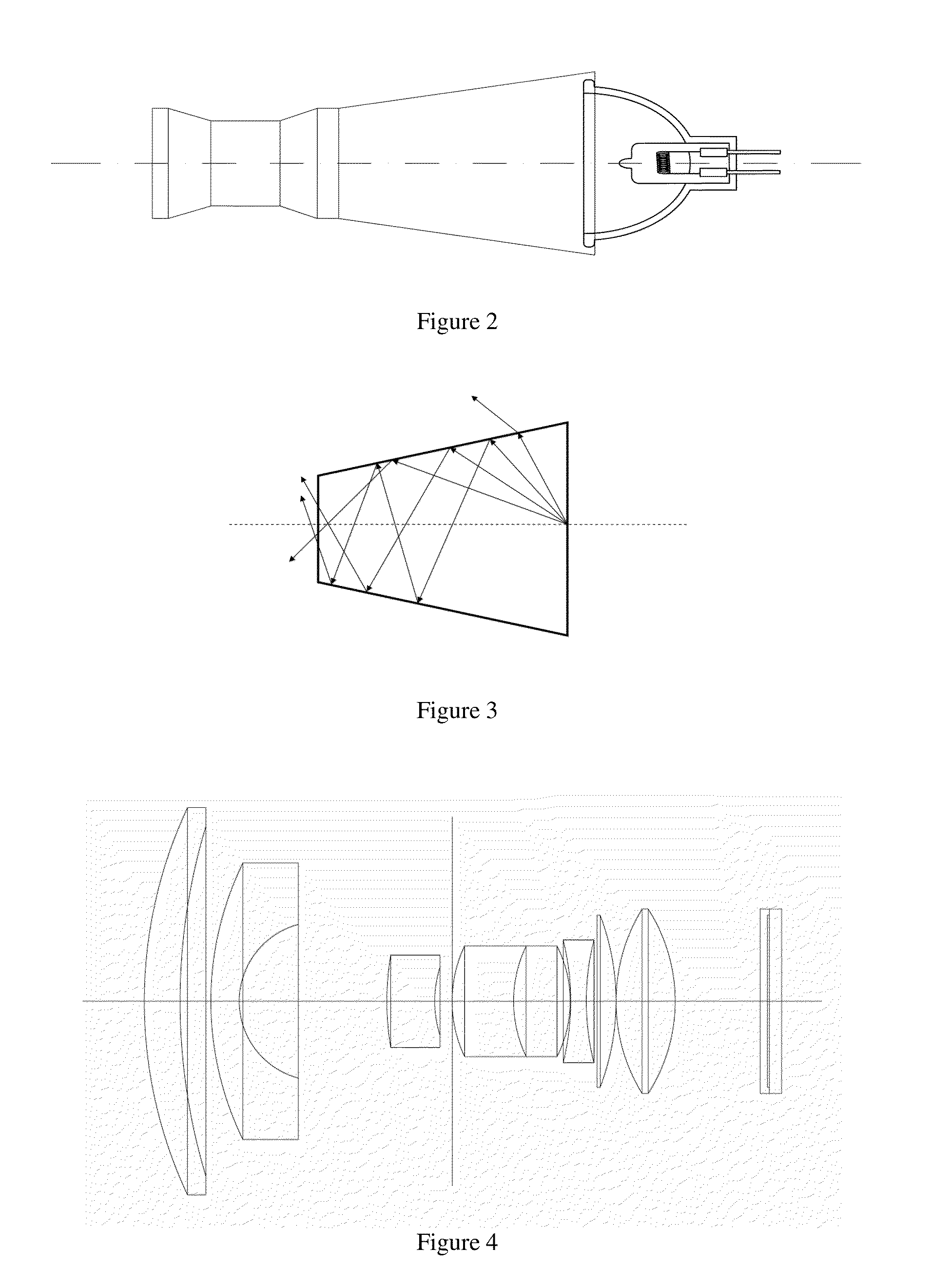

Multispectral imaging color measurement system and method for processing imaging signals thereof

ActiveUS20130293702A1Overcome inaccuraciesImprove spatial resolutionColor signal processing circuitsSpectrum investigationDigital imagingMultispectral image

A multispectral imaging color measurement system, comprising a dark room, a sample platform and an imaging device for capturing said object being measured; a controllable illumination device, a filter wheel unit, an imaging signal processing unit and an electronic control unit. A method for processing imaging signals of the multispectral imaging color measurement is also proposed. The multispectral imaging color measurement system and the method for processing imaging signals thereof can overcome the inaccuracy of traditional digital imaging systems and the limits of spectrophotometer systems and provide users in the textile industry with highly accurate color measurement and evaluation.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

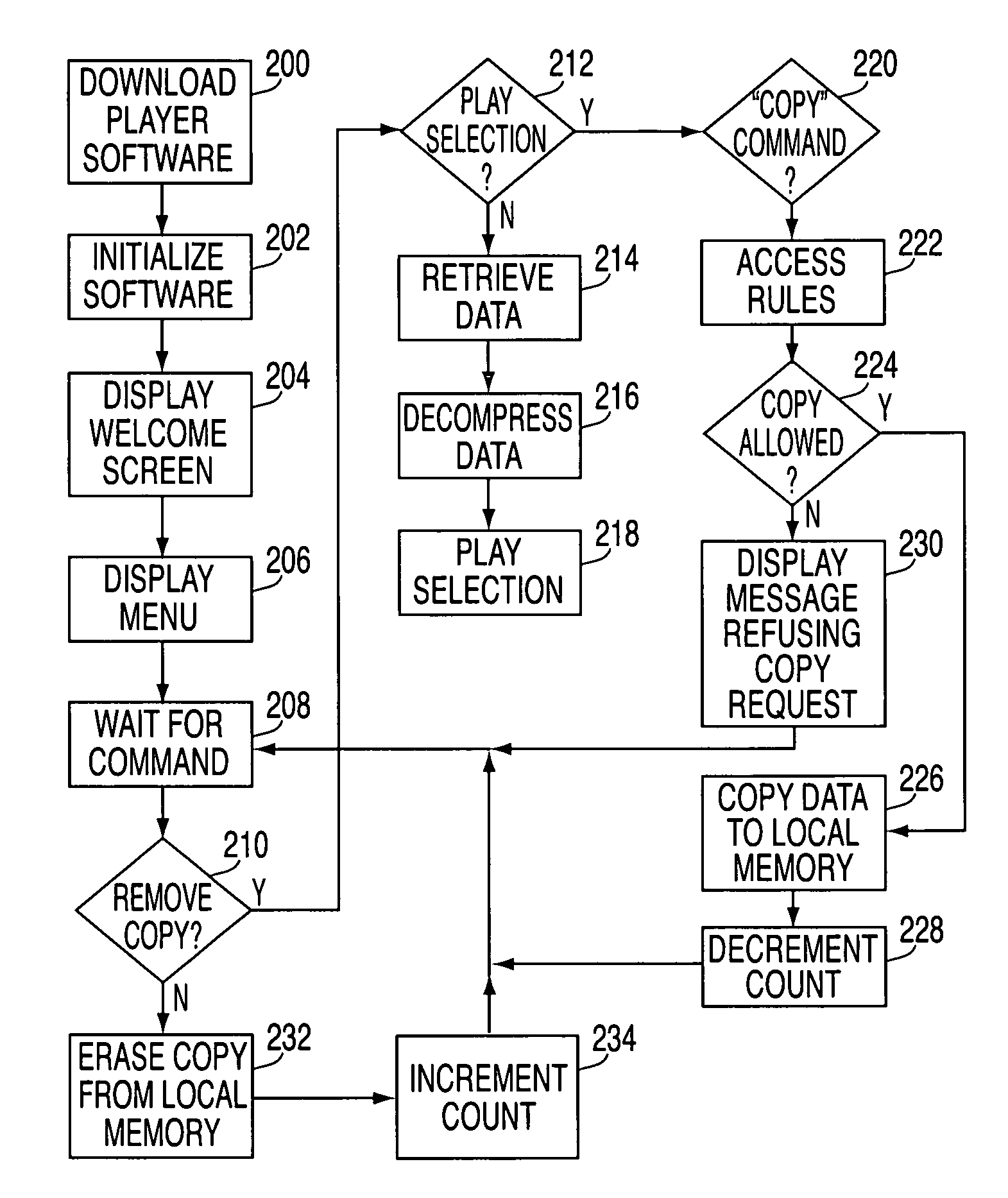

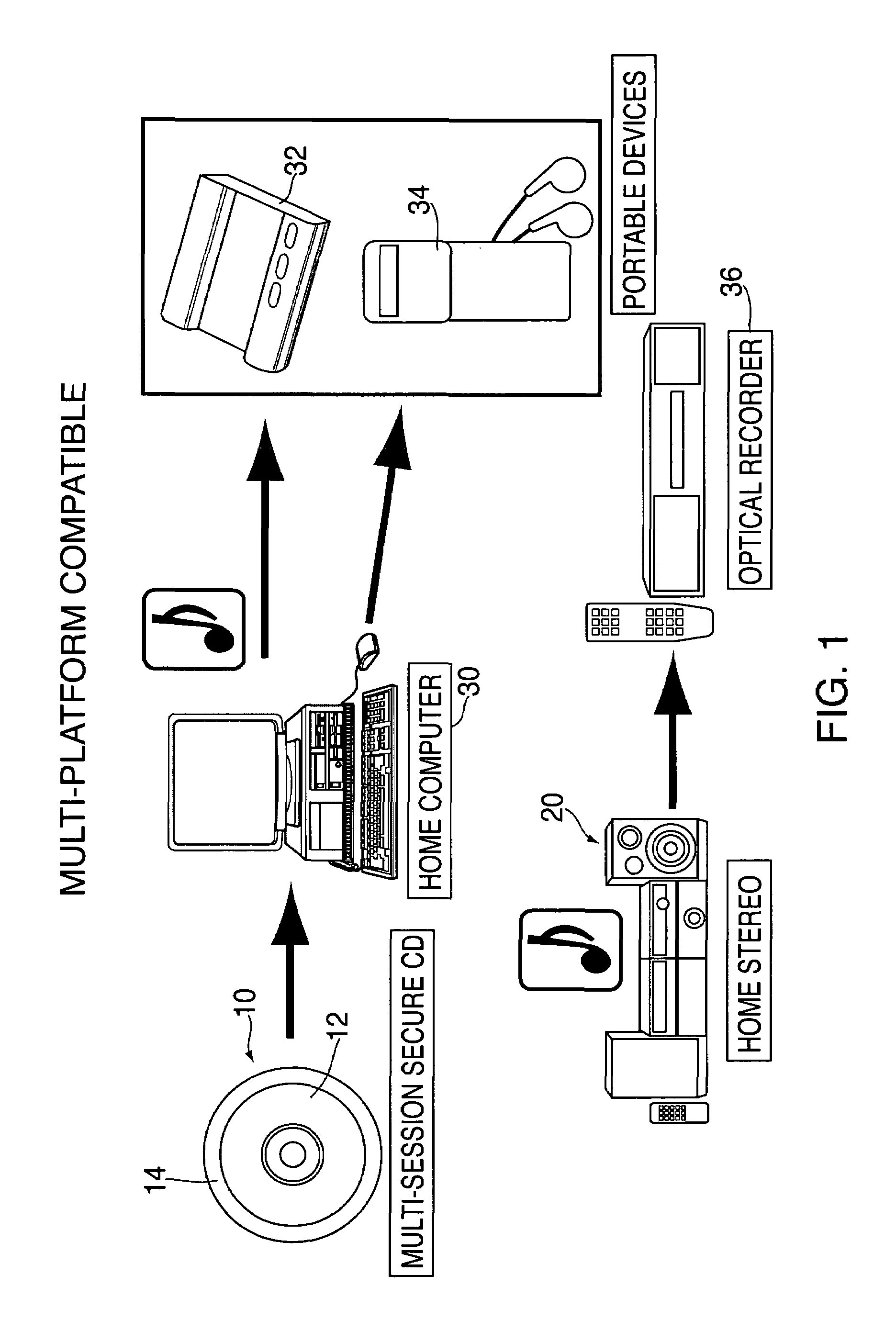

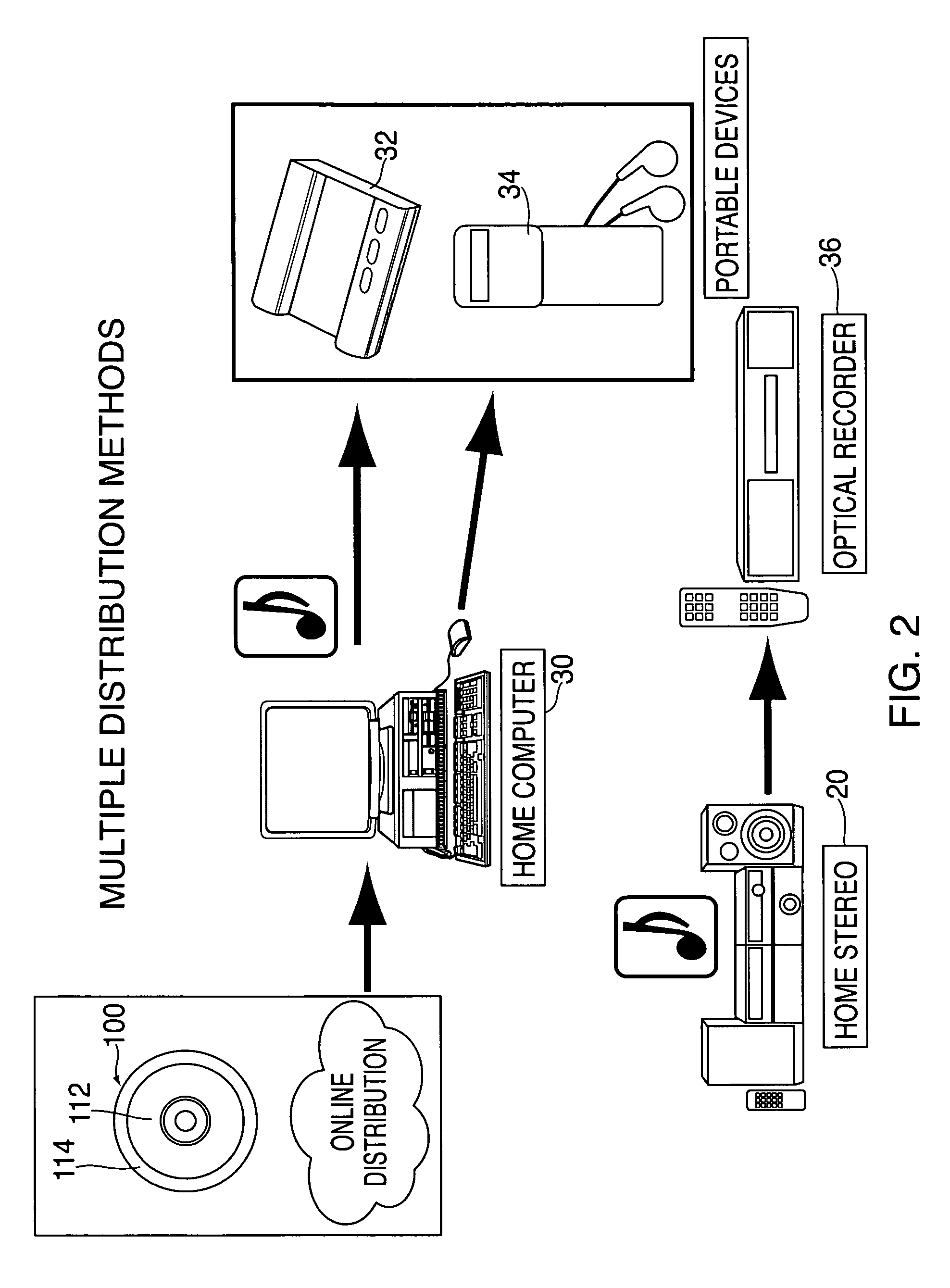

Method and apparatus for distributing multimedia programs

InactiveUS6993509B2Elimination contentData processing applicationsRecord information storageComputer hardwareGraphics

Distribution of audio and other multimedia content is accomplished by generating a multimedia session consisting of at least one multimedia program, generating a data session consisting of digital files including at least one software player program and a digital compressed file corresponding to the multimedia program; and distributing the multimedia and data sessions to consumers. The consumers can selectively play the multimedia program from said multimedia session through a player device, and through a computer by using the software player program to manipulate the compressed file. In one aspect of the invention, the multimedia and data sessions are recorded on a physical medium, such as a CD or DVD, and the medium is then distributed. In another aspect, the sessions are combined and transmitted electronically. The data session can include information associated with the multimedia content, in the form of text and graphic files.

