Covering earth prevention system of rectangular shield tunneling machine and control method of covering earth prevention system

A control method and technology of shield machine, which are applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of surrounding soil layer disturbance, affecting the surrounding environment, lubricating diaphragm, etc., and achieve the effect of reducing back soil phenomenon and sensitive control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

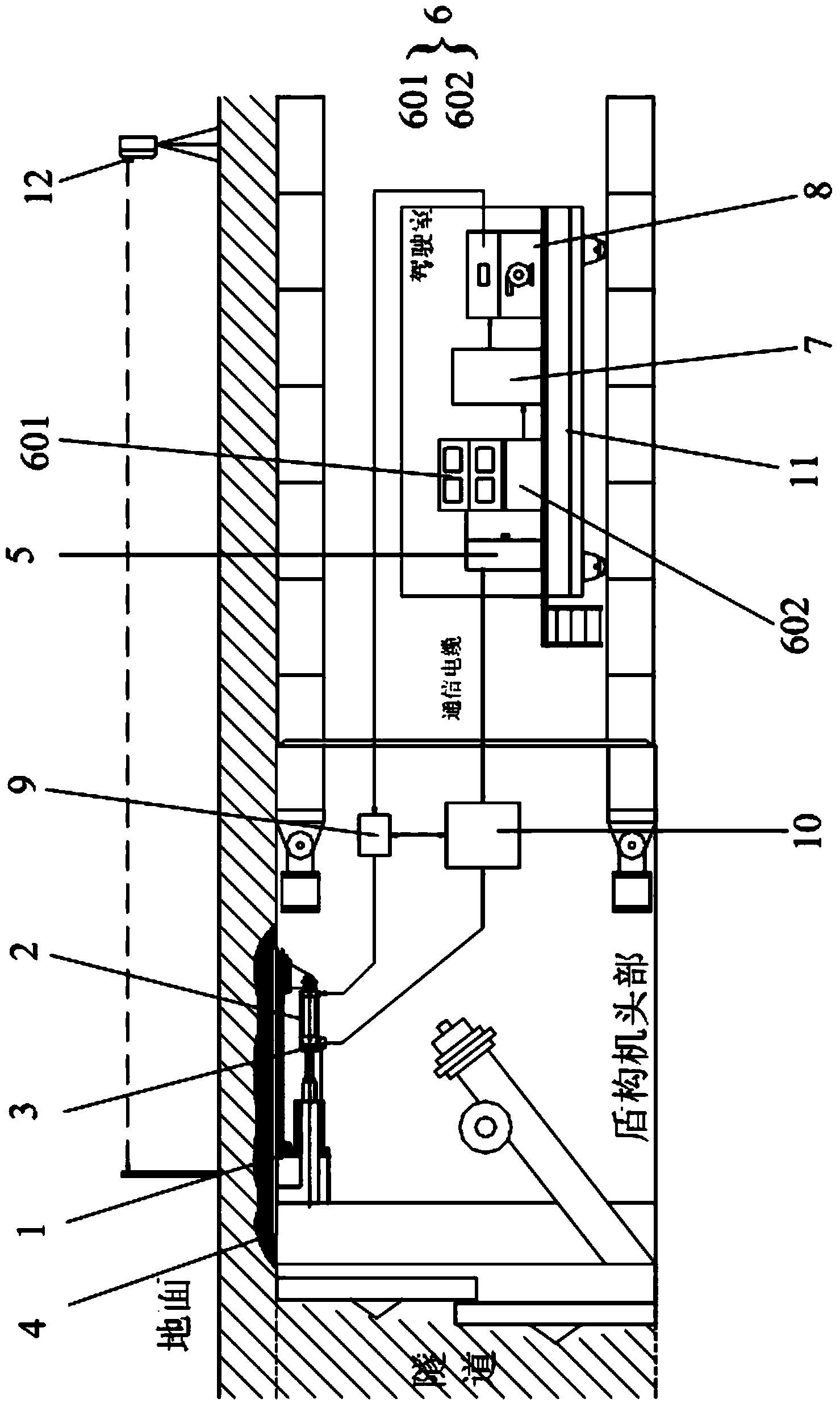

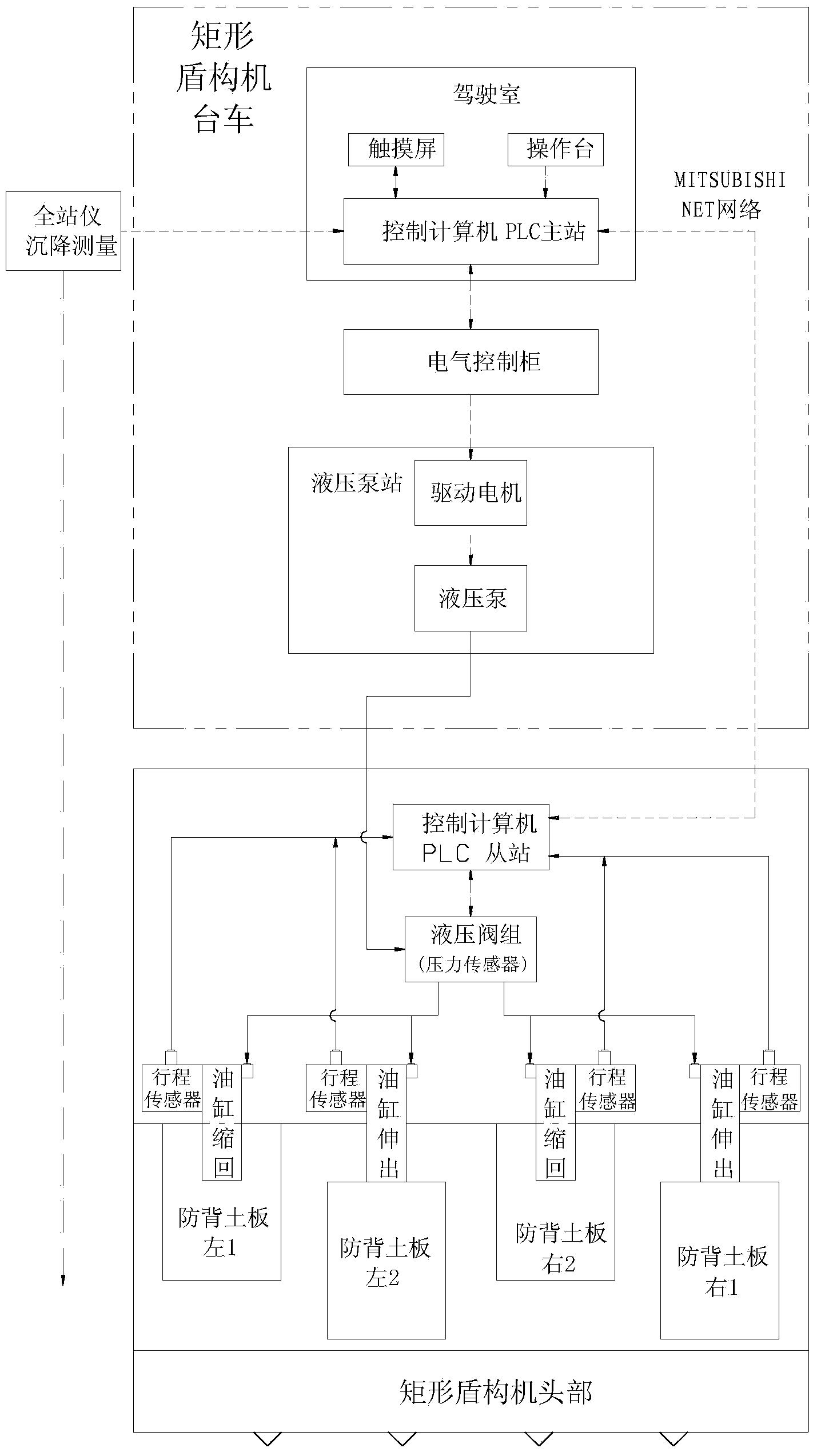

[0032] Please refer to Figure 1 to Figure 3 , this embodiment provides a rectangular shield machine anti-back soil system, including a number of anti-back soil plates 1 arranged above the shell of the shield machine, several groups of oil cylinders 2, and a hydraulic pump station 8 for driving the oil cylinders 2 and control systems;

[0033] The oil cylinders 2 in each group are used to drive one of the anti-back soil plates 1 to move along the upper surface of the shield machine shell; the number of each group can be any number, including 1 or 2, and the present embodiment uses An oil cylinder 2 drives an anti-back soil plate 1 as an example for illustration.

