Garbage leachate treating device

A technology of landfill leachate and treatment device, which is applied in aerobic process treatment, sustainable biological treatment, water/sewage multi-stage treatment, etc., can solve the operation cost of short-term membrane service life, high aeration energy consumption can not reduce process operation Maintenance costs, difficulties in stable operation of new processes, etc., to achieve the effects of reducing the number of membrane cleanings, sensitive control of treatment reaction parameters, and stable operation of treatment processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention provides a landfill leachate treatment device, and the present invention will be further described below in combination with specific embodiments.

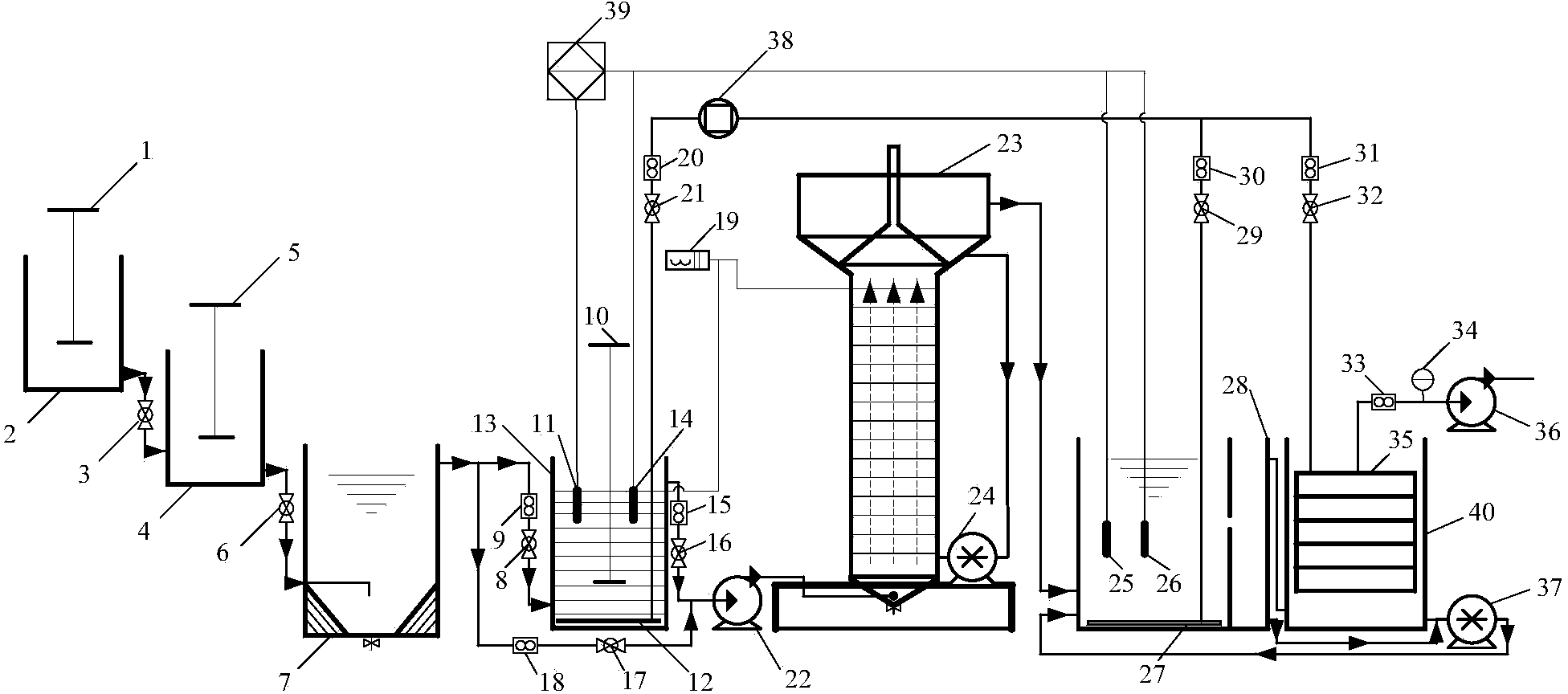

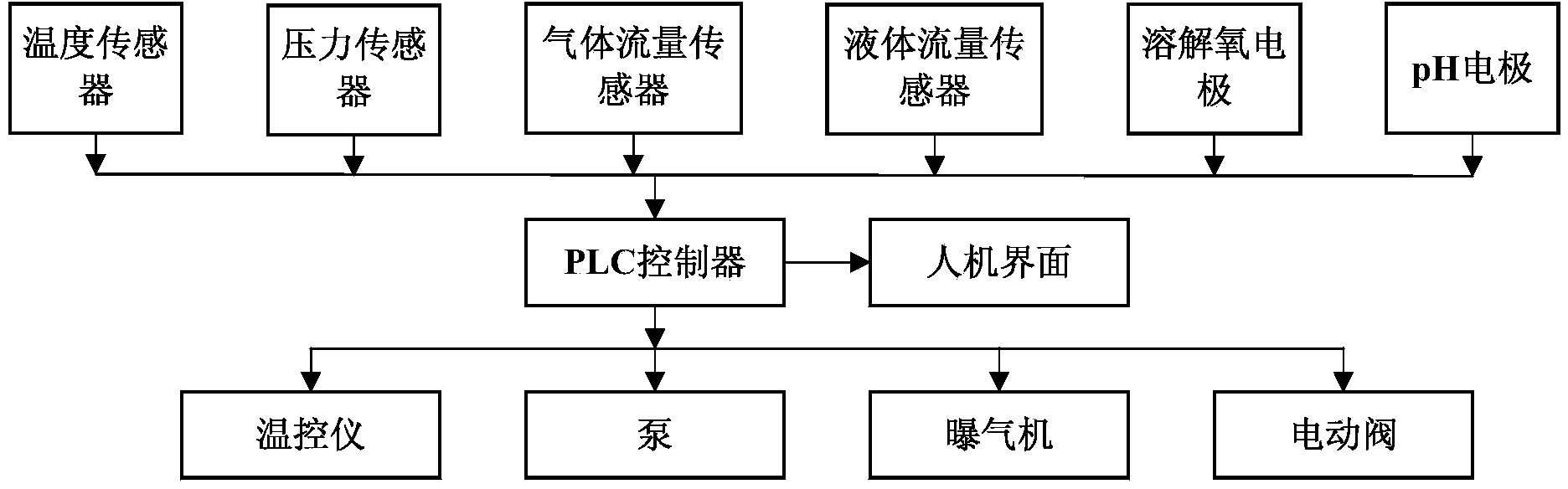