Owner:WARNER MUSIC GROUP

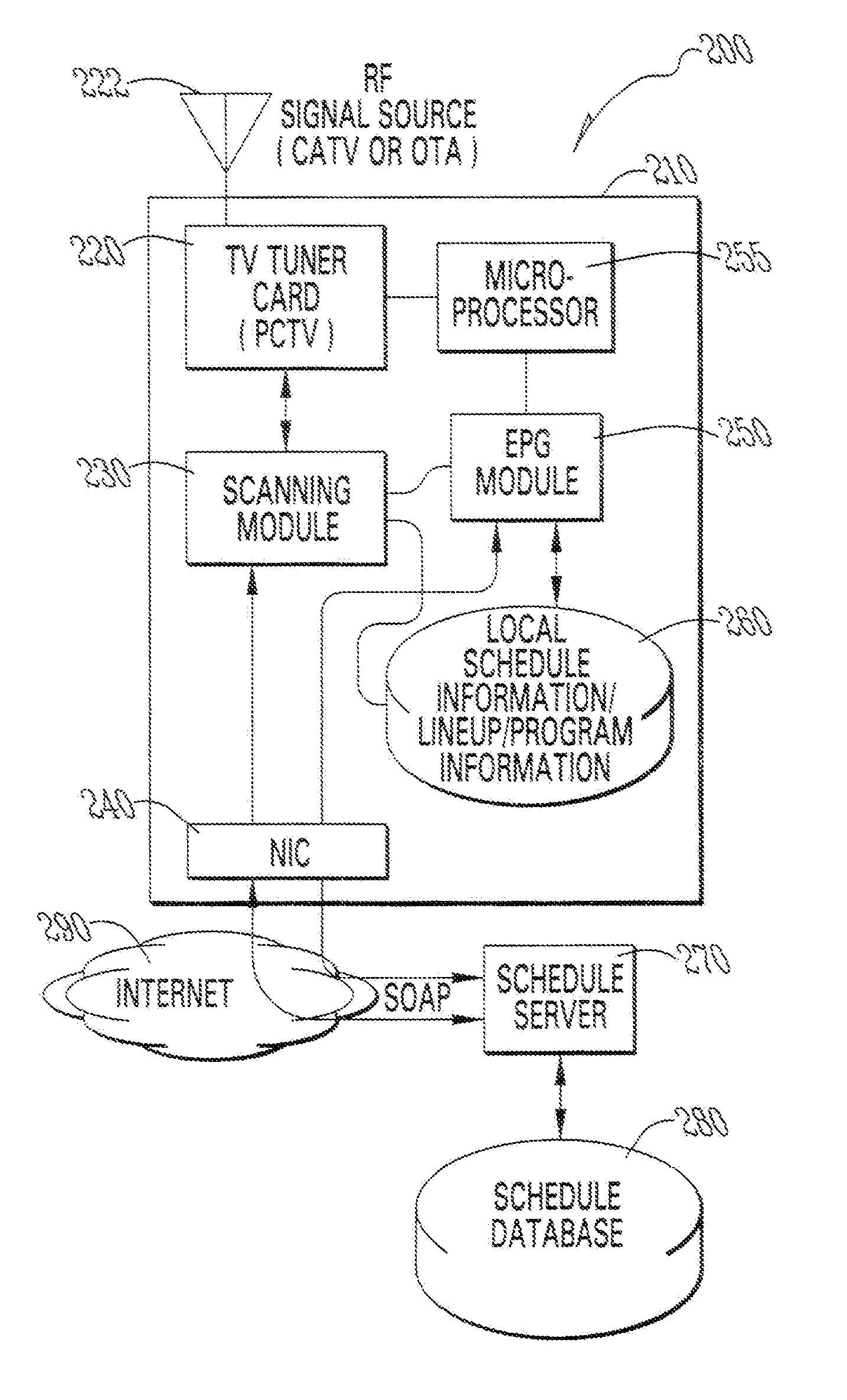

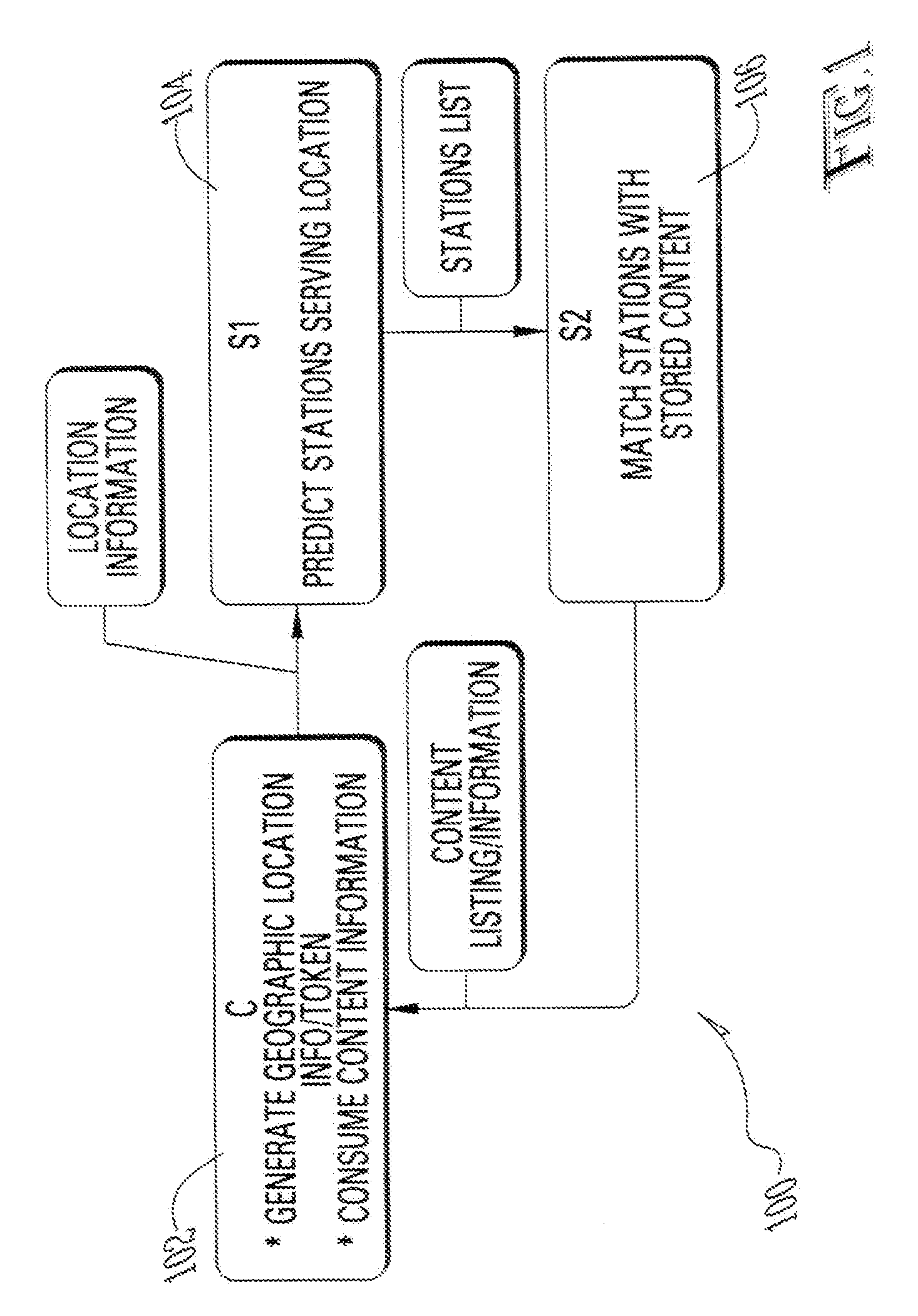

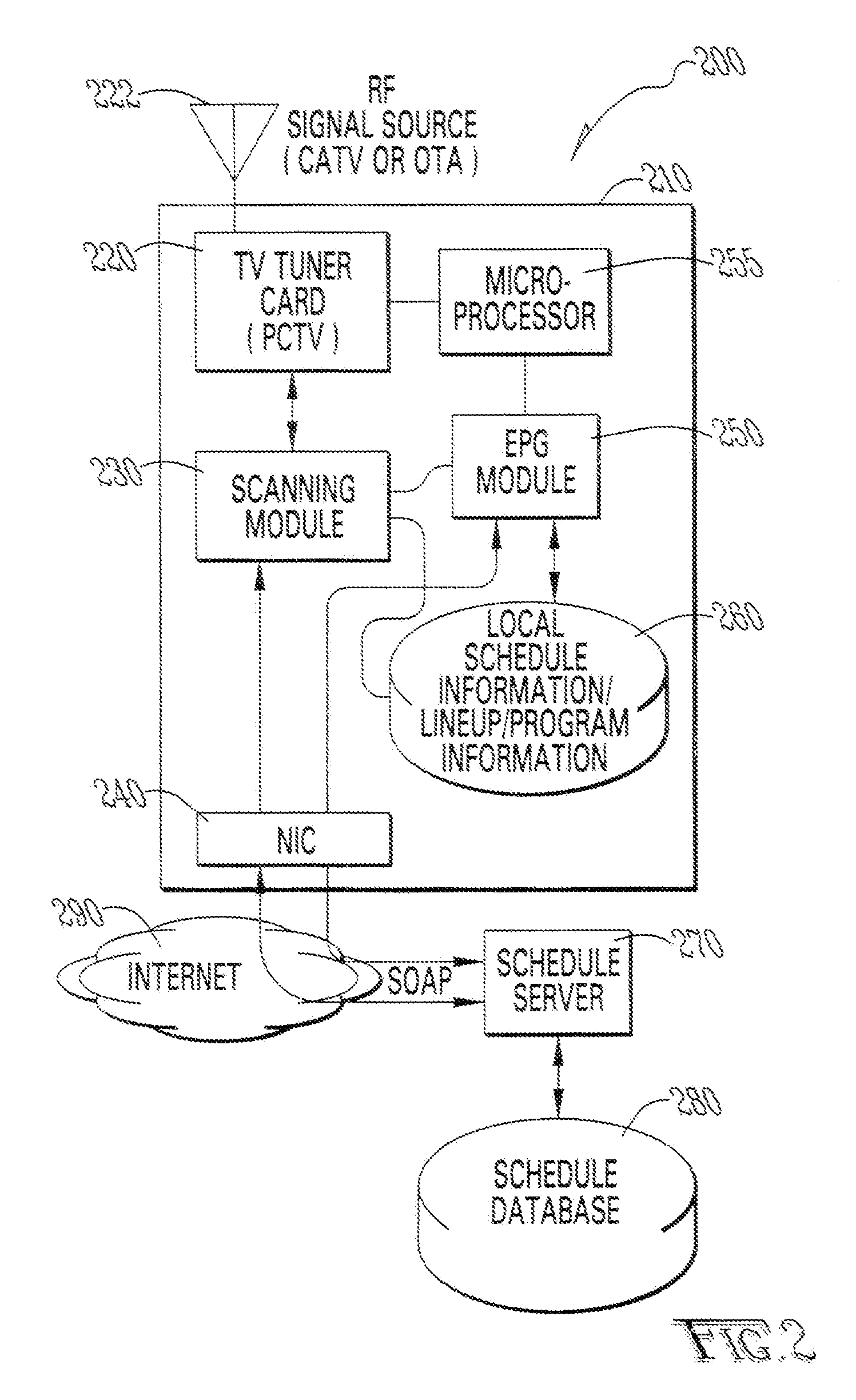

Method and system for creating television programming guide

InactiveUS20070016932A1Elimination contentEliminate requirementsTelevision system detailsColor television detailsTelevision stationElectronic program guide

A household level electronic program guide which provides a PC user with a specific guide of television stations which are available at a location where a cable has been scanned to determine the television channels and stations being broadcast thereon and being provided to the PC.

Owner:TITANTV INC

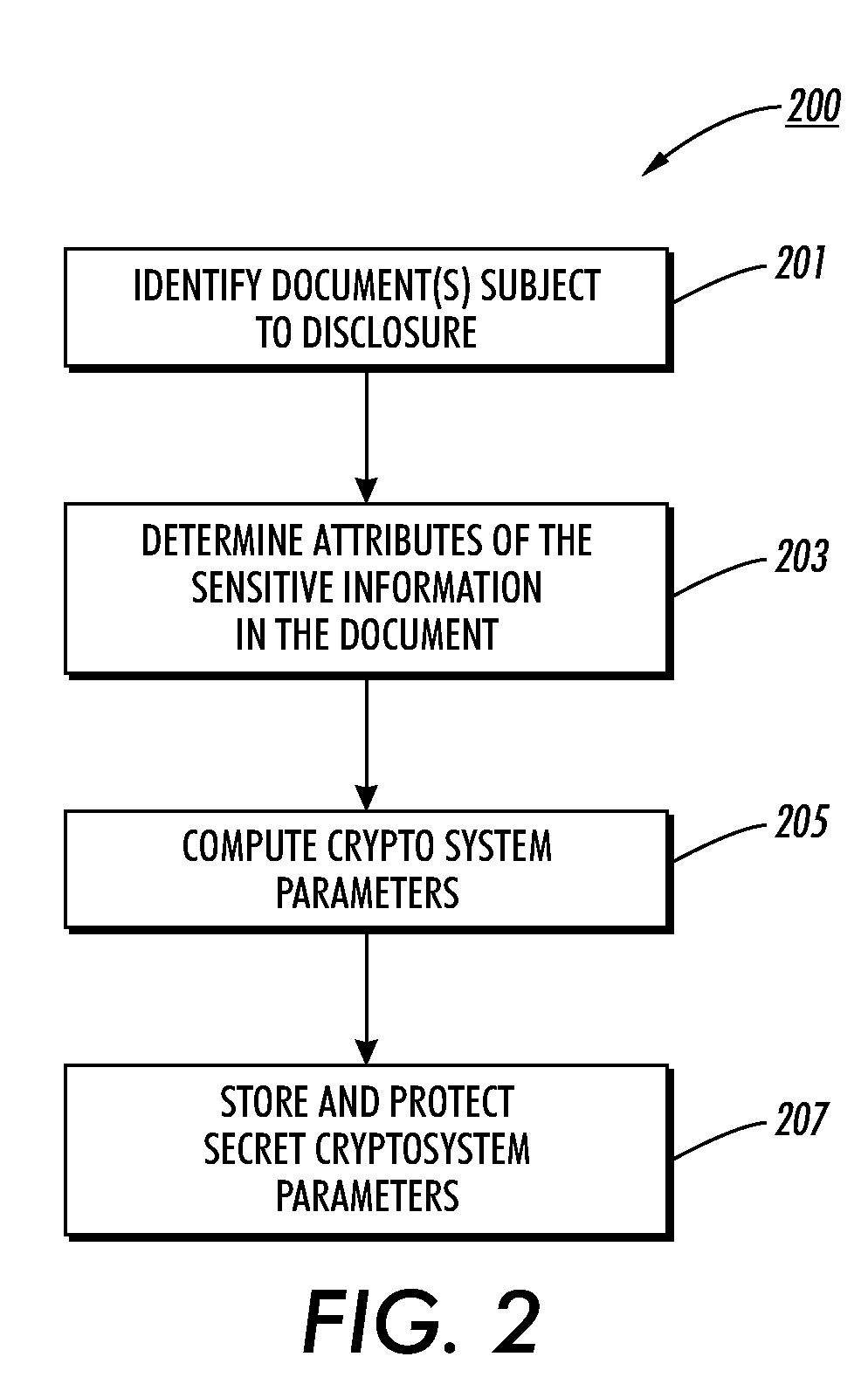

Method, apparatus, and program product for flexible redaction of content

InactiveUS7873838B2Shorten the timeIncrease contentUser identity/authority verificationUnauthorized memory use protectionInternet privacy

A selectively encrypted data unit is generated from an unencrypted data unit. This is accomplished by accessing a list of attributes related to the unencrypted data unit that identify classifications of sensitive information within the unencrypted data unit. In addition, a protection key that is responsive to a random number is selected and auxiliary values computed from the attributes of the sensitive information and the random number are produced. The sensitive information is encrypted with the protection key to create an encrypted version of the sensitive information. The encrypted version is associated with the auxiliary values and linked to an attribute vector that classifies the sensitive information in the encrypted version. Data from the unencrypted data unit and the encrypted version of the sensitive information is stored as the selectively encrypted data unit.