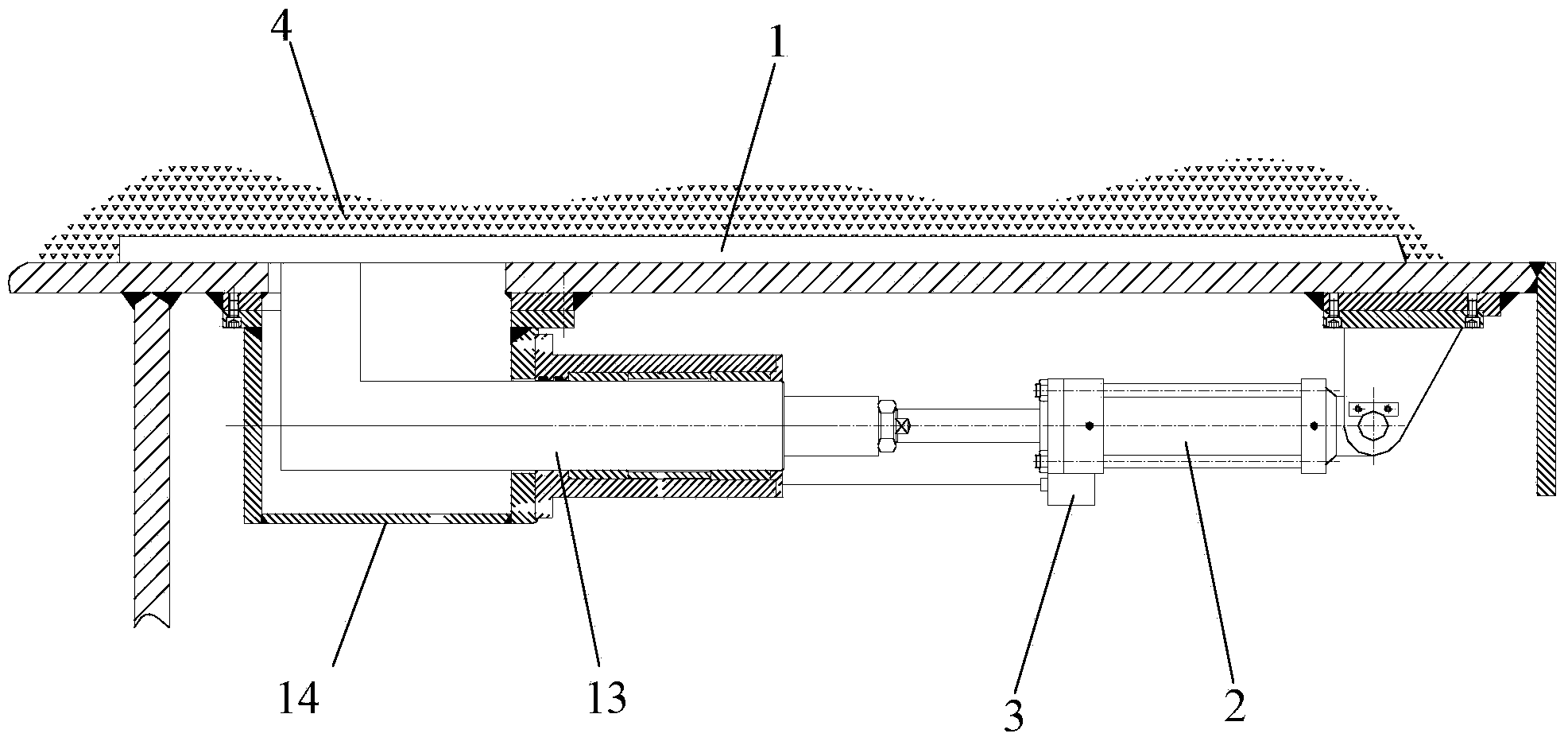

[0034] In this example, please refer to figure 2 , the anti-back soil plate 1 is also connected with the oil cylinder 2 through the connecting body 13, specifically, it is fixedly connected with the piston of the oil cylinder 2, and the connecting body 13 moves along the track body 14, and the track body 14 is con...

Embodiment 2

[0046] This embodiment is the same as the rectangular shield machine anti-soil system used in Embodiment 1. This embodiment can be regarded as a control method in the automatic mode. Figure 7 The shown touch screen 601 is operated, and the mode of the control method is selected first, and then the specific implementation of the control operation is performed.

[0047] In this embodiment, the operator first inputs and selects the quantity of the anti-back soil plate 1, the movement direction of the extension or retraction of the oil cylinder 2, the target stroke of the extension or retraction of the oil cylinder 2, and the hydraulic pressure through the interactive operation device 6. The pressure control range, wherein, the selection of the number of anti-back soil plates 1 can also be further limited to select the anti-back soil plate 1 for action, and then automatically control the oil cylinder 2 through the computer PLC master station 5 to achieve expansion or contraction ...

Embodiment 3

[0052] This embodiment is the same as the rectangular shield machine anti-soil system used in Embodiment 1. This embodiment can be regarded as a control method in the synchronous mode. Figure 7 The shown touch screen 601 is operated, and the mode of the control method is selected first, and then the specific implementation of the control operation is performed.

[0053] In this example, please refer to Figure 5 , two or more anti-back soil plates 1 act synchronously at the same time, and the computer PLC master station 5 generates control instructions according to the stroke data and speed data transmitted by each stroke sensor 3, so that each oil cylinder 2 The stroke is kept in sync with the speed. It can also be applied in the automatic mode, and combined with it, that is, during its implementation, the operation steps in the automatic mode can also be implemented simultaneously.

[0054] When there is a deviation in the telescopic stroke of the anti-back soil plate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com