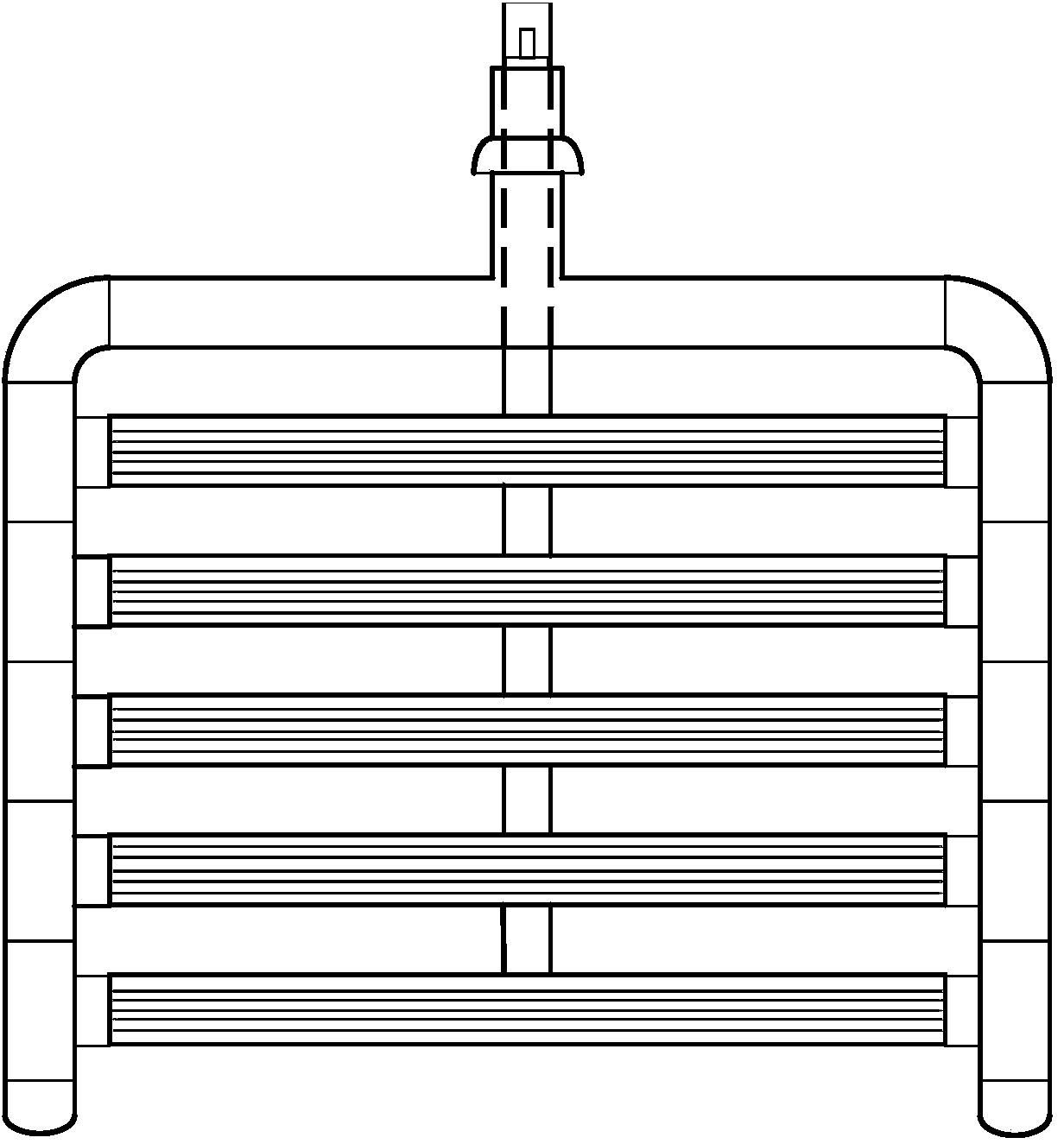

[0034]A landfill leachate treatment device, in which the adsorption tank 2 is connected to the coagulation tank 4 through the first electric valve 3, and the coagulation tank 4 is connected to the sedimentation tank 7 through the second electric valve 6; the sedimentation tank 7 The first liquid flow sensor 9 and the third electric valve 8 are connected to the nitrosation reactor 13 successively, and the sedimentation tank 7 is connected to the water inlet pump 22 through the second liquid flow sensor 18 and the fourth electric valve 17 successively; The nitrification reactor 13 is connected to the water inlet pump 22 successively through the third liquid flow sensor 15 and the fifth electric valve 16, and the nitrosation reactor 13 is connected to the temperature controller 19; the temperature controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com