Owner:MAJANDRO LLC

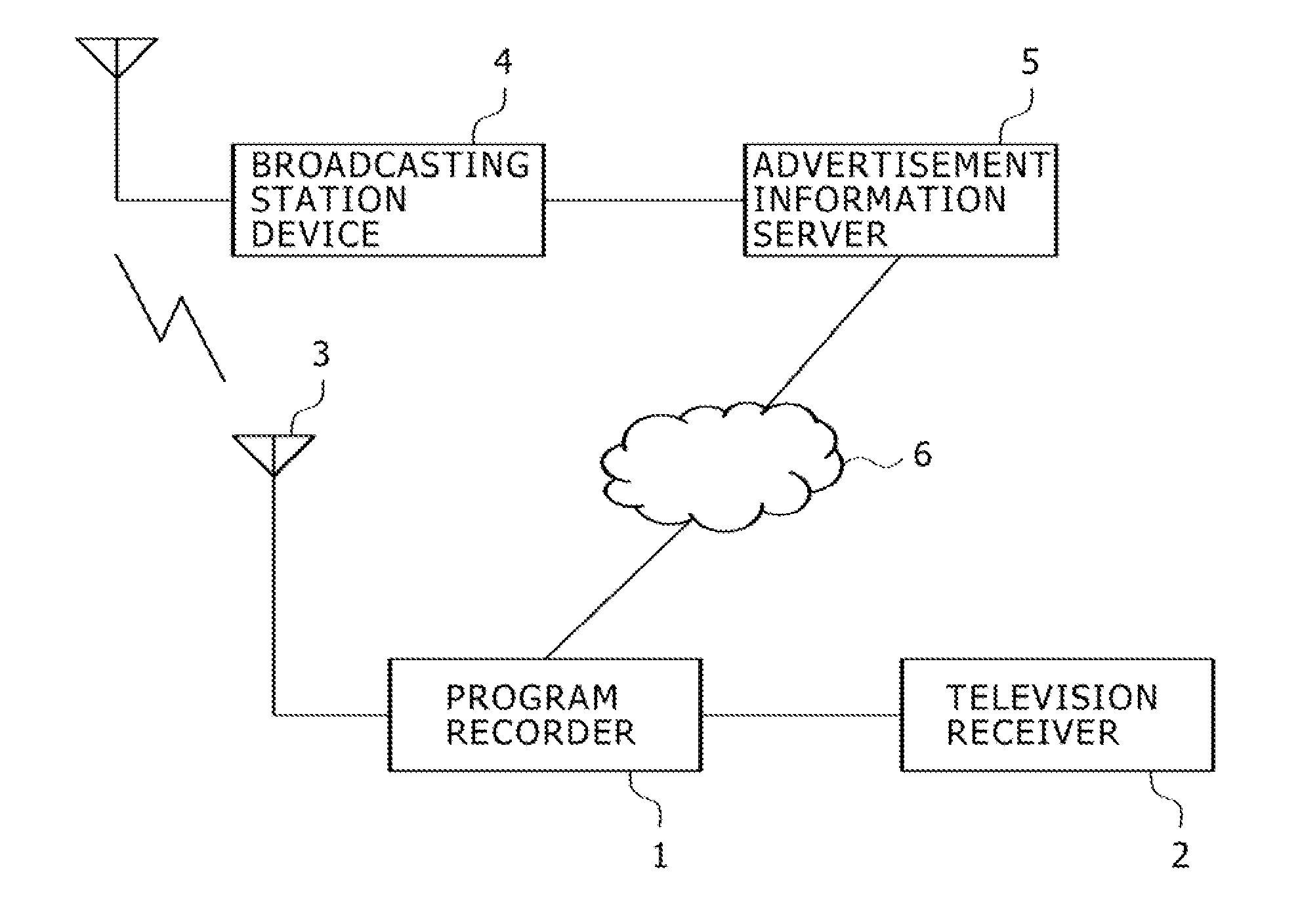

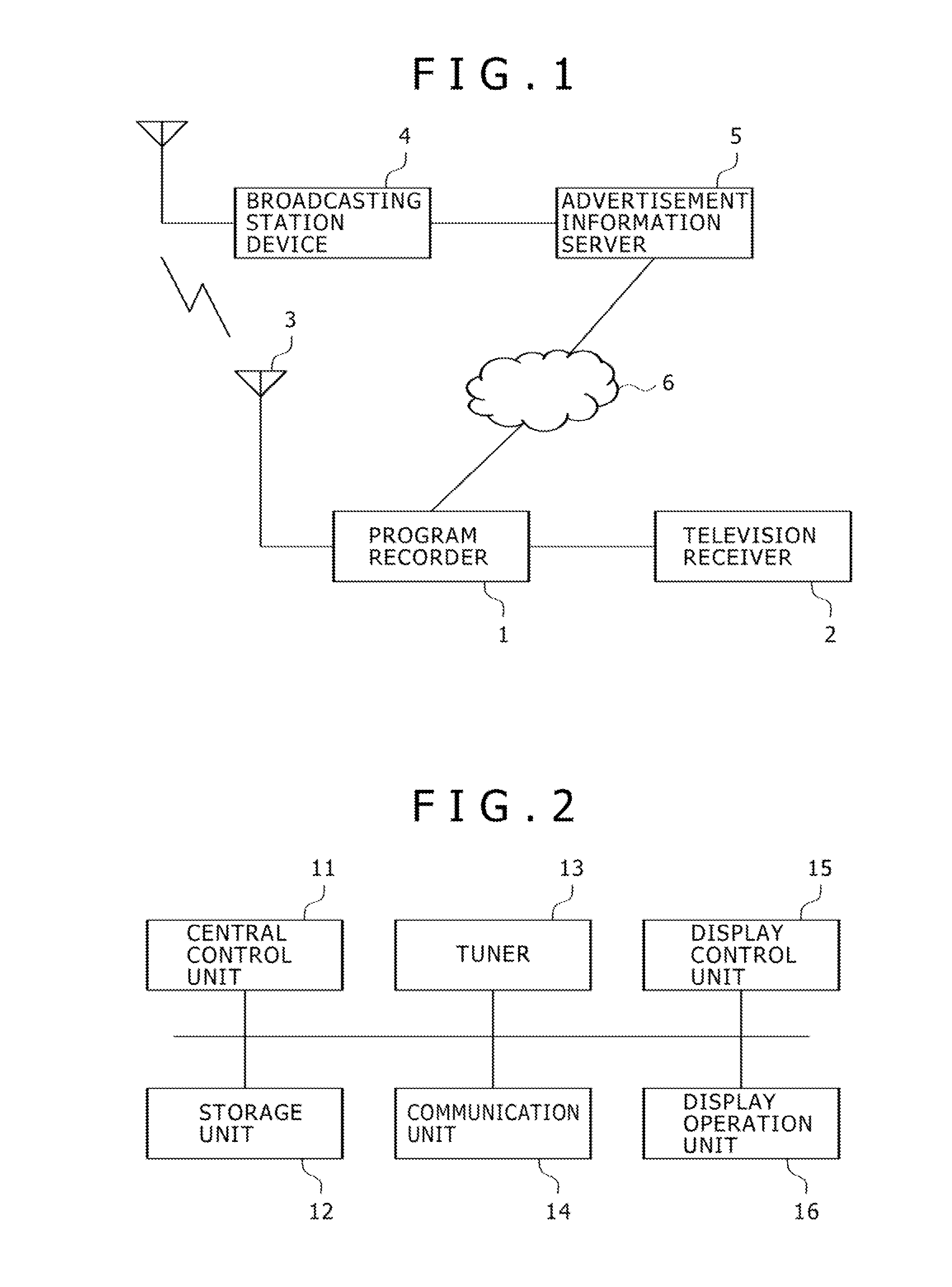

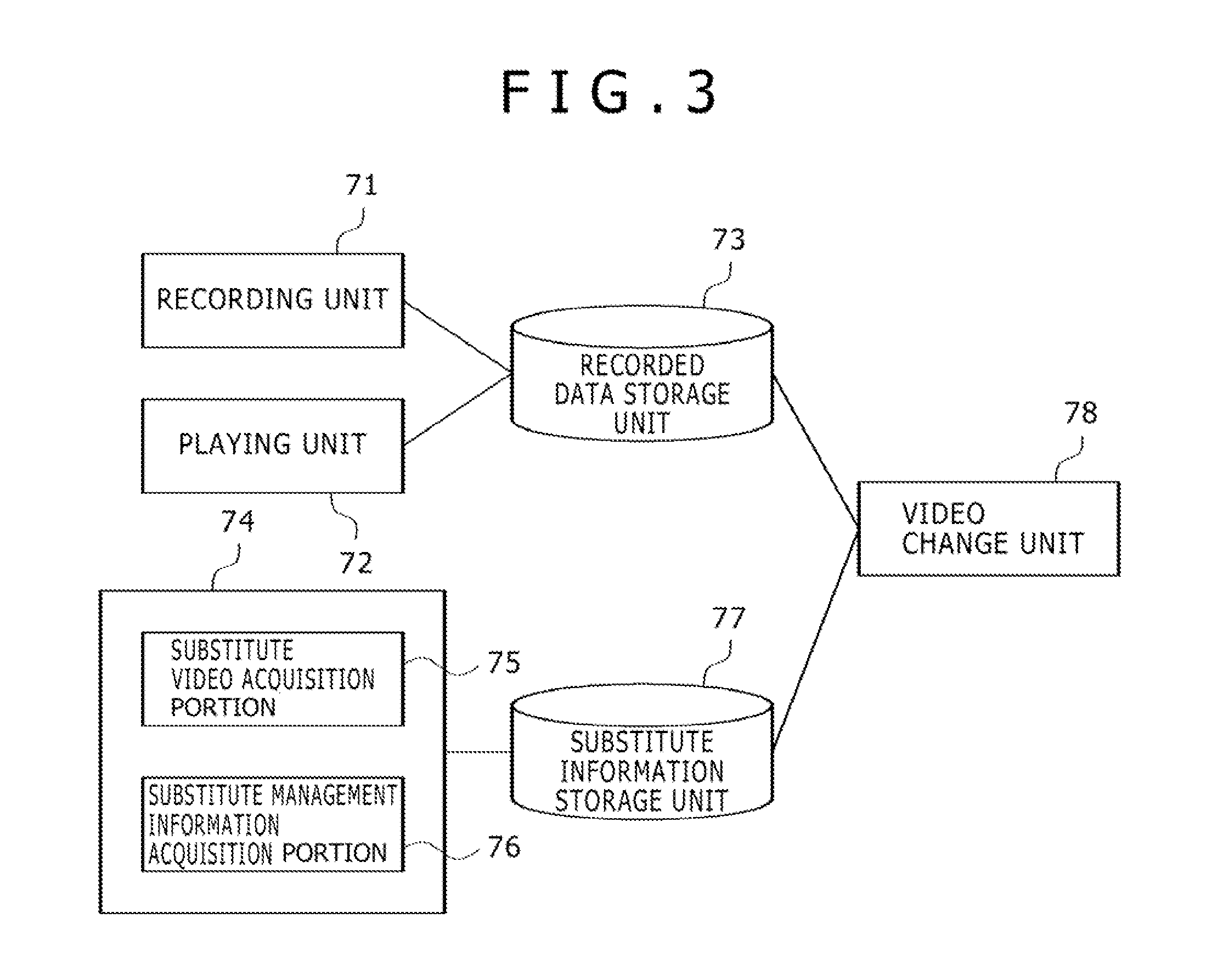

Broadcast program processing device, broadcast program processing method, broadcasting station device, information distribution server, program, and information storage media

ActiveUS20140298381A1Rule out the possibilityElimination contentTelevision system detailsElectronic editing digitised analogue information signalsComputer graphics (images)Broadcasting

A broadcast program processing device includes video content recording unit. The video content recording unit causes a storage unit to store a plurality of pieces of video content each of which includes at least one advertisement video. The broadcast program processing device changes the advertisement video included in a piece of video content stored in the storage unit to a substitute advertisement video before being instructed to play any one of the pieces of video content and plays the piece of video content whose advertisement video has been changed if instructed to play any one of the pieces of video content.

Owner:SONY COMPUTER ENTERTAINMENT INC

Container

InactiveUS20060000840A1Elimination contentCapsPowdered material dispensingEngineeringMechanical engineering

