Processing technology for lowering pectin content in cut stem

A processing technology and technology for cut stems, which are applied in the field of processing technology for reducing the content of pectin in cut stems, can solve the problems of reduced smoke concentration and momentum, limited improvement in the quality of cut stems, low chemical treatment efficiency, etc., so as to reduce the amount of tar. , The effect of improving sensory quality and reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The thick stalks composed of flue-cured tobacco stalks from Yunnan and Hubei origins are cut into 10mm uniform stalks, and the stalks are screened, and the stalks with a diameter greater than 2.38mm are peeled and polished to remove excess cell wall tissue in the epidermis; then use pH Sodium metaphosphate-containing citric acid solution of ≈3.0 soaks the treated stem section, and after cleaning the tobacco stem, keep the temperature at 50°C and soak for half an hour; then wash the stem, feed, press the stem, cut the stem, dry the stem and store it in sequence. Stems and other traditional processes are used to prepare shredded stems.

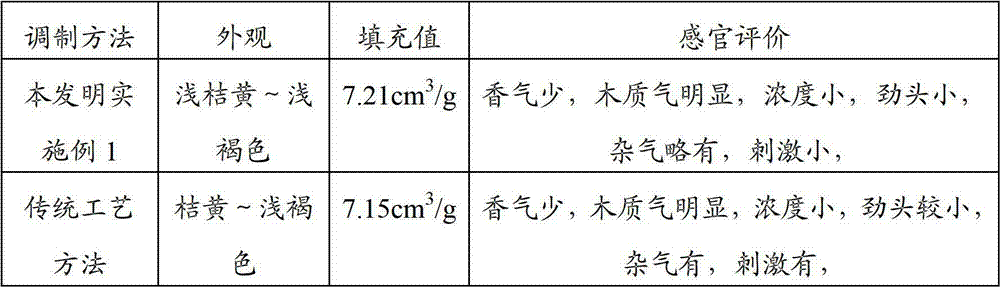

[0021] The shredded stems produced in Example 1 of the present invention are compared with the shredded stems prepared by the traditional method, and the results are as follows:

[0022] Table 1 Comparison of appearance quality of different methods

[0023]

[0024] It can be seen from Table 1 that the quality of the cut stems prepare...

Embodiment 2

[0031] The thick stalks composed of cured tobacco stalks from Yunnan and Sichuan origins were cut into uniform stalks of 8mm, and the stalks were sieved, and the stalks with a diameter greater than 2.38mm were sieved, peeled, and polished; Soak the peeled thick stems in citric acid aqueous solution at a temperature of 55°C for half an hour; after that, perform traditional processes such as washing the stems, adding ingredients, pressing the stems, cutting the stems, drying the stems and storing the stems to prepare shredded stems

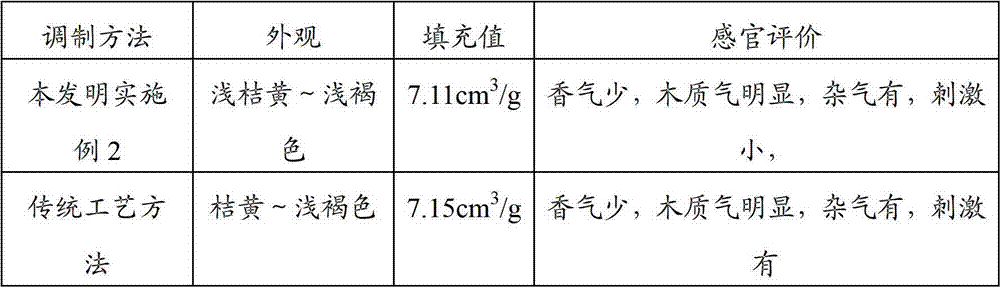

[0032] The shredded stems produced in Example 2 of the present invention are compared with the shredded stems prepared by the traditional method, and the results are as follows:

[0033] Table 3 Comparison of appearance quality of different processes

[0034]

[0035] It can be seen from Table 3 that the quality of cut stems prepared in Example 2 of the present invention is equivalent to the appearance quality and filling property of cut stems ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com