Clean vegetable processing method

A processing method and a technology of cleaning vegetables, which are applied in the directions of keeping fruits and vegetables fresh, preserving fruits/vegetables through dehydration, and protecting fruits/vegetables with a coating protective layer, etc., can solve problems such as intensified enzymatic changes, accelerated respiration, and loss of nutrients, and achieve Effects of inhibiting browning, delaying metabolism, and reducing loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

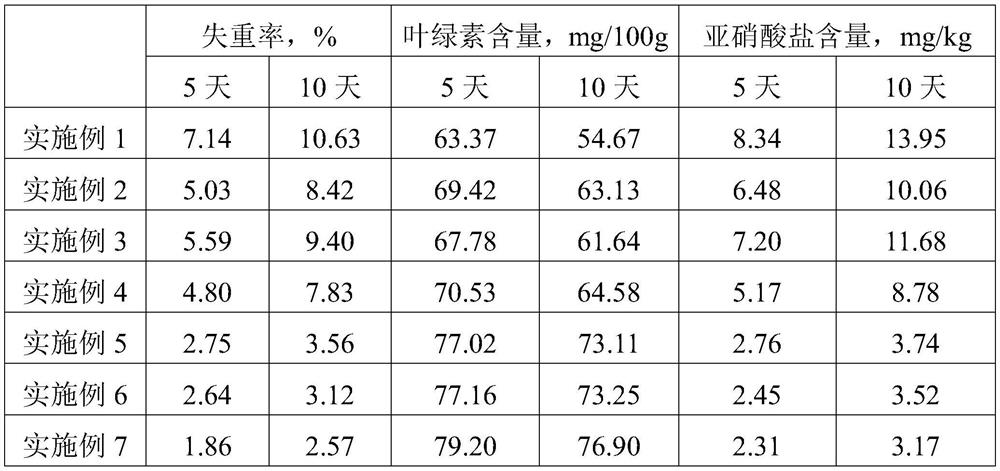

Embodiment 1

[0061] A method for processing clean vegetables, characterized in that it comprises the following steps:

[0062] (1) Harvesting, timely harvesting of vegetables that meet the quality requirements of harvesting, and strictly controlling the quality of vegetables;

[0063] (2) Vacuum pre-cooling. Spray the pretreatment liquid on the surface of the harvested vegetables, then place them in a vacuum chamber, turn on the vacuum pump and refrigeration device, and when the temperature in the vacuum chamber drops to 3°C, turn off the vacuum pump and refrigeration device and keep it for 40 minutes. Pre-cooled vegetables are obtained; wherein the pre-treatment liquid is 2wt% calcium chloride aqueous solution, and the spraying amount of the pre-treatment liquid is 5% of the mass of the harvested vegetables;

[0064] (3) trimming, trimming the precooled vegetables, removing yellow leaves, disease spots, and vegetables that do not meet the requirements, so that the edible part reaches more...

Embodiment 2

[0078] It is basically the same as Embodiment 1, the difference is:

[0079] The preservation solution is composed of the following raw materials in parts by weight: 6% by weight of plant extract, 3% by weight of film-forming agent, 1% by weight of emulsifier, and 90% by weight of deionized water. The preparation method of the preservative solution is as follows: mix the components, stir at 25° C. and 1000 rpm for 5 hours, and then ultrasonically treat for 30 minutes to obtain the preservative solution, wherein the ultrasonic frequency is 40KHz and the ultrasonic power is 500W.

[0080] The plant extract is spinach seed extract.

[0081] The preparation method of the spinach seed extract is as follows: crush the spinach seeds and pass through a 60-mesh sieve, then use 70wt% ethanol to extract 40min at 70°C, an ultrasonic frequency of 40KHz, and an ultrasonic power of 400W according to a solid-liquid ratio of 1g:20mL, and end Suction filtration is then carried out, the filtrat...

Embodiment 3

[0088] It is basically the same as Embodiment 1, the difference is:

[0089] The preservation solution is composed of the following raw materials in parts by weight: 6% by weight of plant extract, 3% by weight of film-forming agent, 1% by weight of emulsifier, and 90% by weight of deionized water. The preparation method of the preservative solution is as follows: mix the components, stir at 25° C. and 1000 rpm for 5 hours, and then ultrasonically treat for 30 minutes to obtain the preservative solution, wherein the ultrasonic frequency is 40KHz and the ultrasonic power is 500W.

[0090] The plant extract is spinach seed extract.

[0091] The preparation method of the spinach seed extract is as follows: crush the spinach seeds and pass through a 60-mesh sieve, then use 70wt% ethanol to extract 40min at 70°C, an ultrasonic frequency of 40KHz, and an ultrasonic power of 400W according to a solid-liquid ratio of 1g:20mL, and end Suction filtration is then carried out, the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com