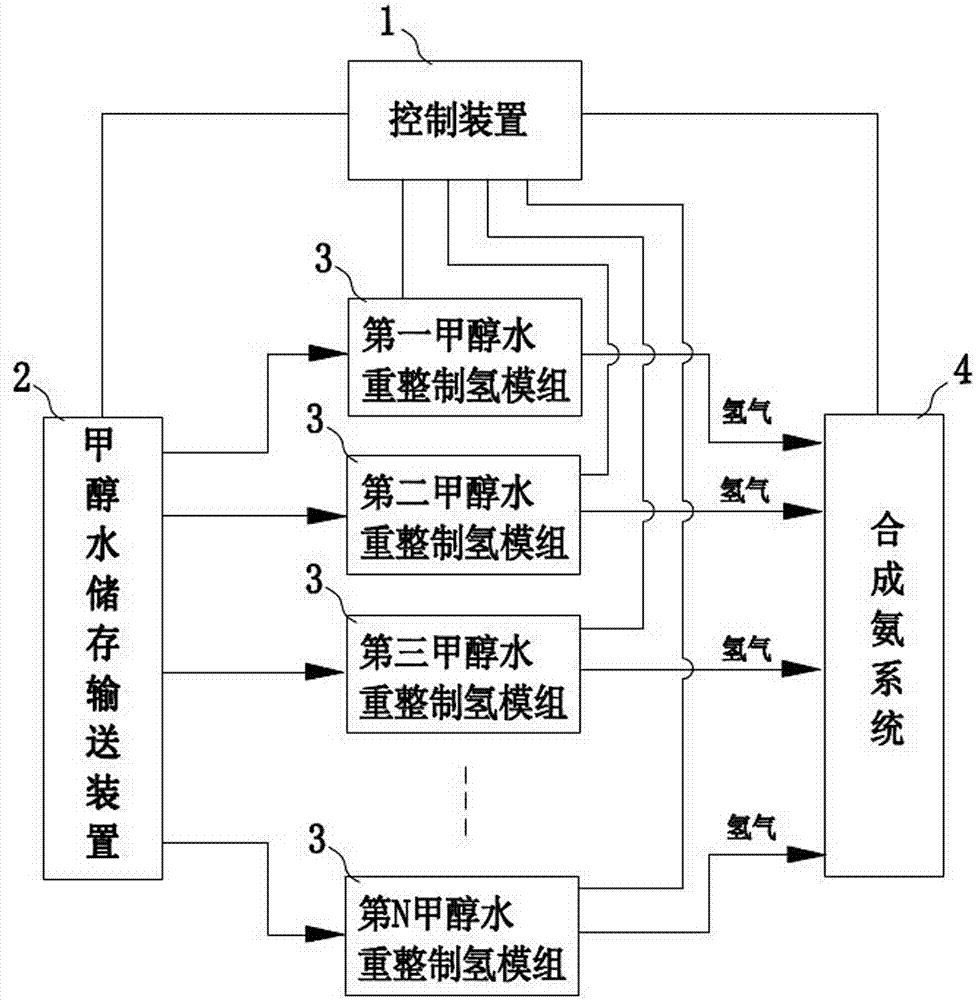

Hydrogen raw material production equipment and process for ammonia synthesis

A kind of production equipment and ammonia synthesis technology, applied in the preparation/separation of ammonia, hydrogen, inorganic chemistry, etc., can solve the problems of difficulty in guaranteeing the stability of ammonia synthesis, waste of methanol raw materials, and inability to modularize, so as to avoid hydrogen leakage and high utilization rate , the overall effect of small energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0039] Such as Figure 9 As shown, it is a block diagram of the overall structure of the ammonia synthesis system. After hydrogen and nitrogen are mixed and compressed in the compressor 6, they enter the synthesis tower 8 after passing through the degreaser 7; the synthesis tower 8 contains an electric heater, a catalyst and a heat exchanger, wherein Synthesis reaction takes place N 2 +3H 2 →2NH 3 , at this time NH 3 It is a high-temperature gaseous state; then, the high-temperature gaseous ammonia and unreacted hydrogen and nitrogen are cooled by the cooling tower 9, and the ammonia turns into a liquid state; then, after being separated by the separator 10, the liquid ammonia enters the liquid ammonia storage tank, and the unreacted hydrogen and nitrogen After being compressed by the circulating compresso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com