Owner:MEAD JOHNSON NUTRITION

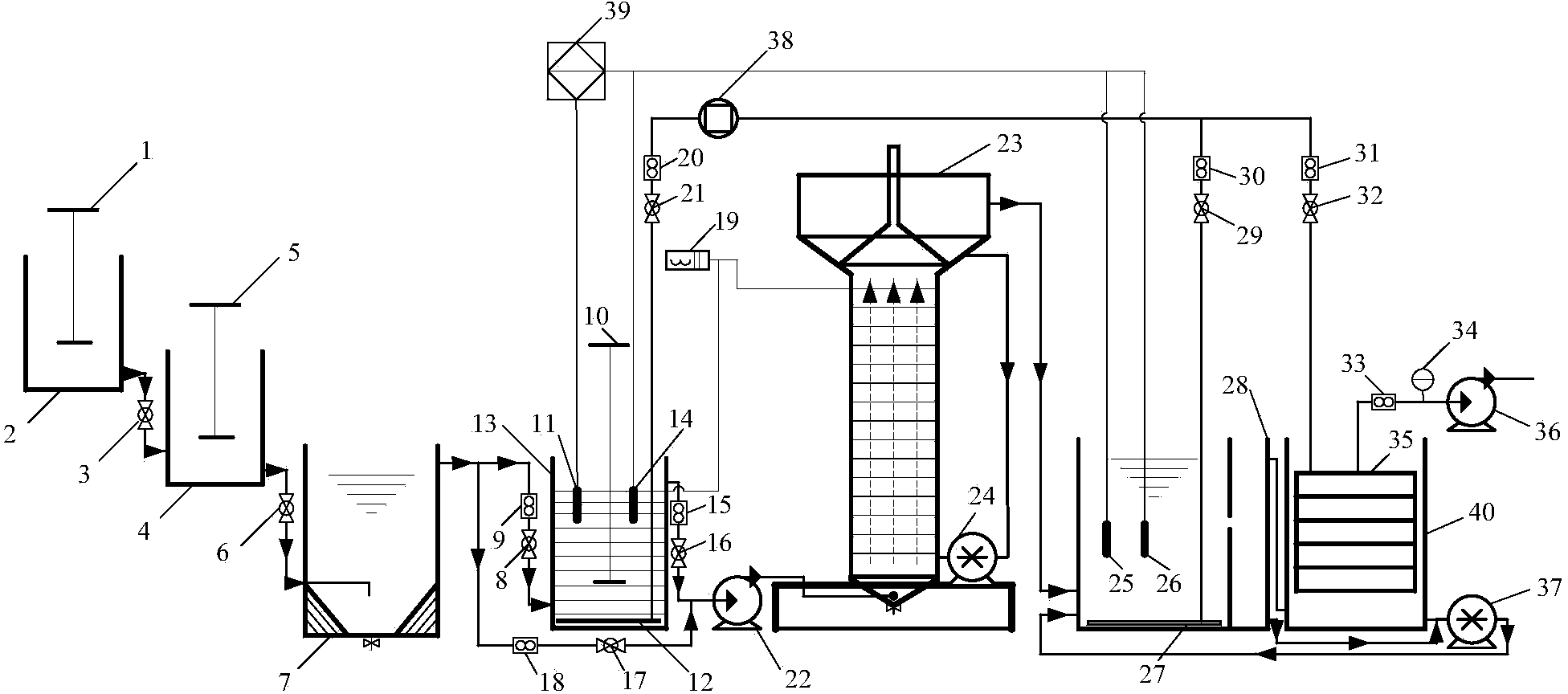

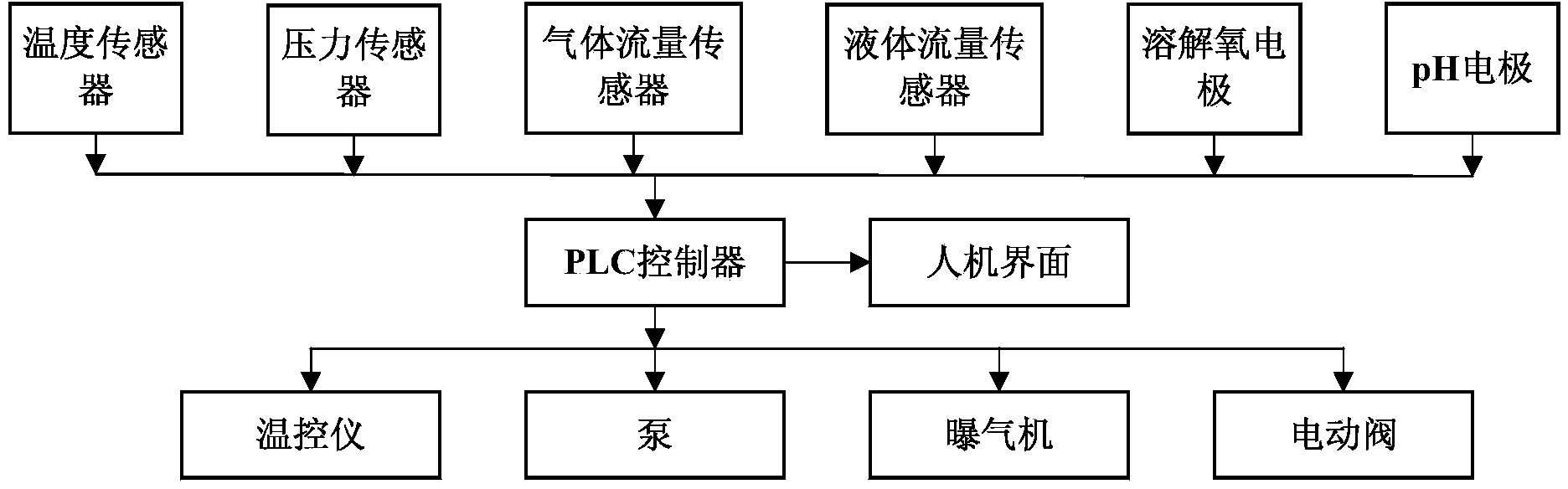

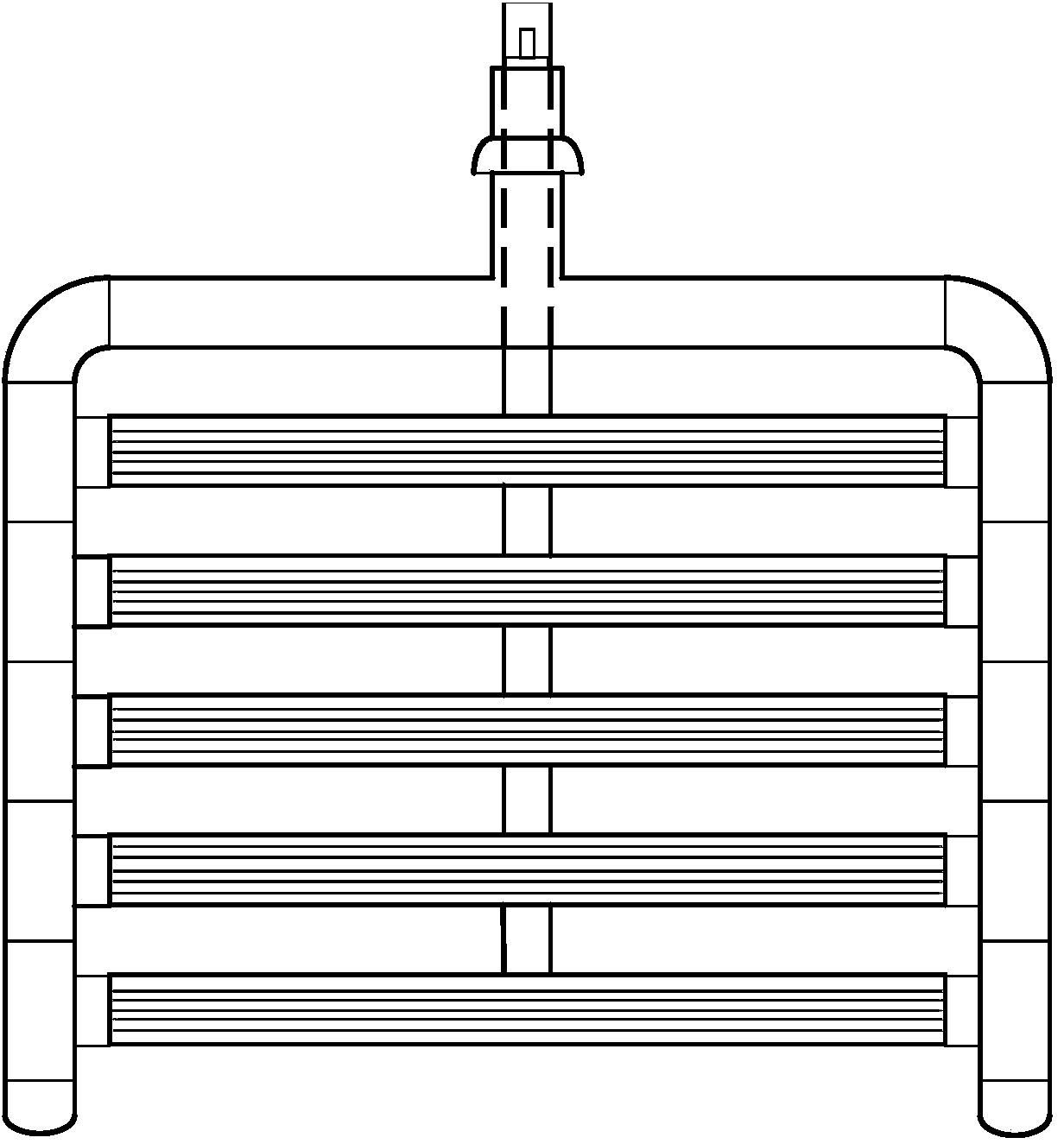

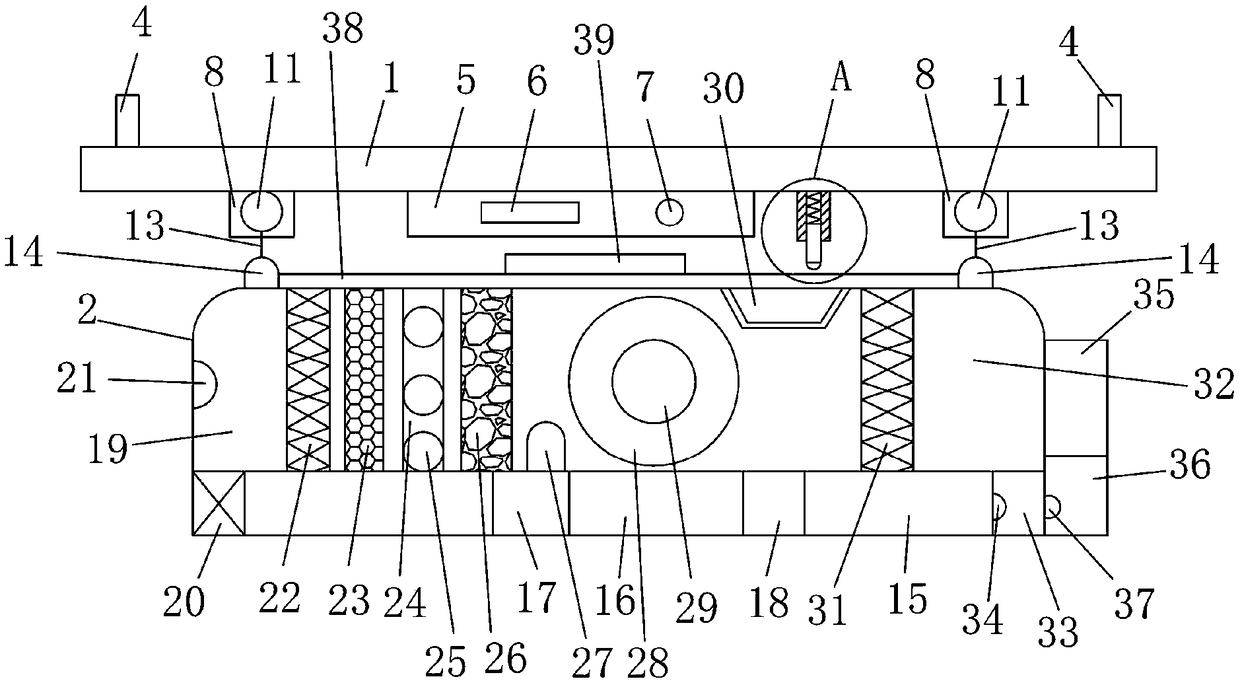

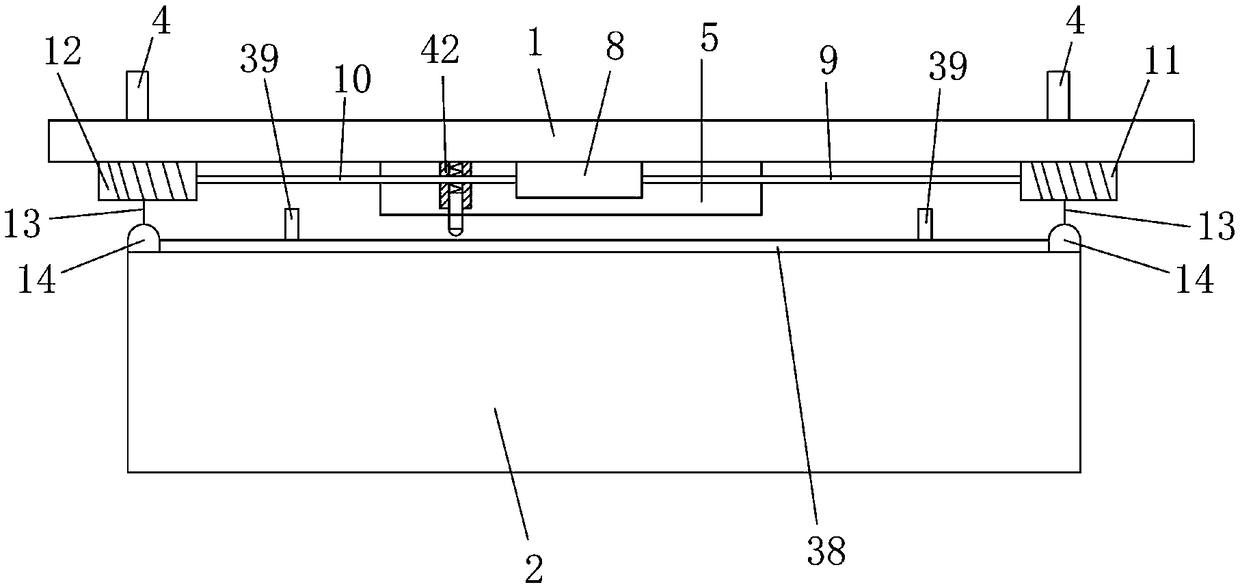

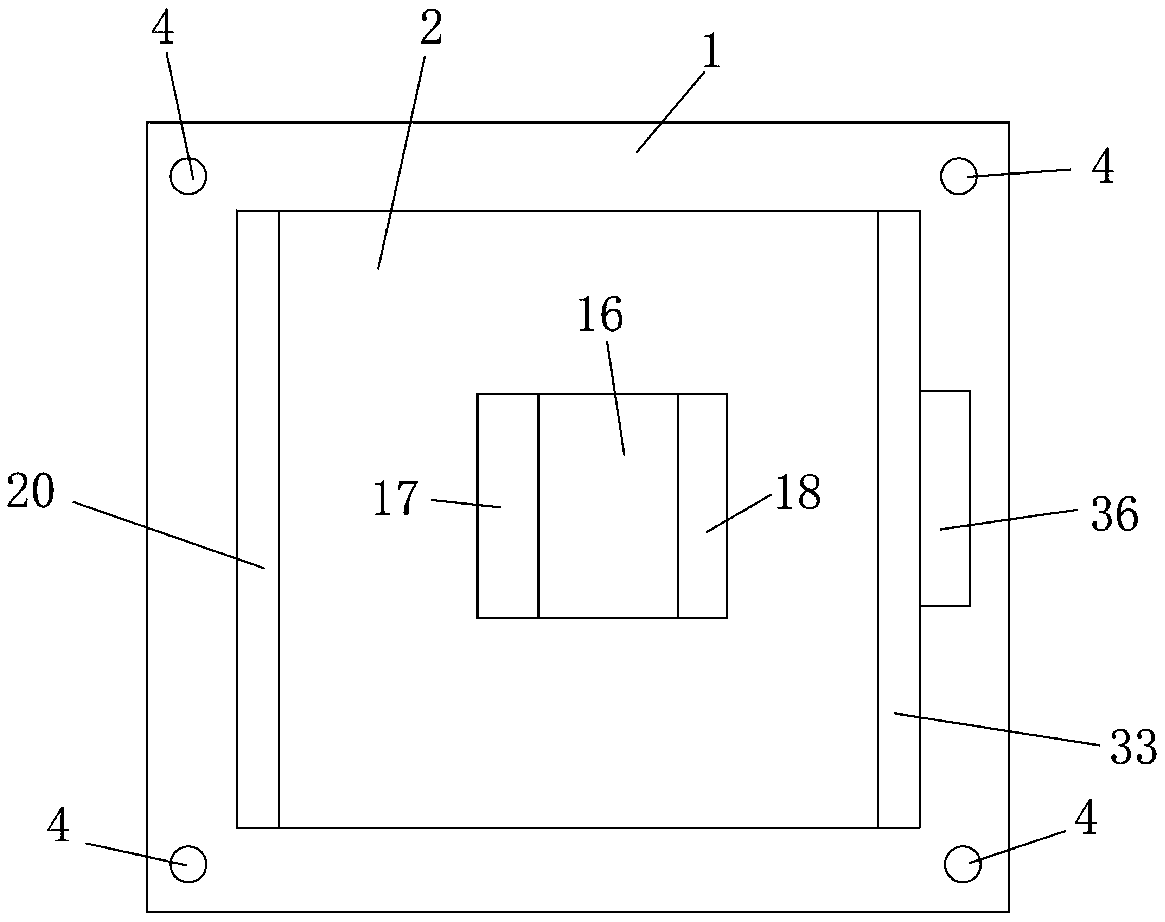

Garbage leachate treating device

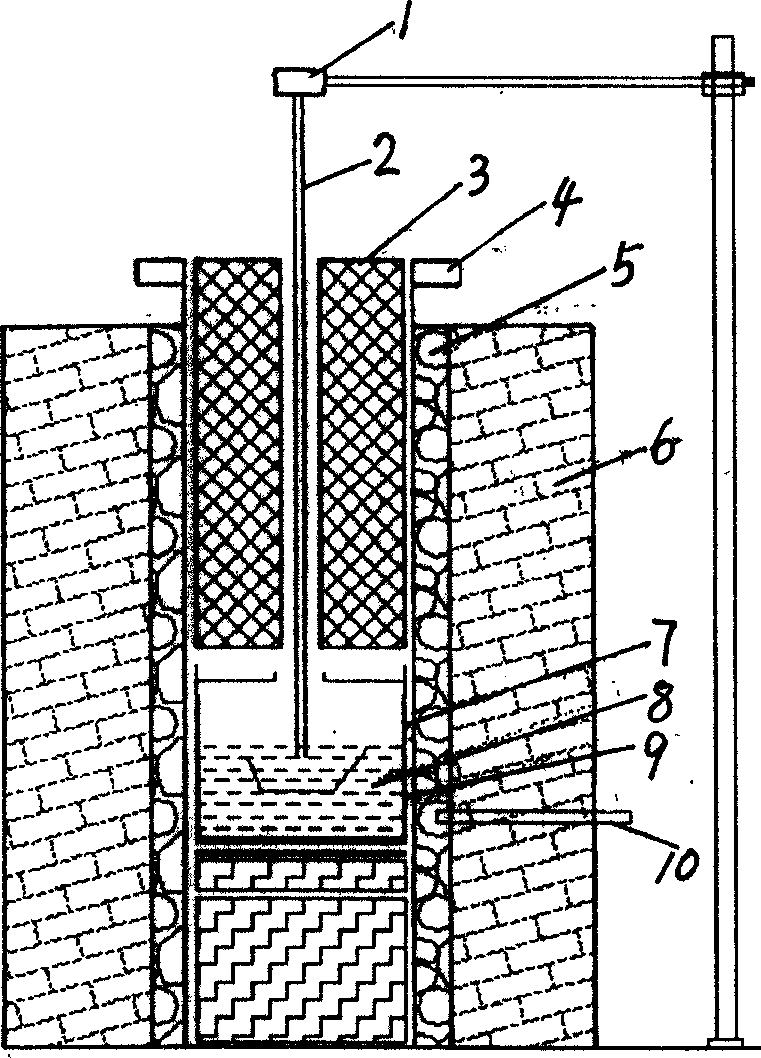

InactiveCN103539319ASensitive controlEasy to manageTreatment using aerobic processesMultistage water/sewage treatmentLitterWater quality

The invention belongs to the technical field of waste water treatment and particularly relates to a garbage leachate treating device. By virtue of the garbage leachate treating device, an adsorption-coagulation-nitrosation-anaerobic ammonium oxidation-aerobic treatment-membrane bioreactor combined process can be applied to the treatment of garbage leachate. The garbage leachate treating device comprises the following three parts: a. a pretreatment part which is formed by means of sequentially connecting an adsorption tank, a coagulation tank and a sedimentation tank; b. a denitrification part which is formed by a nitrosation reactor and an anaerobic ammonium oxidation reactor; and c. a main body treatment part which is formed by an aerobiotic tank and a membrane tank. Aiming at the water quality characteristics of the garbage leachate, the garbage leachate treating device organically combines a physicochemical treatment unit and a biological treatment unit; simultaneously the treating device is transformed reasonably and has the advantages of short and compact technological process, high treatment efficiency, low energy consumption, long membrane-component service life, and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

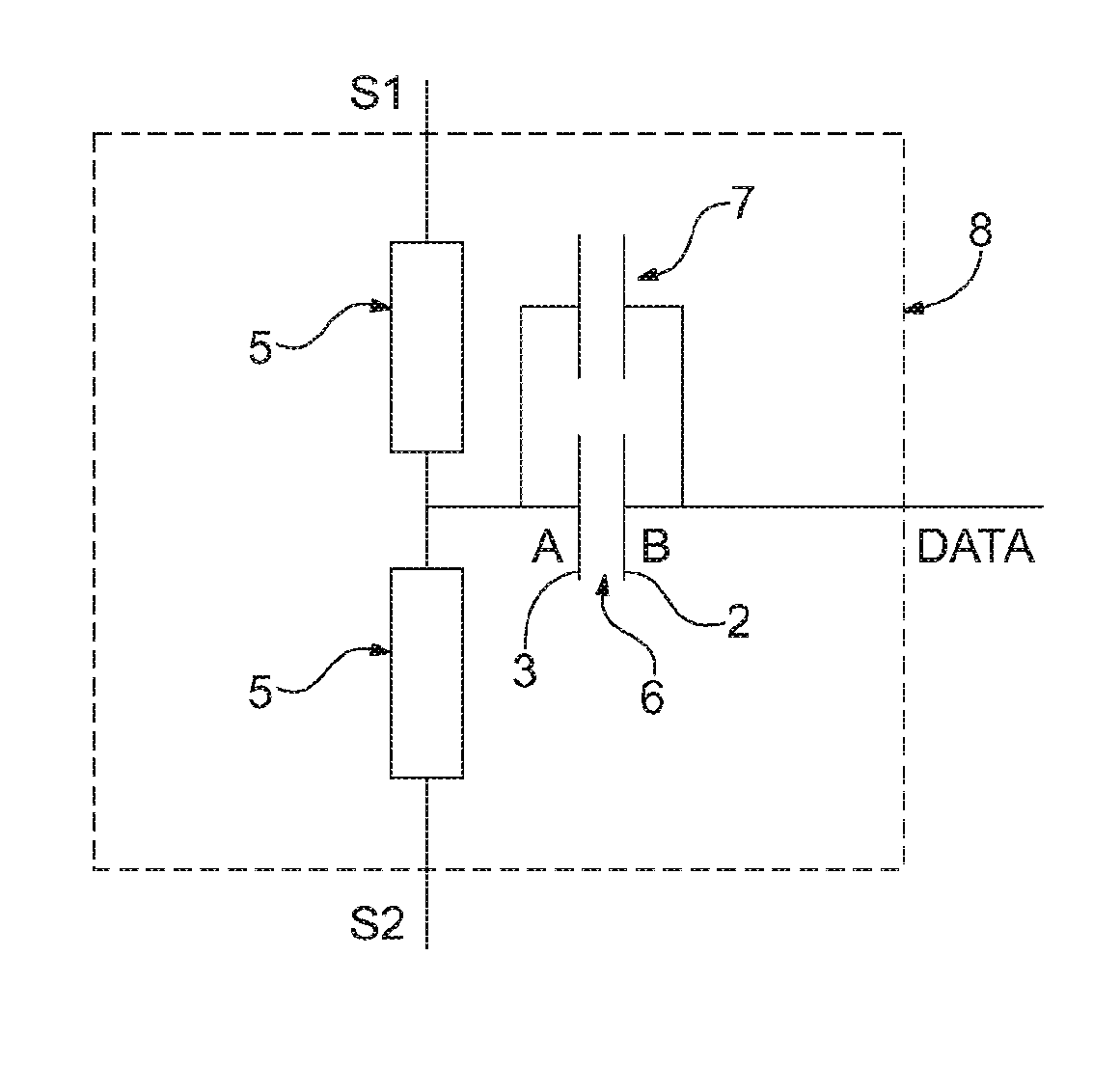

In-Plane Switching Liquid Crystal Display Backplane Using Amorphous Metal Non-linear Resistors as Active Sub-pixel Devices

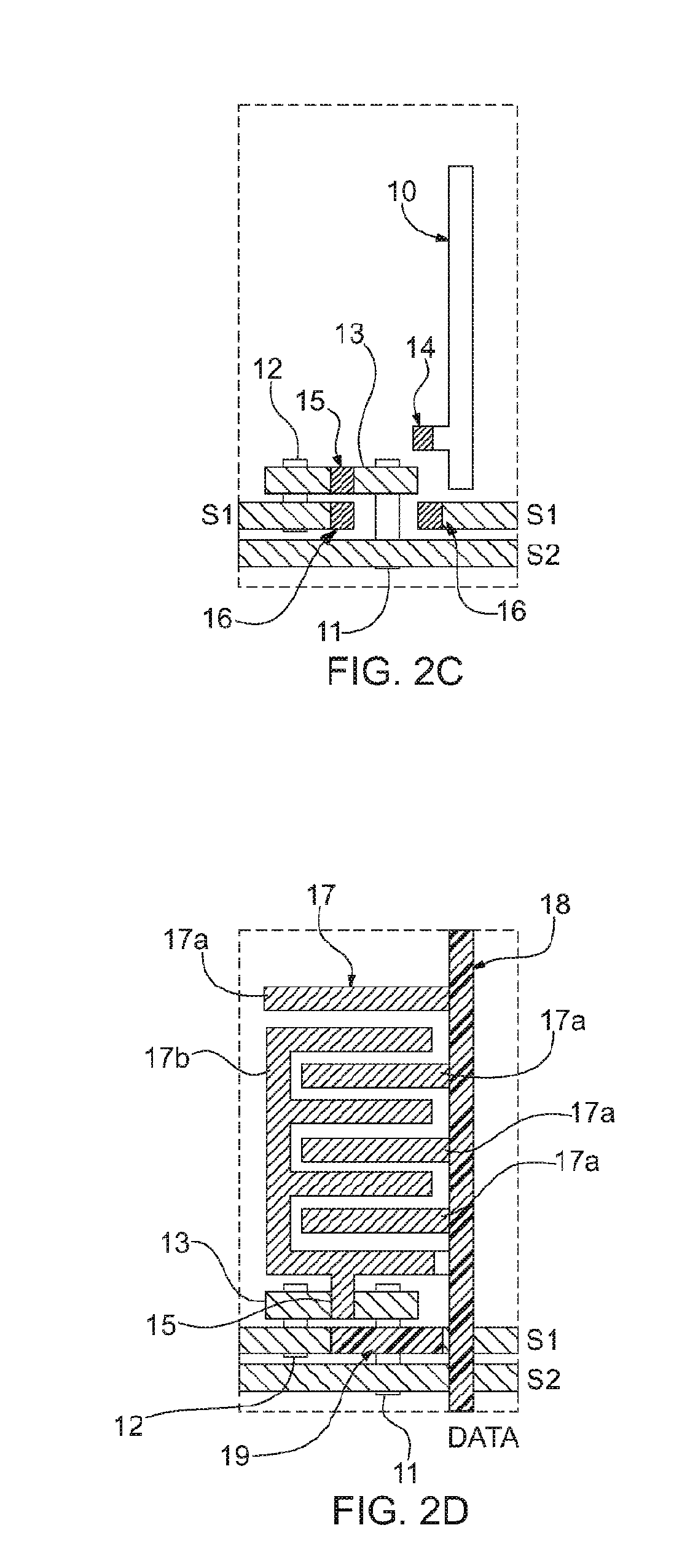

ActiveUS20180203309A1Improve performanceReduce manufacturing costStatic indicating devicesNon-linear opticsEngineeringImaging data

A physical layout for a circuit using amorphous metal non-linear resistors as active devices for an in-plane switching liquid crystal display sub-pixel is provided. The lower interconnect of the two amorphous metal non-linear resistors and the lower electrode of the storage capacitor may be concurrently deposited and patterned. The area of the storage capacitor is defined by the overlap of the data signal inter-connect and the storage capacitor lower electrode, which is easily modified through the size of the lower electrode and / or the size of the data signal interconnect where it overlaps the lower electrode and does not degrade the aperture ratio of the pixel. Two embodiments of sub-pixel circuits are described. One, which employs a select line bridge, enables the use of full dot inversion of the image data. The second only allows row inversion of the image data.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

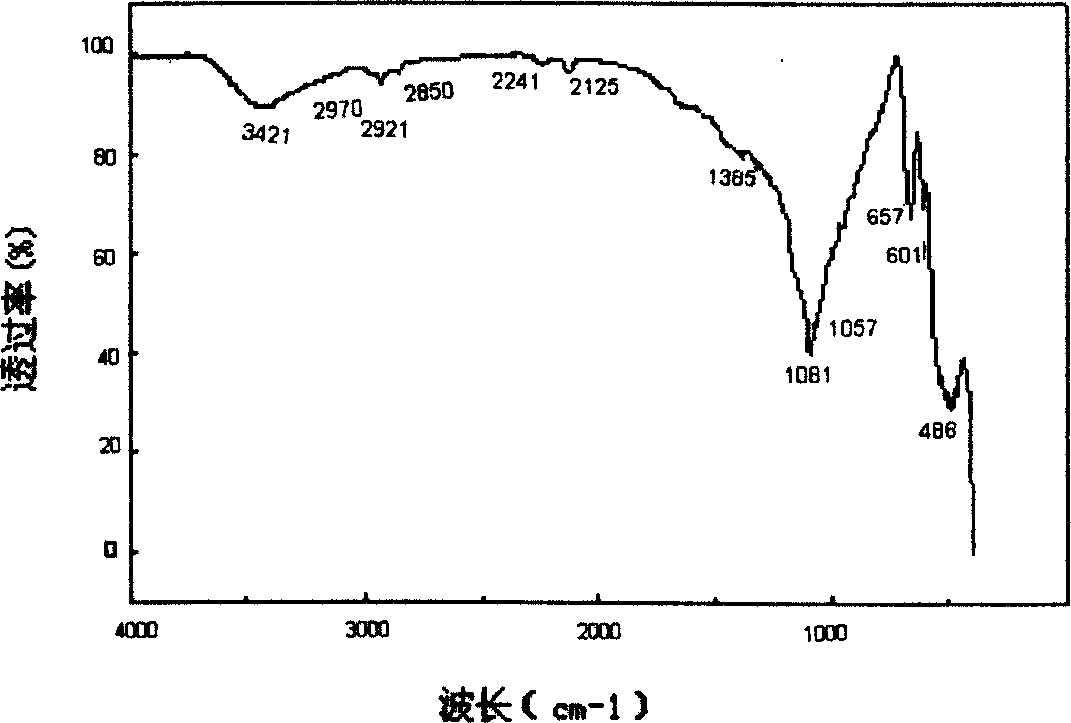

Flux method for growth of gallium phosphate crystal

InactiveCN1763264AImprove piezoelectric performanceElimination contentPolycrystalline material growthFrom melt solutionsLithium carbonateSeed crystal

The present invention is fluxing agent growth process of gallium phosphate crystal. Through using lithium carbonate and molybdenum oxide as flux, gallium oxide and ammonium dihydrogen phosphate as main material, mixing ammonium dihydrogen phosphate, gallium oxide, lithium carbonate and molybdenum oxide in the weight ratio of 1 to 1.23 to 1.12 to 6.57, setting the mixture in platinum crucible, heating to melt inside growth furnace and cooling to the temperature of 10-20 deg.c over the solution saturation point to obtain the mixed melt of gallium phosphate and the flux, introducing seed crystal into the growth furnace, lowering the temperature to 1-2 deg.c over the solution saturation point when the seed crystal begins to melt and rotating the seed crystal in 30 rpm for 24 hr, gallium phosphate crystal is grown. After lowering the temperature, the crystal is taken out of the solution. The process can eliminate water from the crystal and raise the piezoelectric performance of the crystal.

