Flux method for growth of gallium phosphate crystal

A technology of flux, gallium phosphate, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of unfavorable scale production, high equipment requirements, and it is difficult to minimize the water content in the crystal, and achieve the elimination of water. content, the effect of improving piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

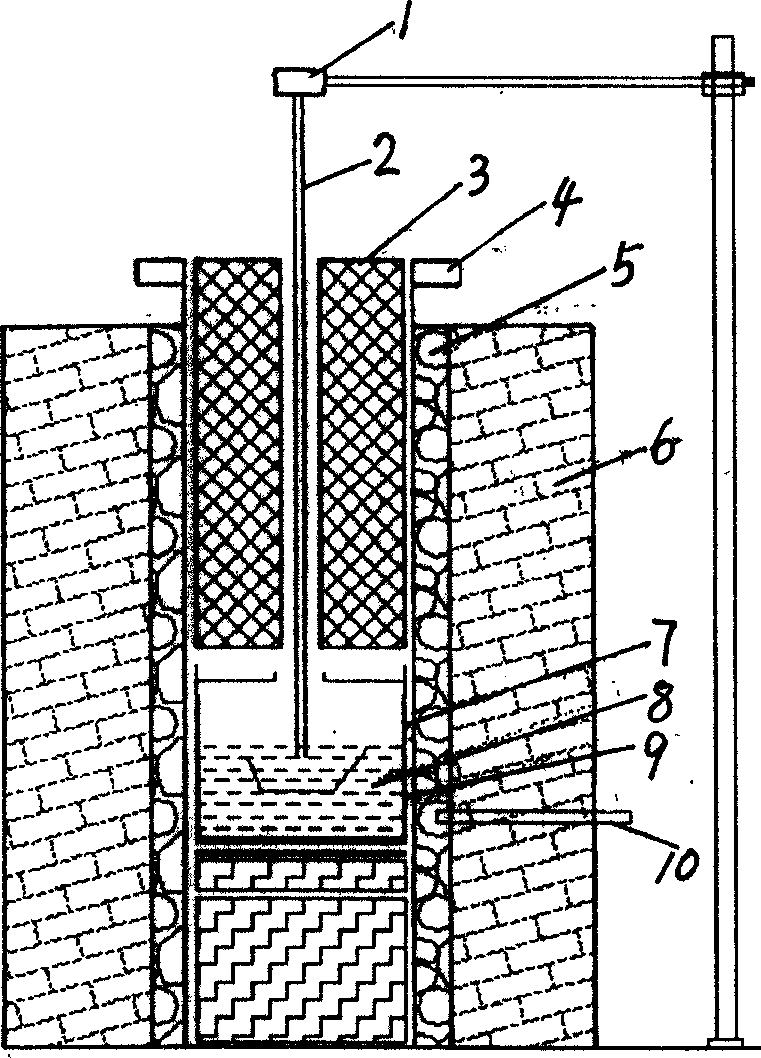

[0016] figure 1 The method of growing GaPO by the present invention is given 4 Schematic diagram of the device structure of the crystal. The device is a vertical resistance wire heating furnace. The seed rod 2 extends into the melt 8 and rotates under the drive of the rotating device 1. The furnace tube 4 is equipped with refractory bricks 3, and the resistance wire 5 is wound on the outer wall of the furnace tube 4. , its outer layer is thermal insulation material 6. The temperature control equipment is FP21 programmable automatic temperature controller, and the temperature control accuracy in the growth temperature area is 0.1%. The crystal incubator 7 is placed in the alumina crucible 9, which is a platinum crucible of 70×90 mm, which can withstand the working temperature below 1774° C., and the melt contained therein is not easy to corrode it. The thermocouple 10 adopts PtRh / Pt, which can effectively control the growth temperature.

[0017] Lithium carbonate-molybdenum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com