A method for reducing the tobacco sheet pectin content through a three-step manner

A technology of pectin and pectinase, which is applied in the field of degrading the pectin content of tobacco flakes in a three-step method, can solve the problems of poor pertinence of pectin degradation, difficulty in controlling the degradation process, and insufficient degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The pectinase prepared by the fermentation of Rhizopus chinensis provided in this embodiment is prepared through the following production steps.

[0062] (1) Strain activation, pick the fermentation strain from the preservation medium, inoculate it into the activation medium, and activate it for about 3 days;

[0063] The fermentation strain is specifically Rhizopus chinensis with the preservation number of CICC 41051 deposited by the China Industrial Microorganism Collection (CICC) under the Institute of Microbiology of the Chinese Academy of Sciences (L188) of the Heilongjiang Academy of Light Industry Science (L188). Buy

[0064] The activation medium is a PDA medium; when strains are picked from the preservation medium and then the activation medium is inoculated, the streaking method is used for inoculation;

[0065] The PDA medium is prepared according to a conventional method, specifically: potato extract 1.0L, glucose 20.0g, agar 15.0g, natural pH;

[0066] The method fo...

Embodiment 2

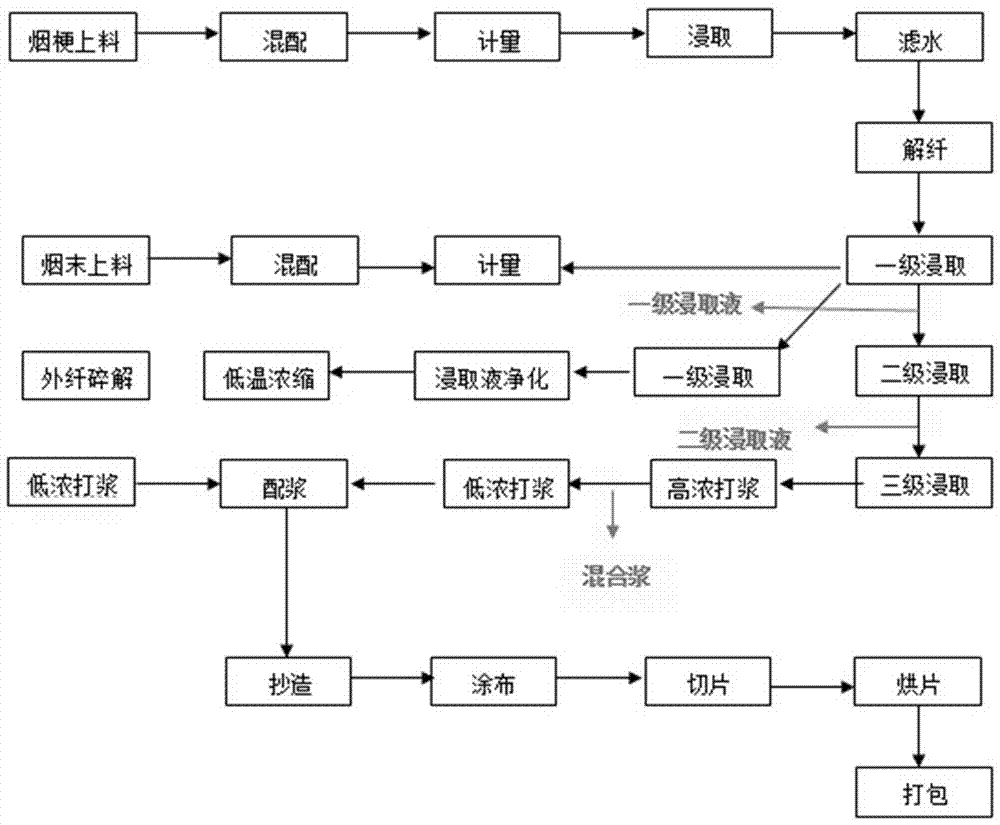

[0078] The crude enzyme solution prepared in Example 1 was applied to the three positions of the primary leaching liquid, the secondary leaching liquid and the mixed slurry on the Henan Zhongyan tobacco sheet production line using the "three-step method" (the production process flow chart is as follows: figure 1 Shown), used to degrade the pectin in the leaching liquid and mixed pulp, the specific usage method is:

[0079] The crude enzyme solution of pectinase prepared in Example 1 (the enzyme activity is 2986.87 U / mL, theoretically, the crude enzyme solution of any enzyme activity prepared in Example 1 can be used for degrading pectin applications, but for certainty Better degradation conditions and actual improvement effects on tobacco, so only the crude enzyme solution prepared in Example 1 with an enzyme activity of 2986.87 U / mL is used as an example for experiment) to properly dilute the diluted crude enzyme solution according to different volumes Ratio (ratio of leaching s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com