Owner:SHANDONG UNIV

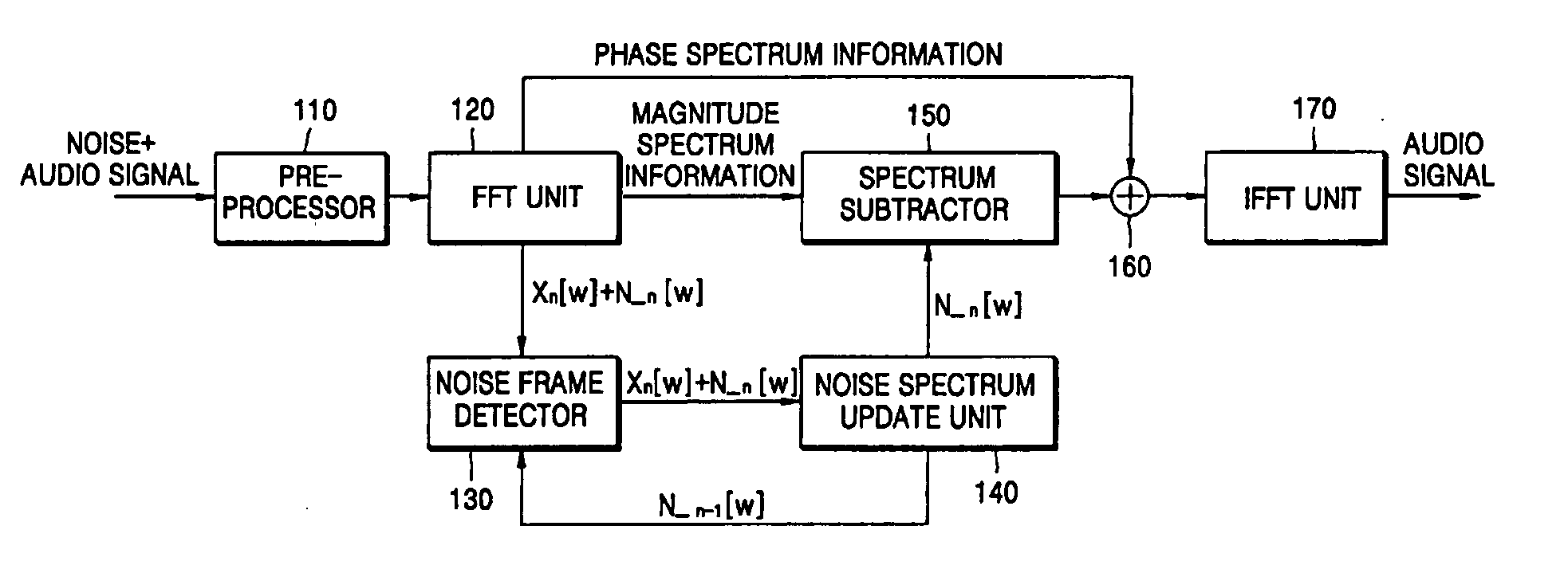

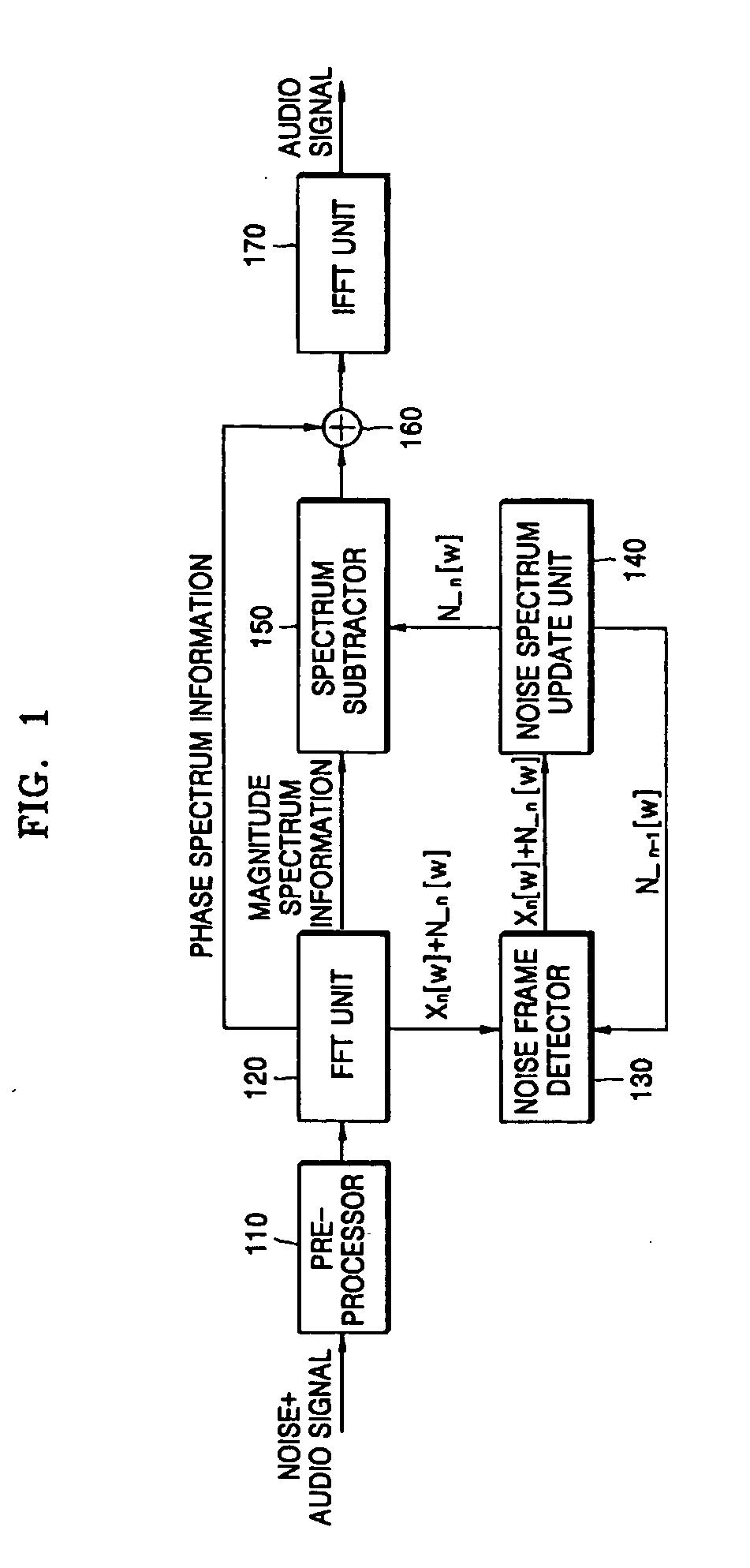

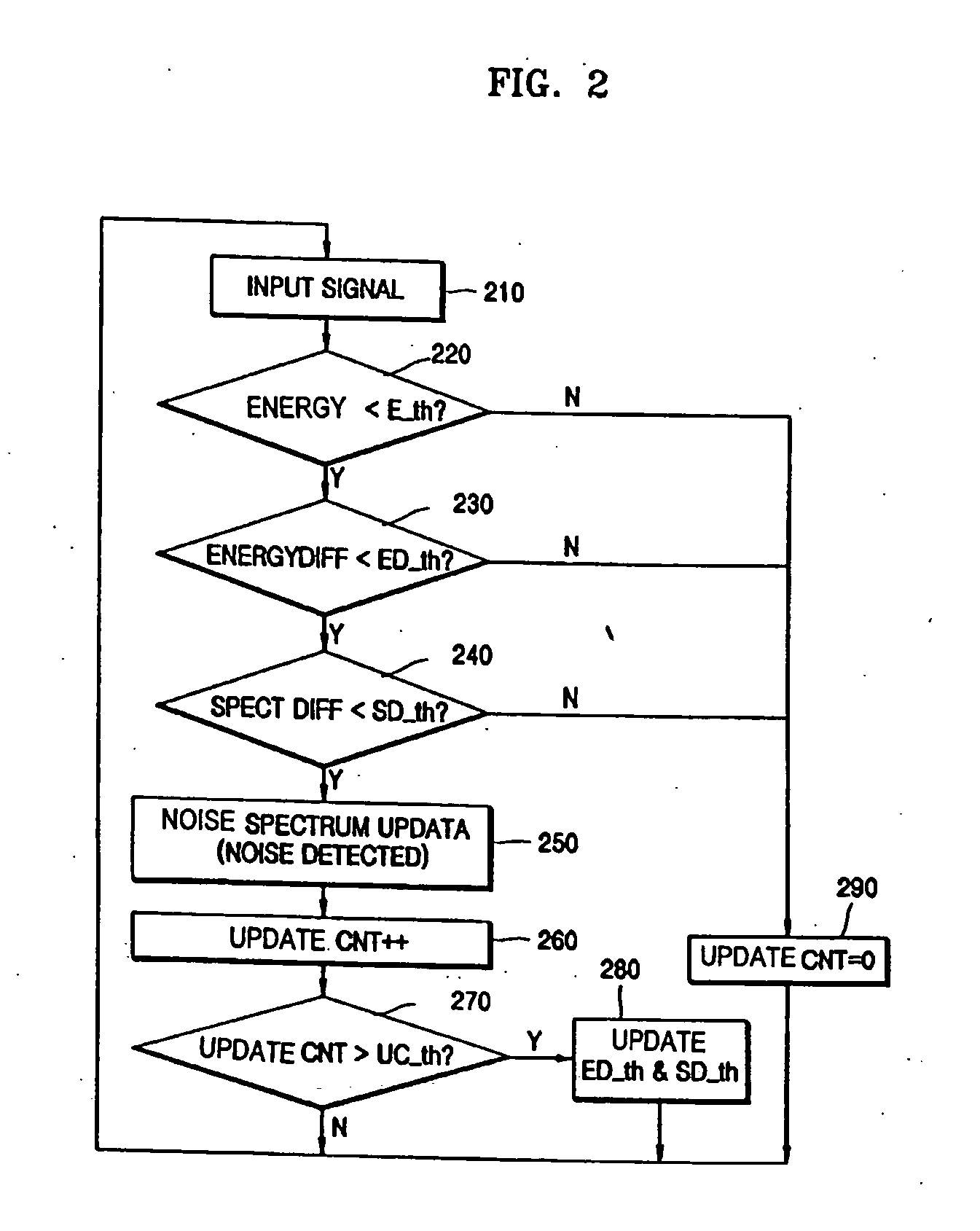

Apparatus and method of eliminating noise from a recording device

InactiveUS20060025992A1Elimination contentTelevision system detailsSignal processing for reducing noiseFrequency spectrumNoise spectrum

A noise elimination apparatus and method of eliminating noise content from a signal including the noise content and audio content input to a recording device, such as a camcorder. The method includes determining whether a noise frame exists by variably setting one or more thresholds independently in zones in which an estimated noise spectrum is updated according to an input audio spectrum of the audio signal, updating the estimated noise spectrum according to a noise spectrum of a previous frame and a noise spectrum of a current frame if the current frame is determined to be a noise frame, and subtracting the estimated noise spectrum from the input audio spectrum of the current frame.

Owner:SAMSUNG ELECTRONICS CO LTD

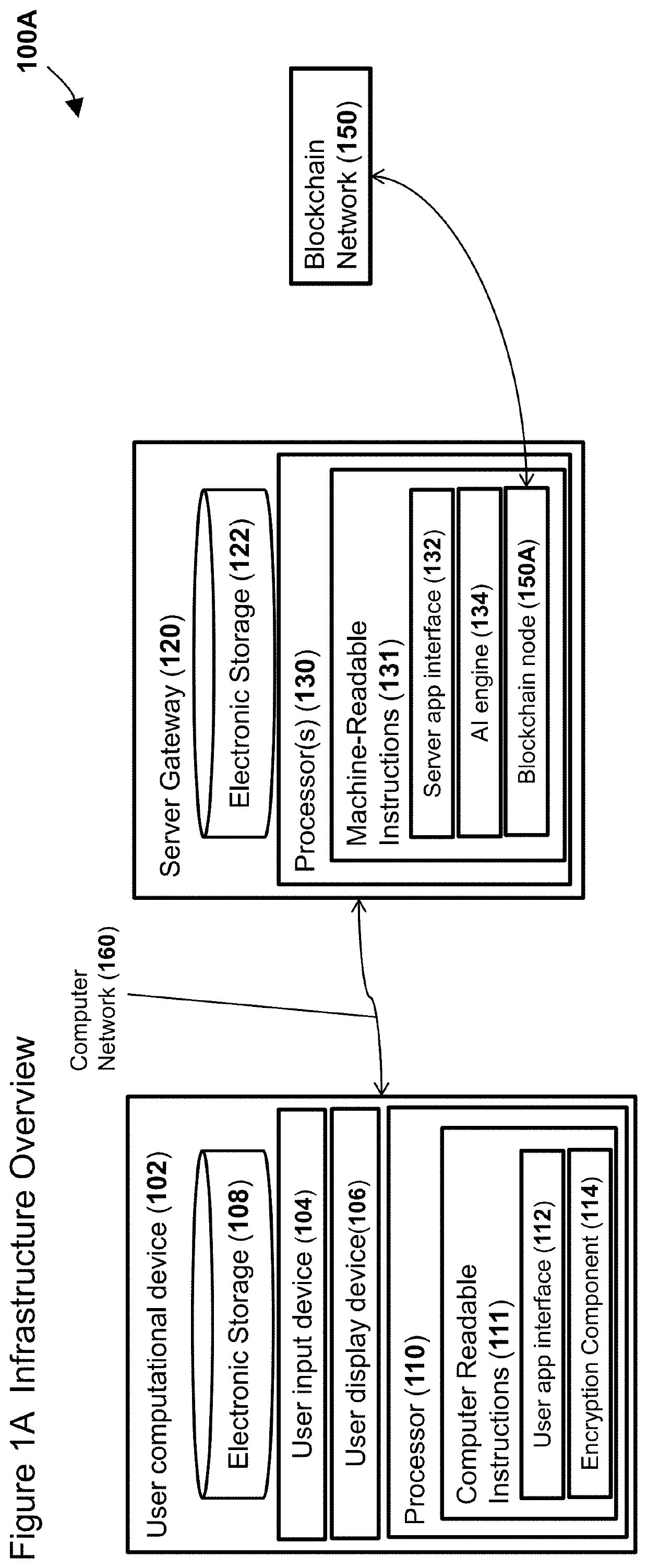

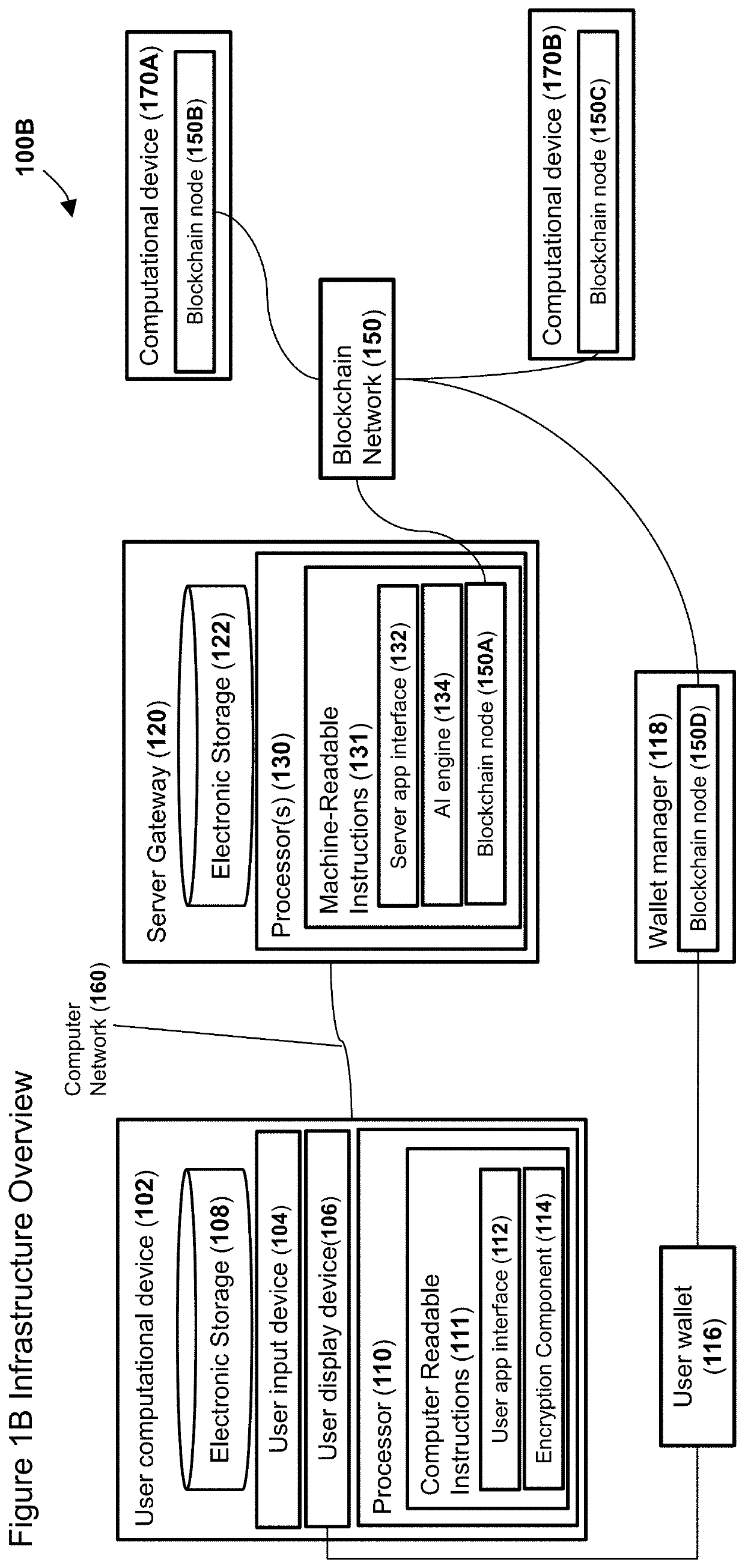

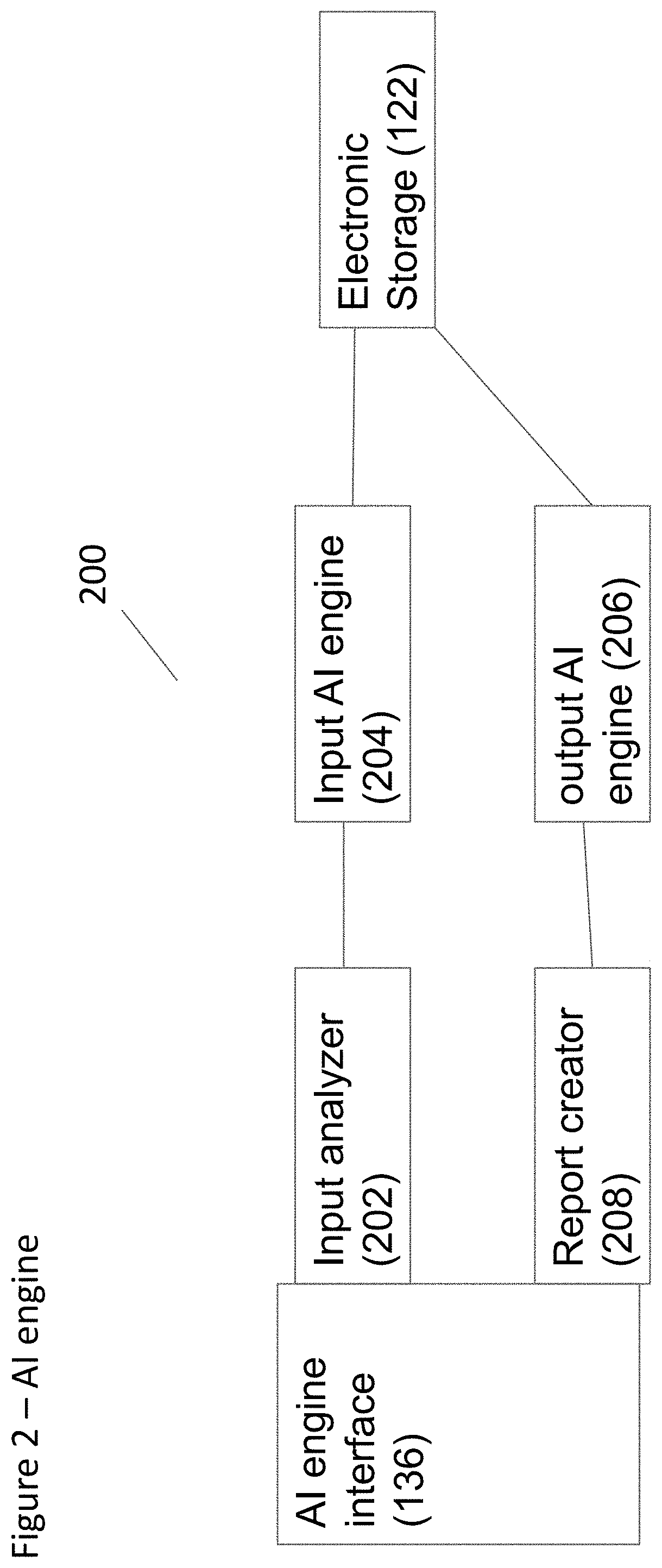

System and method for creating and providing crime intelligence based on crowdsourced information stored on a blockchain

InactiveUS20200143242A1Elimination contentAvoid mistakesKey distribution for secure communicationData processing applicationsEngineeringArtificial intelligence

A system and method for creating and providing crime intelligence based on crowdsourced information stored on a blockchain, where the crowdsourced information is analyzed and evaluated preferably according to an artificial intelligence (AI) model and users are rewarded for providing timely, valuable, and accurate crime tips. The crowdsourced information may be obtained in any suitable manner, including but not limited to written text, such as a document, or audio information.

Owner:INTELLI NETWORK CORP

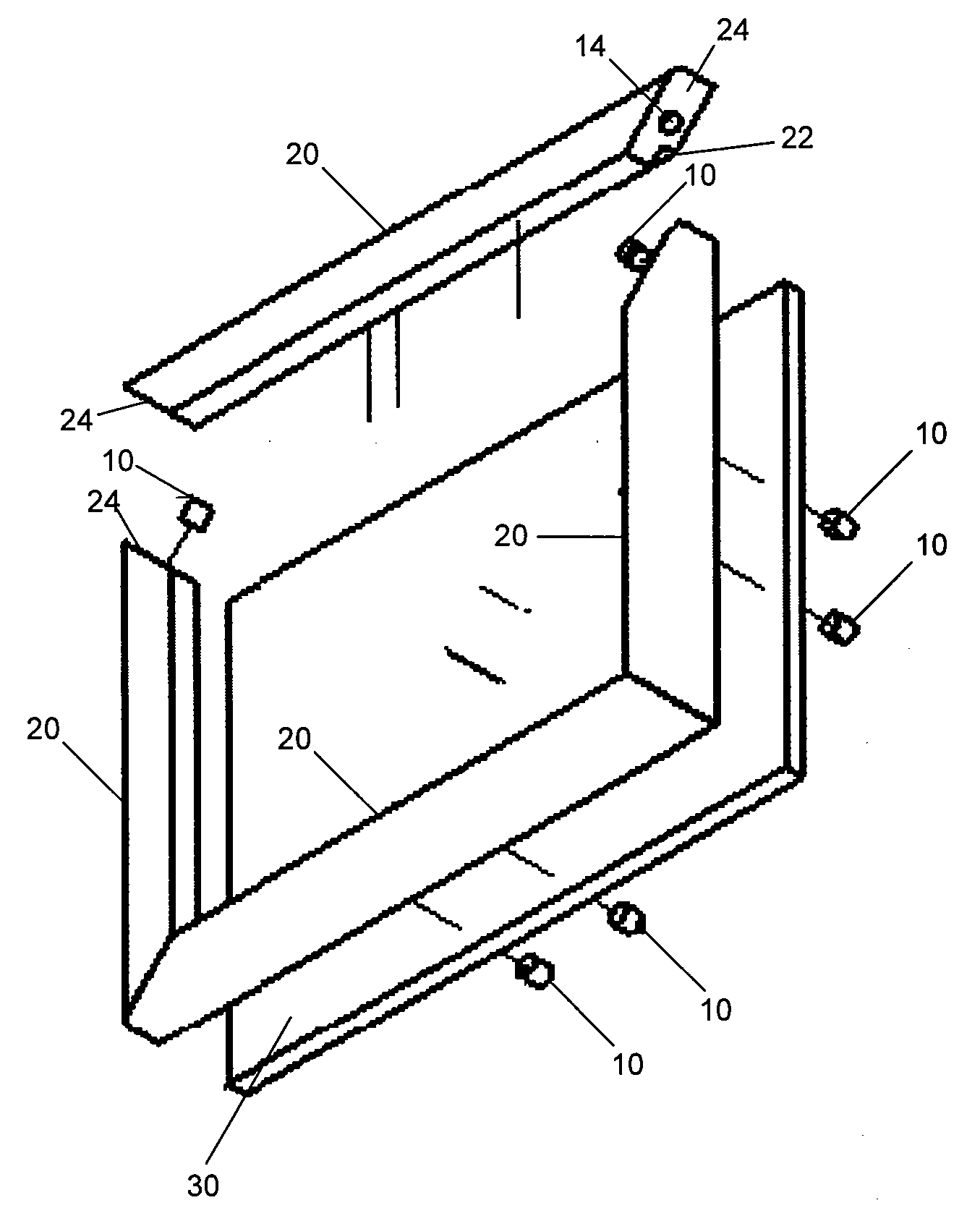

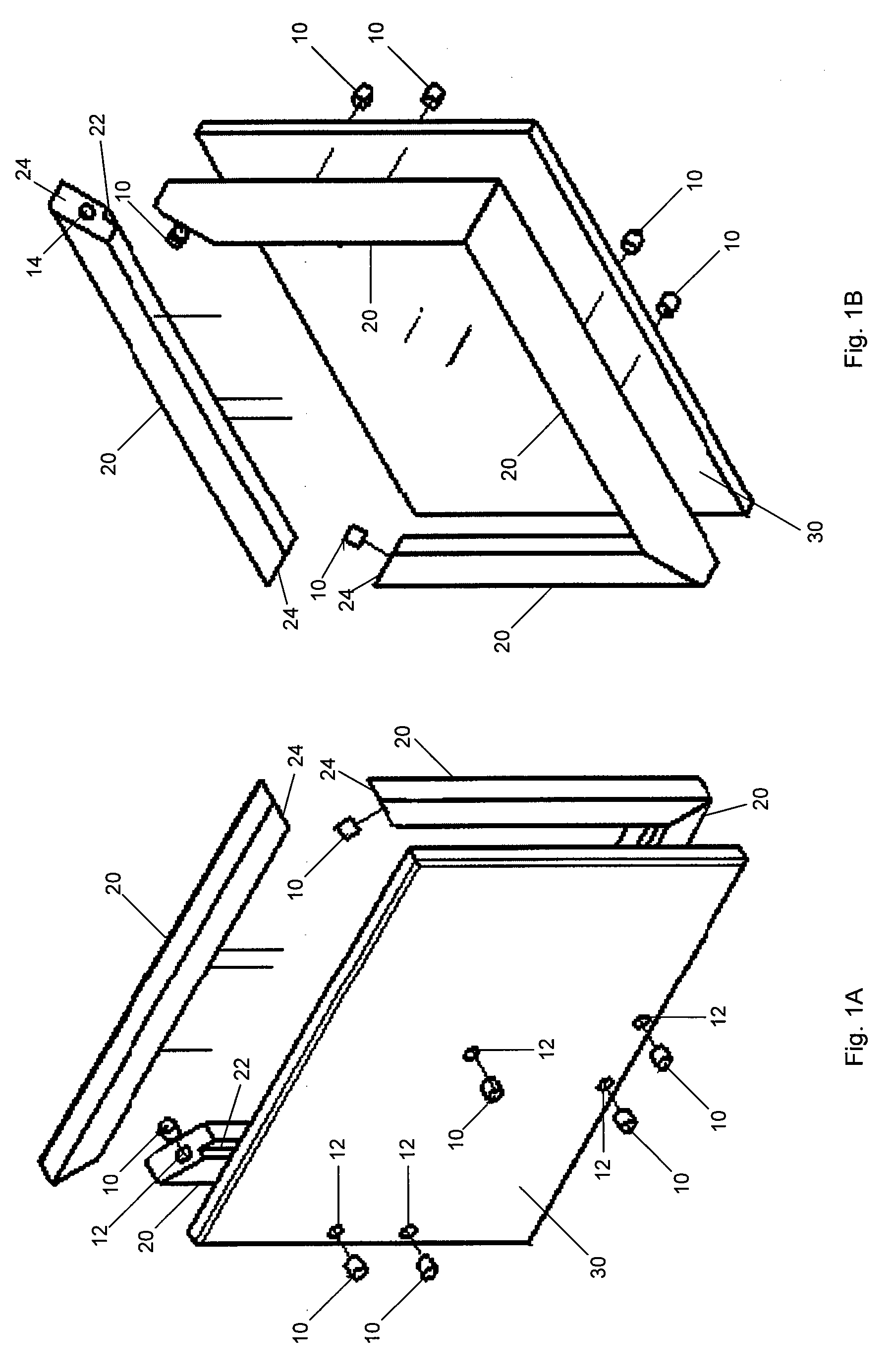

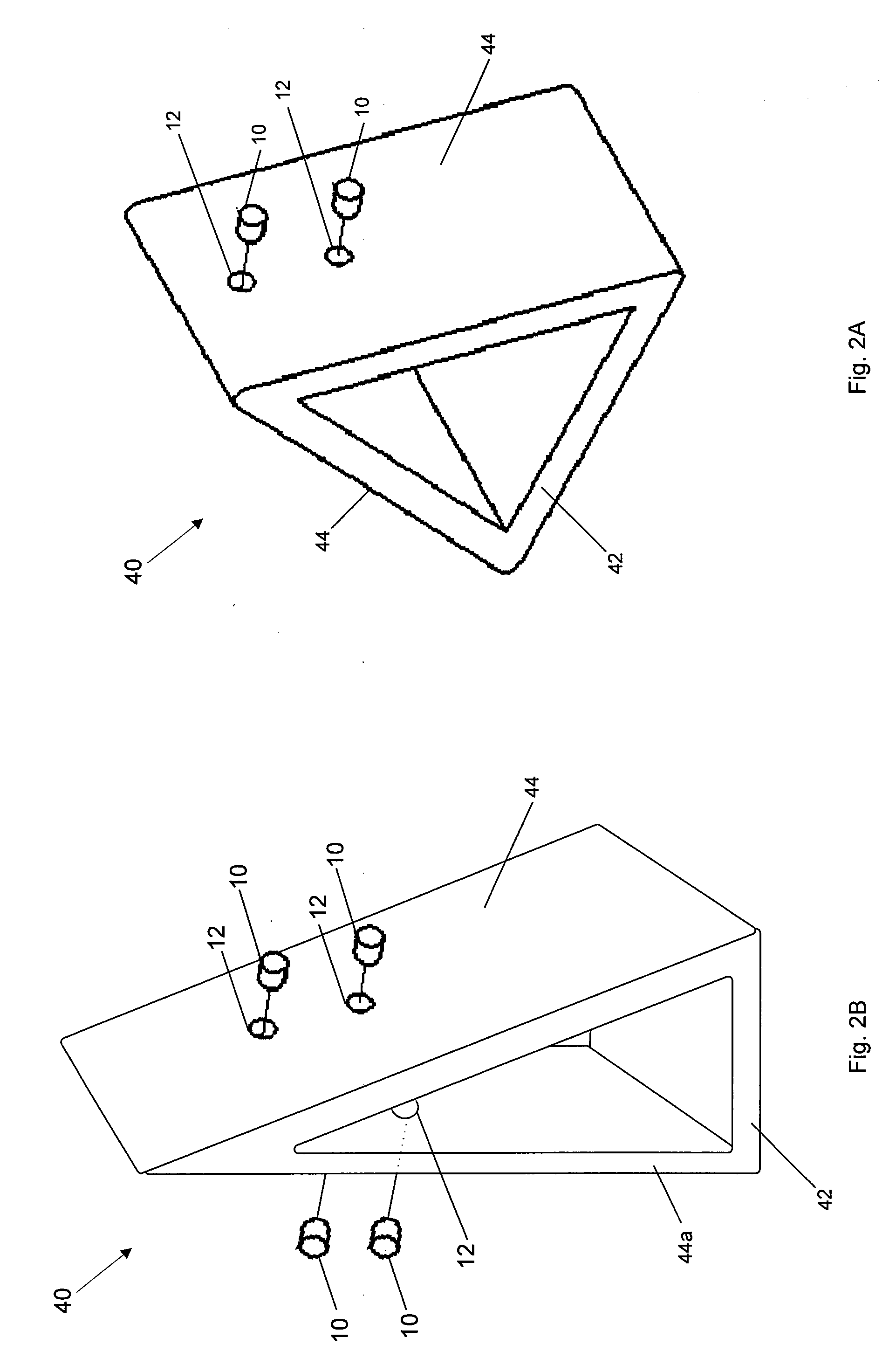

Configurable modular picture frame

InactiveUS20100083548A1Quick changeEasy to reconfigurePicture framesDomestic mirrorsEdge segmentStructural engineering

A picture frame for holding and displaying content. The picture frame has an edge with a channel receiving the content. An edge segment is attachable to and detachable from the remainder of the edge, using magnets, to allow insertion and removal of the content. A back has a front face to which the edge remainder is attached and a rear face including one or more magnets for attaching the back to a magnetically attractive surface. An optional stand has a plurality of elements that engage at least one of the back magnets to support the back in multiple directions and orientations. An optional hanger is made of a magnetically attracted material for engaging at least one of the back magnets and attach the hanger to the back. The hanger is configured to engage a fastener and hang the picture frame from the fastener when the stand is not in use.

Owner:REIS RICHARD C

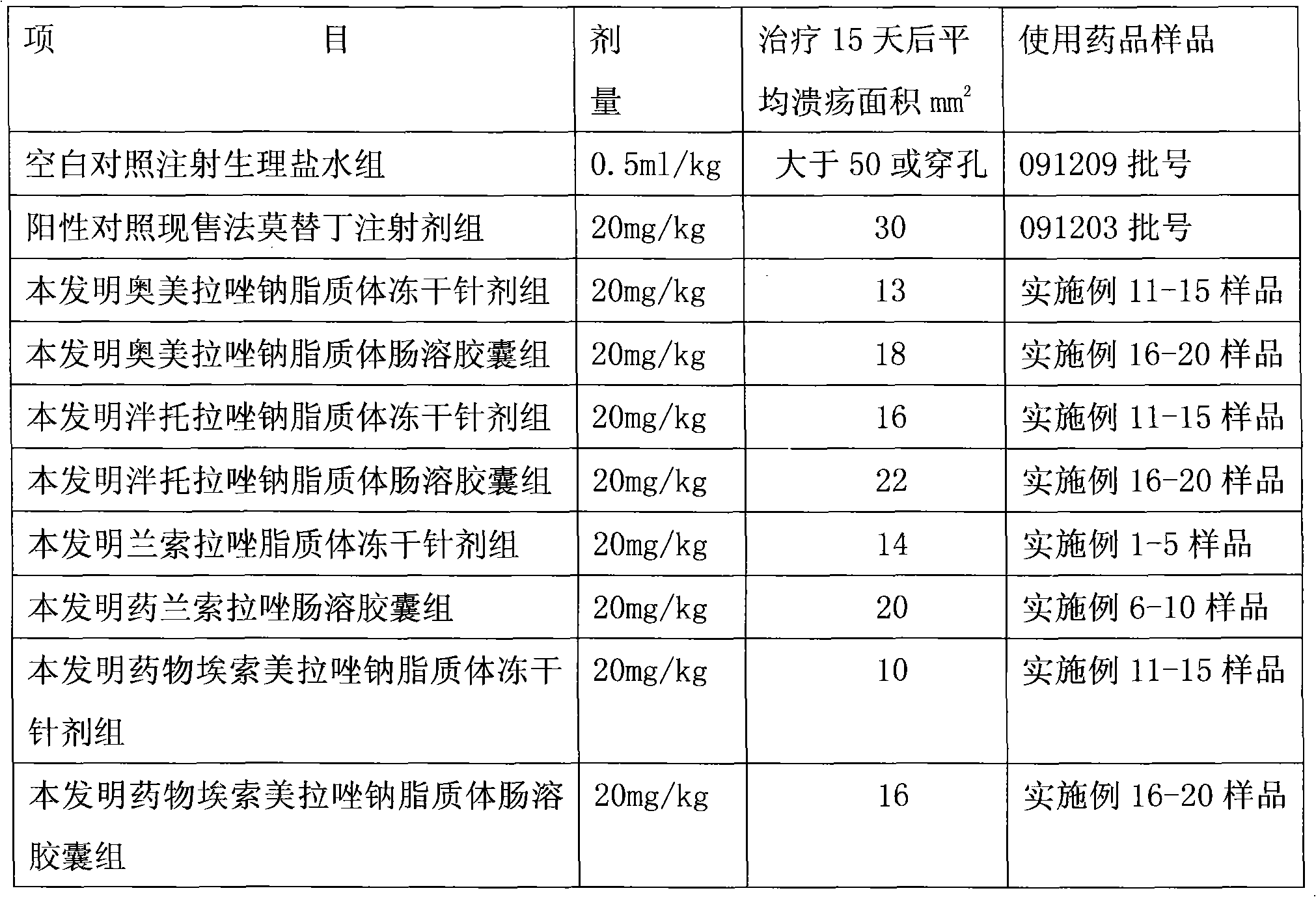

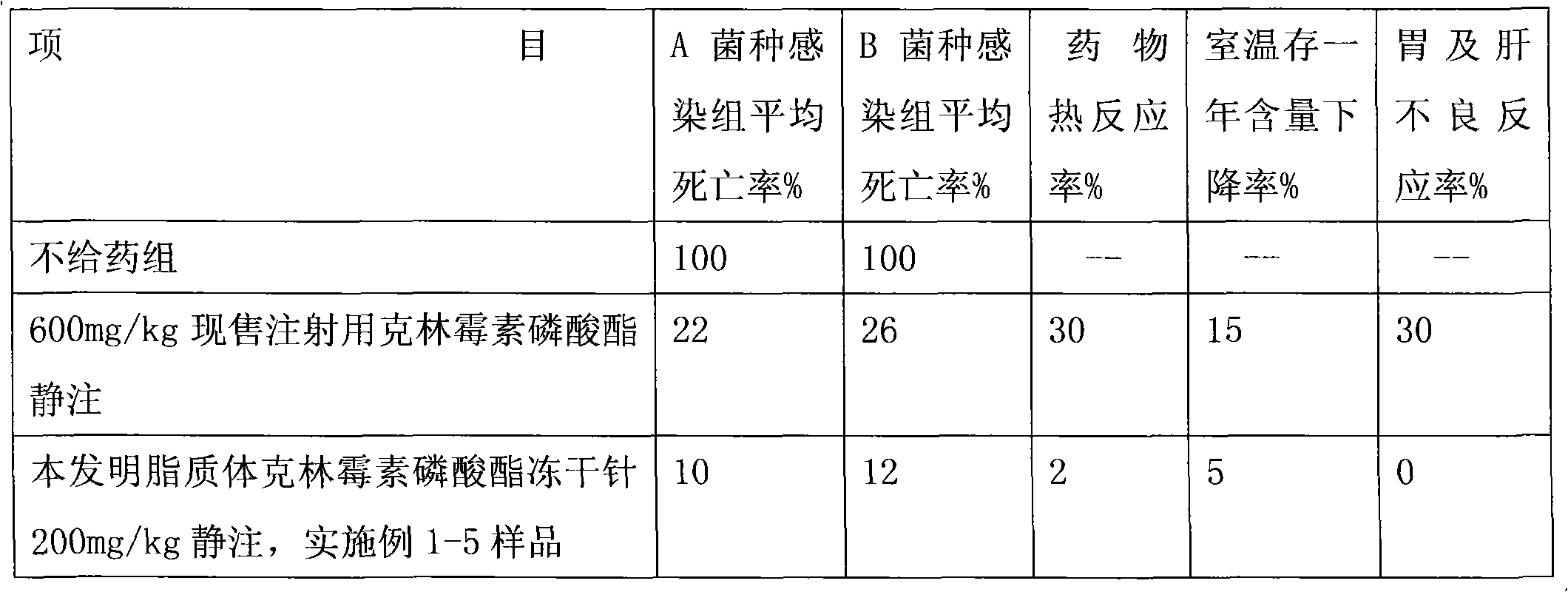

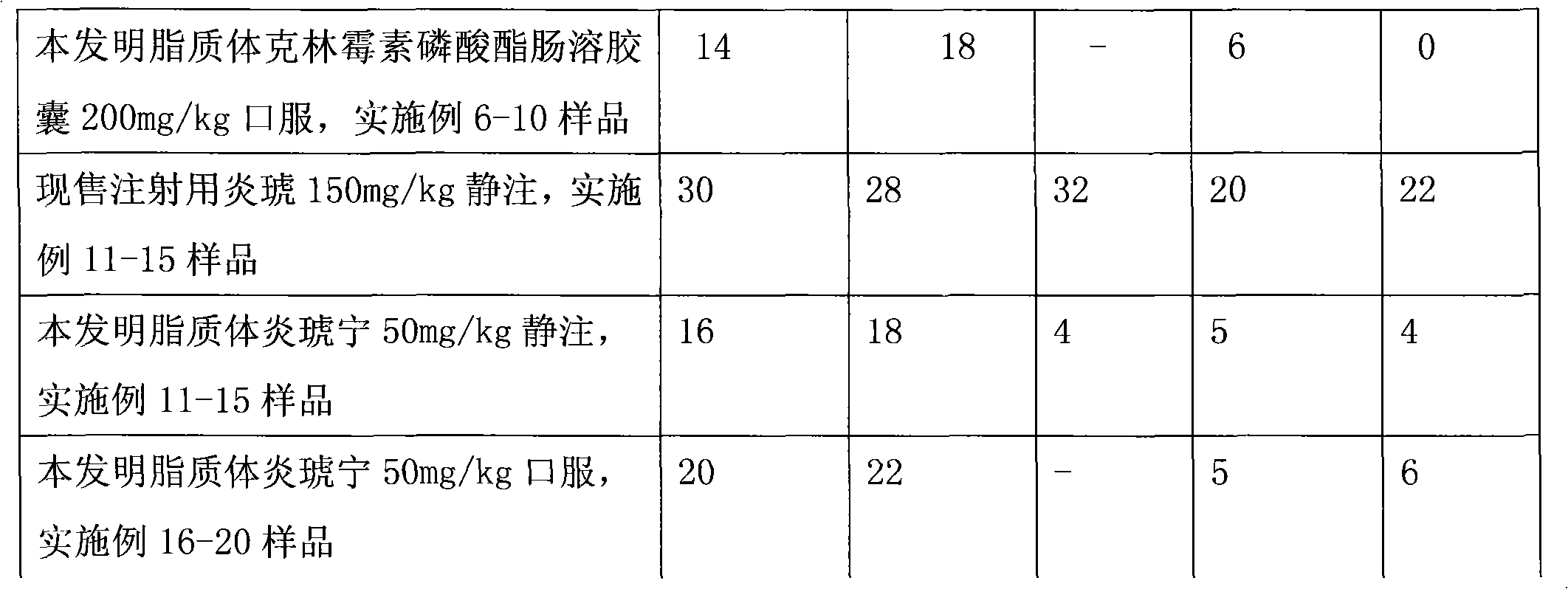

Dissolving ultrafiltration-spray drying-molecule dispersion coating-hydration palletizing-freeze drying method for preparing liposome combination medicine

InactiveCN101912363AImprove therapeutic indexEvenly dispersedPowder deliveryOrganic active ingredientsFreeze-dryingUltrafiltration

The invention relates to a dissolving ultrafiltration-spray drying-molecule dispersion coating-hydration palletizing-freeze drying method, which can industrially prepare both liposome medicine-carrying injections and liposome medicine-carrying oral preparations by utilizing uniform prescriptions, technologies and devices. The invention provides a mole-ratio prescription of various components and materials for preparing liposome medicine-carrying preparations, and provides a technology for preparing nanoliposome lyophilization injections and liposome oral preparations. The invention also provides 20 embodiments for preparing liposome medicine-carrying preparations: an embodiment for preparing anti-gastric-ulcer liposome medicine-carrying preparations, an embodiment for preparing antibiosis and anti-fungus liposome medicine-carrying preparations, an embodiment for preparing anti-tumor liposome medicine-carrying preparations, an embodiment for preparing anti-viral liposome medicine-carrying preparations, an embodiment for preparing anti-emetic liposome medicine-carrying preparations, an embodiment for preparing nutrition-supplement liposome medicine-carrying preparations and an embodiment for preparing anti-diabetics and cardio- and cerebro-vascular drug liposome medicine-carrying preparations.

Owner:蔡海德

Method, apparatus, and program product for enabling access to flexibly redacted content

InactiveUS7865742B2Shorten the timeIncrease contentDigital data processing detailsUnauthorized memory use protectionCryptosystemComputer security

A capability key is generated that provides access to sensitive information within a selectively encrypted data unit created from an unencrypted data unit. A user specifies access rights as a monotone boolean relationship between a selection of a list of attributes related to the unencrypted data unit. This relationship is used to compute a key descriptor. Next one or more shares of a master secret is generated responsive to the monotone boolean relationship and a random number. Next a unique capability key is computed from one or more cryptosystem parameters, the one or more shares and the random number. The unique capability key and the key descriptor together enable decryption of sensitive information within a selectively encrypted data unit created from an unencrypted data unit. Finally, the unique capability key and the key descriptor are provided to allow decryption of sensitive information within the selectively encrypted data unit.

Owner:MAJANDRO LLC

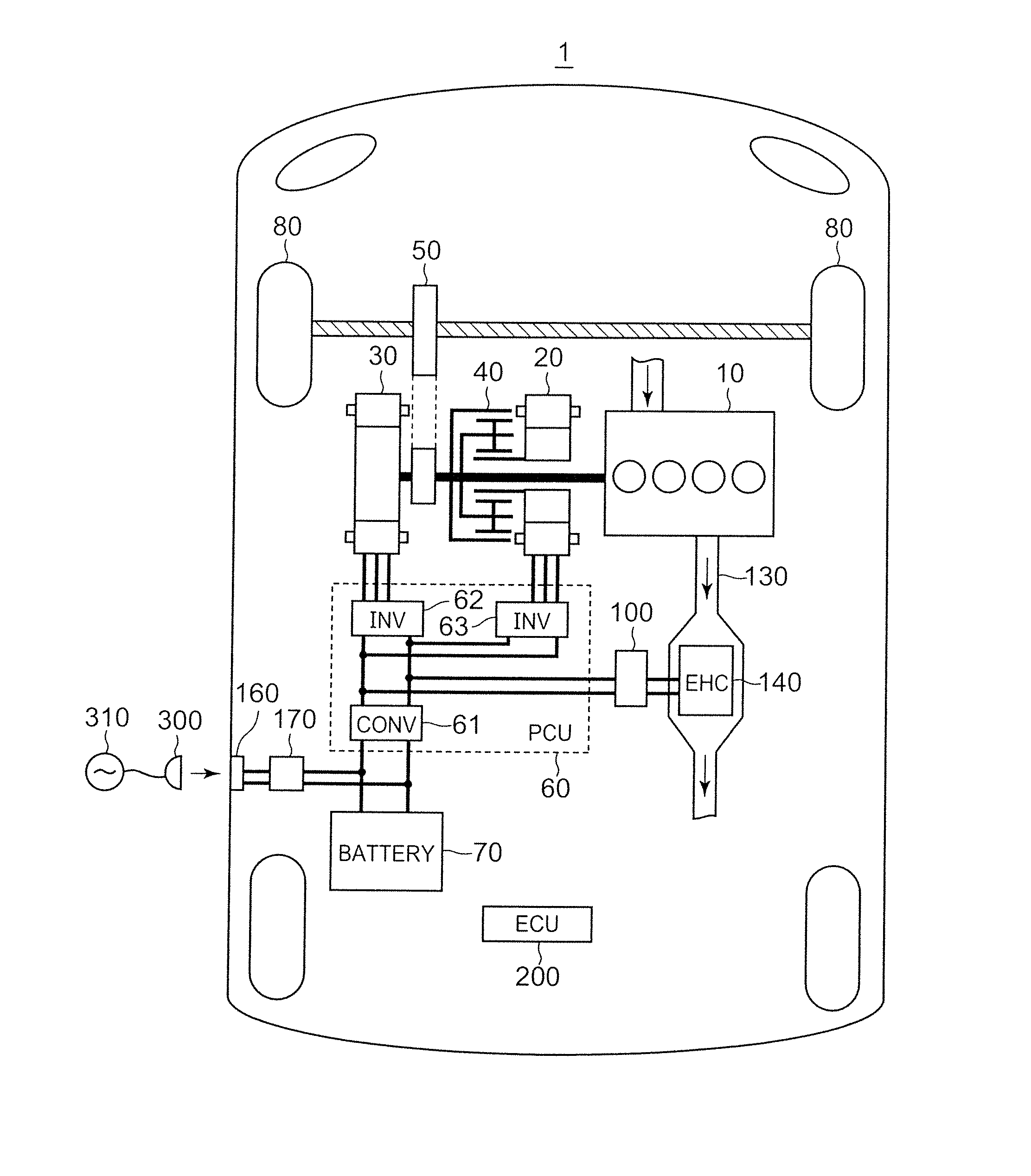

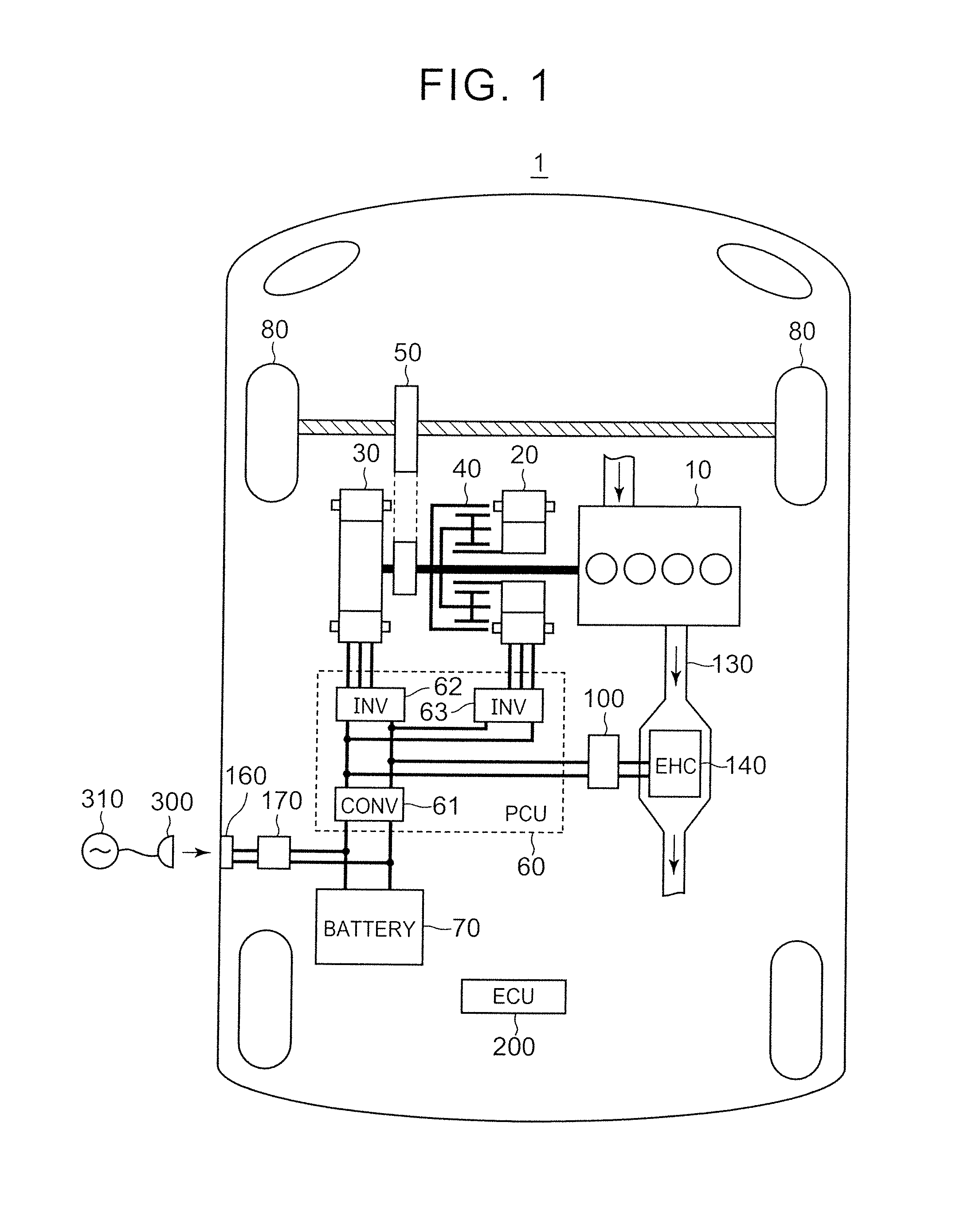

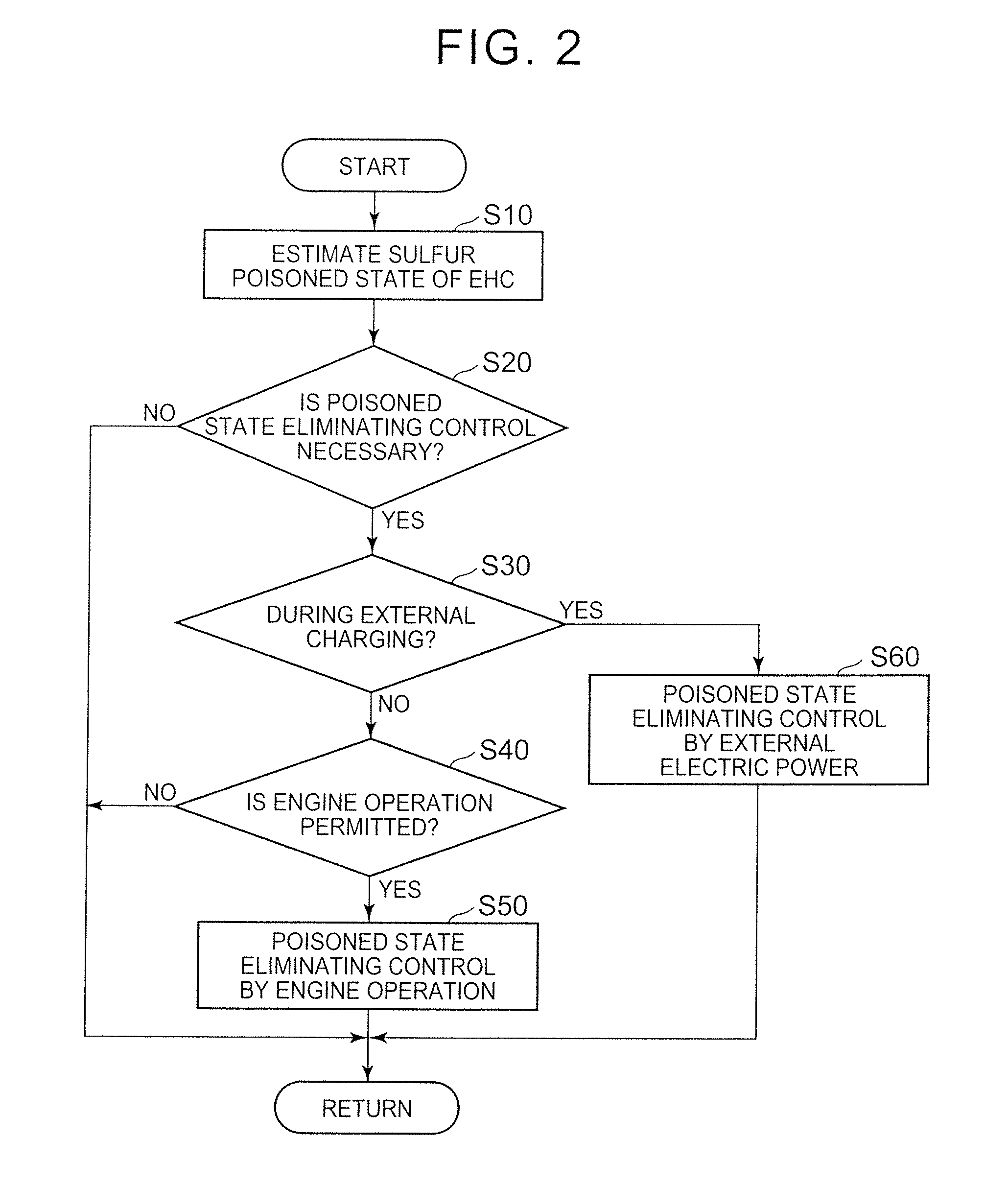

Vehicle

ActiveUS20150075142A1Increase temperatureRemove sulfur contentHybrid vehiclesElectrical controlSulfurEngineering

In a plug-in hybrid vehicle that includes an EHC, an ECU eliminates a sulfur poisoned state by supplying external electric power to the EHC when it is necessary to eliminate a state in which adhesion to a catalyst in the EHC degrades a function of the catalyst and external charging is being performed. On the other hand, when it is necessary to eliminate the sulfur poisoned state, the external charging is not being performed, and operation of an engine is permitted, the sulfur poisoned state is eliminated by operating the engine.

Owner:TOYOTA JIDOSHA KK

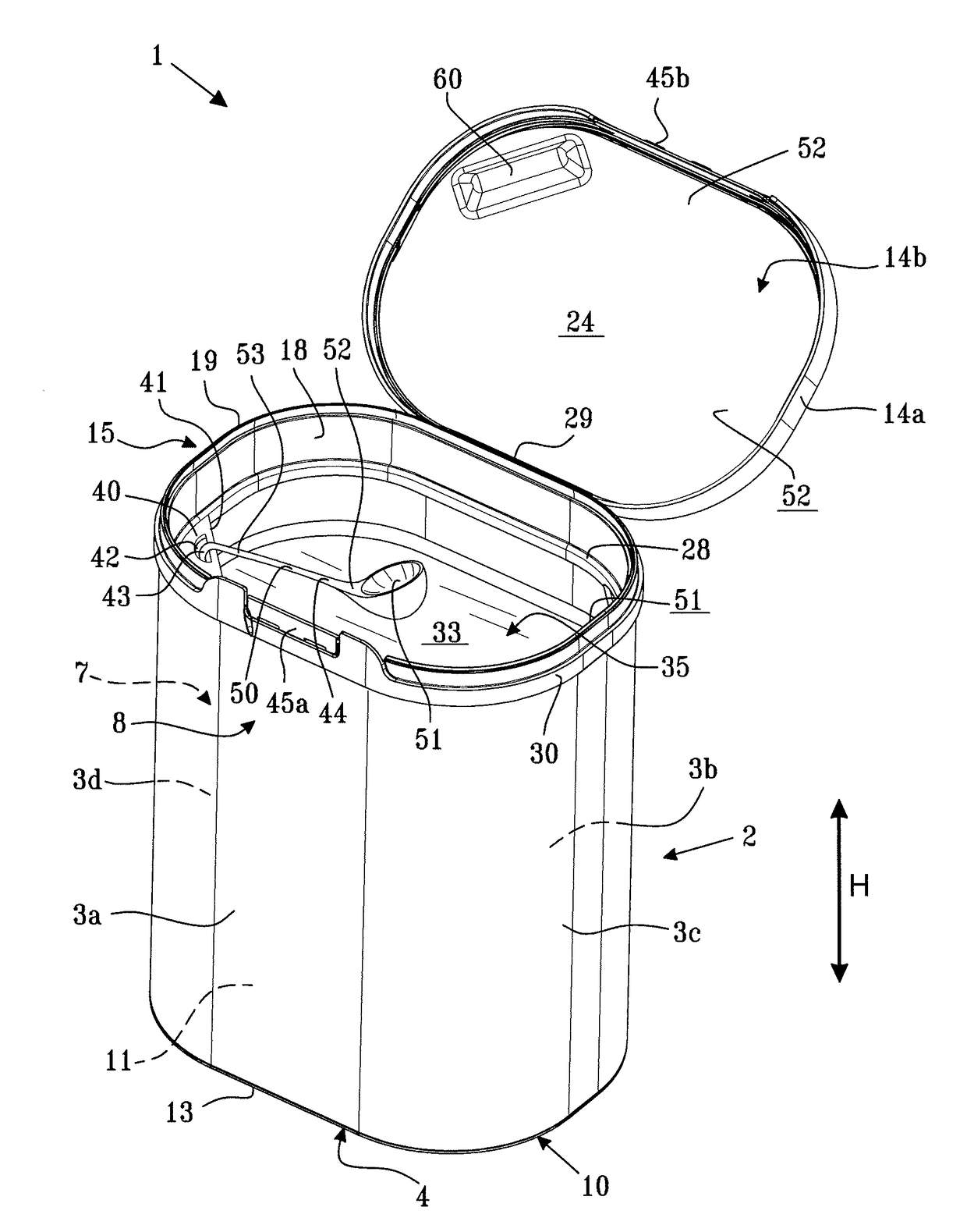

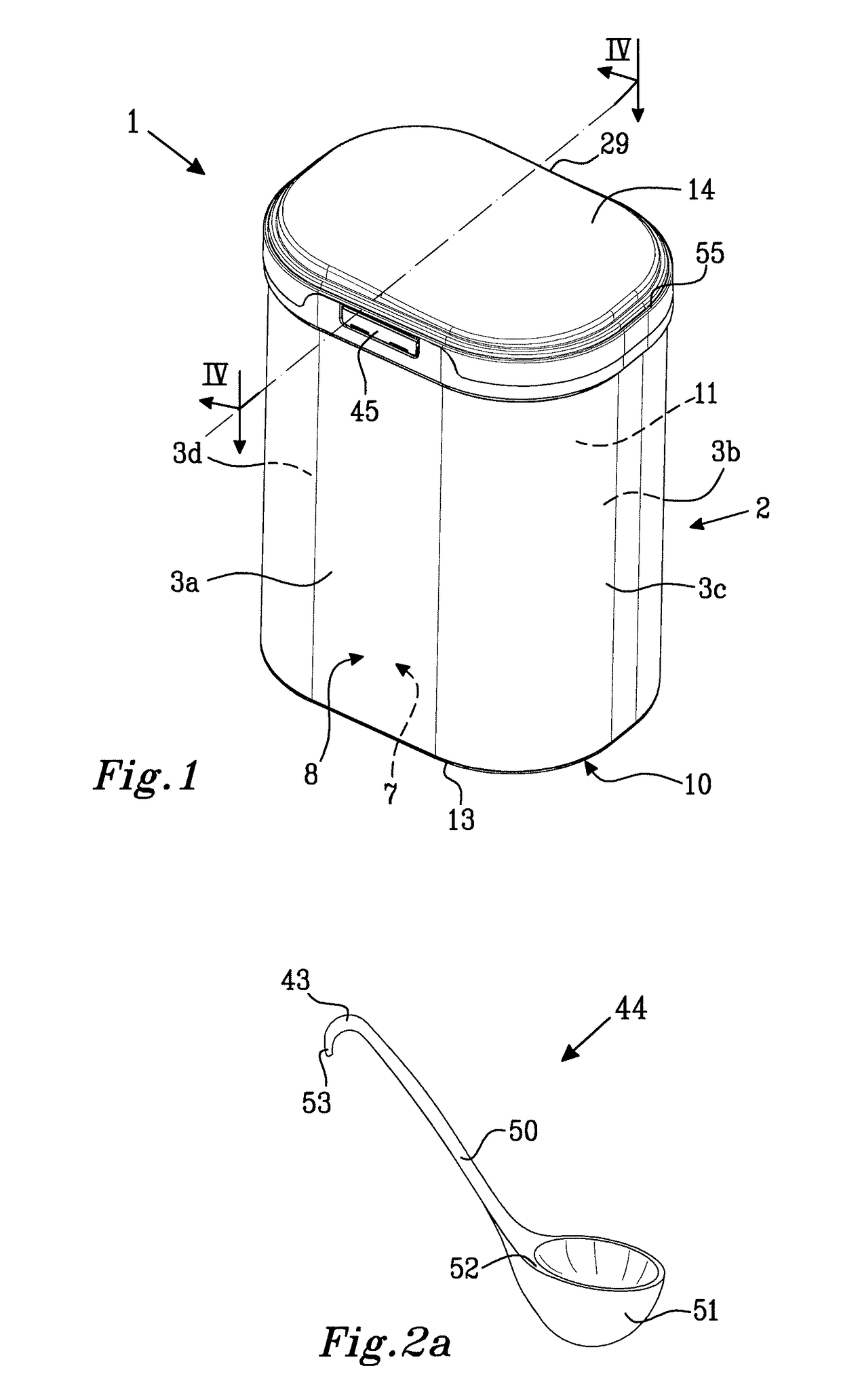

Packaging container for scoopable contents

InactiveUS20180022505A1Tighter and slimmer attachmentEasy to controlClosure with auxillary devicesLidsEngineeringMechanical engineering

Owner:AR PACKAGING SYST AB

Ceiling-type air purifier

InactiveCN108981014ATake advantage ofAvoid easy cloggingMechanical apparatusLighting and heating apparatusHEPAFiltration

The invention relates to a ceiling-type air purifier and belongs to the technical field of purifier equipment. Through a top base, a purifier body is suspended to a ceiling through lifting ropes, so that thorough utilization of an indoor space is achieved; a coarse filter screen, an electrostatic filter layer, an HEPA filter layer, ultraviolet sterilization lamps, an activated carbon filter layerfor filtration and an negative ion generator are used for filtering and purifying passing air; an electric heating screen can be used for heating the passing air, and a humidifier can humidify the passing air; a fresh aromatic can be placed in an aromatic placing box according to the preference of people indoors; an air quality detector detects the air pollution degree; a temperature sensor measures the temperature of the air blown out from an air outlet duct, and the indoor temperature is displayed through a digital displayer; a smoke detector can detect fire conditions, and if generated smoke is too dense, and an audio gives out an alarming sound. When it is needed to replace or clean each filter layer in the purifier body, the purifier body descends downward with the lifting ropes, anda user can easily replace or clean each filter layer without climbing up.

Owner:绍兴大科环保科技有限公司

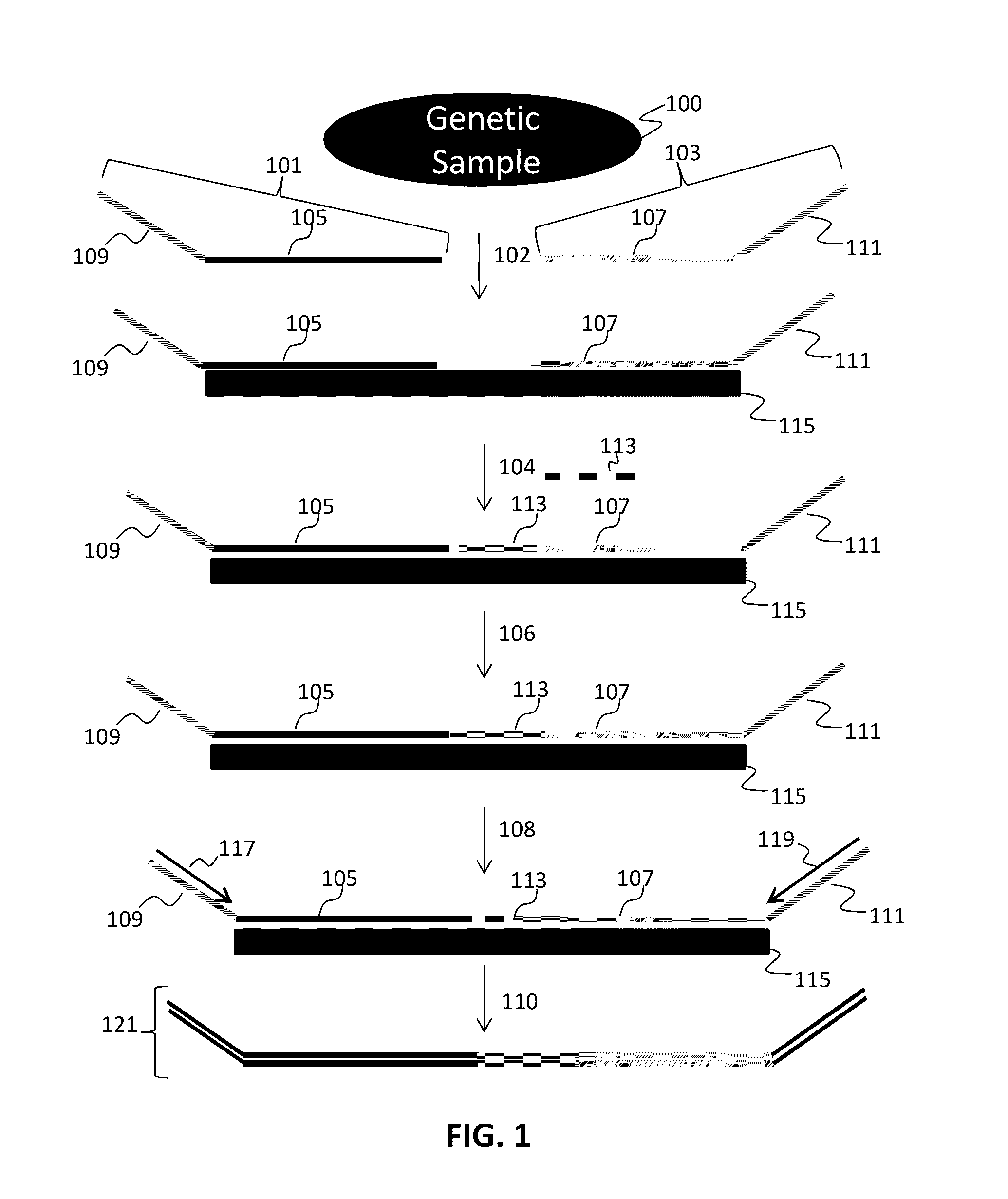

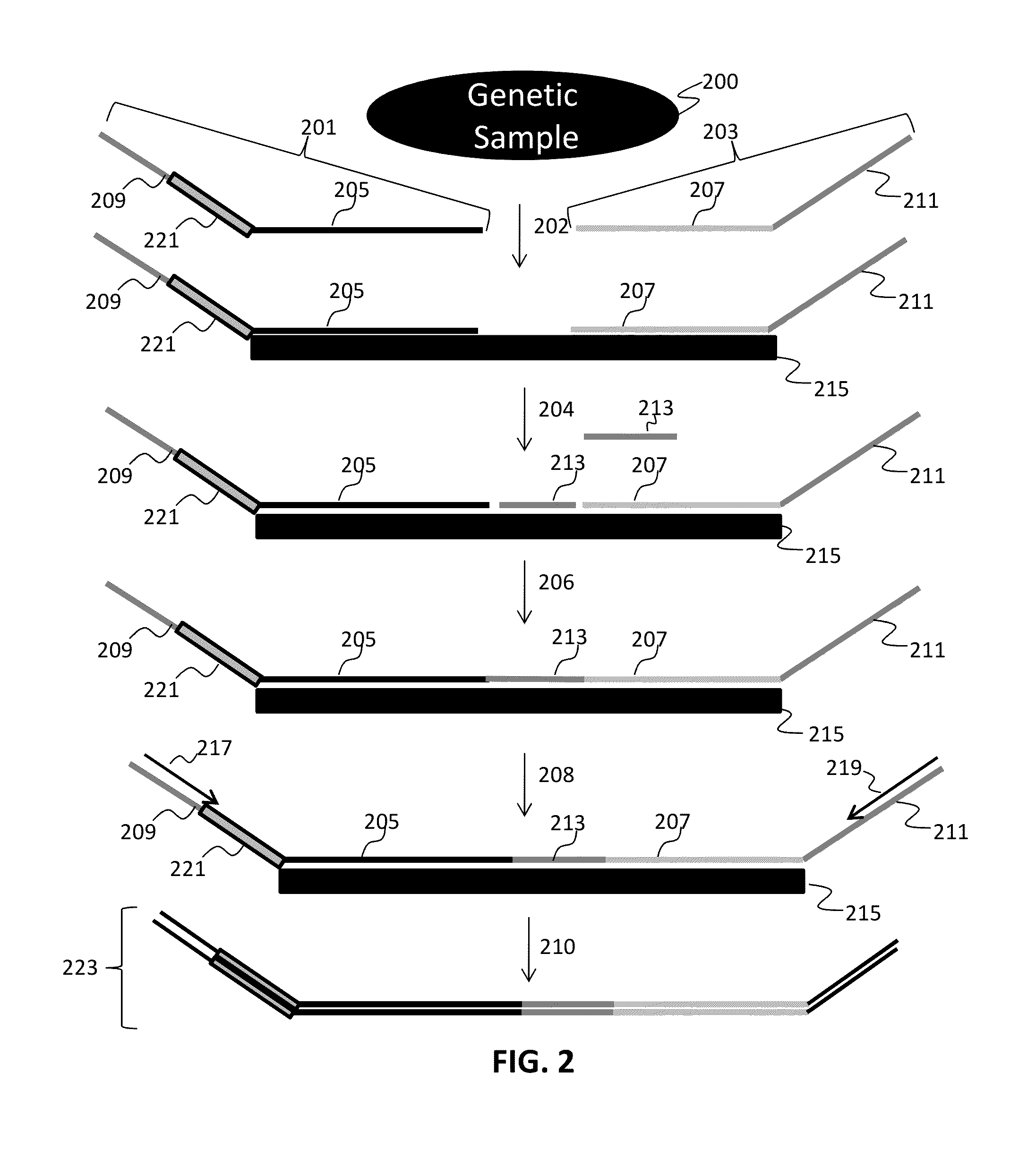

Processing technology for lowering pectin content in cut stem

ActiveCN102783704AReduce pectin contentReduce manufacturing costTobacco treatmentSODIUM METAPHOSPHATEHydrogen

The invention provides a processing technology for lowering pectin content in a cut stem, which comprises the following steps of: A) sieving and peeling: cutting a thick stem into even stem sections of 8-10mm, sieving according to the thickness, enabling the thick stem section of which a diameter is less than 2.38mm to directly enter the next working procedure, peeling and polishing the thick stem of which a diameter is more than or equal to 2.38mm, and removing the bast part of a tobacco stem by mechanical force; B) chemical stem cleaning and dipping: after the tobacco stem is cleaned with sodium metaphosphate contained citric acid solution of which the pH (potential of hydrogen) is 3.0+ / -0.5, keeping the temperature of 50-60DEG C, and dipping for half hour; C) washing the stem with clean water; D) after feeding, pressing and cutting off the stem; and E) drying and storing the stem. Compared with the cut stem prepared by the traditional technology, the cut stem prepared with the method disclosed by the invention has the advantages that the physical behavior does not have obvious difference, but the aesthetic quality is obviously improved, the irritation is reduced, and the miscellaneous qi is reduced. After the cut stem is added into rolled cigarettes, the cigarette sucking comfort can be improved, and the tar content is lowered.

Owner:HUBEI CHINA TOBACCO IND

Ligation-based detection of genetic variants

InactiveUS20130261003A1Elimination contentMicrobiological testing/measurementLibrary member identificationNucleotideGenetics

The present invention provides assays systems and methods for detection of genetic variants in a sample, including copy number variation and single nucleotide polymorphisms. The invention preferably employs the technique of tandem ligation—e.g., the ligation of two or more fixed sequence oligonucleotides and one or more bridging oligonucleotides complementary to a region between the fixed sequence oligonucleotides—combined with detection of levels of particular genomic regions using array hybridization.

Owner:ROCHE MOLECULAR SYST INC

Preparation method of sterol ester

The application relates to a method for extracting phytosterol from oil slick asphaltum and a preparation method of sterol ester. The method comprises the following steps: carrying out saponification on tall oil pitch to obtain a crude sterol product; leaching the crude sterol product to obtain a sterol product with the purity of 70-90%; distilling to remove fatty alcohol in the sterol product; crystallizing the obtained product, wherein the purity of the crystal is larger than or equal to 98%. The method in the invention can be used for effectively removing the content of the fatty alcohol in a phytosterol product, improving the purity of the finial product of phytosterol; the steps are simple and easy to operate, and are suitable for industrial production.

Owner:内蒙古昶辉生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com